Chemical hydride hydrogen storing material system, hydrogen preparing method and hydrogen preparing device

A technology for hydrogen storage material and hydrogen production device, which is applied in the production of borane/diborane hydride and hydrogen, etc., can solve the problem of reducing the load firmness, and the hydrogen storage system cannot respond quickly to changes in hydrogen demand and reduce the system hydrogen storage capacity and other issues, to achieve the effect of reducing material costs, prolonging hydrogen production efficiency, and improving hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

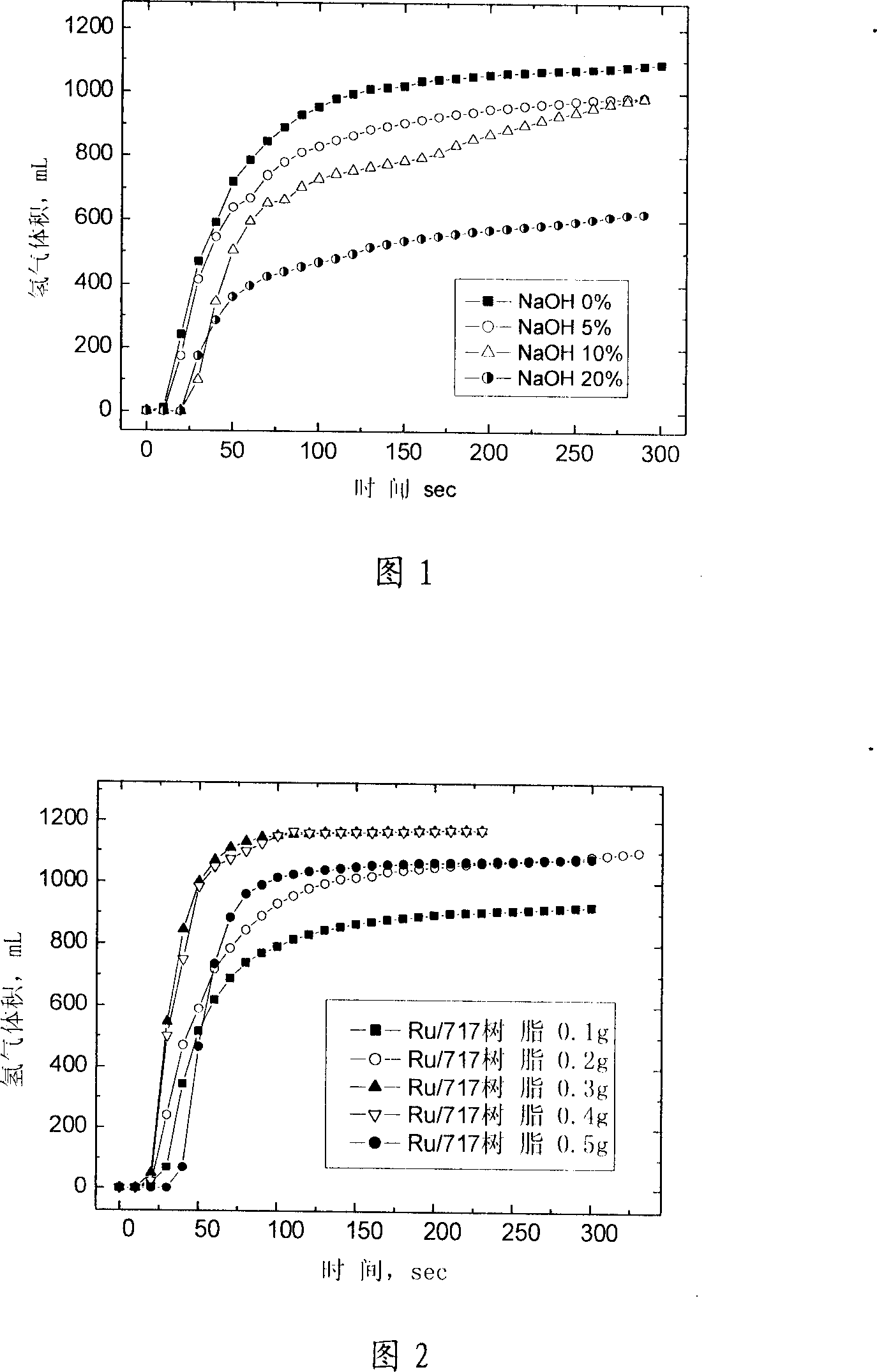

[0050] Adopt no NaOH in the raw material, all the other raw materials and test method, test condition are the same as comparative example 1. The dosage of the catalyst is 0.1-0.5 grams, accounting for 2-9% of the total weight of the hydrogen storage material system.

