Patents

Literature

65results about How to "Guaranteed specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stacks of internally connected surface-mediated cells and methods of operating same

ActiveUS20130162216A1Improve power densityEasy dischargePrimary cell to battery groupingBatteries circuit arrangementsSupercapacitorEngineering

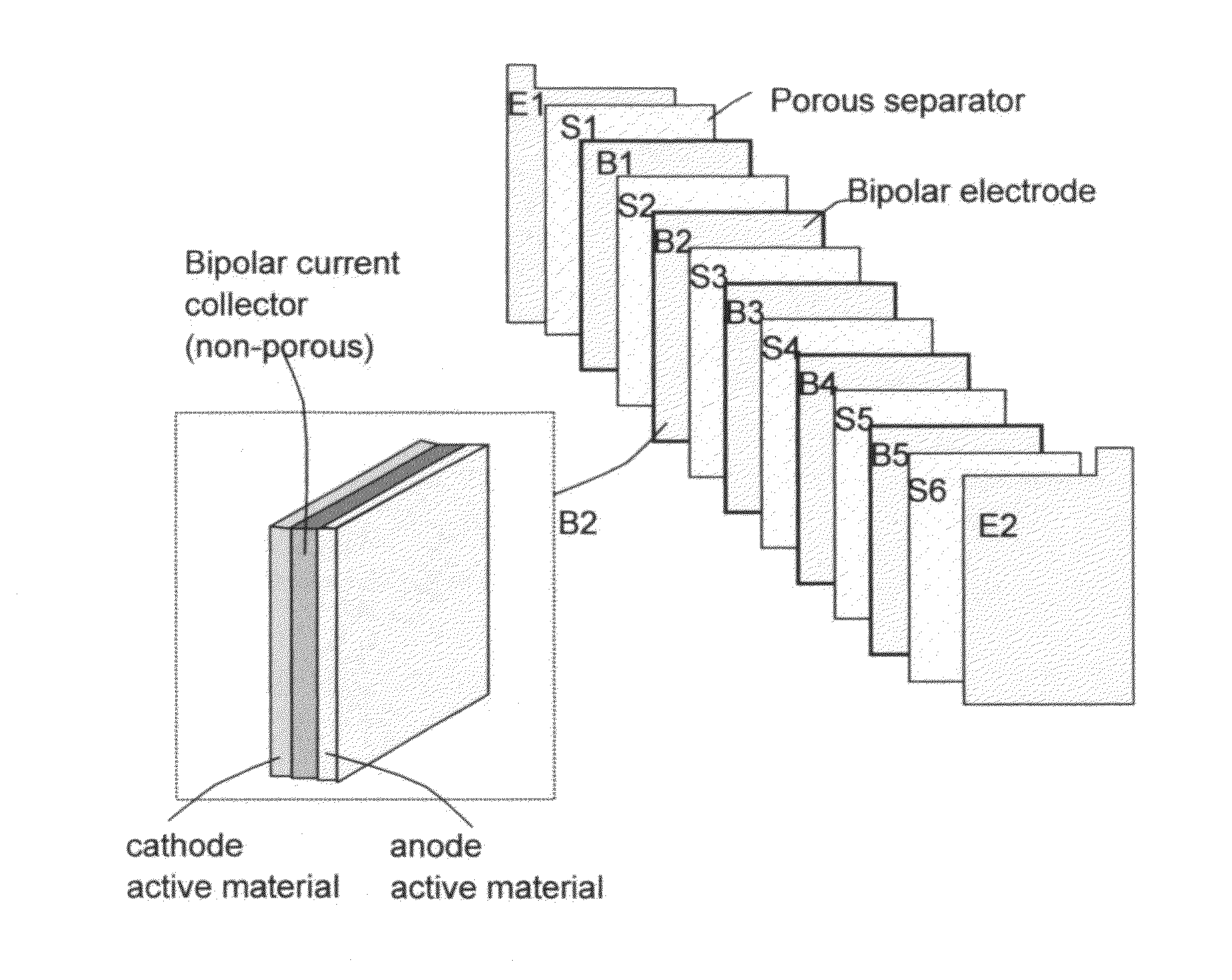

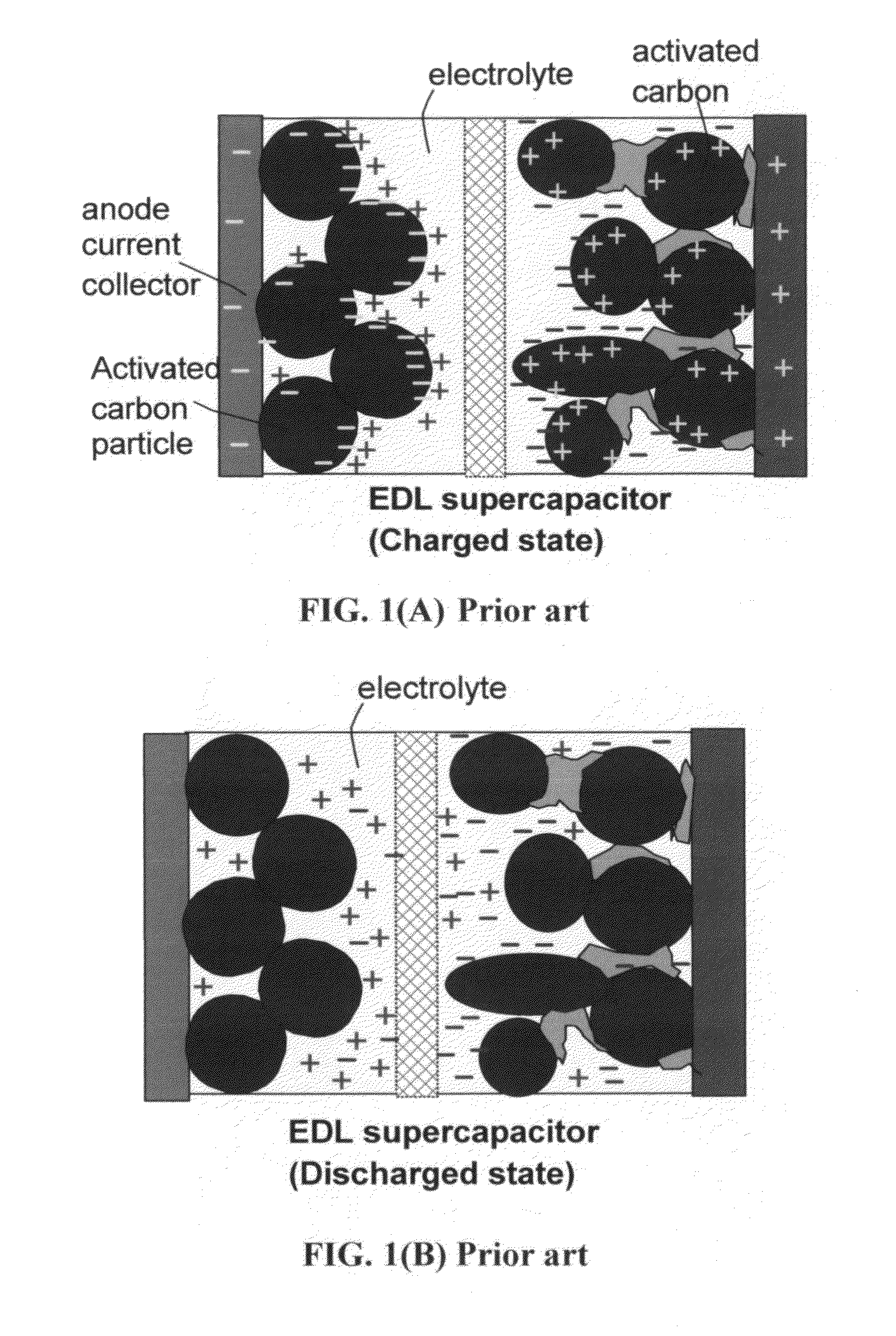

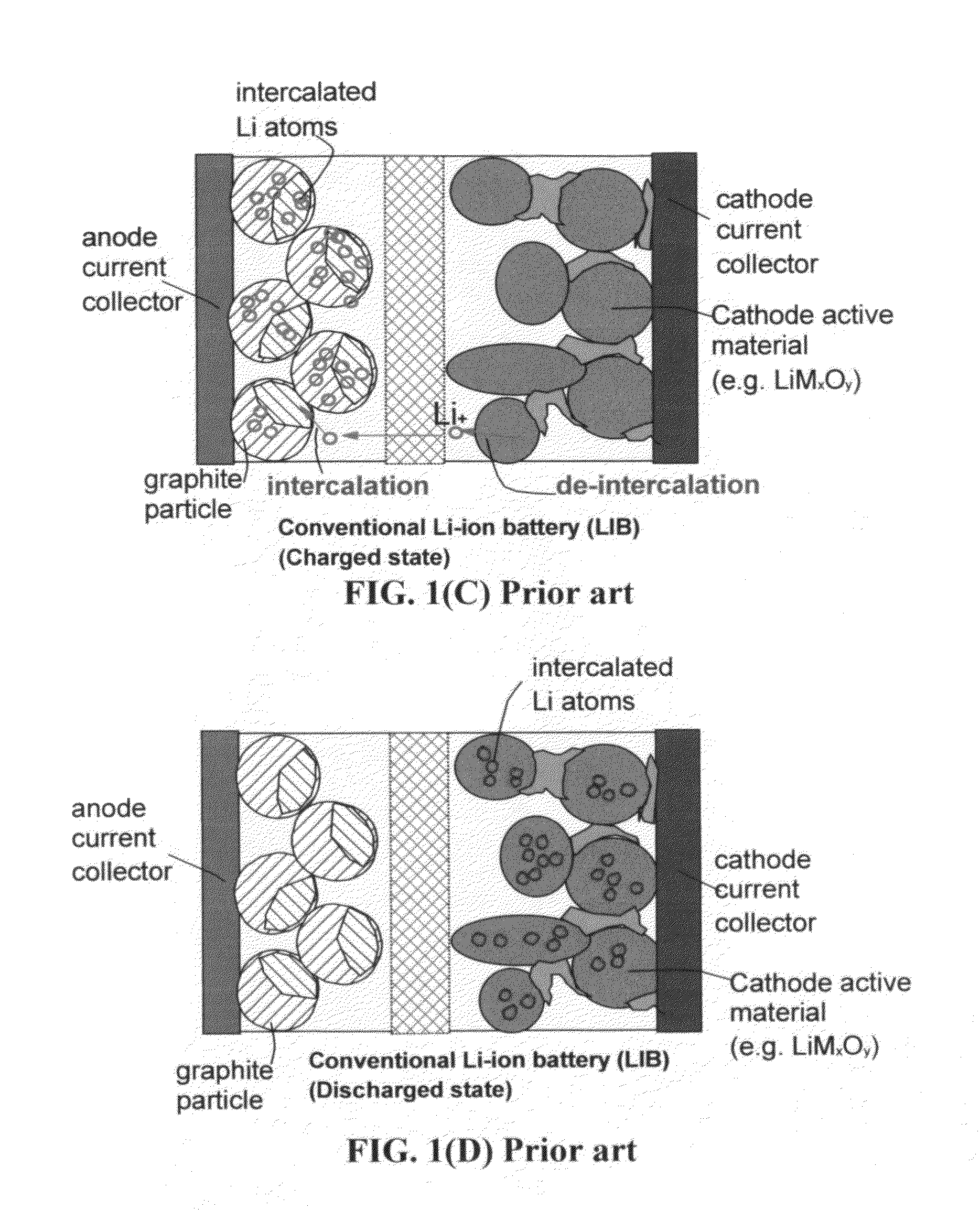

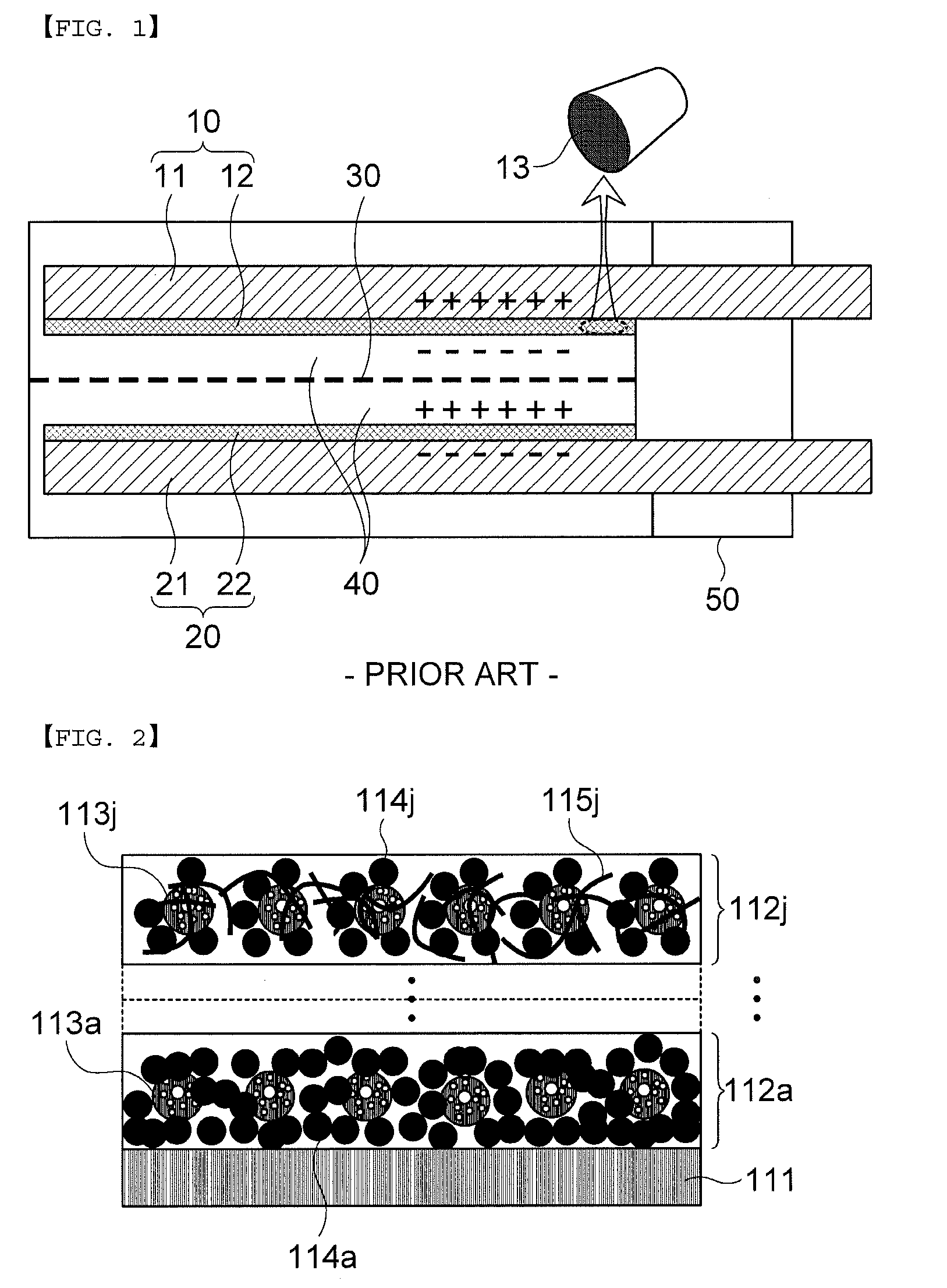

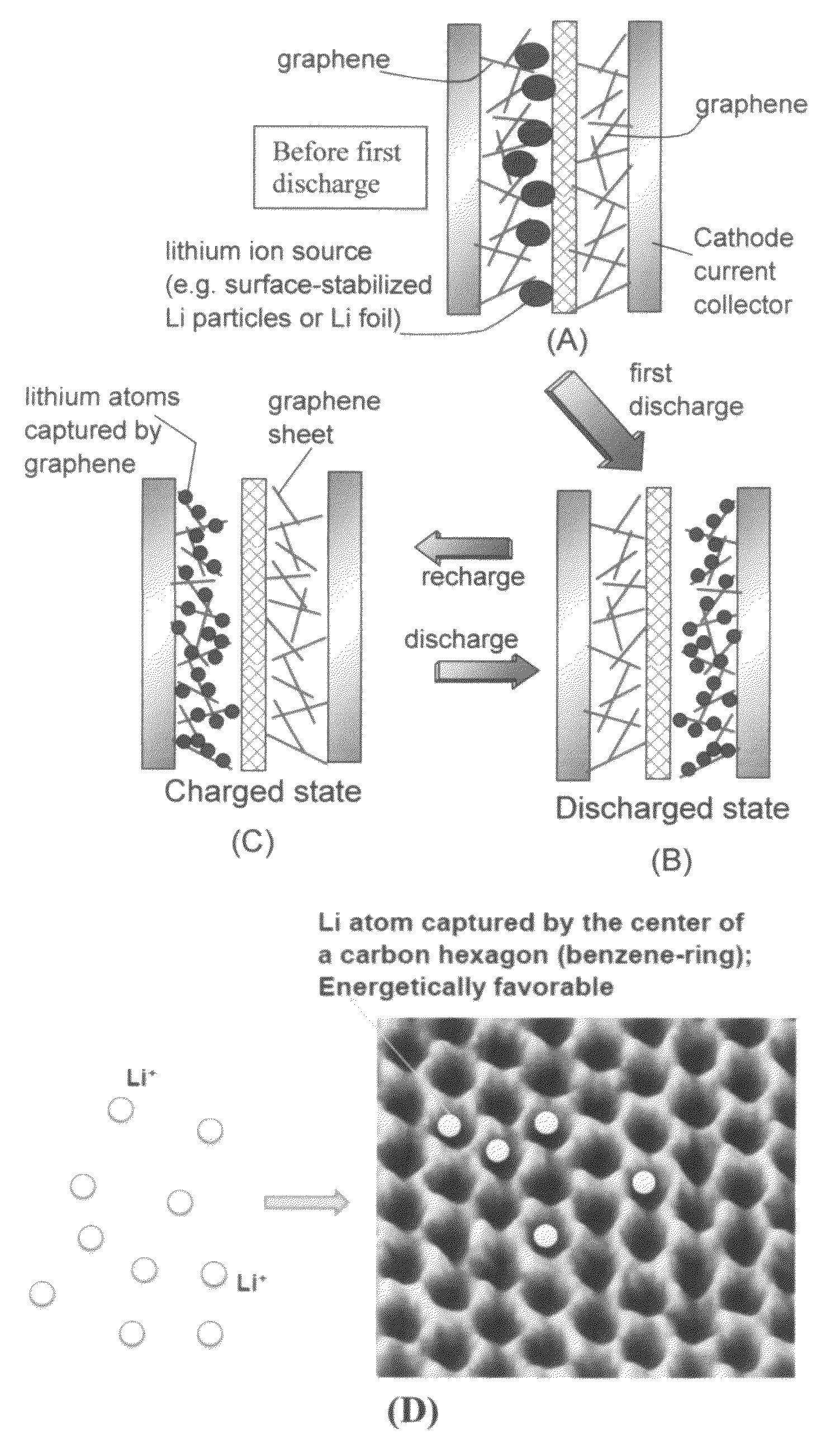

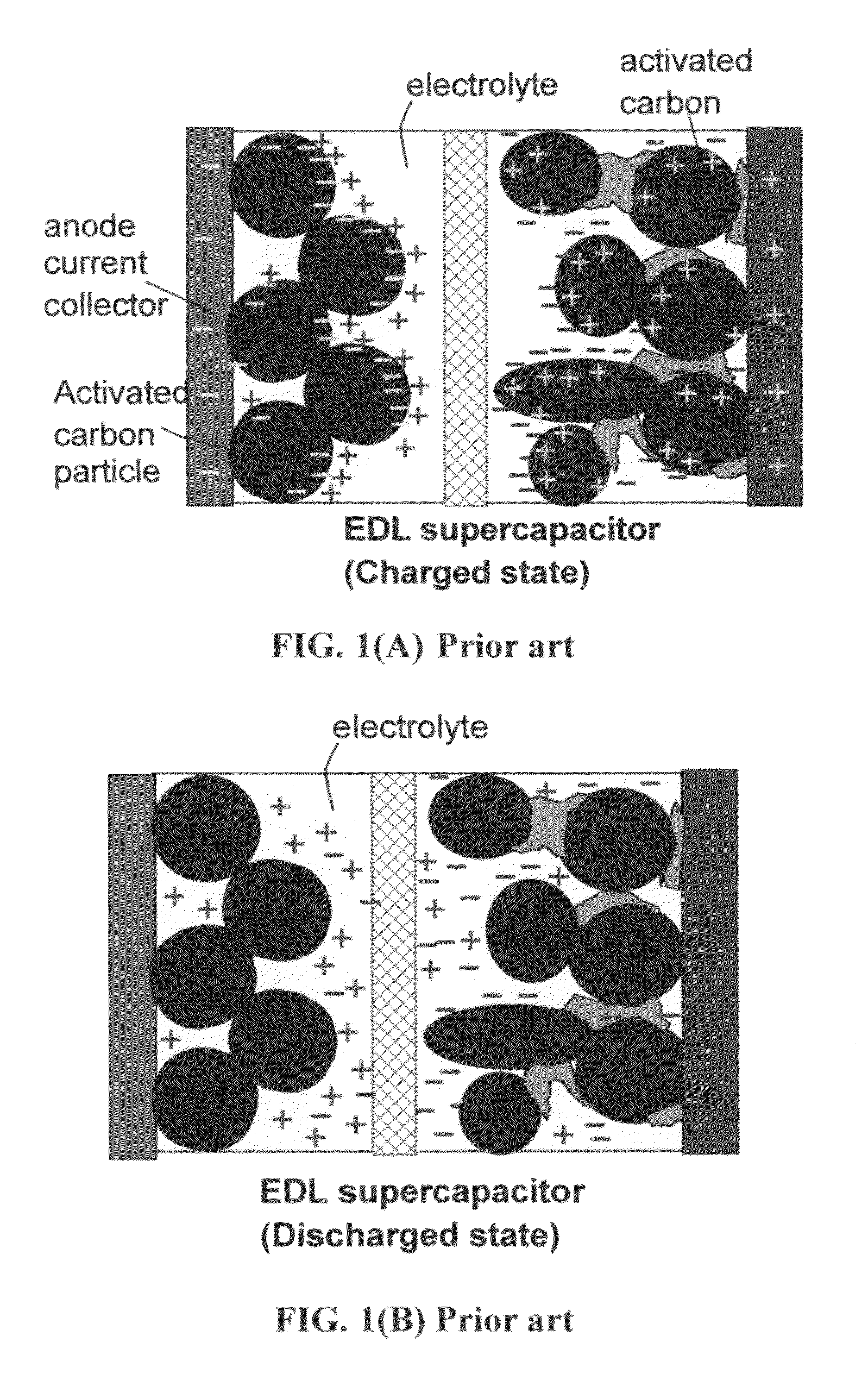

An energy storage stack of at least two surface-mediated cells (SMCs) internally connected in parallel or in series. The stack includes: (A) At least two SMC cells, each consisting of (i) a cathode comprising a porous cathode current collector and a cathode active material; (ii) a porous anode current collector; and (iii) a porous separator disposed between the cathode and the anode; (B) A lithium-containing electrolyte in physical contact with all the electrodes, wherein the cathode active material has a specific surface area no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; and (C) A lithium source. This new-generation energy storage device exhibits the highest power densities of all energy storage devices, much higher than those of all the lithium ion batteries, lithium ion capacitors, and supercapacitors.

