Preparation method for three-dimensional reticular nitrogen-doped graphene composite cobalt hydroxide hexagonal nano-sheet electrode material

A technology of nitrogen-doped graphene and three-dimensional network, which is applied in the field of preparation of supercapacitor electrode materials, can solve the problem of specific surface area reduction and achieve the effect of ensuring specific surface area, good industrial application prospects, experimental conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

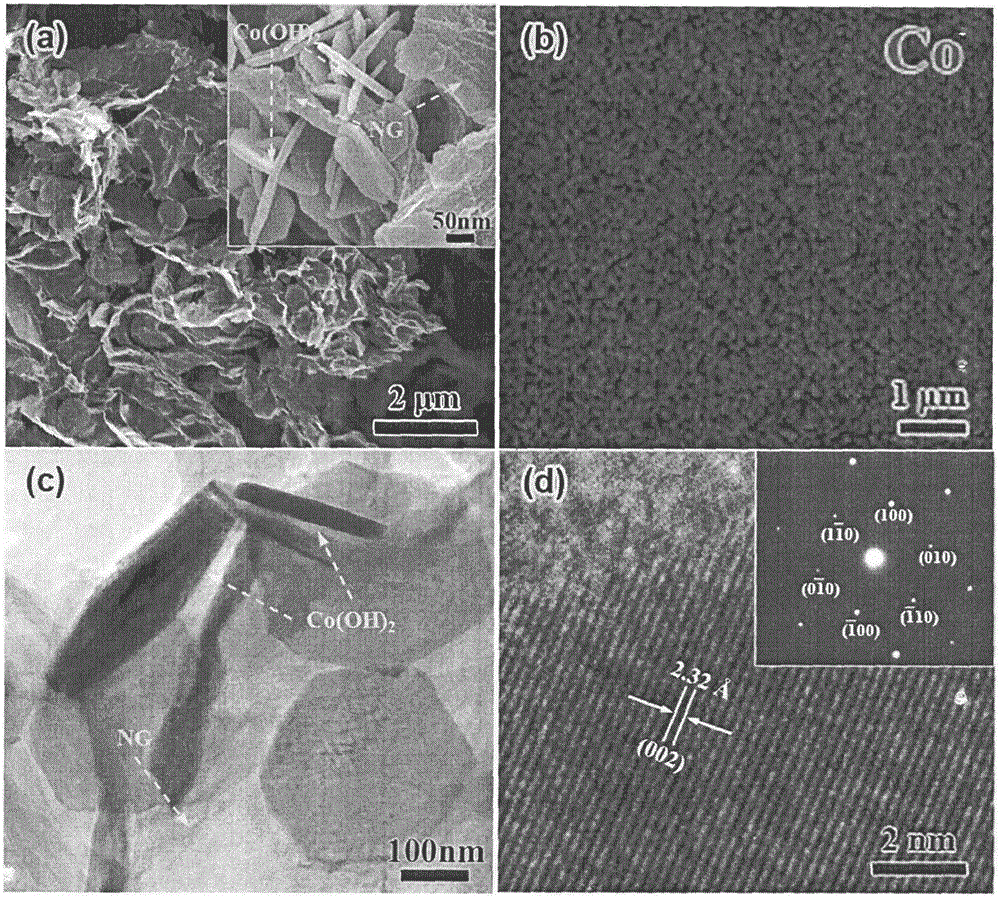

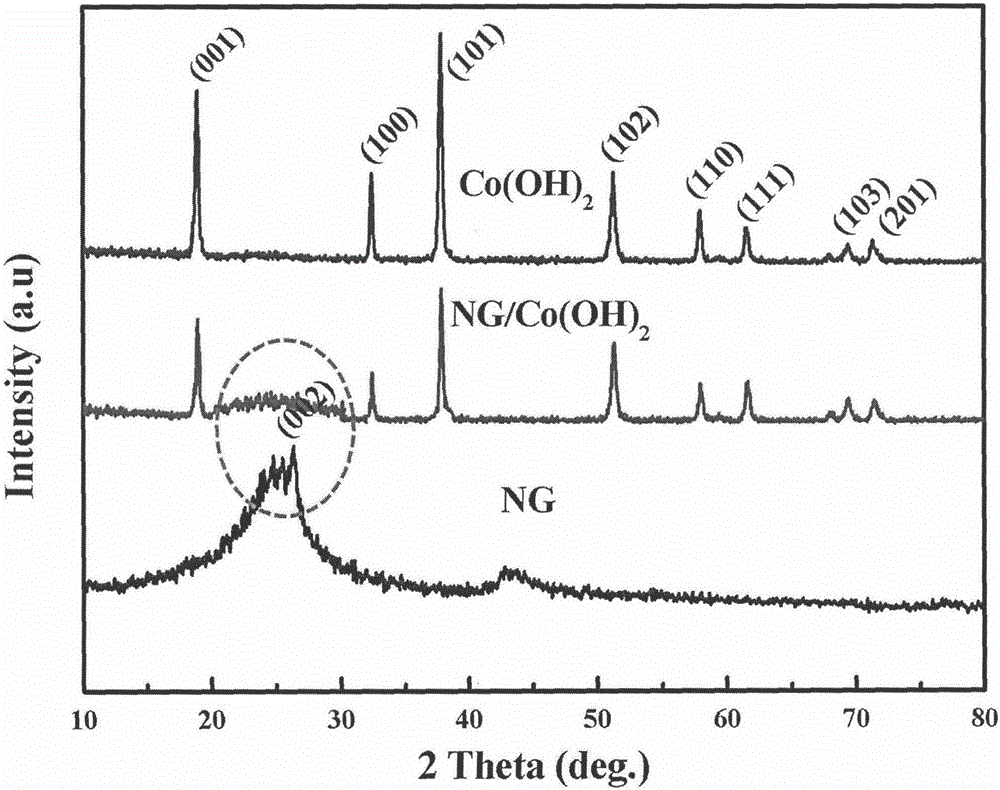

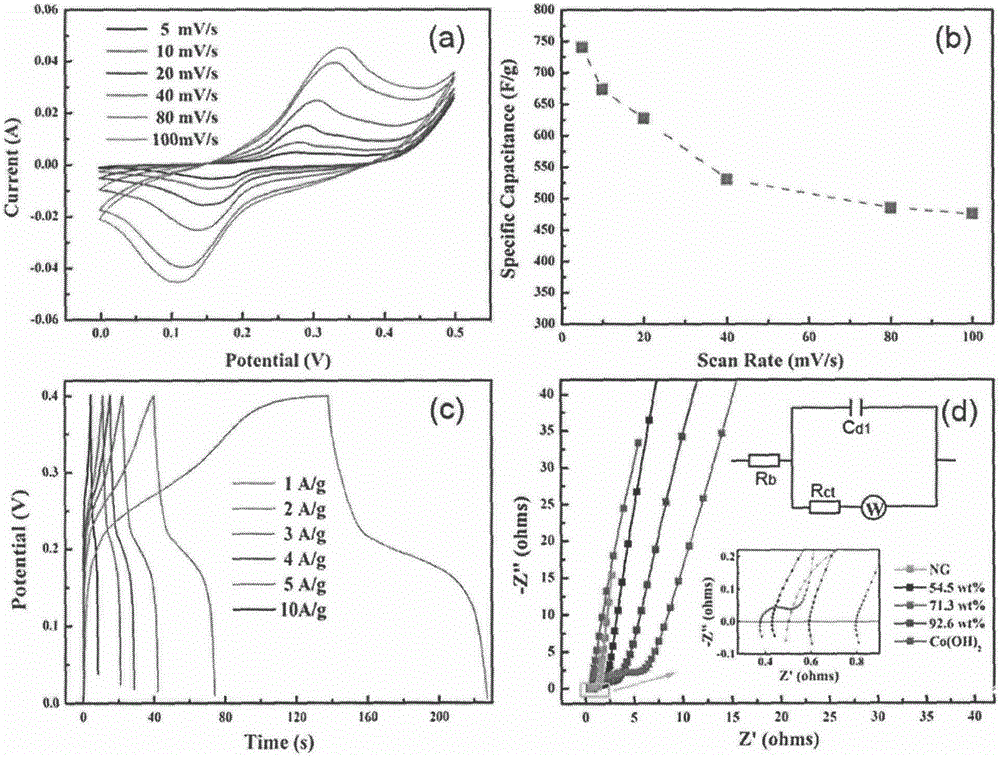

Embodiment 1

[0032] Under vigorous stirring conditions, 1.0g of cobalt chloride hydrate, 5.9g of sodium citrate and 2.1g of hydrated sodium dihydrogen phosphate were dissolved in 100ml of deionized water in turn, and the latter was added after the former reactant was completely dissolved. , the concentrations of the three are 0.04M, 0.2M and 0.15M respectively; add 8.0g of sodium hydroxide in a water bath at 50°C, the final concentration of sodium hydroxide is 2.0M, and then continue to stir for 30min; take another 100ml of deionized water, Add 0.2g of graphite oxide powder, and ultrasonicate for 1.0h at 100W power to obtain a 2.0mg / ml graphene oxide suspension; mix the mixed solution and the graphene oxide suspension at a volume ratio of 1:3 to form a 40ml reaction solution, and add 500 μl of ethyl alcohol Diamine, magnetically stirred and reacted for 15 minutes; the reaction solution was transferred into a 50ml reaction kettle, reacted at 180°C for 12 hours, and cooled naturally; finally,...

Embodiment 2

[0037] The volume ratio of the mixed solution and the graphene oxide solution was changed to 1:0.5, and other conditions were the same as in Example 1.

Embodiment 3

[0039] The volume ratio of the mixed solution and the graphene oxide solution was changed to 1:5, and other conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com