[0051] Figure 2 shows the effect of the amount of catalyst on the amount of hydrogen produced by the system and the rate of hydrogen production. With the increase of the amount of catalyst, the amount of hydrogen production and the rate of hydrogen production both increased.

Embodiment 2

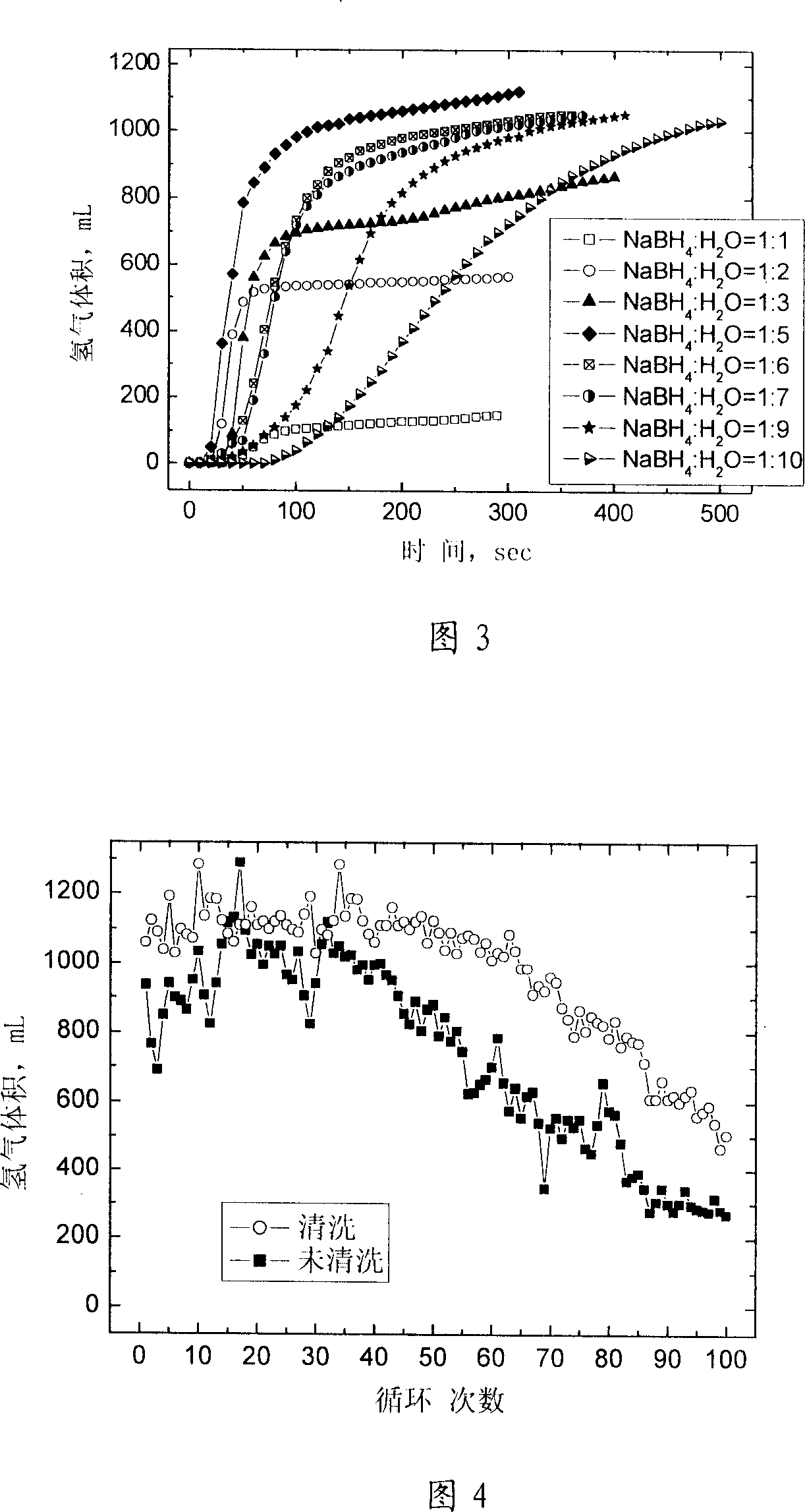

[0053] Adopt raw material and test method, test condition with embodiment 1. NaBH 4 The concentration of the aqueous solution is: NaBH 4 :H 2 O=1:1-1:10. The amount of catalyst used is 0.3 g, accounting for 5% of the total weight of the hydrogen storage material system.