Owner:GLOBAL GRAPHENE GRP INC +1

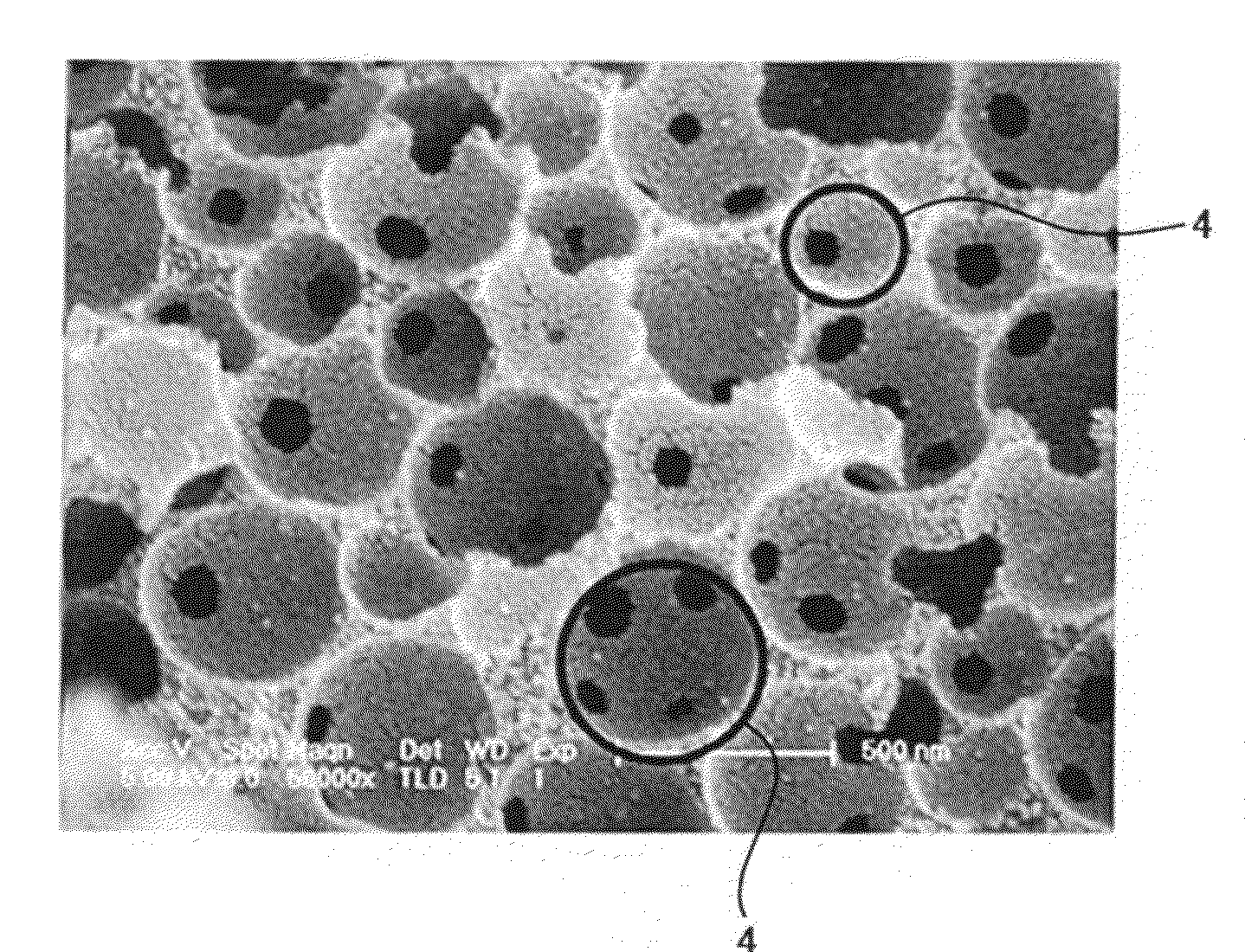

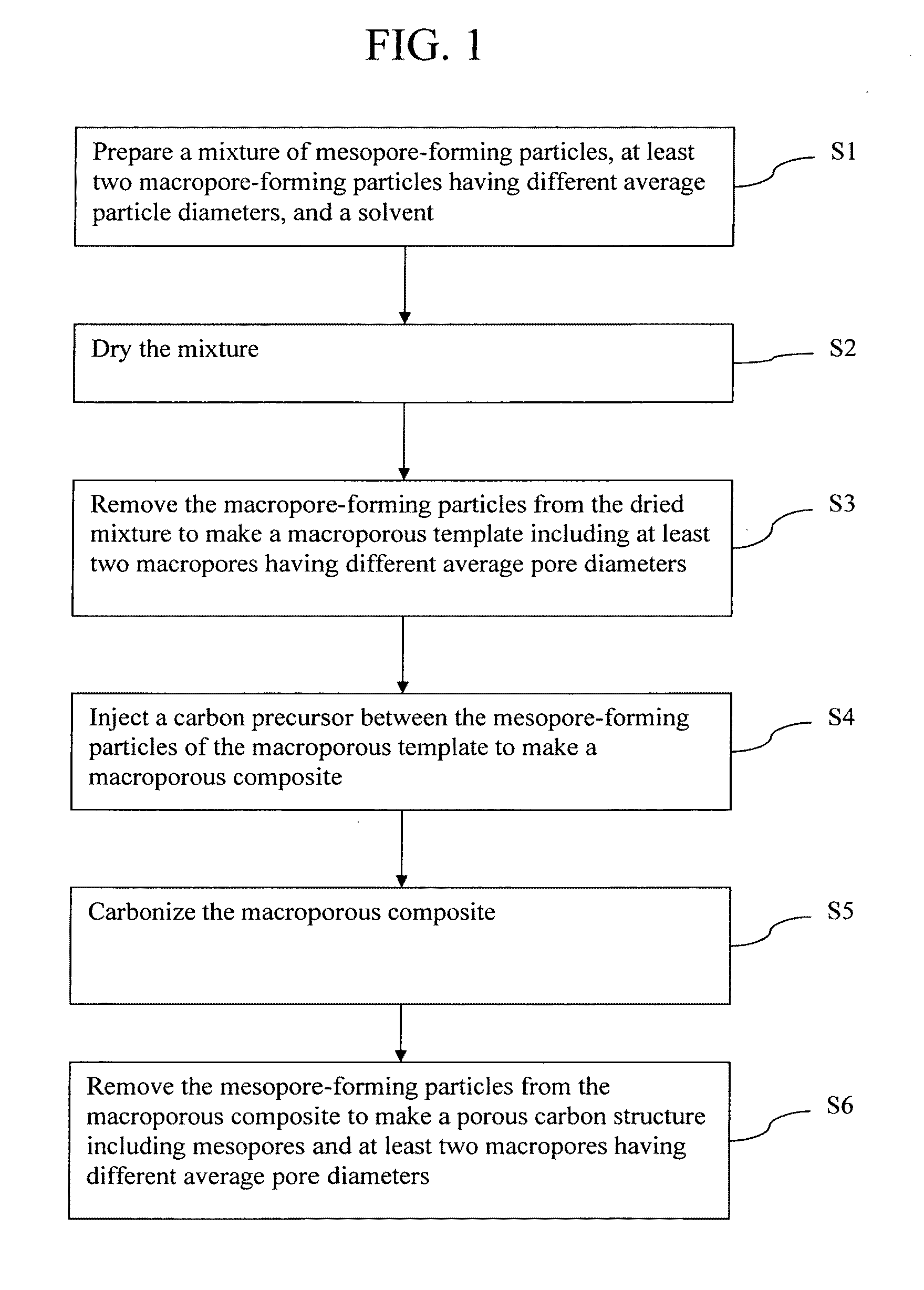

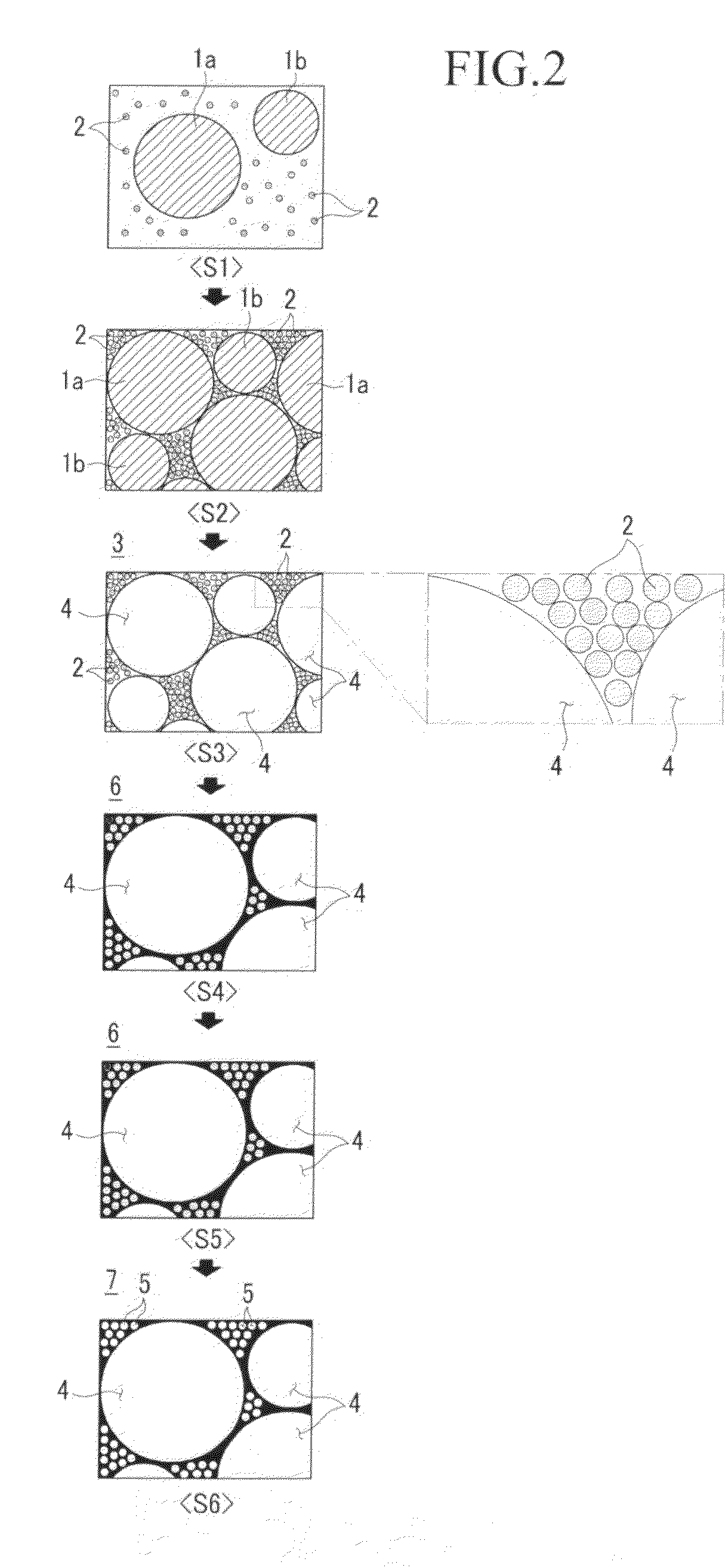

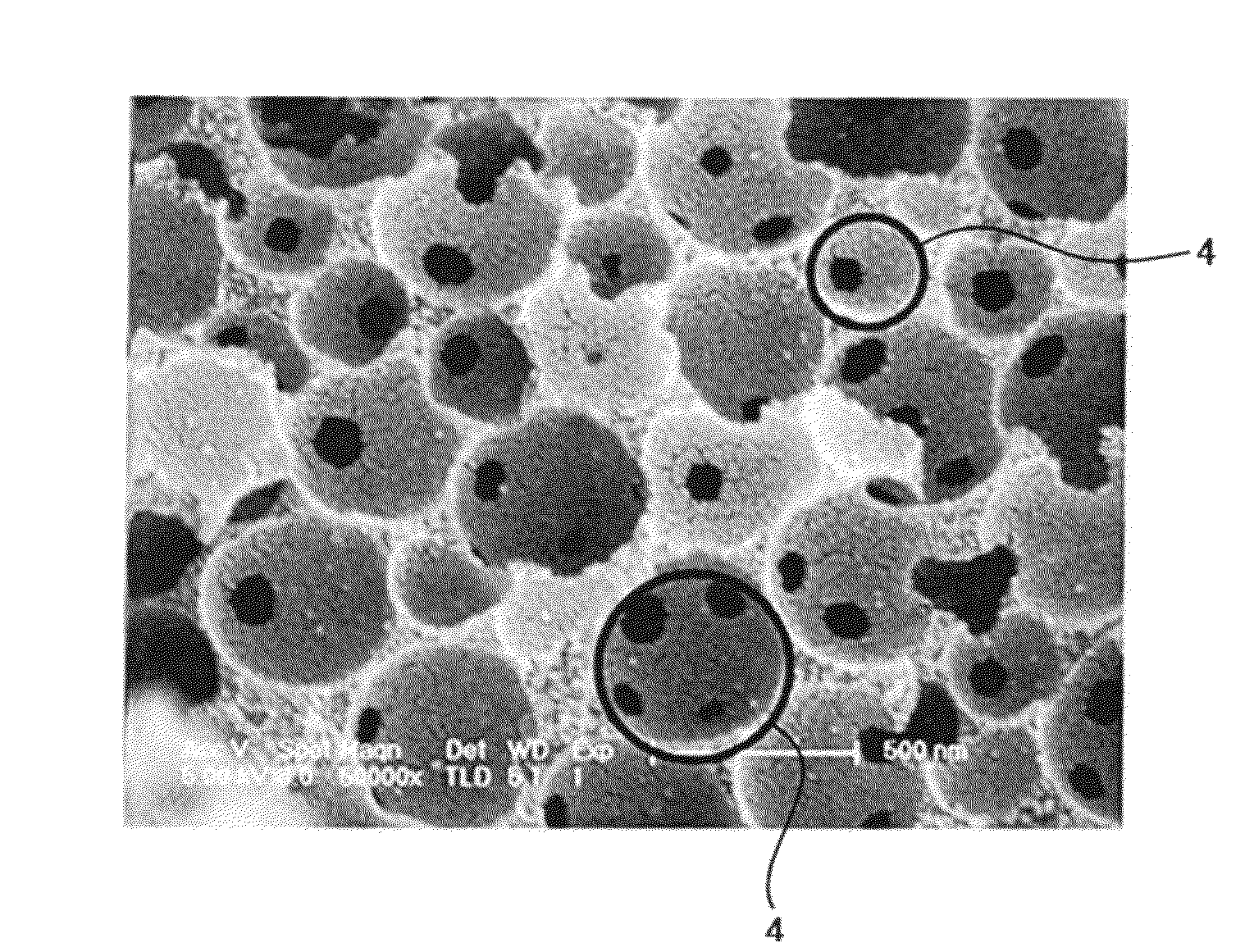

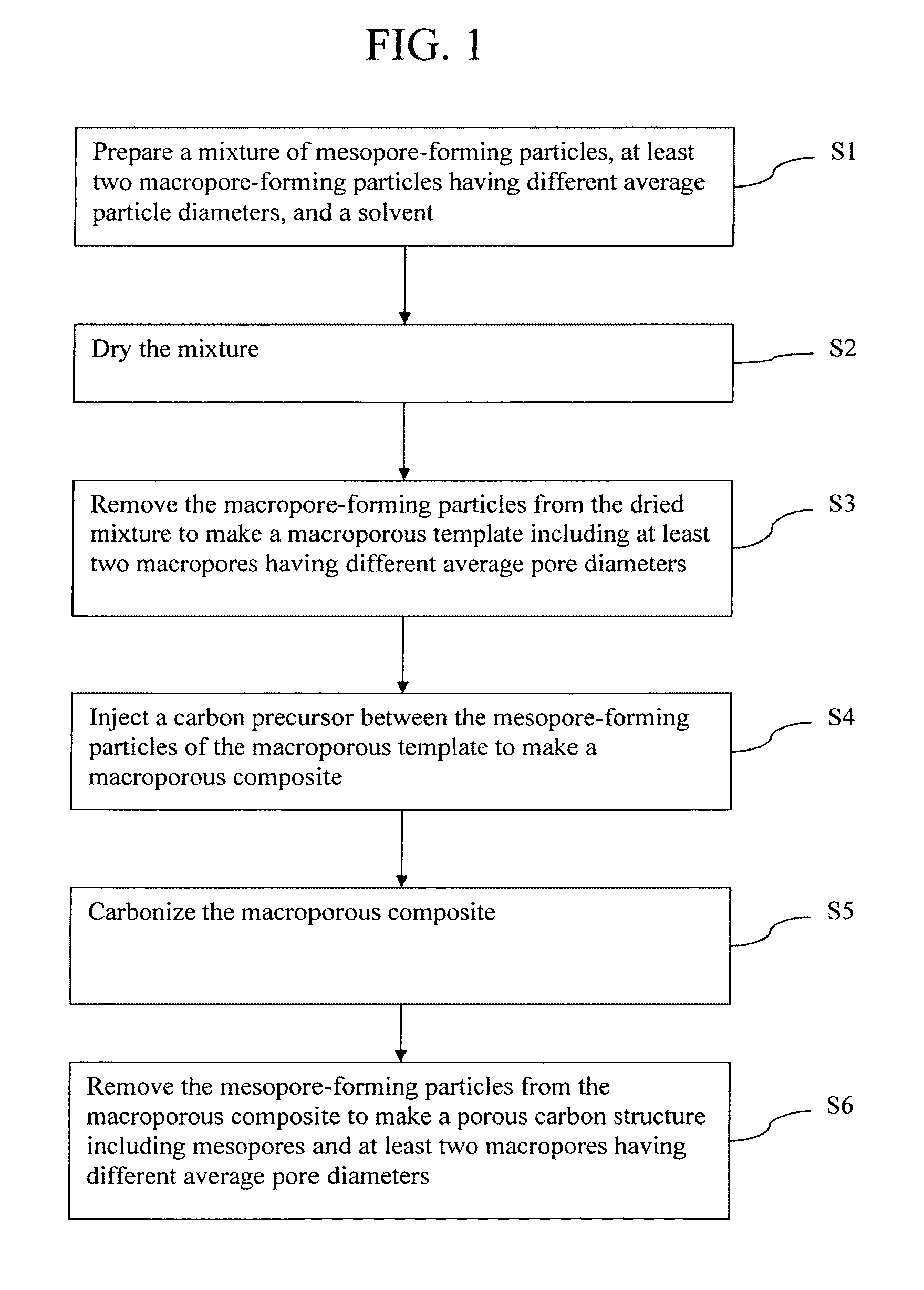

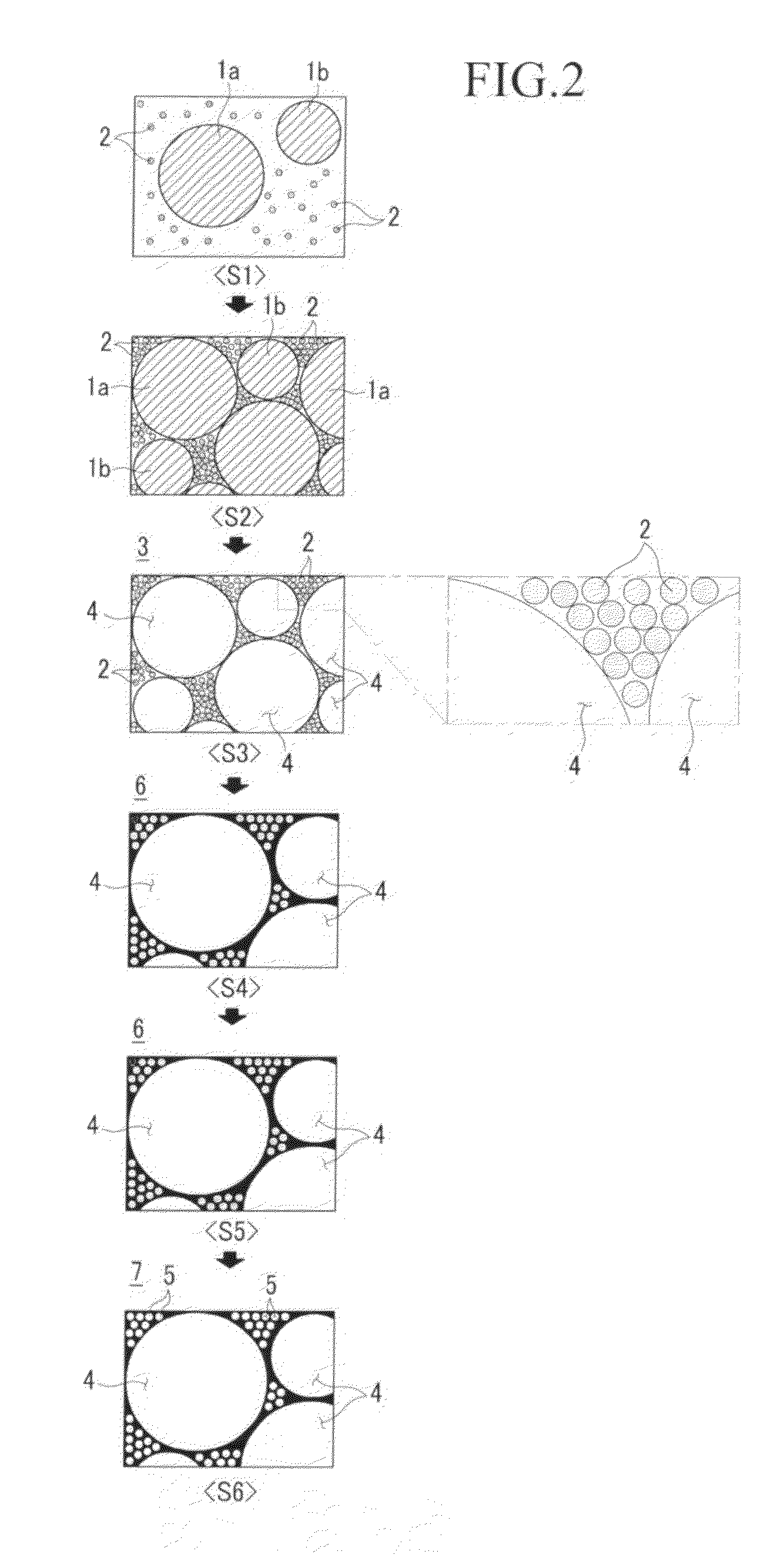

Porous carbon structure, method for preparing same, electrode catalyst for fuel cell, and electrode and membrane-electrode assembly including same

ActiveUS20090136808A1Improve electronic conductivityLarge specific surface areaFinal product manufactureLayered productsFuel cellsPorous carbon

The porous carbon structure according to one embodiment of the present invention includes mesopores, and at least two kinds of macropores having different average pore diameters. The porous carbon structure includes inter-connected pores and thereby increases specific surface area and improves electronic conductivity.

