Hydrogenation control device and method

A control method and technology of a control device, which are applied in the directions of adaptive control, container filling method, general control system, etc., can solve the problems of difficulty in realization and communication between vehicles and hydrogen refueling stations, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

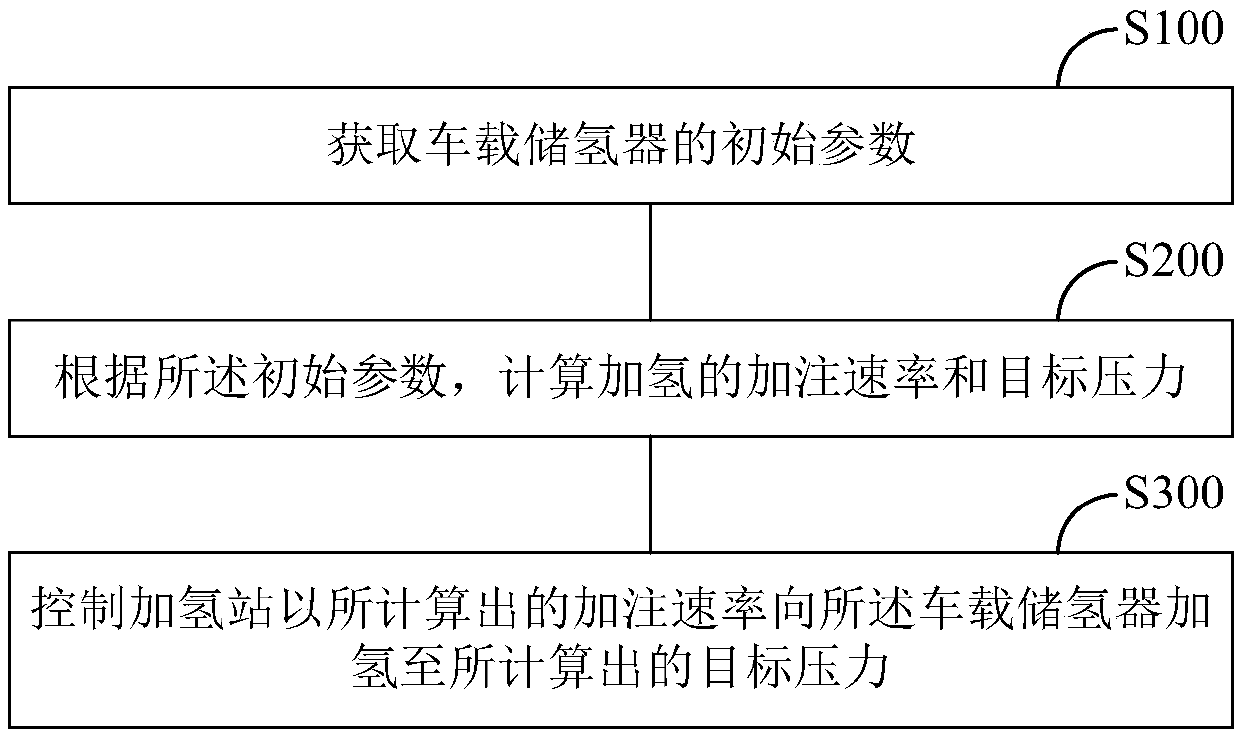

[0039] figure 1 It is a schematic flow chart of the hydrogenation control method in Embodiment 1 of the present invention. Such as figure 1 As shown, the hydrogenation control method may include the following steps:

[0040] Step S100, acquiring the initial parameters of the on-board hydrogen storage device.

[0041] In this embodiment, the initial parameters include the volume of the on-board hydrogen storage device, the initial hydrogen pressure, and the initial ambient temperature, and these three parameters will be described in detail below.

[0042] Regarding the volume of the on-board hydrogen storage device, there are hydrogen storage bottles of various volumes on the market, such as 100L and 200L. However, the volume of the hydrogen storage bottle is usually not considered in the existing hydrogenation process. In order to ensure that the hydrogen temperature does not rise too fast, no matter for a 100L hydrogen storage bottle or a 200L hydrogen storage bottle, the ...

