A rare earth metal hydride hydrogen storage alloy suitable for solid-state hydrogen storage and preparation method thereof

A technology of hydrogen storage alloys and hydrides, applied in chemical instruments and methods, non-metallic elements, hydrogen, etc., can solve the problems of small hysteresis, hysteresis in kinetic properties, low hydrogen storage capacity of alloys, etc., and achieve simple and stable operation and equipment , Process conditions are easy to control, and the effect of high volume hydrogen storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

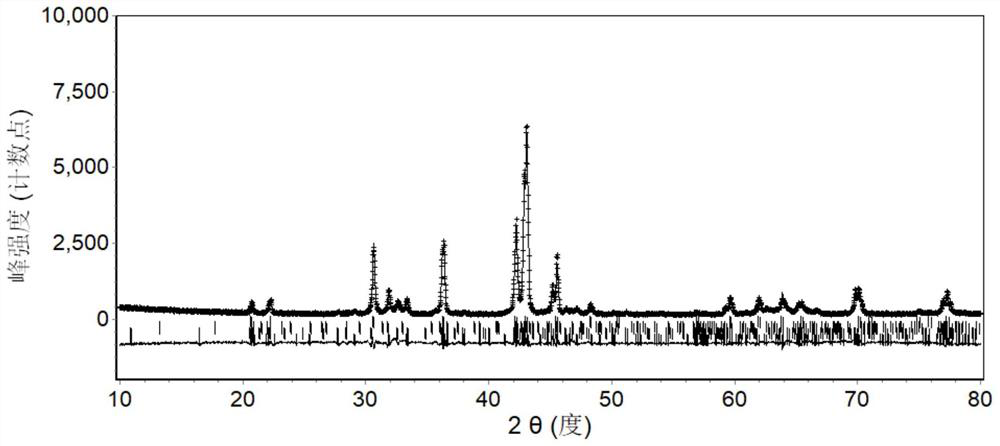

Embodiment 1

[0053] This embodiment provides a rare earth metal hydride hydrogen storage alloy suitable for solid-state hydrogen storage, and the composition of the hydrogen storage alloy is: Sm 0.92 Mg 0.08 Ni 4.11 Co 0.13 Al 0.06 , and its preparation method is carried out in sequence according to the following steps:

[0054] (11) batching: select metals Sm, Mg, Ni, Co, Al as raw materials, carry out batching according to the alloy chemical composition of the present embodiment, consider the volatilization loss in the preparation, and supplement the volatilization amount of the corresponding element during batching;

[0055] (12) Smelting: The as-cast alloy is prepared by induction melting method. Before melting, the furnace chamber is evacuated to 0.08MPa, and then high-purity argon gas is introduced to 0.01MPa; In order to ensure the uniformity of the alloy, the metal Mg is carried out by means of secondary feeding, and finally the alloy is cast into a water-cooled ingot mold, and...

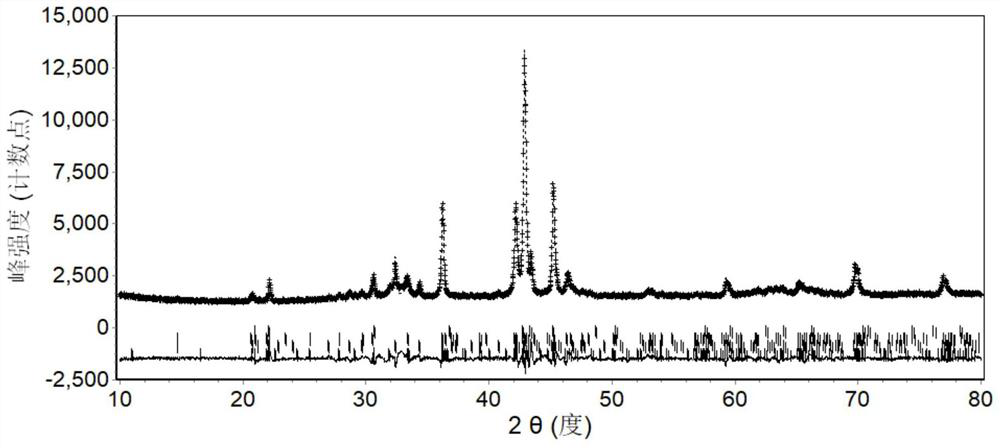

Embodiment 2

[0064] This embodiment provides a rare earth metal hydride hydrogen storage alloy suitable for solid-state hydrogen storage, and the composition of the hydrogen storage alloy is: Nd 0.60 Ce 0.10 Ti 0.10 Mg 0.20 Ni 3.92 Co 0.05 Si 0.05 , and its preparation method is carried out in sequence according to the following steps:

[0065] (21) Batching: select metals Nd, Ti, Mg, Ni, Co, Si, Ce as raw materials, and perform batching according to the alloy chemical composition of the present embodiment. Considering the volatilization loss during preparation, the volatilization amount of the corresponding element is supplemented and increased during batching ;

[0066] (22) Smelting: The as-cast alloy is prepared by induction melting method. Before melting, the furnace chamber is evacuated to 0.08MPa, and then high-purity argon gas is introduced to 0.04MPa; In order to ensure the uniformity of the alloy, the metal Mg is carried out by means of secondary feeding, and finally the a...

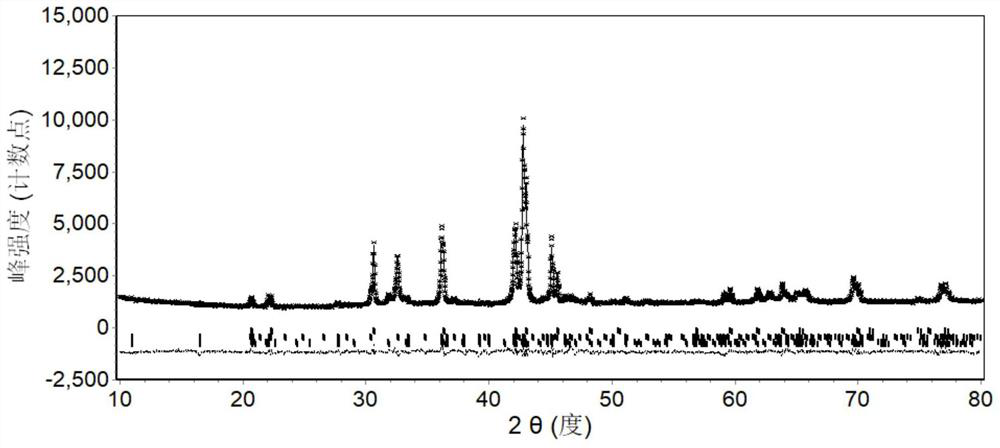

Embodiment 3

[0075] This embodiment provides a rare earth metal hydride hydrogen storage alloy suitable for solid-state hydrogen storage, and the alloy composition is: Y 0.65 Sm 0.15 La 0.10 Mg 0.10 Ni 3.90 Co 0.10 Al 0.05 Mn 0.05 , and its preparation method is carried out in sequence according to the following steps:

[0076] (31) batching: select metals Y, Sm, La, Mg, Ni, Co, Al, and Mn as raw materials, and carry out batching according to the alloy chemical composition of the present embodiment. Considering the volatilization loss during preparation, the volatilization amount of the corresponding element is used for batching. supplementary increase;

[0077] (32) Smelting: The as-cast alloy is prepared by induction melting method. Before melting, the furnace chamber is evacuated to 0.08MPa, and then high-purity argon gas is introduced to 0.02MPa; In order to ensure the uniformity of the alloy, the metal Mg is carried out by means of secondary feeding, and finally the alloy is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com