Owner:SAMSUNG SDI CO LTD

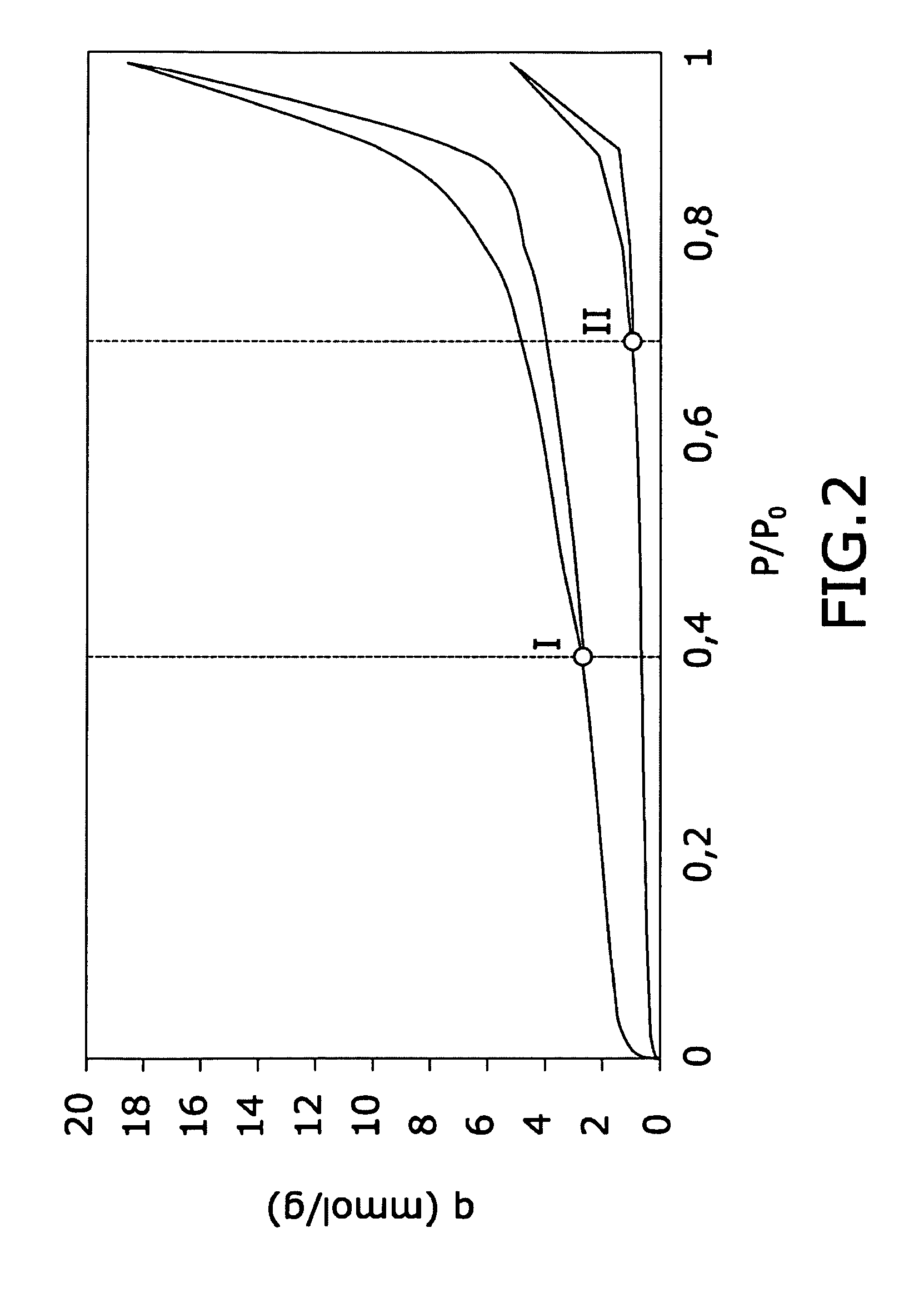

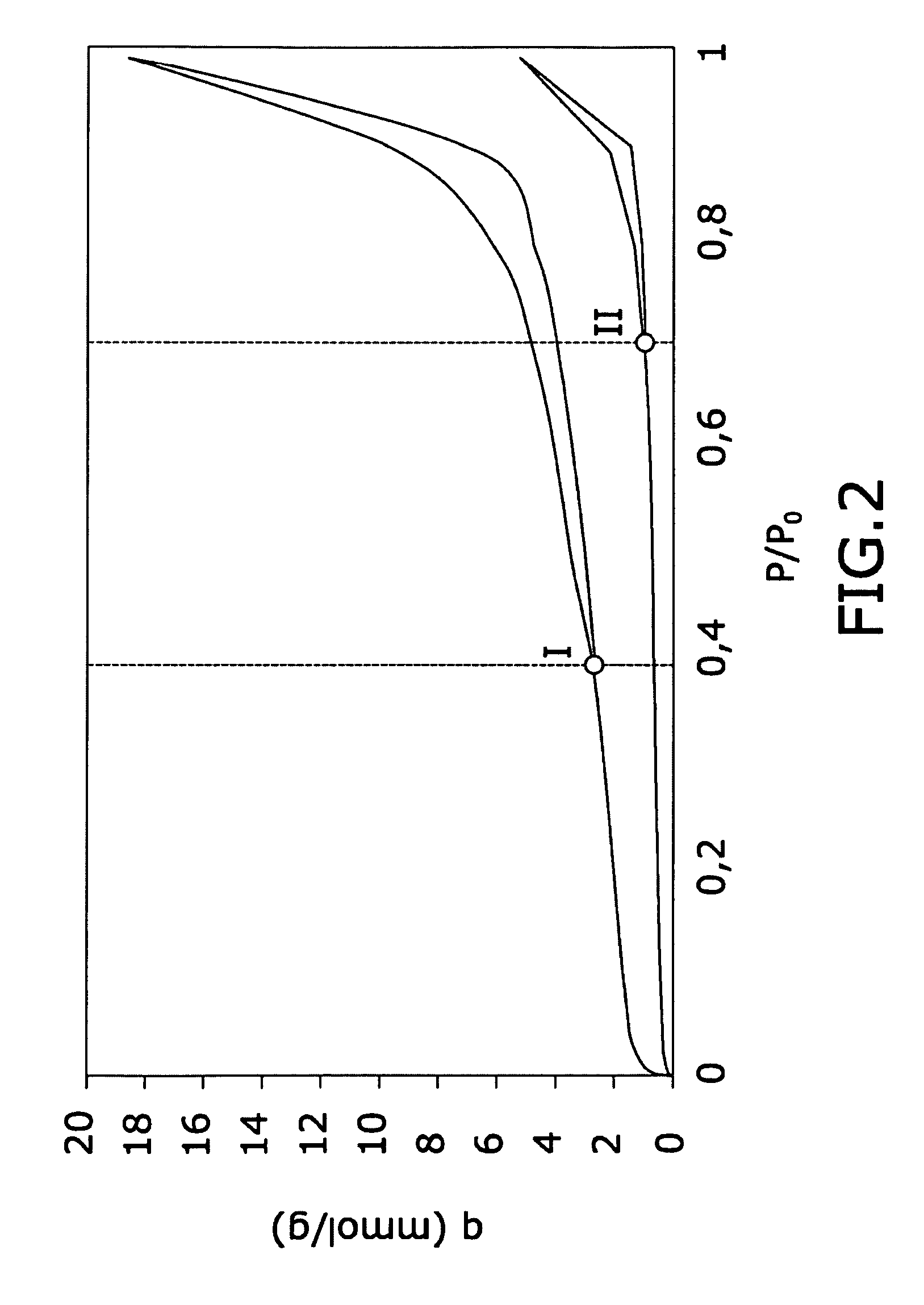

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1High specific surface area and graphitization degreeHigh productivityMaterial nanotechnologyCarbon compoundsSpecific volumeChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRUPO ANTOLIN ING

High specific surface area mixed oxide of cerium and of another rare earth, preparation method and use in catalysis

ActiveUS20100329954A1Effective supportReduce the risk of contaminationNitrogen compoundsInternal combustion piston enginesMixed oxideLiquid medium

The mixed oxide of the invention mainly consists of cerium oxide and of at least one oxide of another rare earth. It has a specific surface area of at least 20 m2 / g after calcining at 1000° C. for 5 hours. It is obtained by forming a liquid medium comprising a cerium compound; by heating this medium; by adding to the precipitate obtained a compound of the other rare earth, by heating the medium thus obtained and by bringing its pH to a basic value and by calcining the precipitate. The mixed oxide may be used as a catalyst support.

