MoS2/MoO2/Ru composite material as well as preparation method and application thereof

A composite material, H2O2 technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as high energy consumption, carbon dioxide emissions, etc., achieve high yield, easy operation, and simple reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

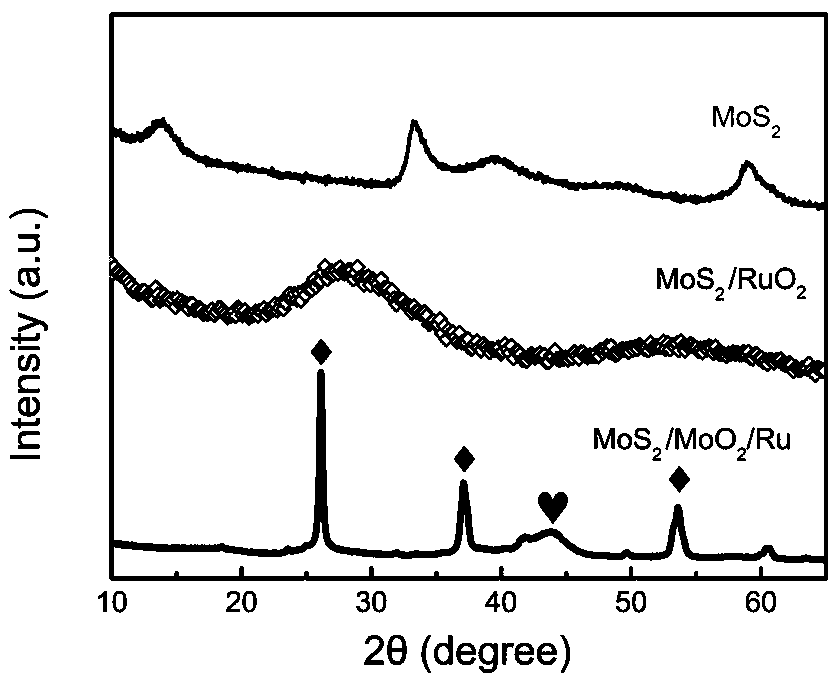

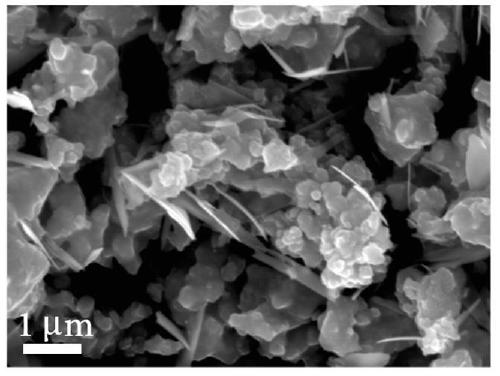

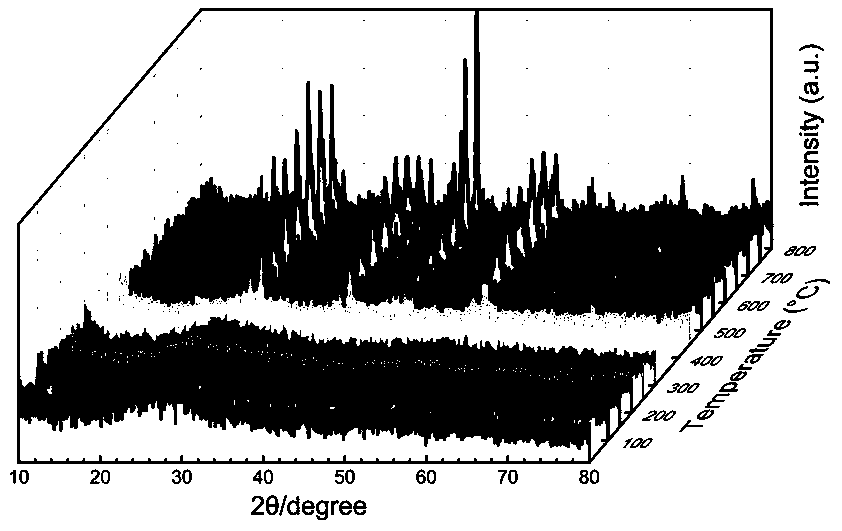

[0026] A kind of MoS 2 / MoO 2 The preparation method of / Ru composite material, step is as follows:

[0027] (1) Nano-MoS 2 Preparation of:

[0028] Using ammonium molybdate tetrahydrate and thiourea as raw materials to prepare 3D flower-like nano molybdenum disulfide: 0.2 g PVP (K-30) was dissolved in 100 ml deionized water, 1.22 g (NH 4 ) 6 Mo 7 o 24 4H 2 O and 1.78 g NH 2 CSNH 2 Add it to the above solution, stir for 30 min to obtain a clear solution; transfer the solution to a 200 ml autoclave, react at 200 °C for 24 h, after cooling, centrifuge to separate the precipitate, and wash it three times alternately with ethanol and deionized water , put the product in a vacuum drying oven at 60 °C and dry for 12 h to obtain 3D flower-like nanomolybdenum disulfide;

[0029] (2), MoS 2 / RuO 2 Preparation of composite materials:

[0030] Take 0.2 g of MoS prepared in step (1) 2 Disperse into 40 ml of deionized water, sonicate for 3 h under ice bath conditions, then pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com