Evaluation method for gram volume of graphite cathode material

A graphite negative electrode and evaluation method technology, which is applied in the direction of material electrochemical variables, can solve the problems of absolute value test failure, inability to compare different materials, and the influence of lithium-ion capacity button battery assembly conditions, etc., to improve efficiency and simplify experiments conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

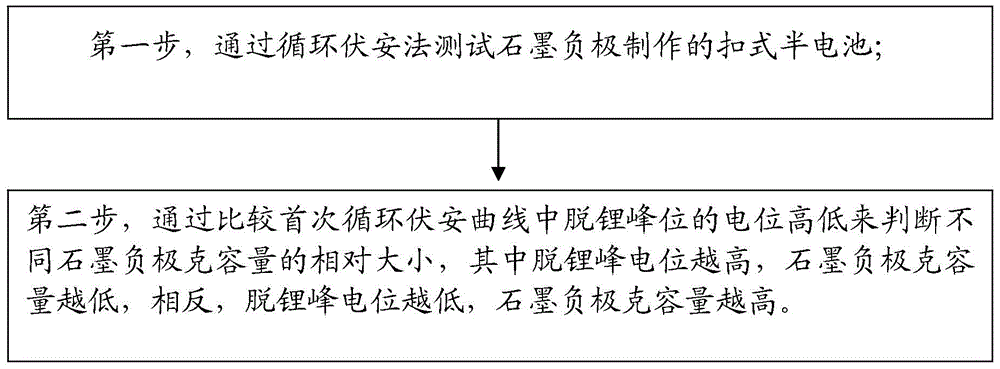

Method used

Image

Examples

Embodiment 1

[0031] Cyclic voltammetry test conditions: the scanning voltage range is 0V to 2V, and the scanning rate is 0.3mV / s.

[0032] Button battery assembly: commercial button battery assembly CR2430, including bottom cover, gasket, spring leaf, top cover.

[0033] Graphite negative electrode sheet: prepared by coating graphite negative electrode sample 1, sample 2, and sample 3 on copper foil.

[0034] Diaphragm: polyethylene diaphragm

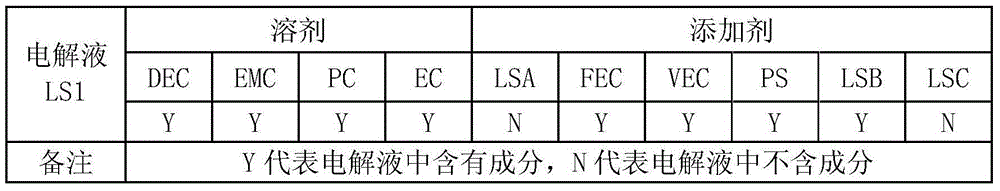

[0035] Table 1

[0036]

[0037] Test results, as shown in Table 2:

[0038] Table 2

[0039] Graphite material sample

Embodiment 2

[0041] Cyclic voltammetry test conditions: the scanning voltage range is 0V to 2V, and the scanning rate is 0.2mV / s

[0042] Button battery assembly: commercial button battery assembly CR2430, including bottom cover, gasket, spring leaf, top cover.

[0043] Graphite negative electrode sheet: prepared by coating graphite negative electrode sample 1, sample 2, and sample 4 on copper foil respectively.

[0044] Diaphragm: Polypropylene diaphragm

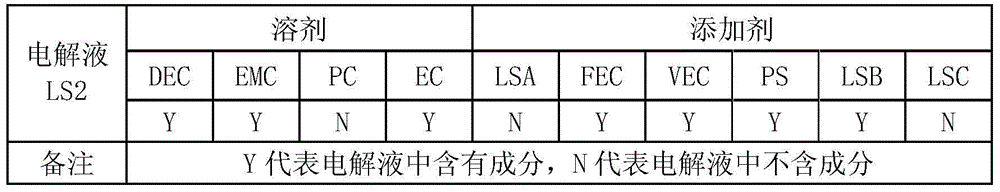

[0045] table 3

[0046]

[0047] Test results, as shown in Table 4:

[0048] Graphite material sample

Embodiment 3

[0050] Cyclic voltammetry test conditions: the scanning voltage range is 0V to 1.5V, and the scanning rate is 0.3mV / s

[0051] Button battery assembly: commercial button battery assembly CR2430, including bottom cover, gasket, spring leaf, top cover.

[0052] Graphite negative electrode sheet: prepared by coating graphite negative electrode sample 1, sample 2, and sample 3 on copper foil.

[0053] Diaphragm: polyethylene diaphragm

[0054] table 5

[0055]

[0056] Table 6

[0057] Graphite material sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com