Owner:ANAN KASEI CO LTD

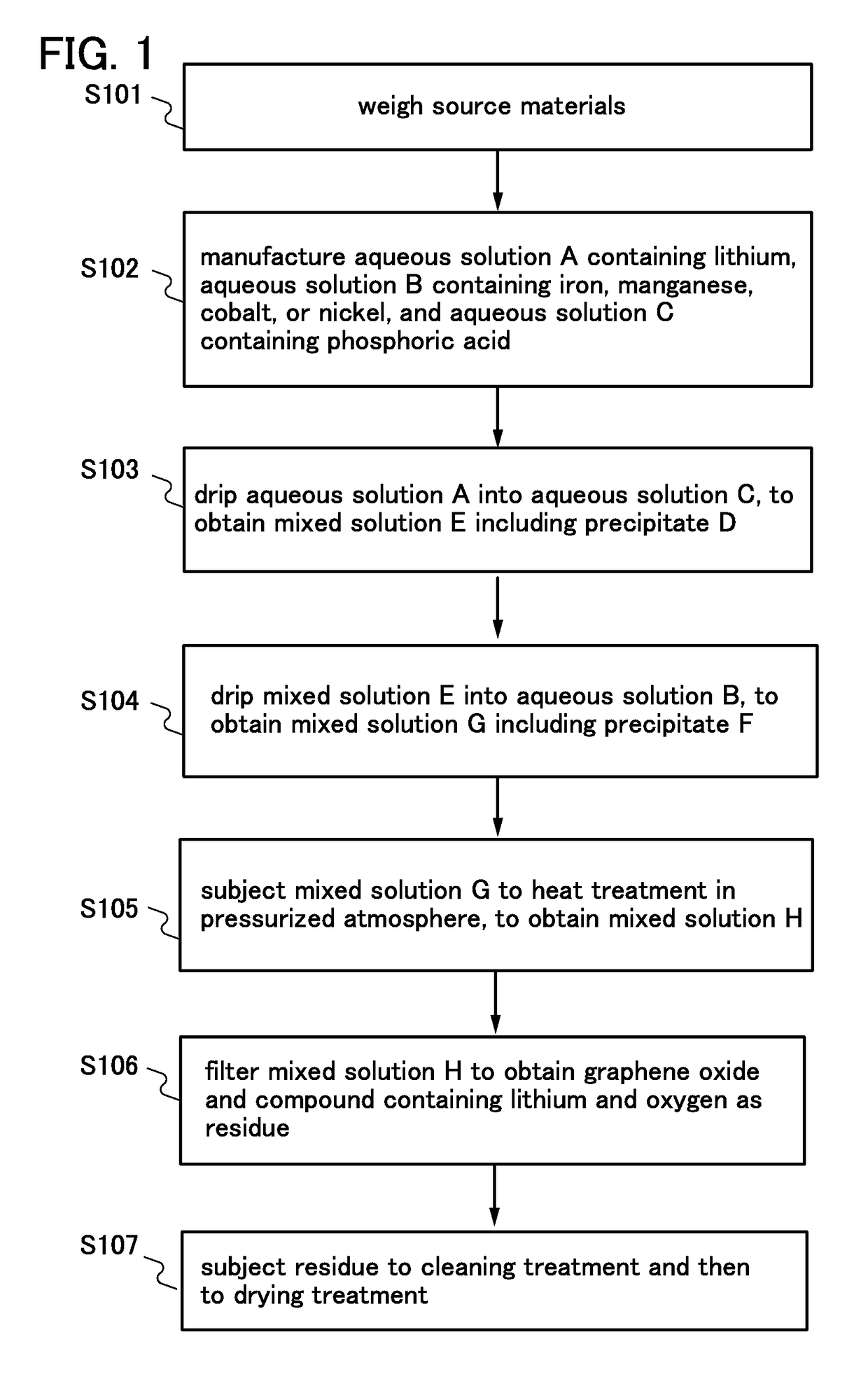

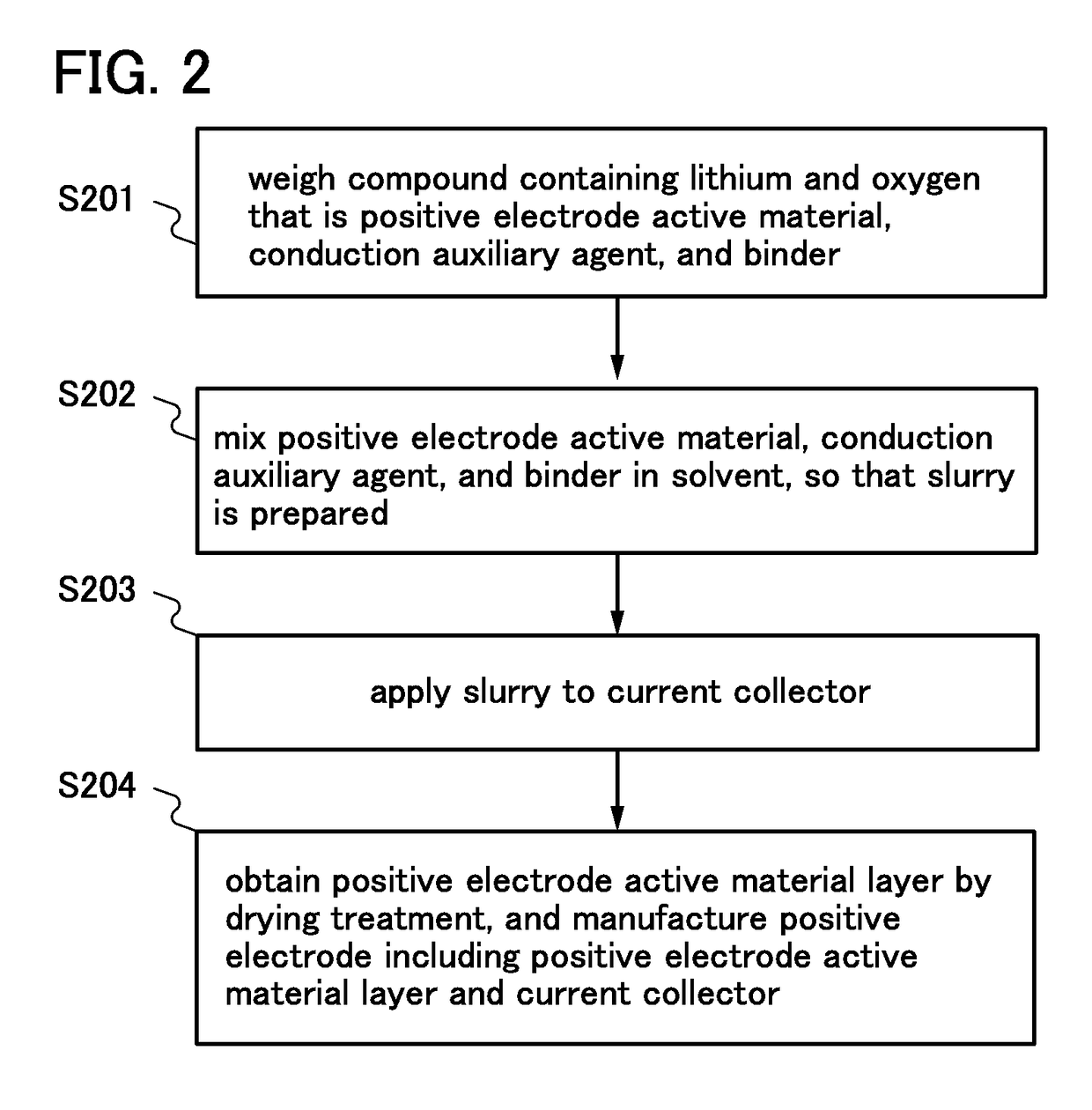

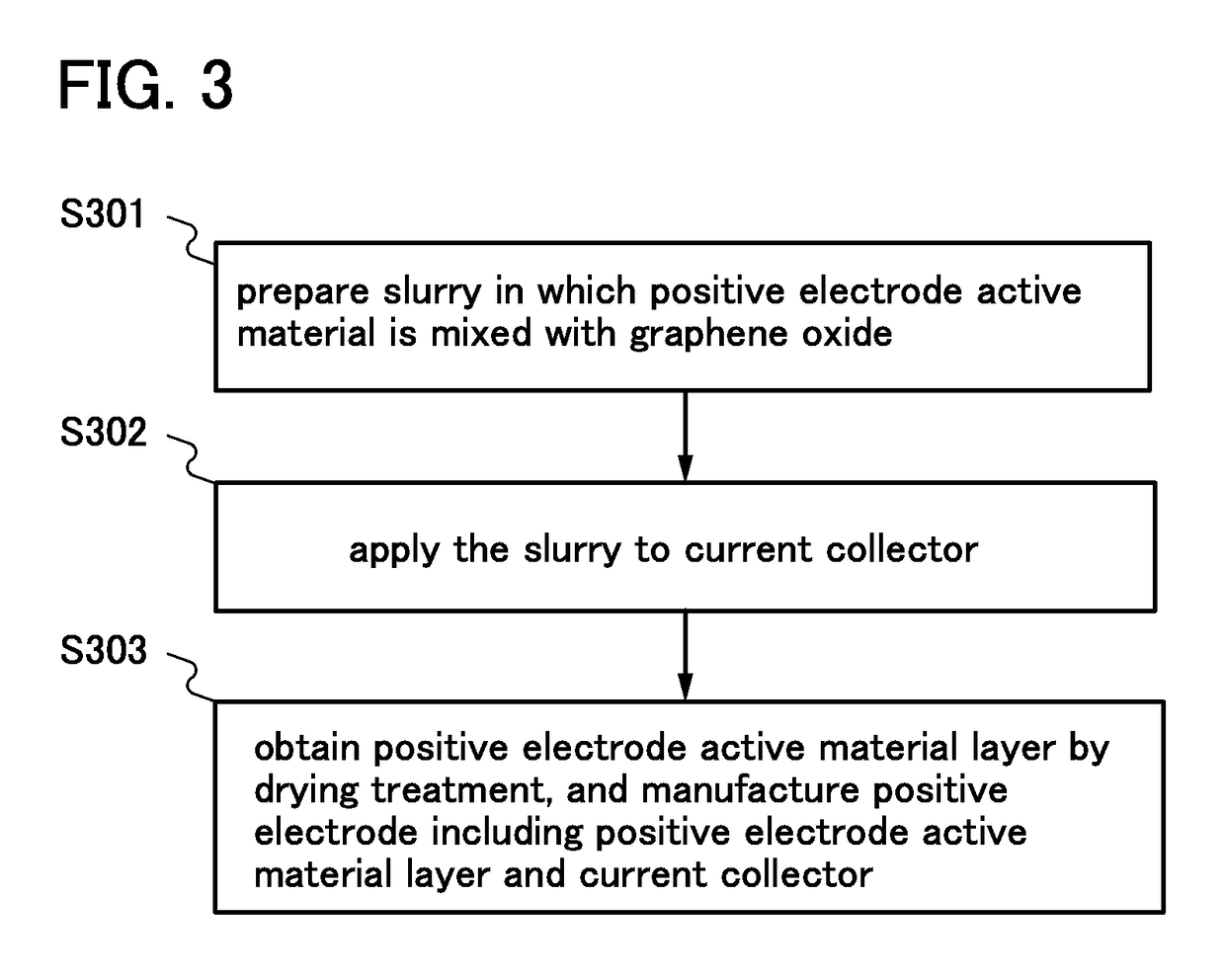

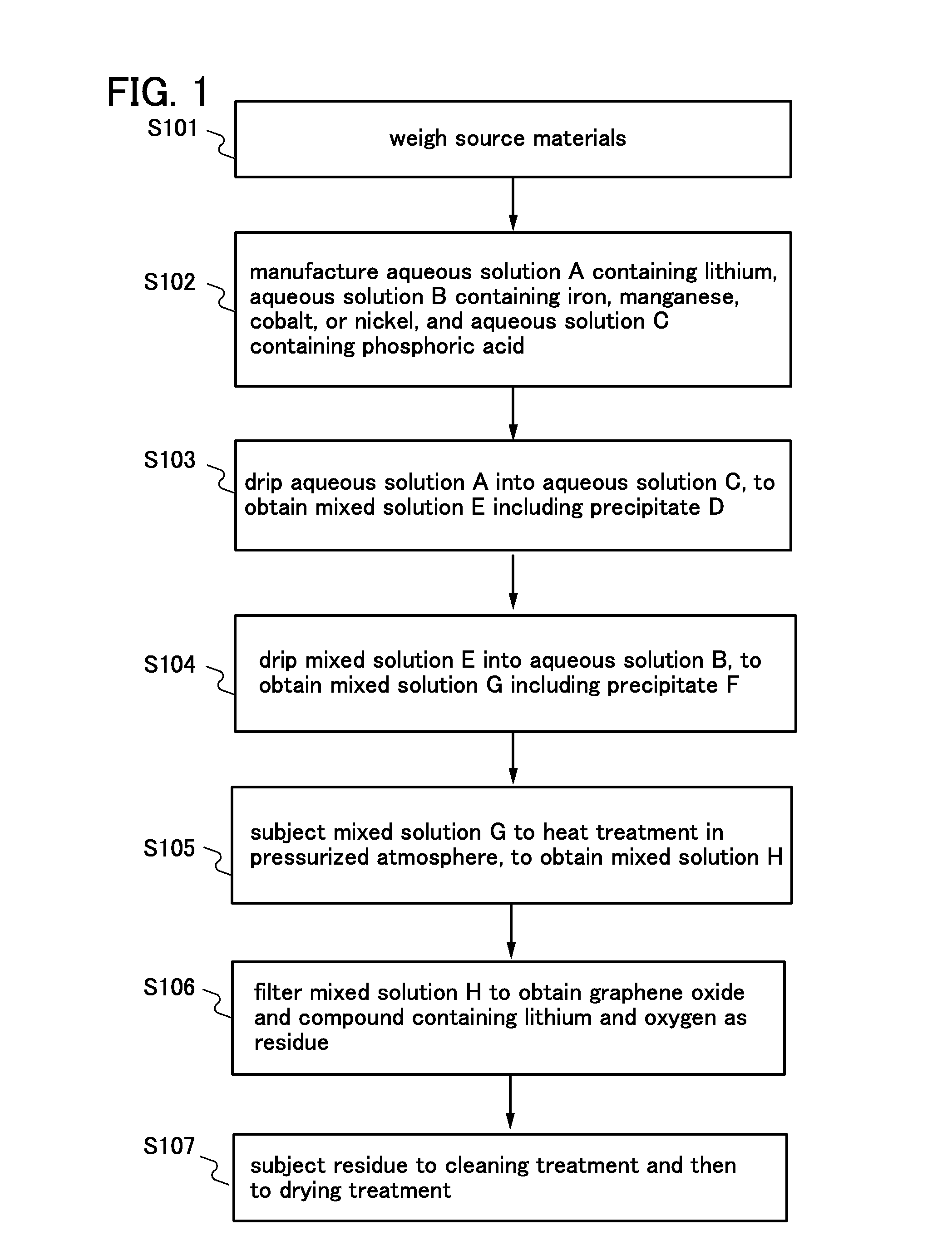

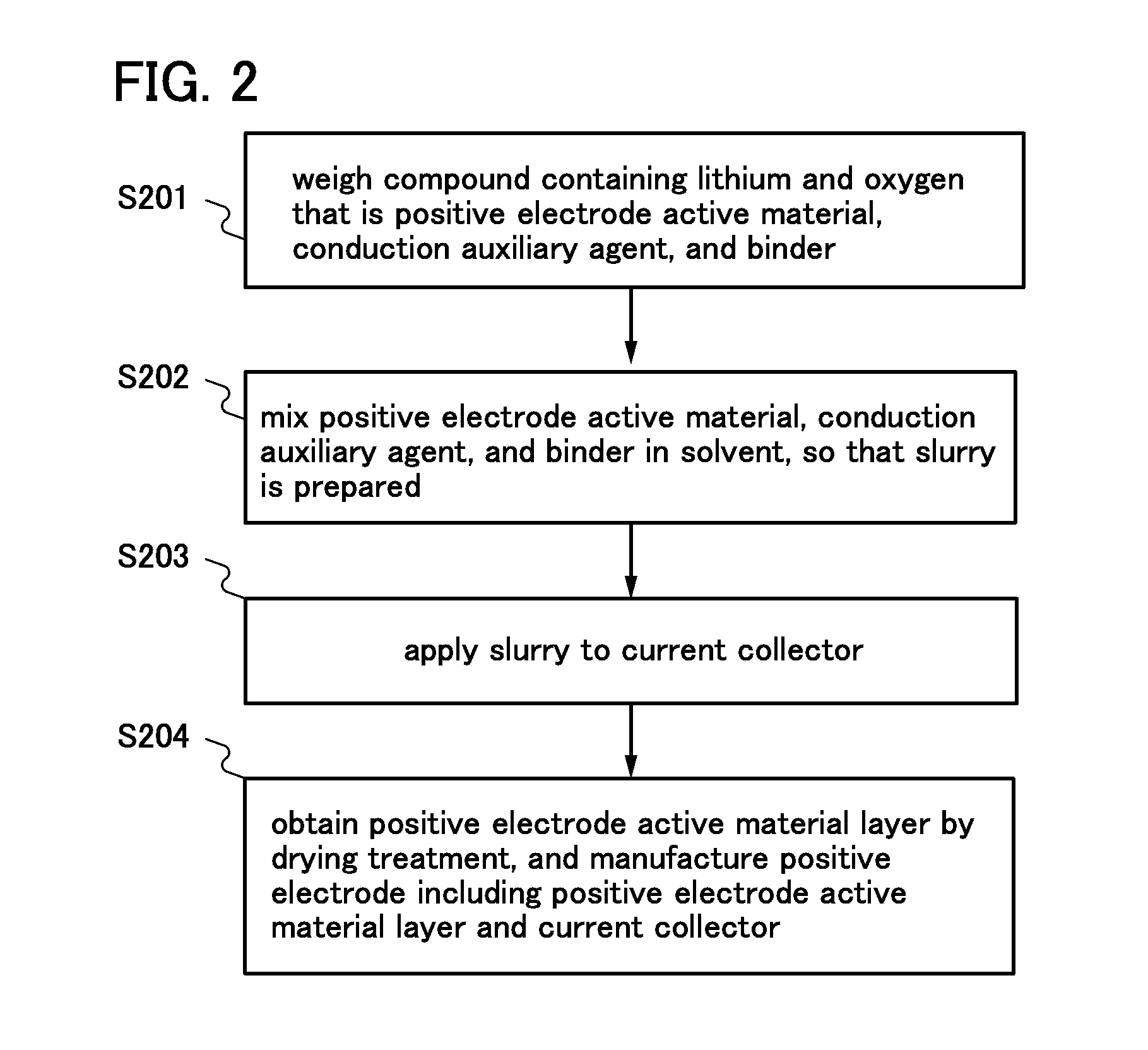

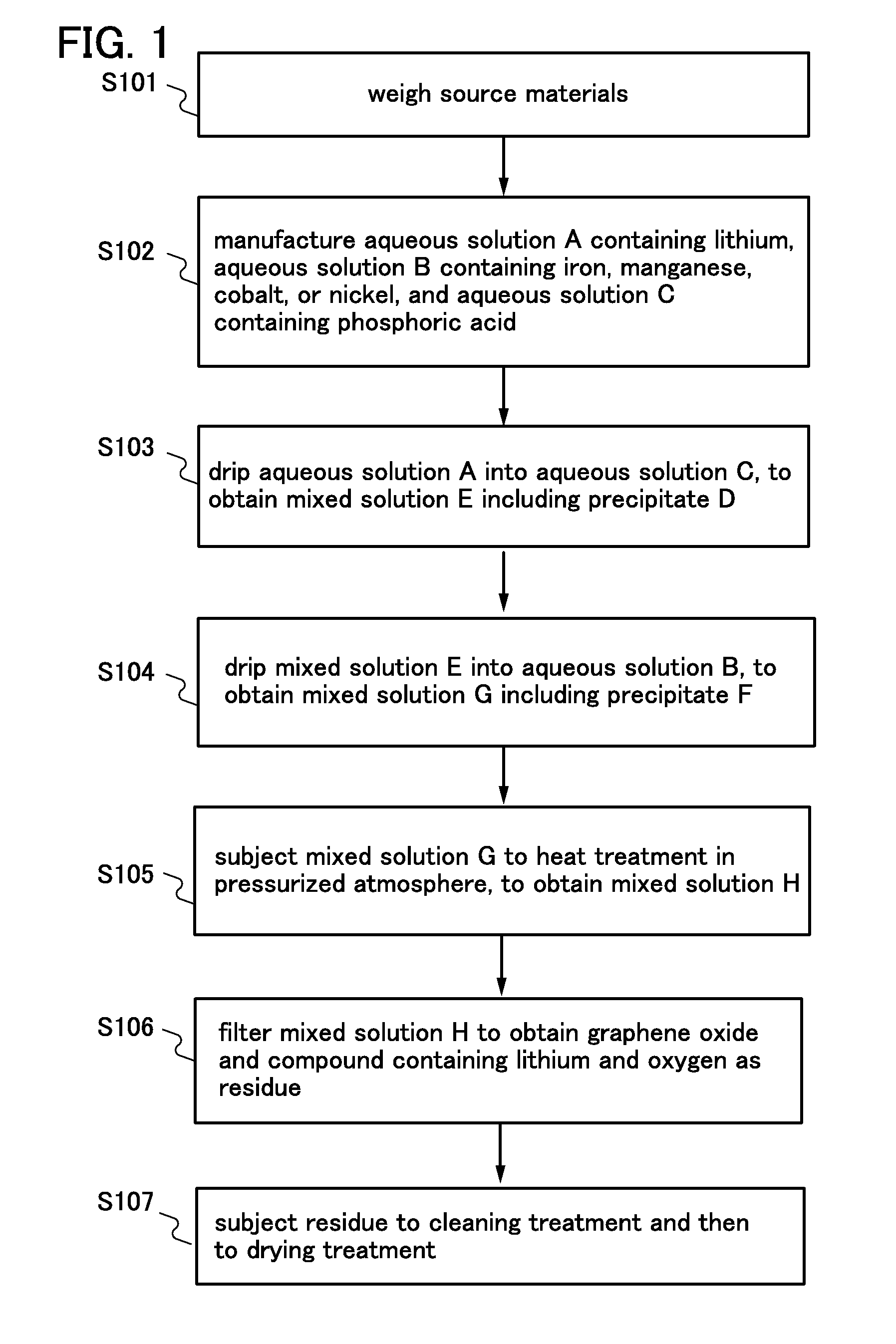

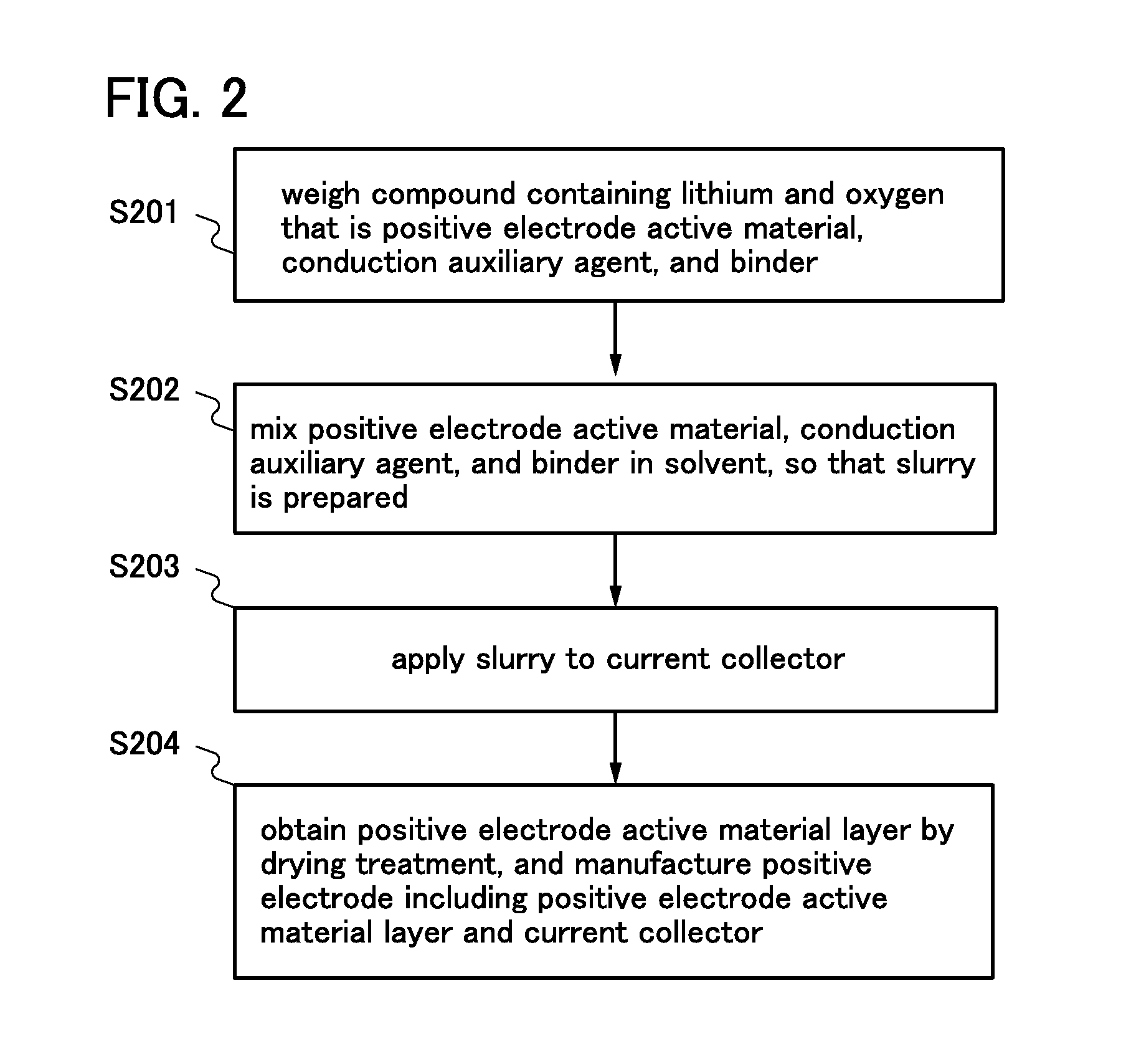

Method of manufacturing positive electrode active material for lithium ion battery

ActiveUS8470477B2Reduce production processImprove productivityMaterial nanotechnologyElectrolytic capacitorsManganesePhosphoric acid

At least one of an aqueous solution A containing lithium, an aqueous solution B containing iron, manganese, cobalt, or nickel, and an aqueous solution C containing a phosphoric acid includes graphene oxide. The aqueous solution A is dripped into the aqueous solution C, so that a mixed solution E including a precipitate D is prepared. The mixed solution E is dripped into the aqueous solution B, so that a mixed solution G including a precipitate F is prepared. The mixed solution G is subjected to heat treatment in a pressurized atmosphere, so that a mixed solution H is prepared, and the mixed solution H is then filtered. Thus, particles of a compound containing lithium and oxygen which have a small size are obtained.

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing positive electrode active material for lithium ion battery

ActiveUS20130047423A1Increase surface areaImprove productivityMaterial nanotechnologyElectrolytic capacitorsPhosphoric acidManganese

At least one of an aqueous solution A containing lithium, an aqueous solution B containing iron, manganese, cobalt, or nickel, and an aqueous solution C containing a phosphoric acid includes graphene oxide. The aqueous solution A is dripped into the aqueous solution C, so that a mixed solution E including a precipitate D is prepared. The mixed solution E is dripped into the aqueous solution B, so that a mixed solution G including a precipitate F is prepared. The mixed solution G is subjected to heat treatment in a pressurized atmosphere, so that a mixed solution H is prepared, and the mixed solution H is then filtered. Thus, particles of a compound containing lithium and oxygen which have a small size are obtained.

Owner:SEMICON ENERGY LAB CO LTD

Sheetlike products and works

InactiveUS20090321028A1Good hygroscopicityGuaranteed specific surface areaNon-fibrous pulp additionSpecial paperMoisture absorptionMetal

This invention is to provide a sheet product that is excellent in moisture absorption amount, moisture absorption speed and moisture release speed and is capable of keeping a powder from falling off and that can have a large content of a moisture adsorbent, and the sheet product of this invention contains (a) a moisture adsorbent formed of a tubular or fibrous metal oxide, (b) a cellulosic fibrillated fiber, and (c) an organic fiber having a fineness of 0.01 dtex to 0.45 dtex and is characteristically produced by a paper-making method.