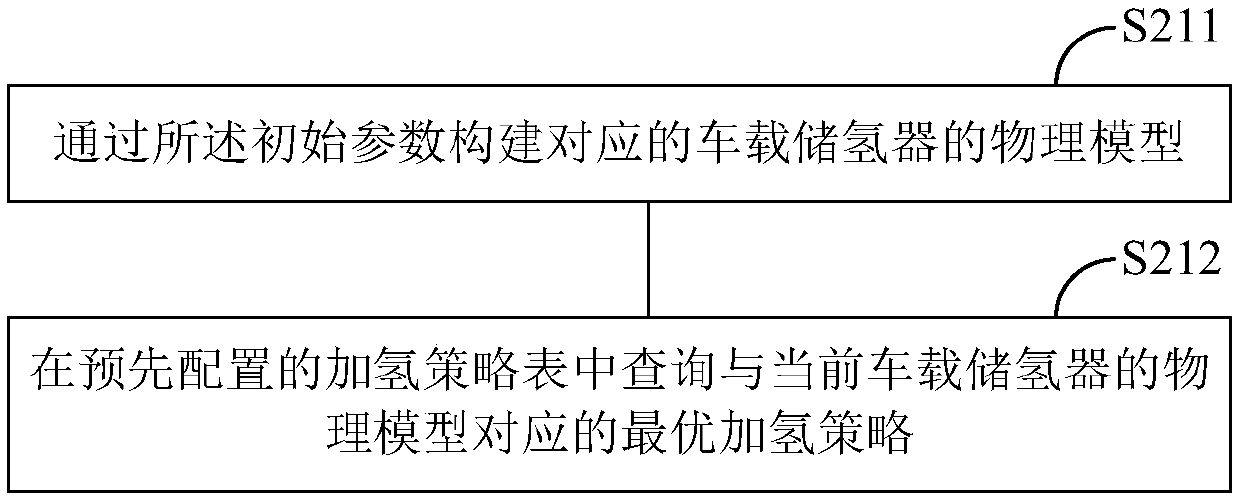

Embodiment 2

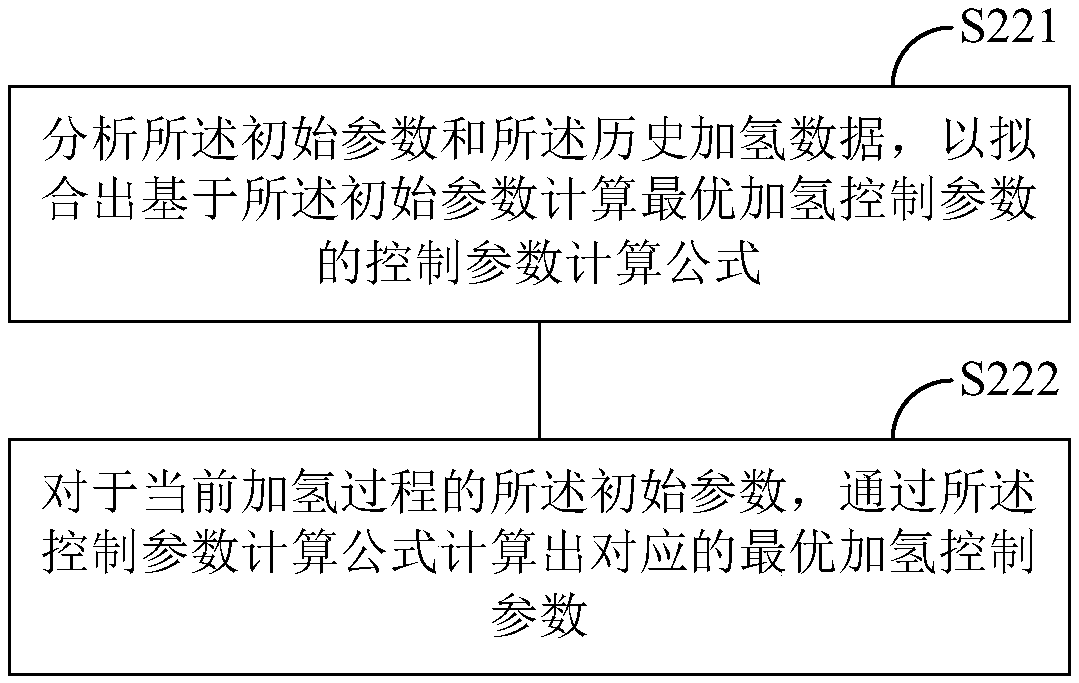

[0065] Compared with the above-mentioned first embodiment, the second embodiment of the present invention mainly differs in the scheme of calculating the filling rate and the target pressure according to the initial parameters in step S200. An embodiment of the present invention provides a formula calculation method to calculate the filling rate and the target pressure according to the initial parameters. in, image 3 It is a schematic flow chart of the formula calculation method of the embodiment of the present invention. Such as image 3 As shown, the formula calculation method may include the following steps:

[0066] Step S221 , analyzing the initial parameters and the historical hydrogenation data to fit a control parameter calculation formula for calculating optimal hydrogenation control parameters based on the initial parameters.

[0067] Wherein, the optimal hydrogenation control parameters include the filling rate and the target pressure.

[0068] For example, the...

Embodiment 3

[0077] Compared with the above two embodiments, the main difference of this third embodiment lies in the scheme of calculating the filling rate and the target pressure according to the initial parameters in step S200. An embodiment of the present invention provides a differential pressure calculation method to calculate the filling rate and the target pressure according to the initial parameters. in, Figure 4It is a schematic flow chart of the differential pressure calculation method of the embodiment of the present invention. Such as Figure 4 As shown, the differential pressure calculation method may include the following steps:

[0078] Step S231 , according to parameters such as the volume of the on-board hydrogen storage device and the ambient temperature, the required filling rate is determined.

[0079] Among them, the values of parameters such as the volume of the on-board hydrogen storage and the ambient temperature can be measured at the hydrogenation machine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com