[0054] Figure 3 gives the NaBH 4 The influence of the concentration on the amount of hydrogen produced and the rate of hydrogen production in the system. with NaBH 4 As the concentration increases, the amount of hydrogen produced by the system and the rate of hydrogen production increase first, and reach the optimum when it reaches 1:5, and continue to increase the NaBH 4 Concentrations lead to a decrease in the rate of hydrogen production.

Embodiment 3

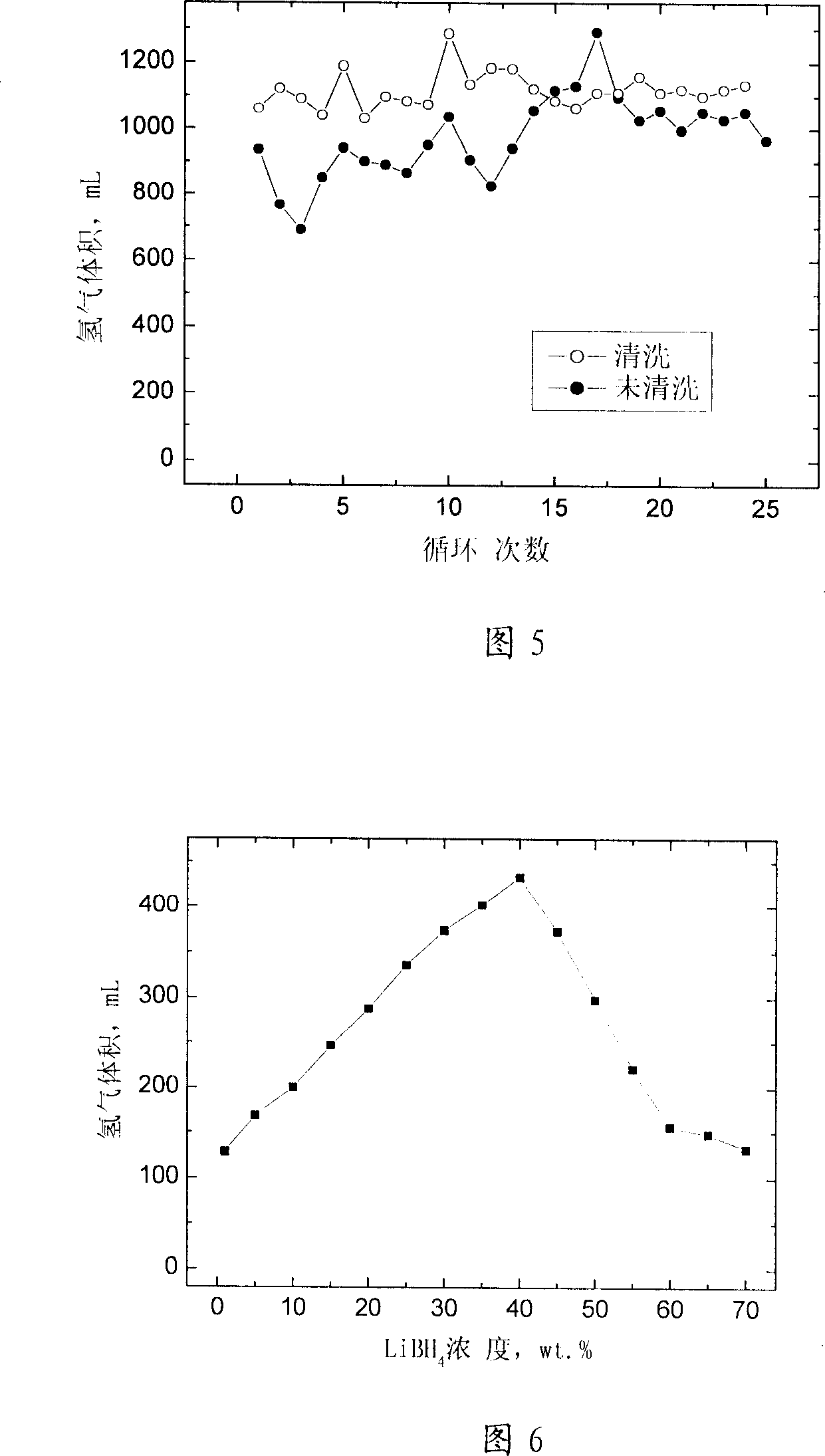

[0058] Adopt raw material and test method, test condition with embodiment 1. Figure 5 shows the influence of the number of hydrolysis cycles and catalyst cleaning treatment on the hydrogen production of the system without adding NaOH. For the material system without adding NaOH, the amount of hydrogen production is generally stable with the increase of the number of cycles, and the catalyst cleaning treatment can further improve the stability of the hydrogen release amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com