Owner:MITSUBISHI PAPER MILLS LTD

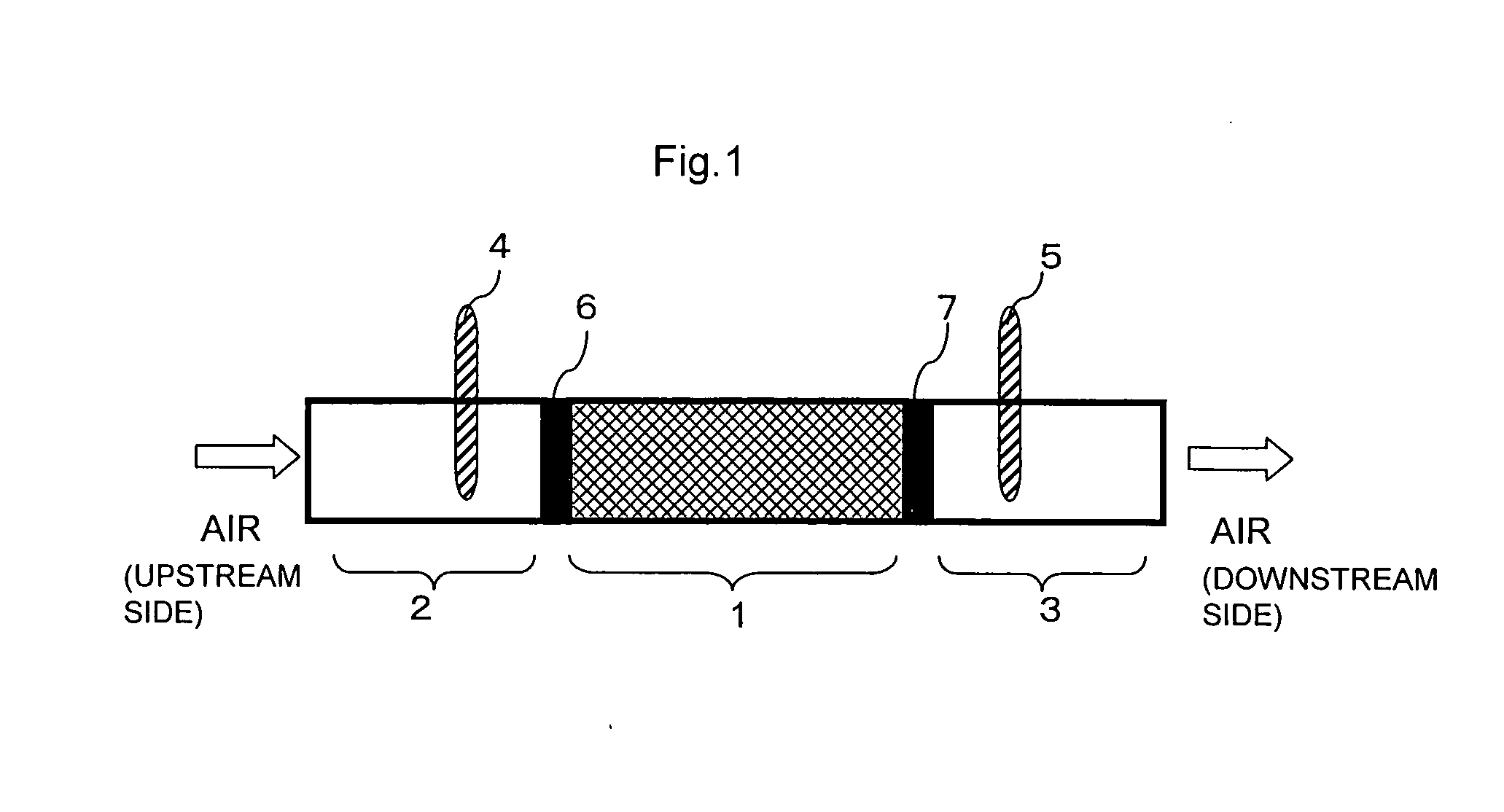

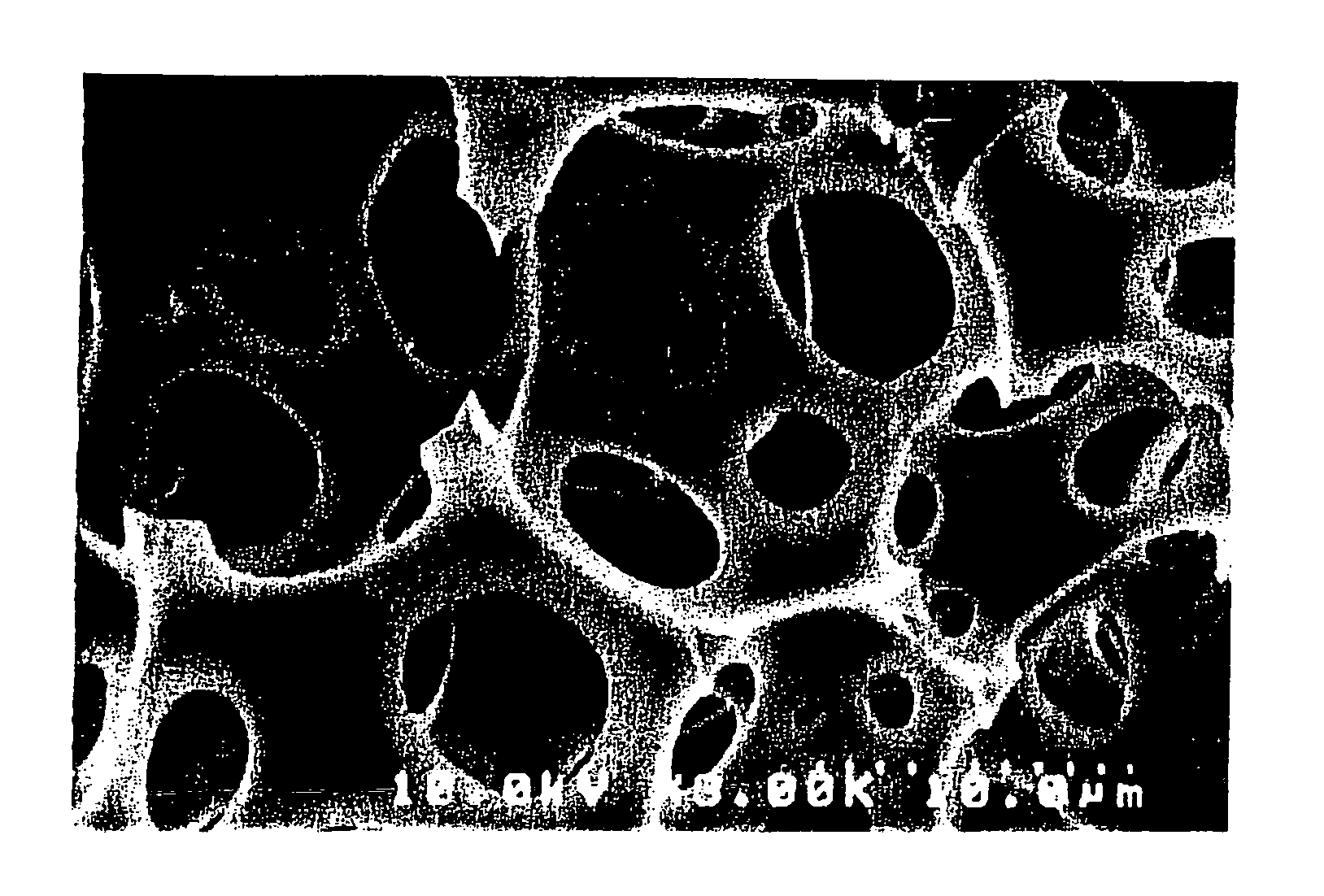

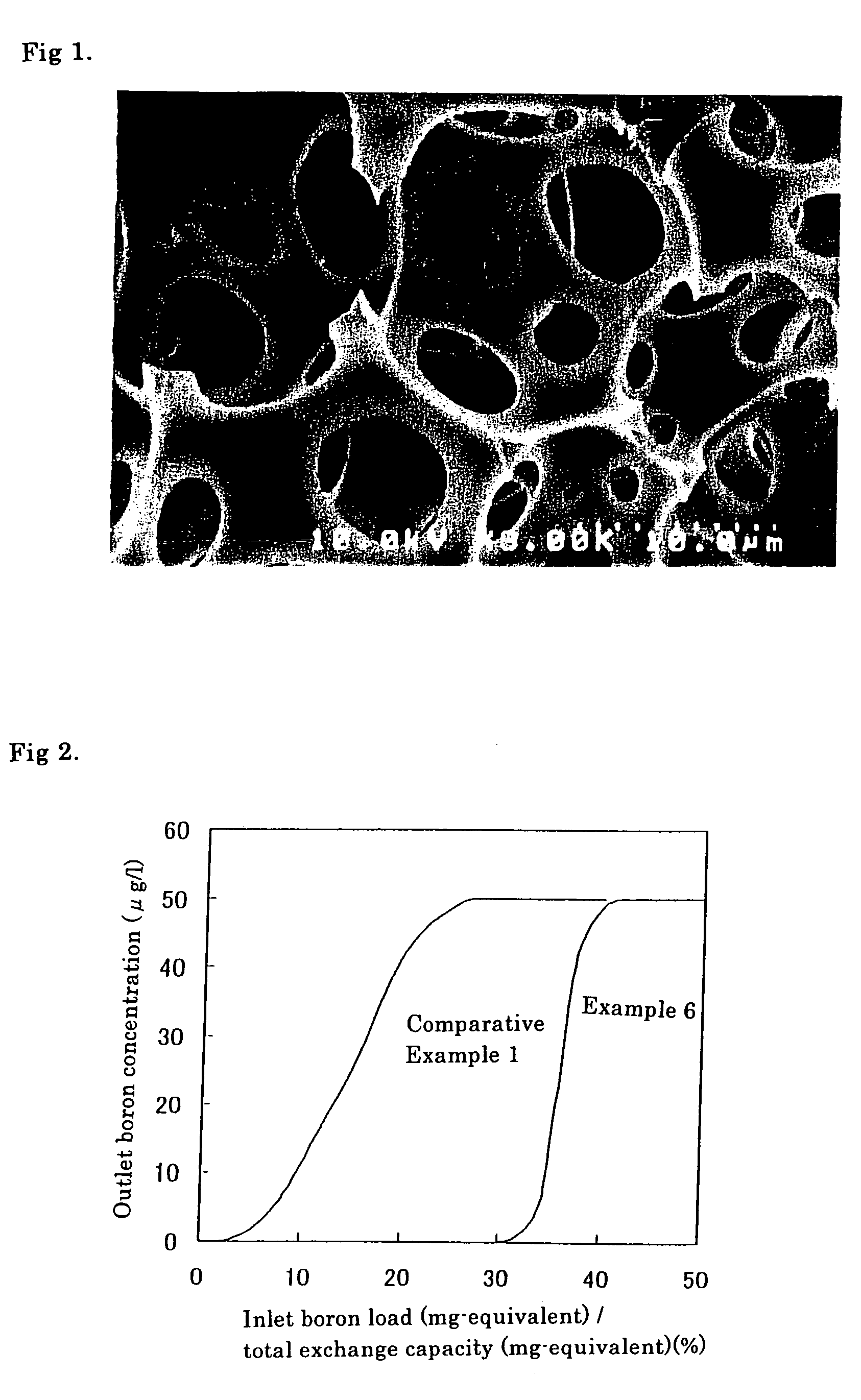

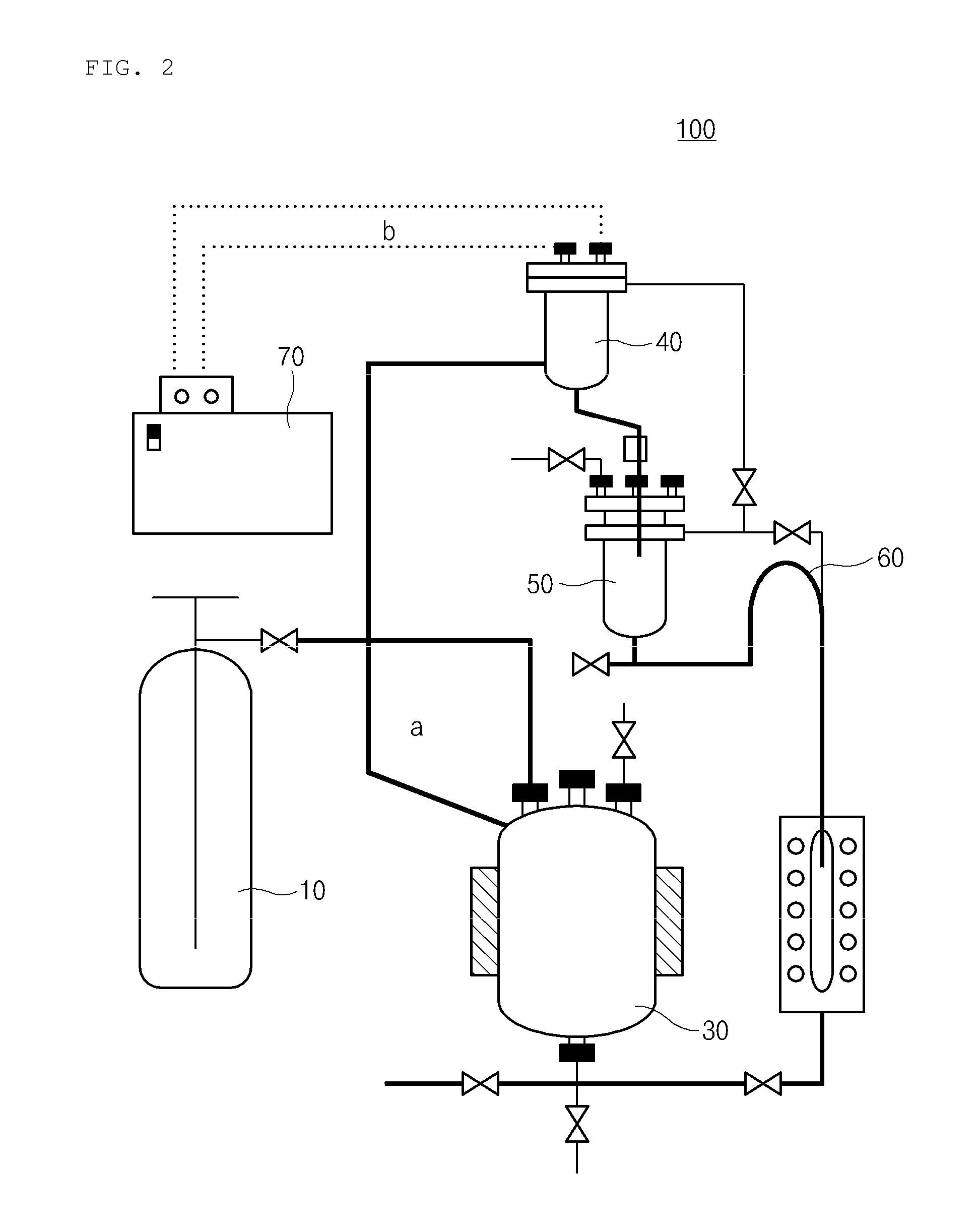

Organic porous article having selective adsorption ability for boron, and boron removing module and ultra-pure water production apparatus using the same

InactiveUS7094349B2Improve efficiencyImprove abilitiesLoose filtering material filtersCartridge filtersWater productionPore diameter

An organic porous material having selective adsorption ability for boron, characterized in that it has an open cell structure comprising macro pores jointed to one another and, formed within the wall of the macro pore, meso pores having a pore diameter of 0.02 to 200 μm, has a total pore volume of 1 to 50 ml / g, and contains a compound capable of forming a complex with boric acid introduced through a covalent bonding in an amount of 1 μmol / g-dry porous material or more. The organic porous material exhibits improved ability for adsorbing boron and also is excellent in stability, and a boron removing module and an ultra-pure water production apparatus using the porous material have extremely high utility.

Owner:ORGANO CORP

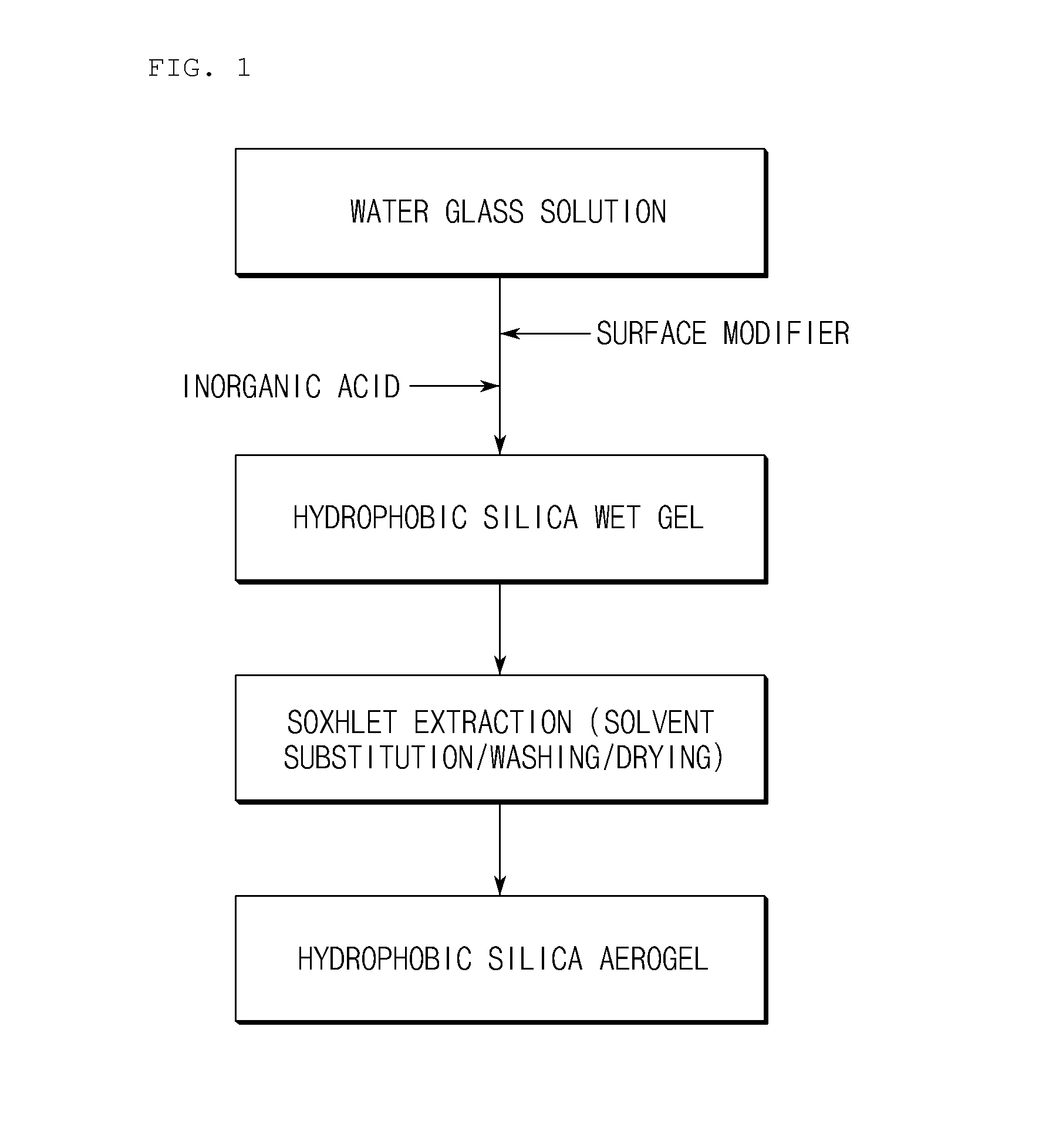

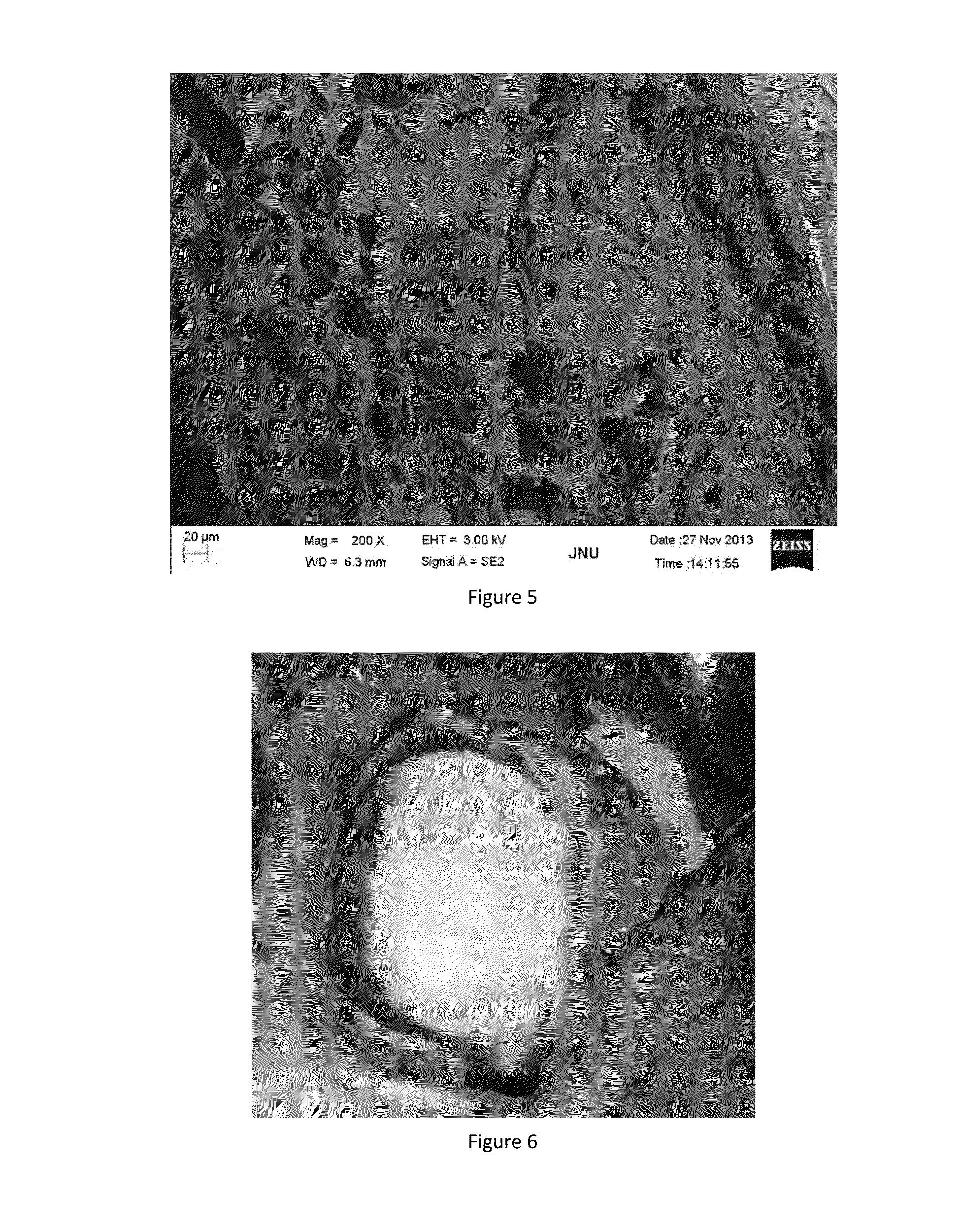

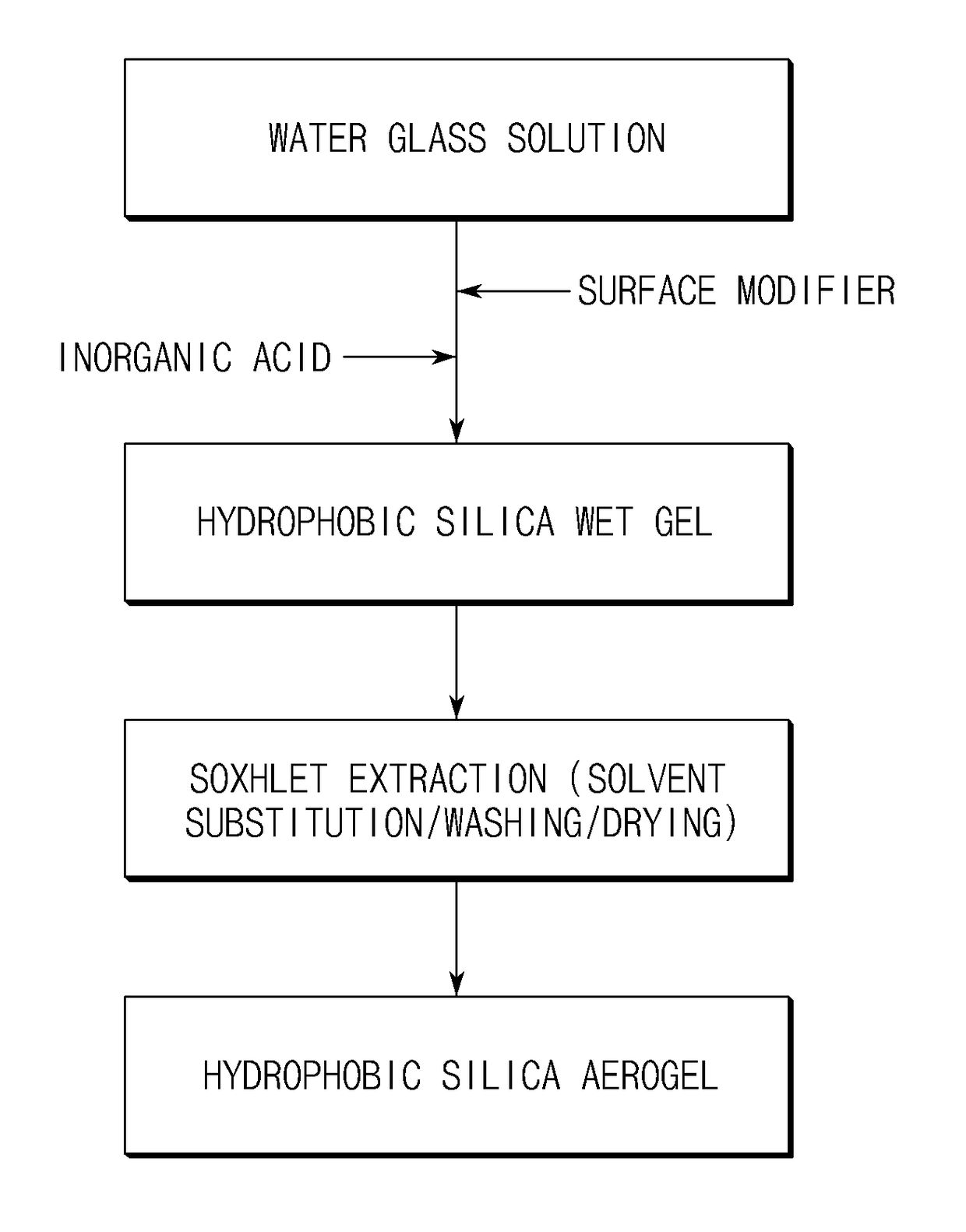

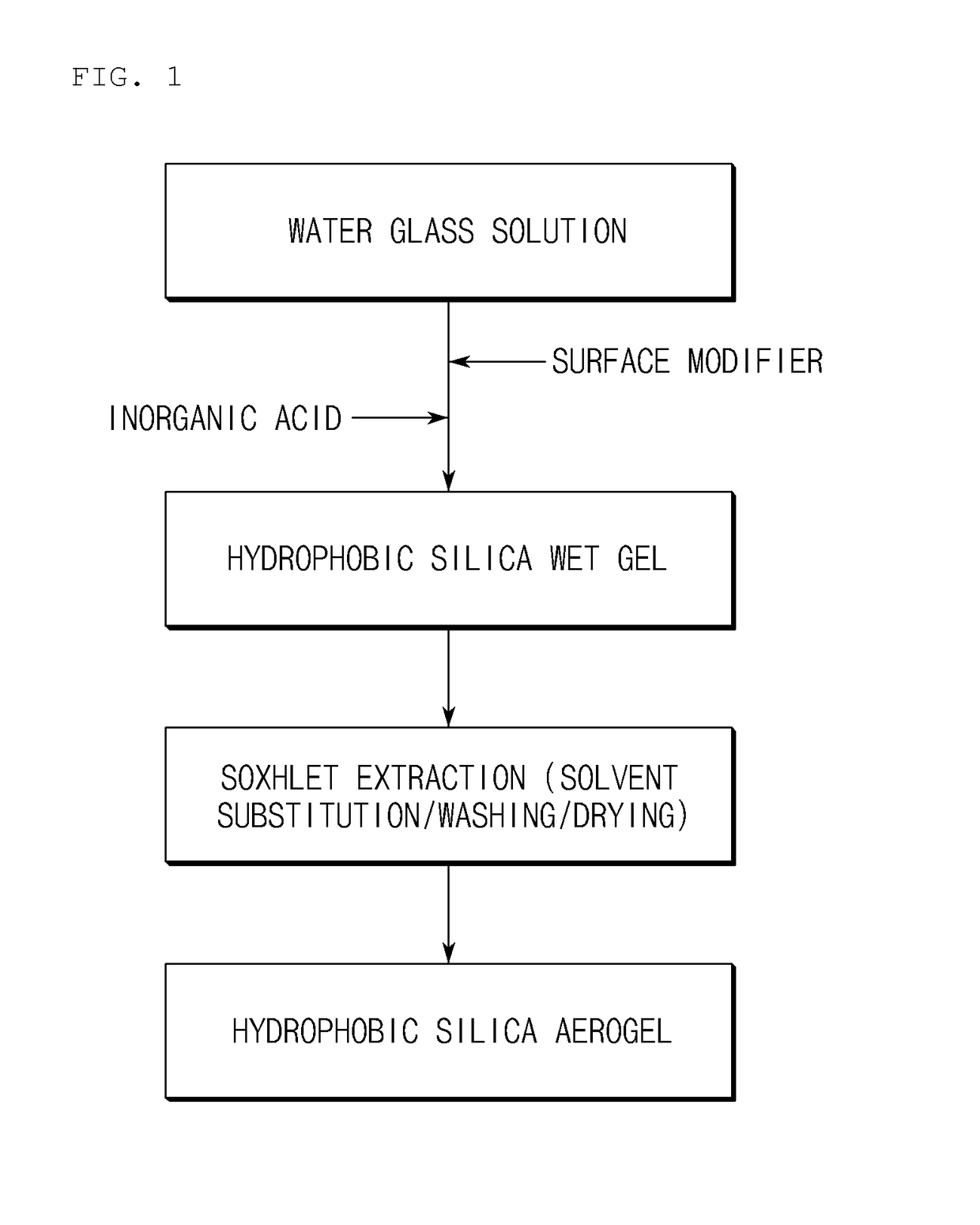

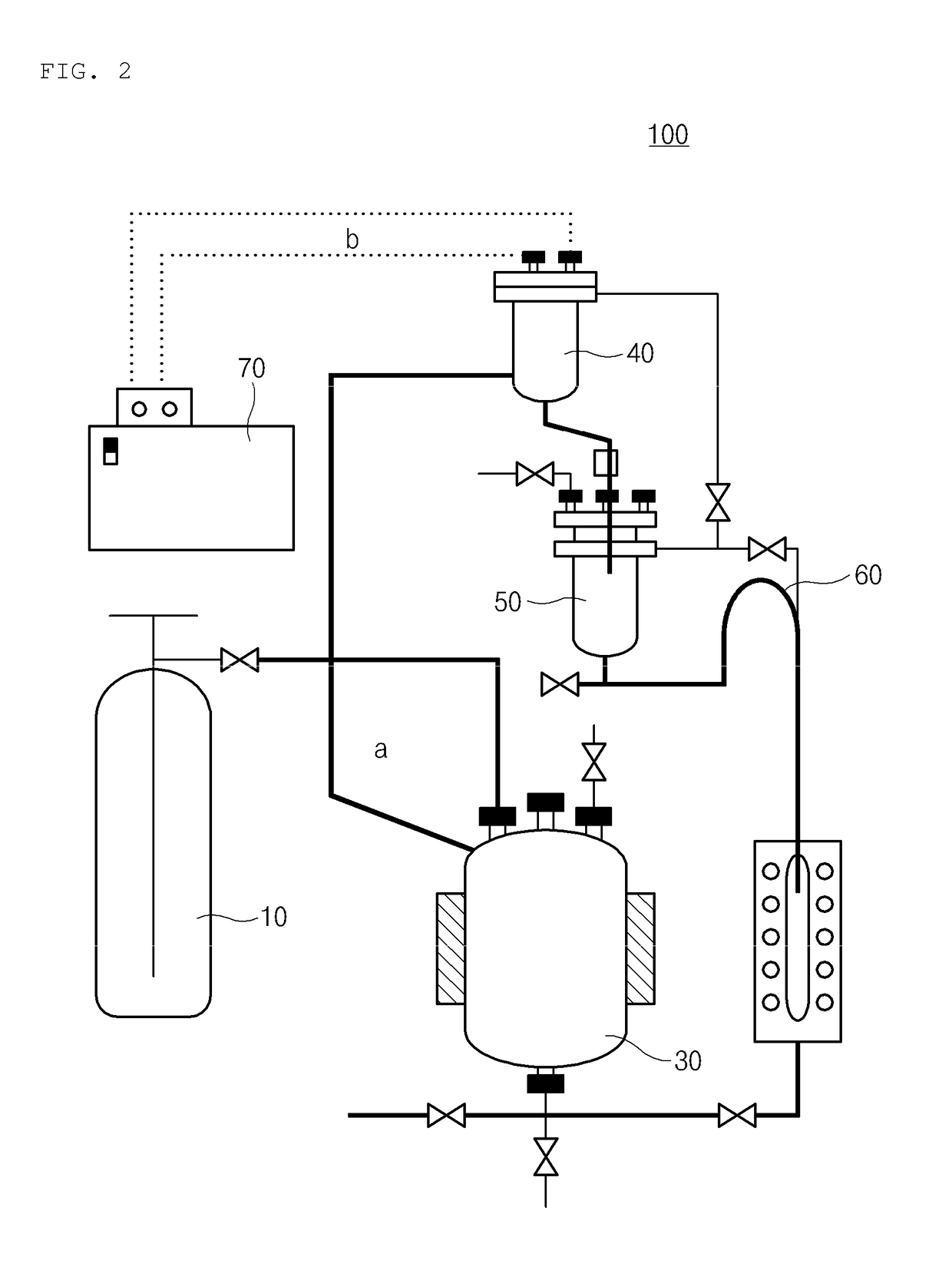

Preparation method of hydrophobic silica aerogel

Provided is a method for preparing a hydrophobic silica aerogel by using a Soxhlet extraction, and a hydrophobic silica aerogel prepared by using the method. Since the preparation method according to the present invention may simultaneously perform washing and drying of a hydrophobic silica wet gel as well as solvent substitution and may remove an extraction solvent without an additional separation process, a hydrophobic silica aerogel having low tap density and high specific surface area may be easily prepared.

Owner:LG CHEM LTD

Manganese dioxide nanowire @ multidimensional mesoporous metal-organic framework adsorbent and preparation therefor

ActiveUS20180056269A1Improve performanceEfficient use ofOther chemical processesWater contaminantsNanowireSorbent

A manganese dioxide nanowire @ multidimensional mesoporous metal-organic framework adsorbent and application method thereof for removing heavy metals from water. A multidimensional mesoporous metal-organic framework material is prepared from metal ions and organic ligands by means of a self-assembly reaction; a manganese dioxide nanowire is prepared from manganese salt and thiosulfate by means of reaction in a reaction kettle. The adsorbent possesses not only the characteristics of a multidimensional mesoporous metal-organic framework material, such as reticulated pore adaptation, a large specific surface area, and abundant reaction sites, but also the oxidative and catalytic properties of manganese dioxide nanowire.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Method of surface treatment of aluminum foil and its alloy and method of producing immobilized nanocatalyst of transition metal oxides and their alloys

InactiveUS20110287926A1Effectiveness of treatmentLow aluminum contentMaterial nanotechnologyCatalyst activation/preparationAlloyPolymer solution

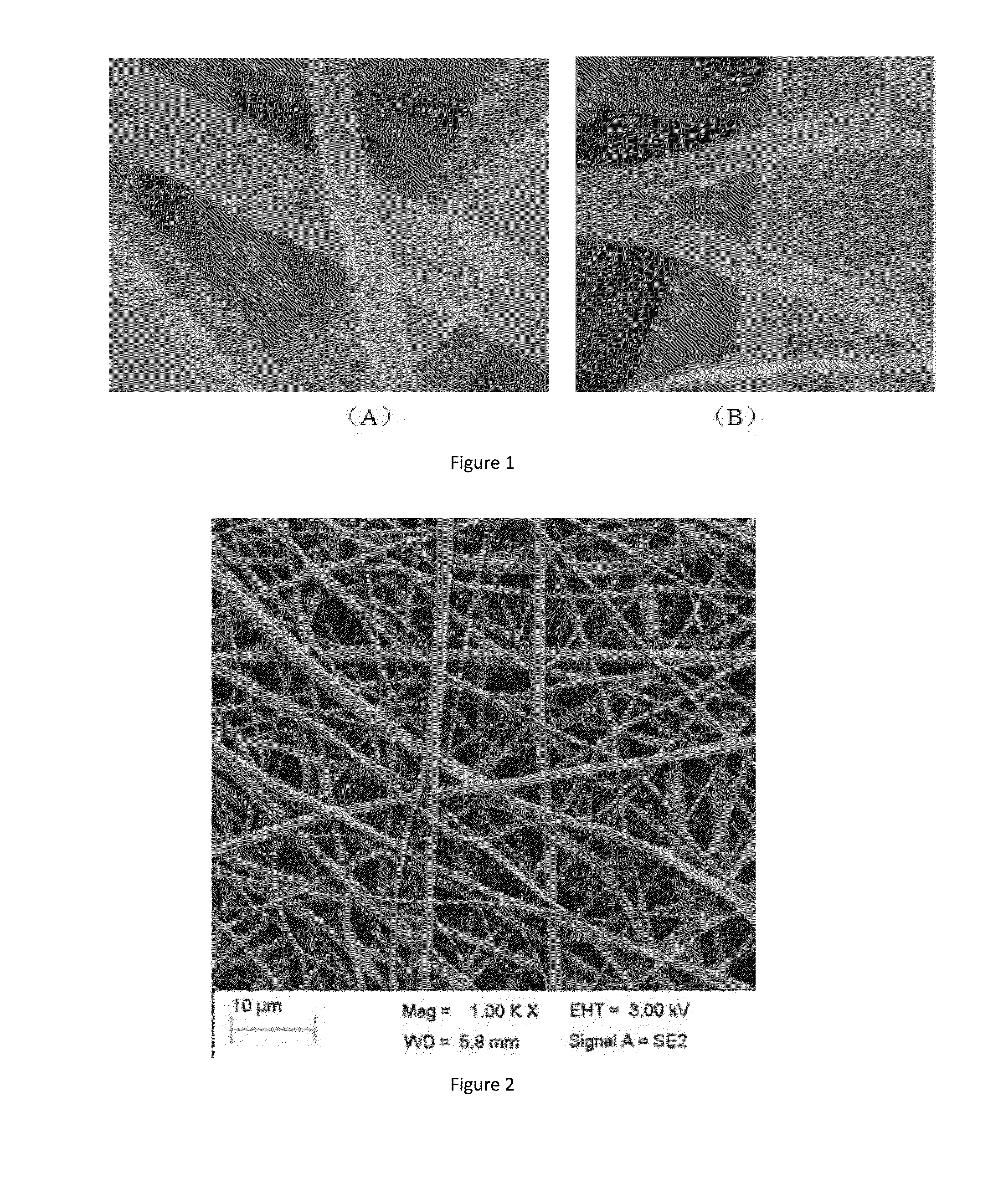

The present invention relates to surface treatments of aluminum foils and aluminum foil alloys. The process for surface treatment includes steps of applying an etching solution to chemically etch at least one surface of the foil to form an etched surface, and forming an aluminium oxidized coating on the etched surface.The present invention also relates to a method of producing an immobilized transition metal nanofibre using an electrospinning apparatus having a spinning tip, the method including the steps of, mixing an organo-metallic salt of a transition metal with a low boiling solvent mixture and polymer solution, the polymer solution having an average viscosity selected at between about 110 cp to 180 cp, preferably 130 cp to 160 cp, providing the spinning tip at a location spaced from a support surface, electrospinning the resultant mixture from the spinning tip onto a support surface in an environment substantially isolated from external air currents.

Owner:UNIVERSITY OF WINDSOR

Porous carbon structure, method for preparing same, electrode catalyst for fuel cell, and electrode and membrane-electrode assembly including same

ActiveUS8361663B2Improve electronic conductivityLarge specific surface areaFinal product manufactureLayered productsFuel cellsPorous carbon

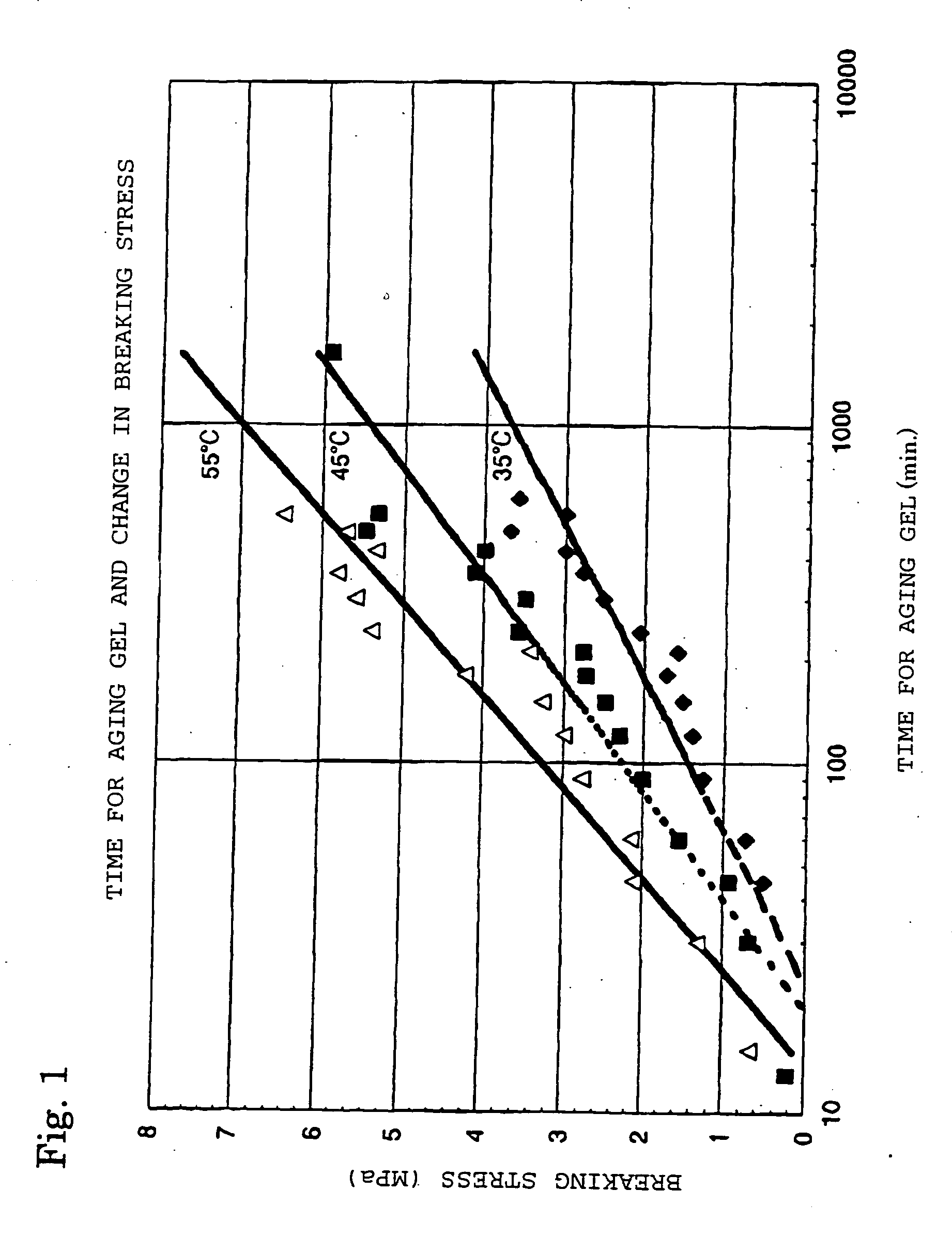

The porous carbon structure according to one embodiment of the present invention includes mesopores, and at least two kinds of macropores having different average pore diameters. The porous carbon structure includes inter-connected pores and thereby increases specific surface area and improves electronic conductivity.

Owner:SAMSUNG SDI CO LTD

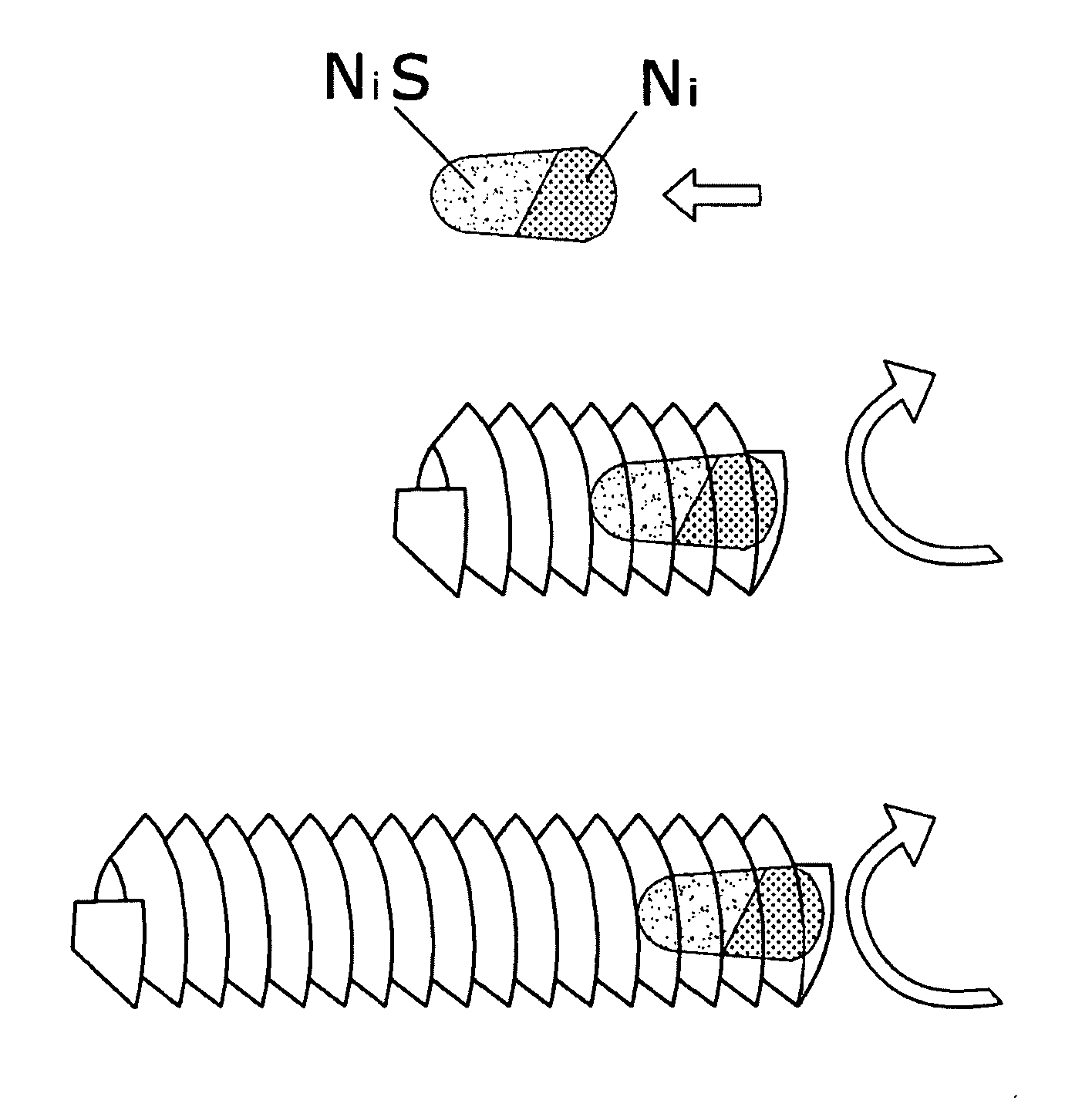

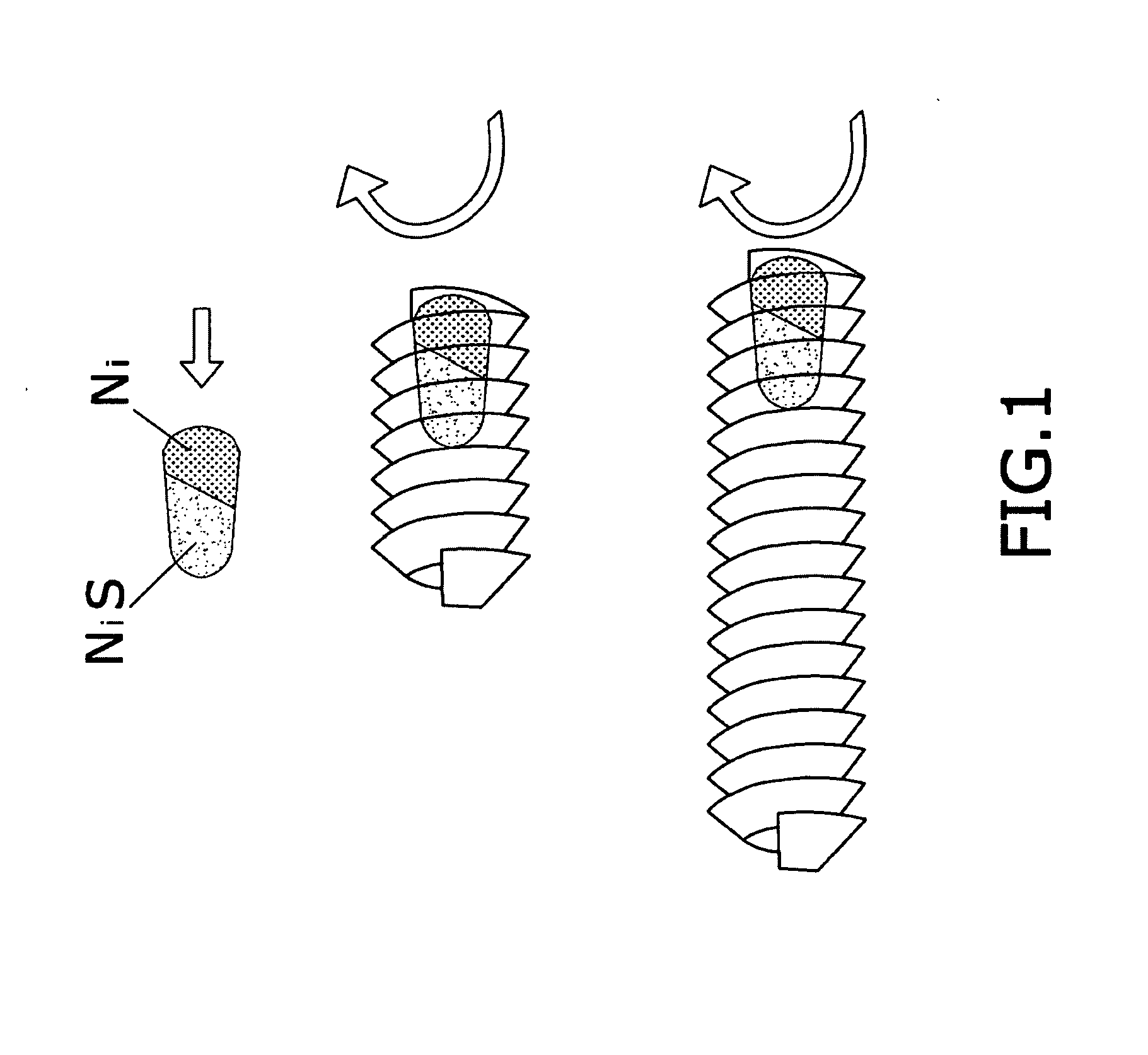

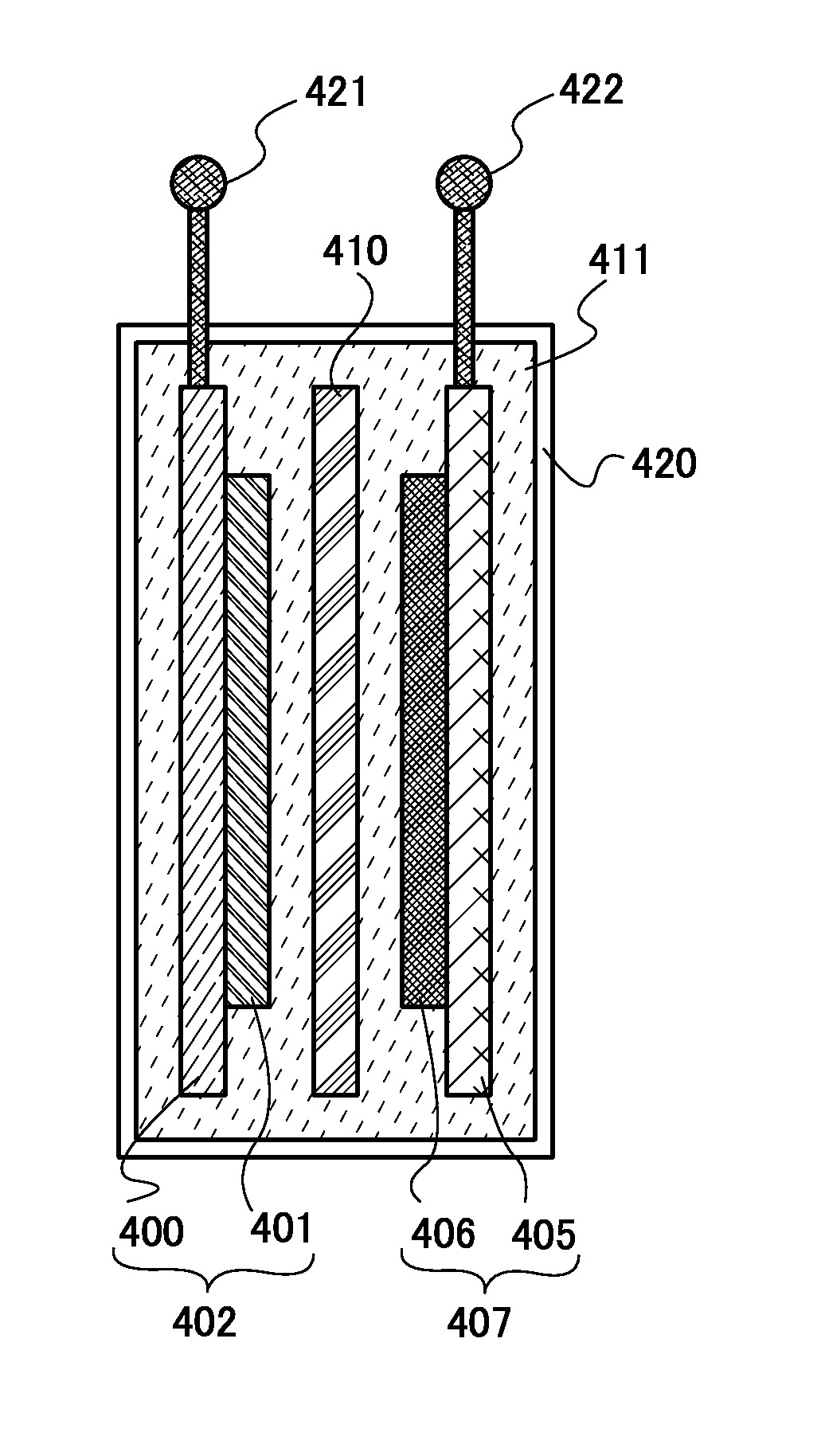

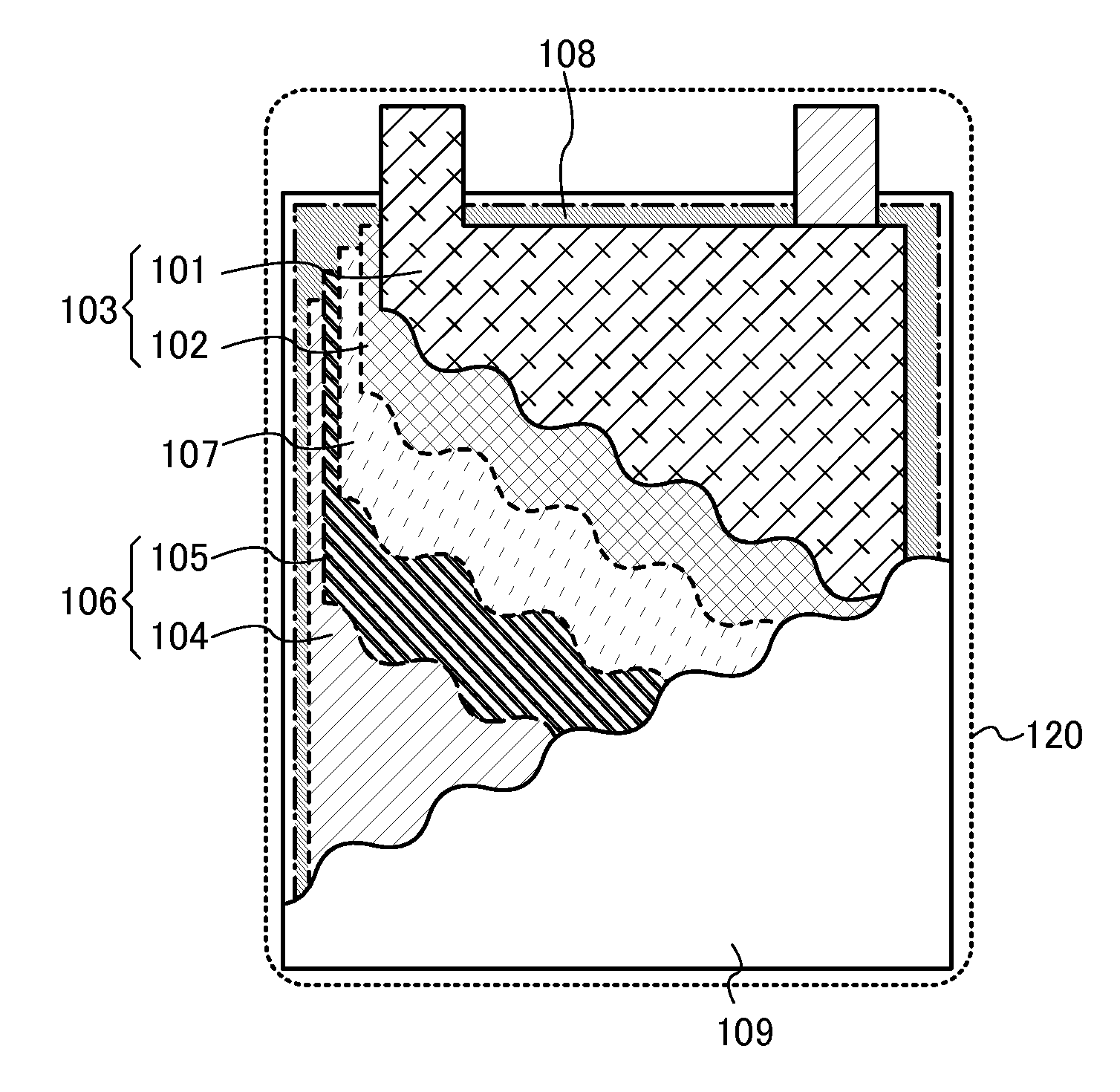

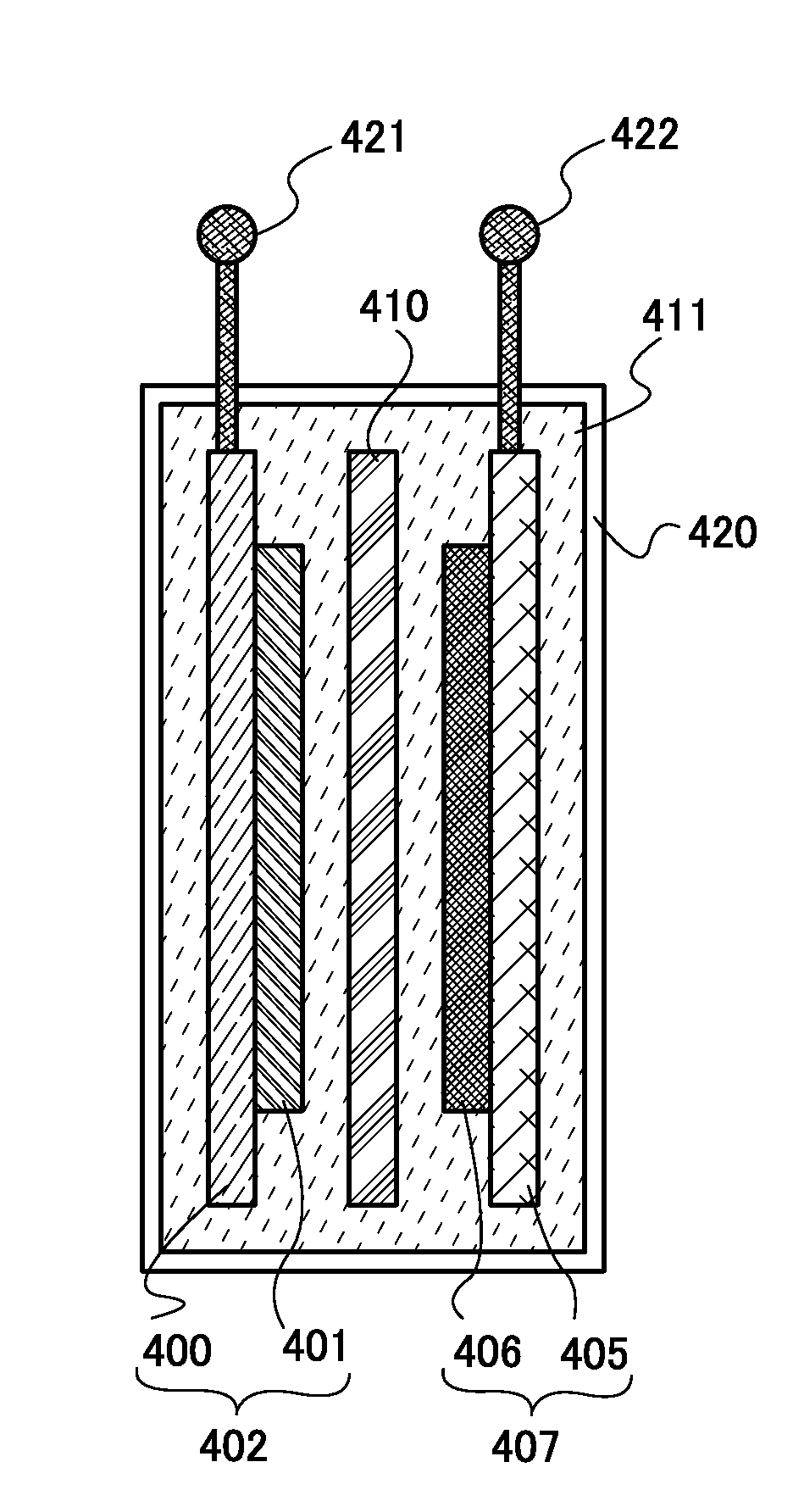

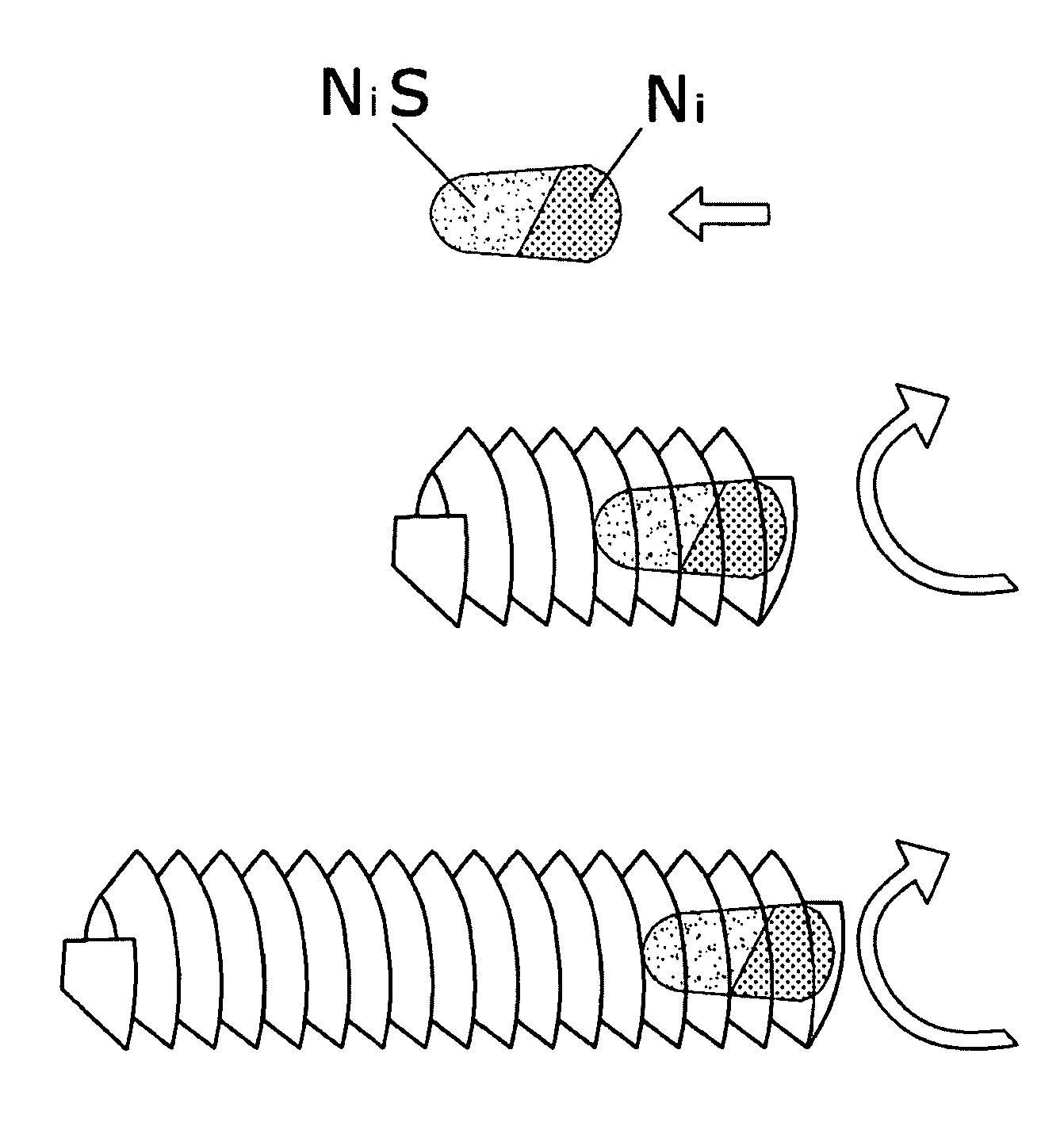

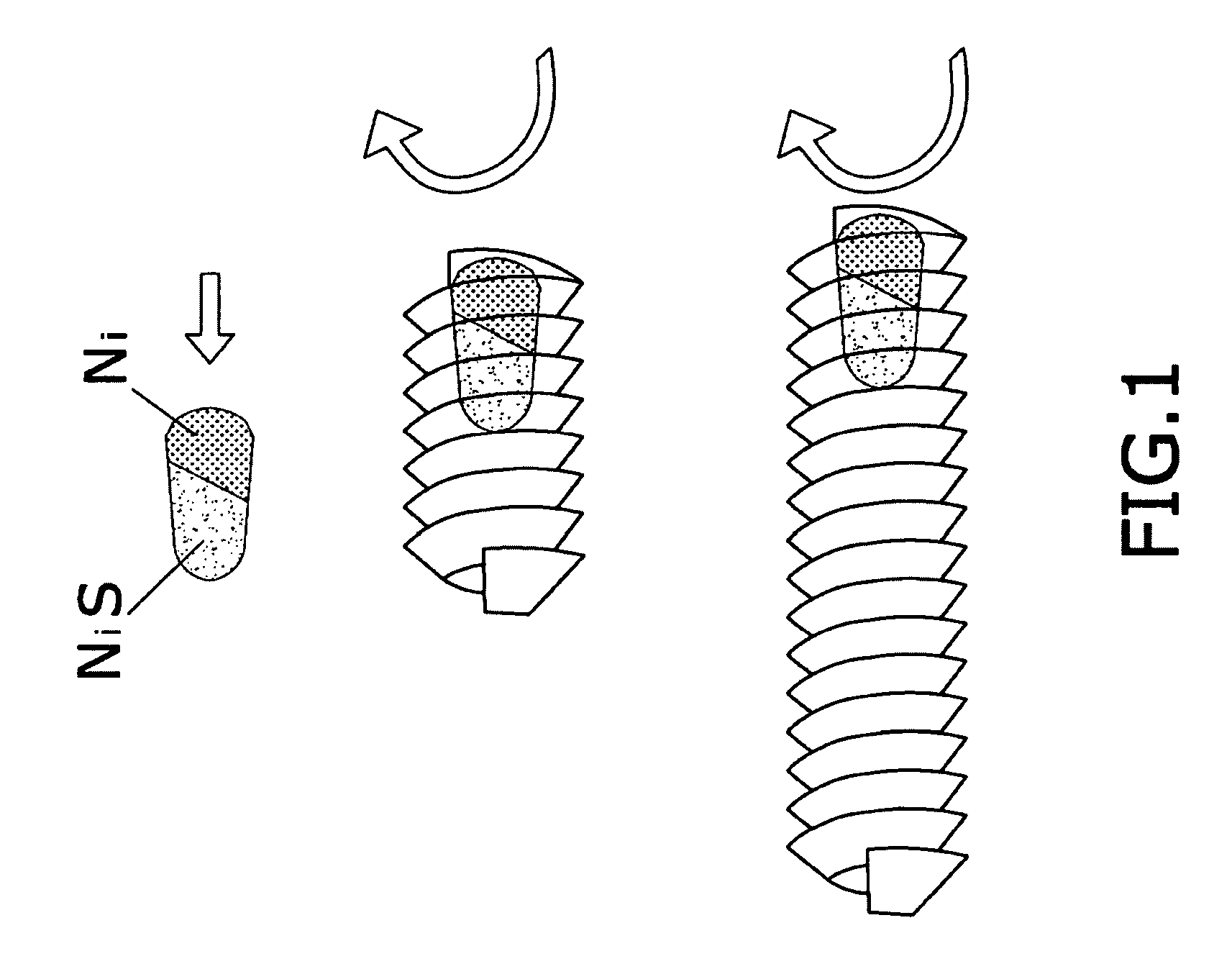

Power storage device

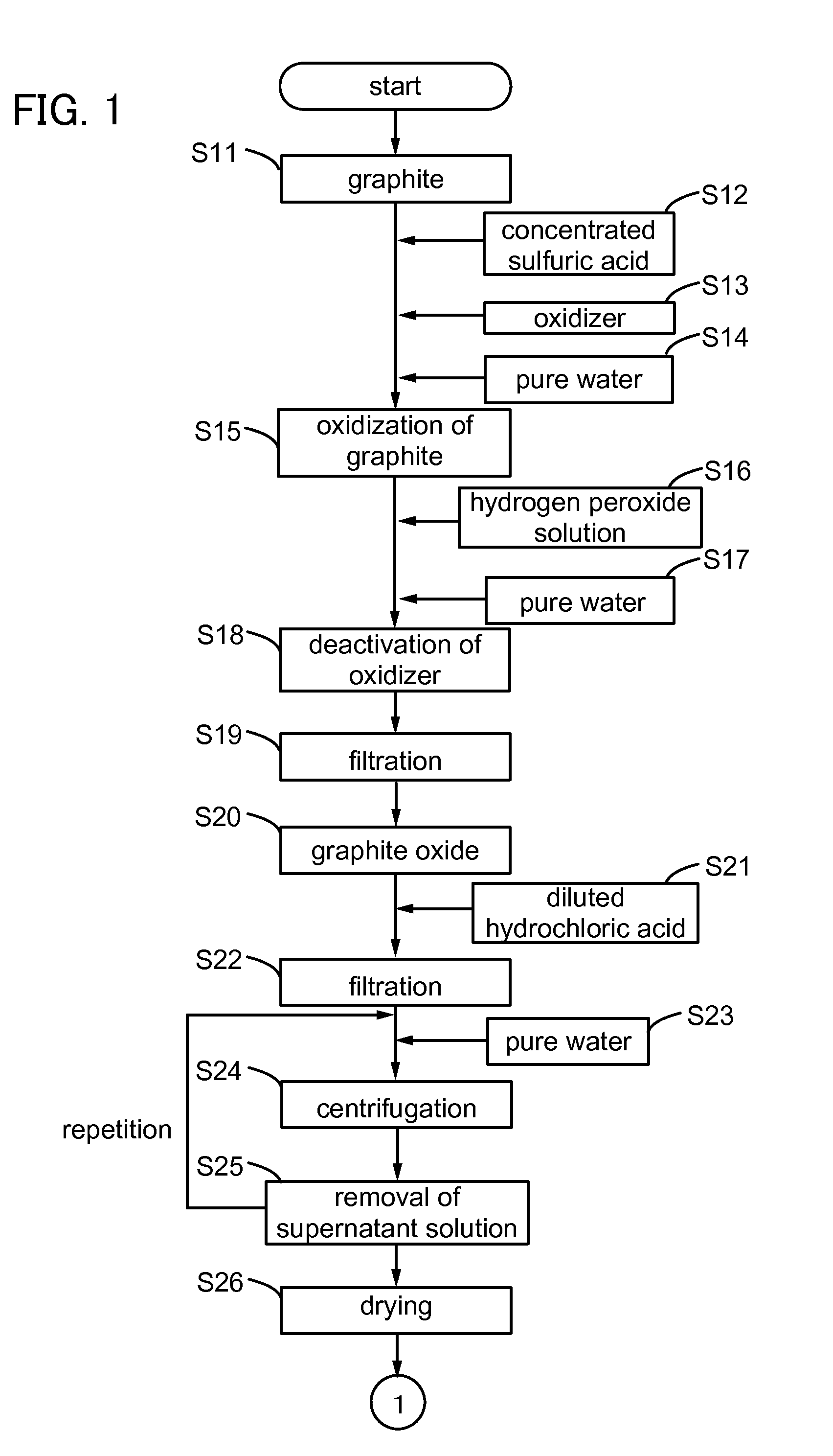

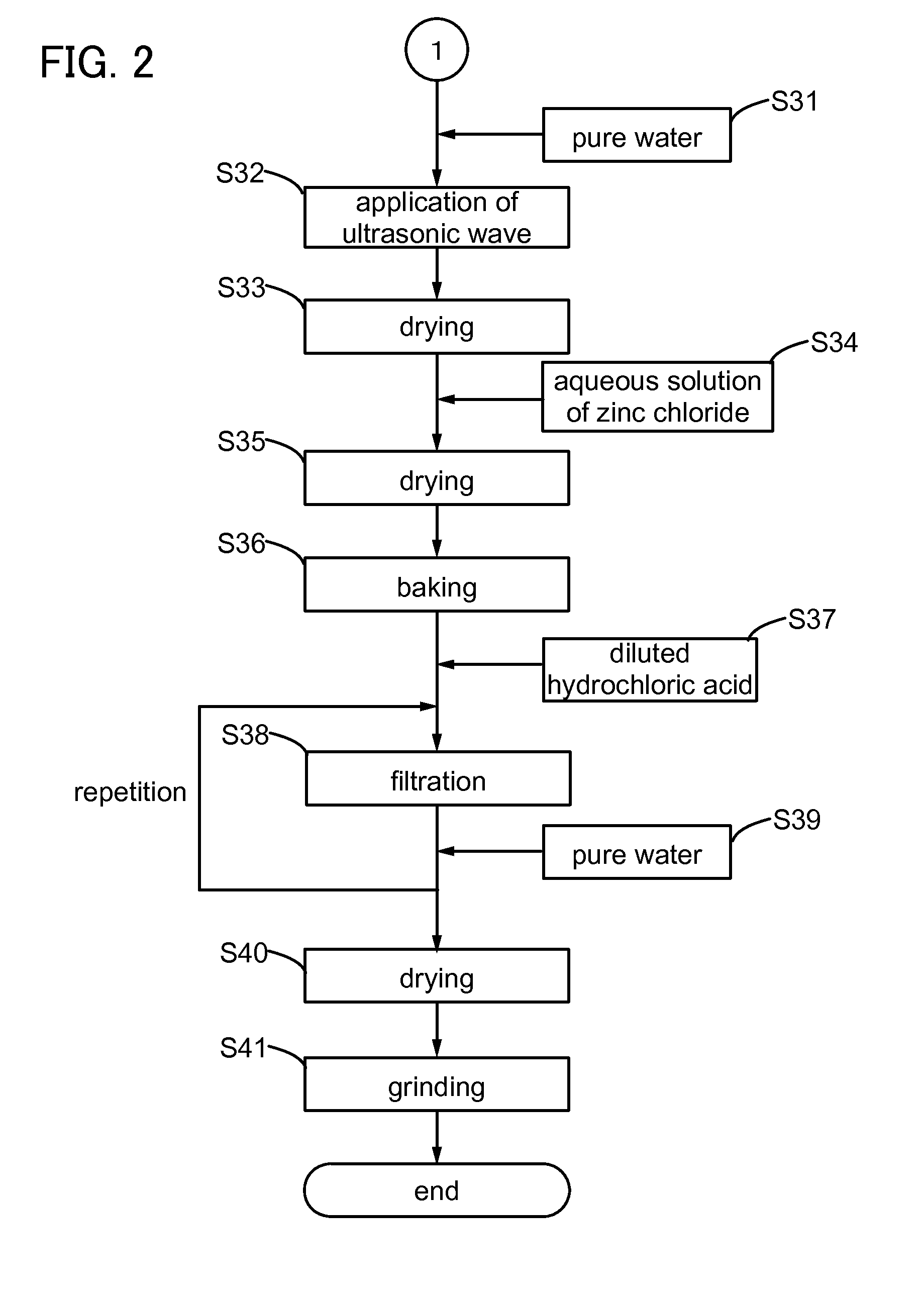

ActiveUS20130052526A1Large specific surface areaLower electrode resistanceElectrode thermal treatmentCapacitor and primary/secondary cellsGraphiteEngineering

A power storage device with high output is provided, in which the specific surface area is increased while keeping the easy-to-handle particle size of its active material. The power storage device includes a positive electrode including a positive electrode current collector and a positive electrode active material layer, a negative electrode including a negative electrode current collector and a negative electrode active material layer, and an electrolyte. The negative electrode active material layer includes a negative electrode active material which is a particle in which a plurality of slices of graphite is overlapped with each other with a gap therebetween. It is preferable that the grain diameter of the particle be 1μm to 50 μm. Further, it is preferable that the electrolyte be in contact with the gap between the slices of graphite.

Owner:SEMICON ENERGY LAB CO LTD

Tissue repair scaffold and preparation method and purpose thereof

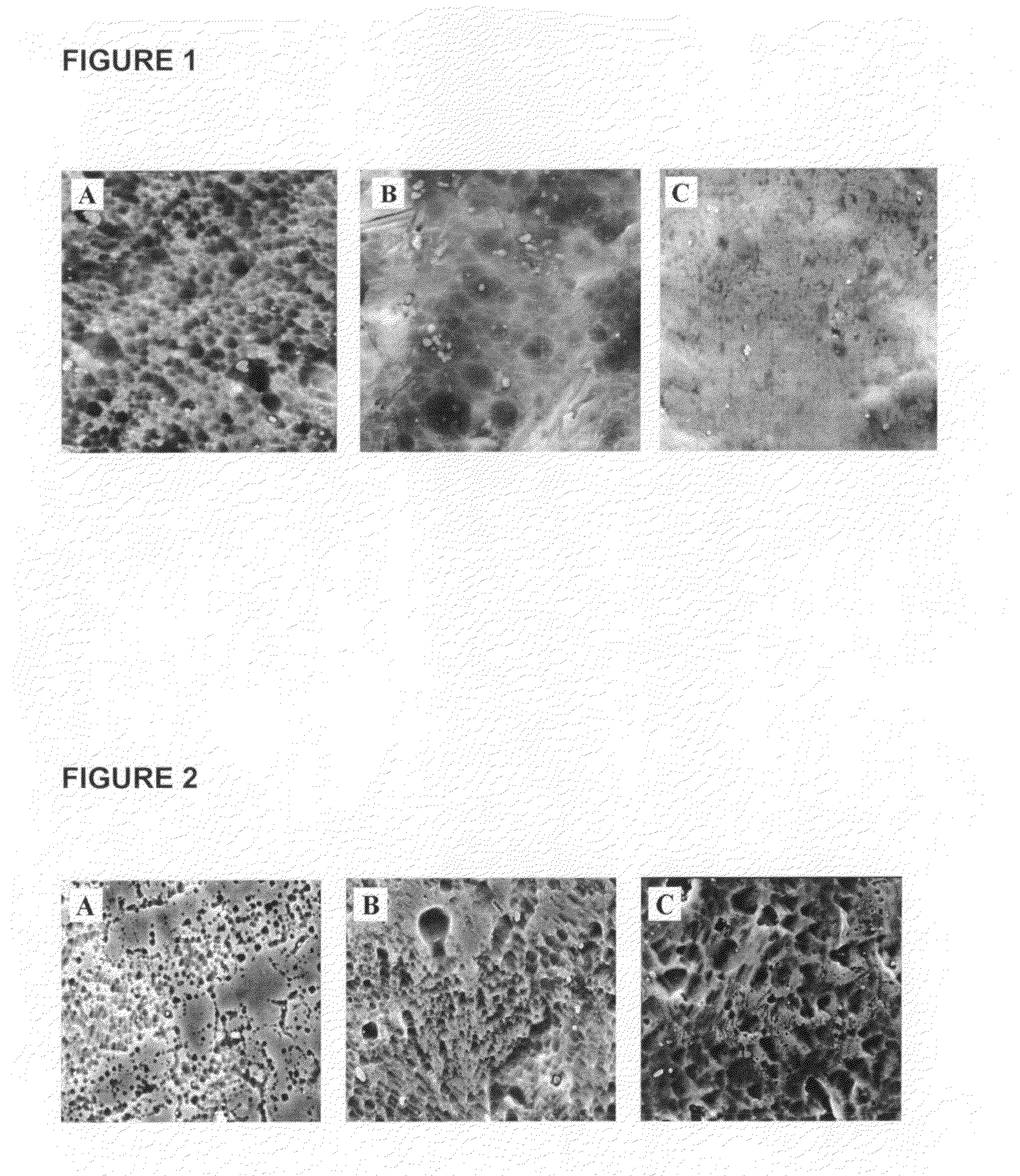

InactiveUS20160175487A1Unique structureHigh porosityElectric discharge heatingPeptide/protein ingredientsTissue repairReticular formation

The present invention provides a tissue repair scaffold and a preparation method and purpose thereof. The tissue repair scaffold comprises at least one composite fiber layer, and the composite fiber layer comprises a composite fiber formed by an adhesion factor and a hydrophobic synthetic material. The composite fiber layer may further form a porous three-dimensional mesh structure with a hydrophilic material. The tissue repair scaffold is applied to brain meninge repair, spinal meninge repair, a tissue engineering scaffold material, artificial skin, a wound assistant, a biological membrane, a wound cladding material, a hemostatic material, a postoperative adhesion prevention material, or a cosmetic material.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Preparation method of hydrophobic silica aerogel

Provided is a method for preparing a hydrophobic silica aerogel by using a Soxhlet extraction, and a hydrophobic silica aerogel prepared by using the method. Since the preparation method according to the present invention may simultaneously perform washing and drying of a hydrophobic silica wet gel as well as solvent substitution and may remove an extraction solvent without an additional separation process, a hydrophobic silica aerogel having low tap density and high specific surface area may be easily prepared.

Owner:LG CHEM LTD

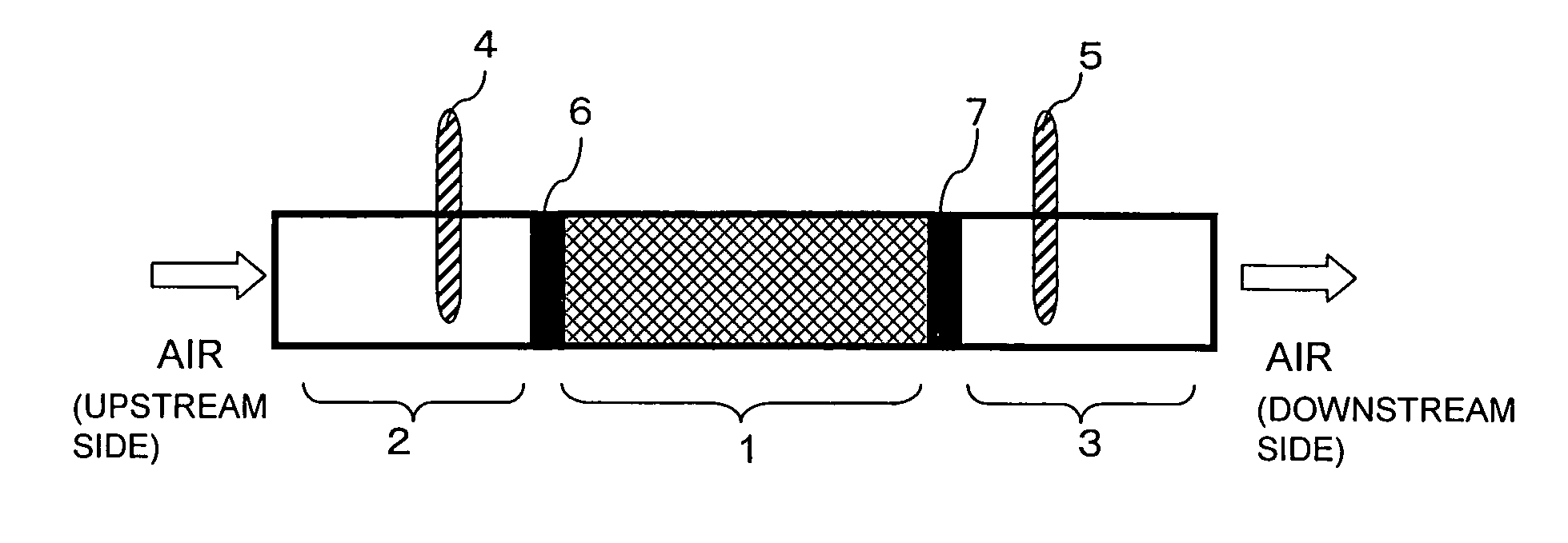

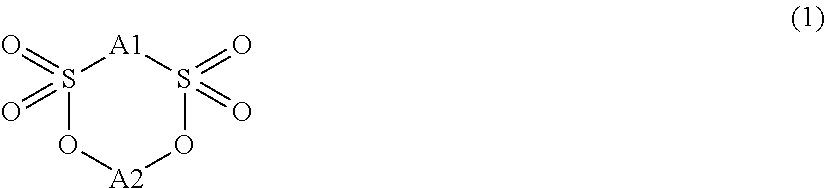

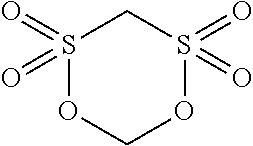

Lithium ion secondary battery and charging method therefor

ActiveUS20150380777A1Solve problemsGuaranteed specific surface areaCell electrodesFinal product manufactureLithiumCarboxymethyl cellulose

A method for charging a lithium ion secondary battery including at least a positive electrode, a negative electrode provided with a negative electrode active material layer that includes carbon as a negative electrode active material, an electrolytic solution, and a sheathing material that encloses the positive electrode, the negative electrode and the electrolytic solution; the negative electrode active material layer including carboxymethyl cellulose and the electrolytic solution including an additive that can be decomposed at a predetermined voltage includes: preliminary charging including constant-current charging in which charging is performed at a fixed current value and, following the constant-current charging, constant-voltage charging in which charging is performed at a fixed voltage; degassing in which gas is removed from within the sheathing material after the preliminary charging; and main charging that follows the degassing in which the lithium ion secondary battery is charged. The fixed voltage during the constant-voltage charging is at least 3.3 V per cell.

Owner:ENVISION AESC ENERGY DEVICES LTD

Process for producing a lithium-cobalt composite oxide for a positive electrode for a lithium secondary cell

InactiveUS7501209B2Improve scalabilityHigh densityElectrode manufacturing processesAlkali metal oxidesAlkaline earth metalCobalt

The present invention provides a positive electrode, which has a large volume capacity density, high safety, and is excellent in the coating uniformity, the charge and discharge cyclic durability and the low-temperature properties.Further, the present invention provides a process for producing a lithium-cobalt composite oxide for a positive electrode for a lithium secondary cell, the lithium-cobalt composite oxide being represented by the formula LipCoxMyOzFa (wherein M is a transition metal element other than Co, aluminum or an alkaline earth metal element, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1 and 0≦a≦0.02).

Owner:AGC SEIMI CHEM CO LTD

Method of manufacturing positive electrode active material for lithium ion battery

ActiveUS20130283603A1Reduce production processImprove productivityMaterial nanotechnologyElectrolytic capacitorsManganesePhosphoric acid

At least one of an aqueous solution A containing lithium, an aqueous solution B containing iron, manganese, cobalt, or nickel, and an aqueous solution C containing a phosphoric acid includes graphene oxide. The aqueous solution A is dripped into the aqueous solution C, so that a mixed solution E including a precipitate D is prepared. The mixed solution E is dripped into the aqueous solution B, so that a mixed solution G including a precipitate F is prepared. The mixed solution G is subjected to heat treatment in a pressurized atmosphere, so that a mixed solution H is prepared, and the mixed solution H is then filtered. Thus, particles of a compound containing lithium and oxygen which have a small size are obtained.

Owner:SEMICON ENERGY LAB CO LTD

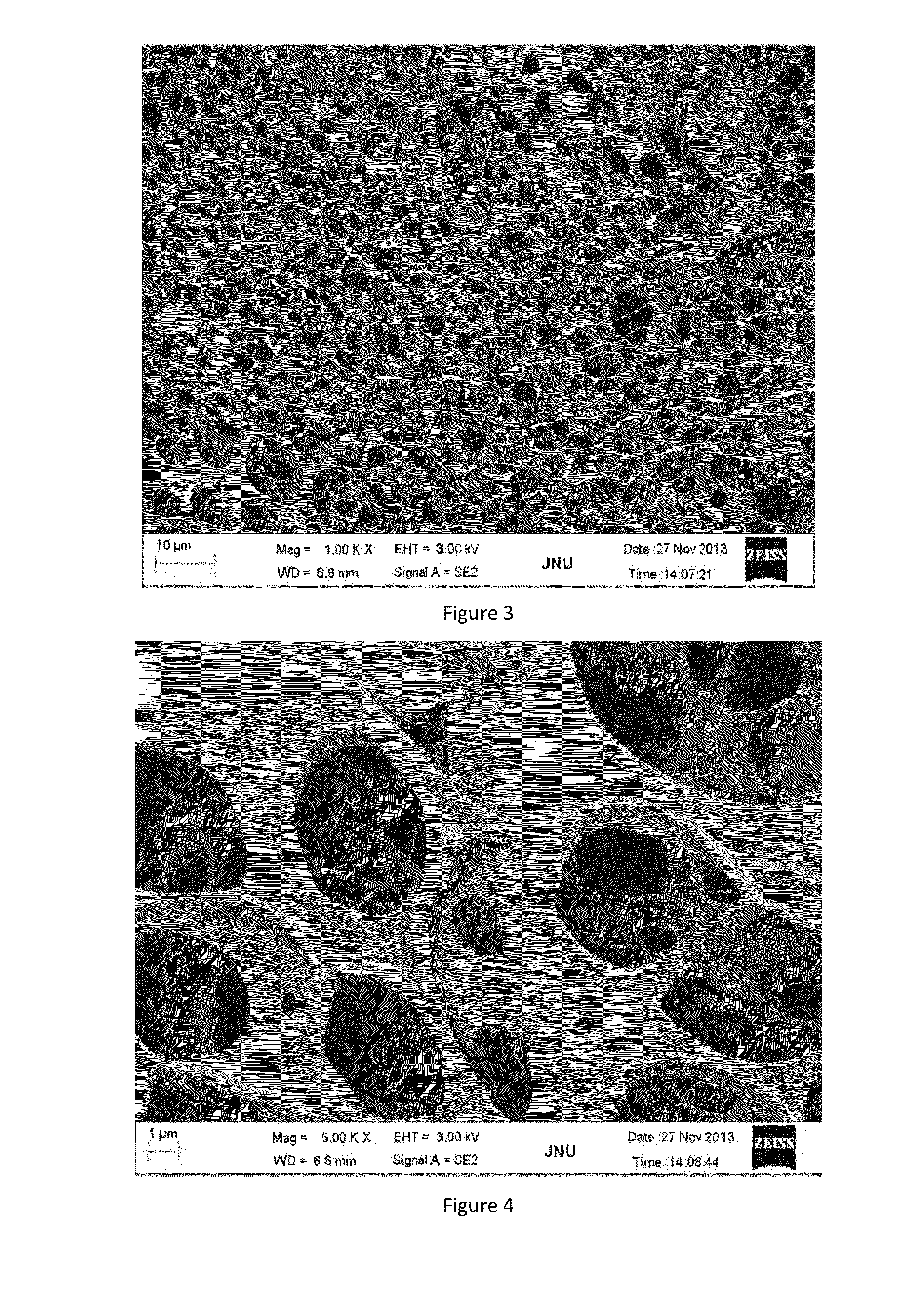

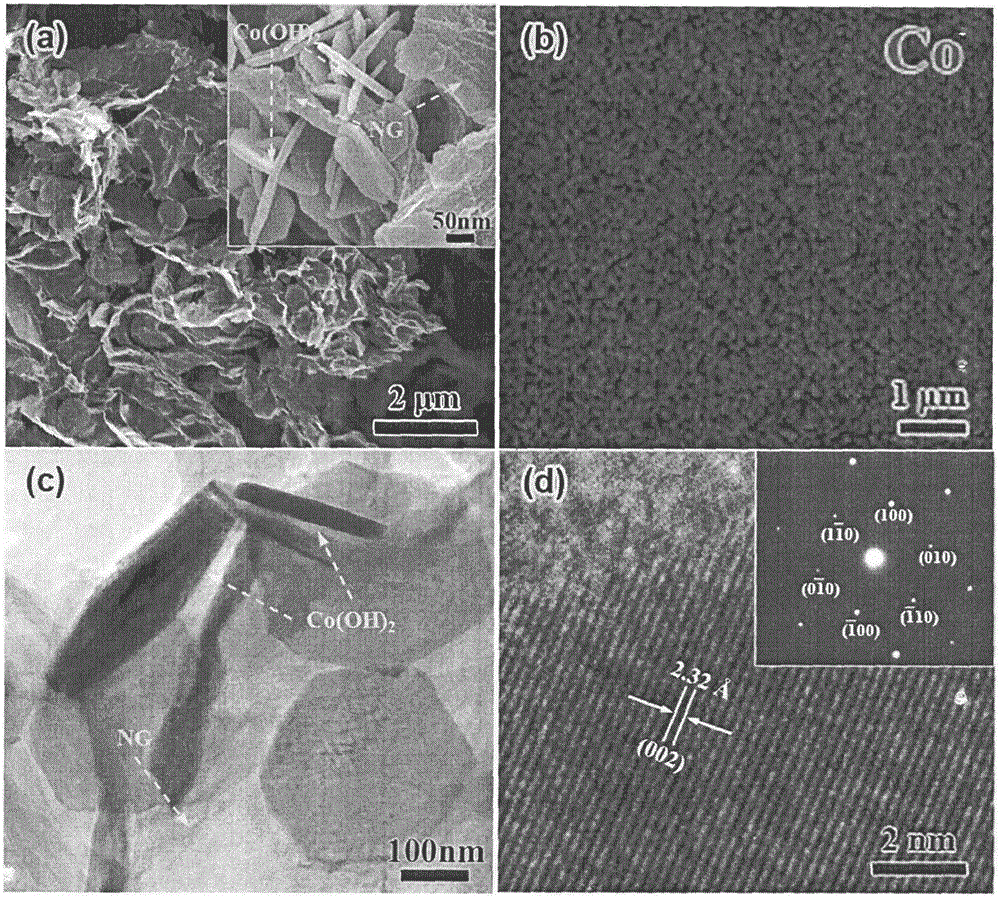

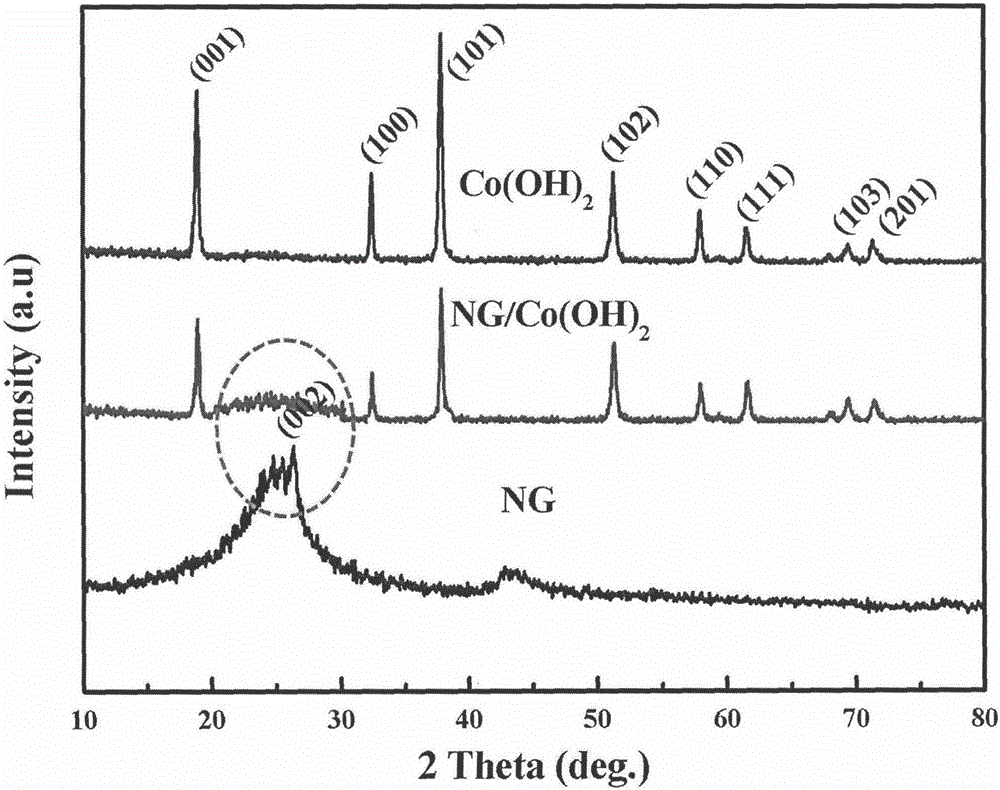

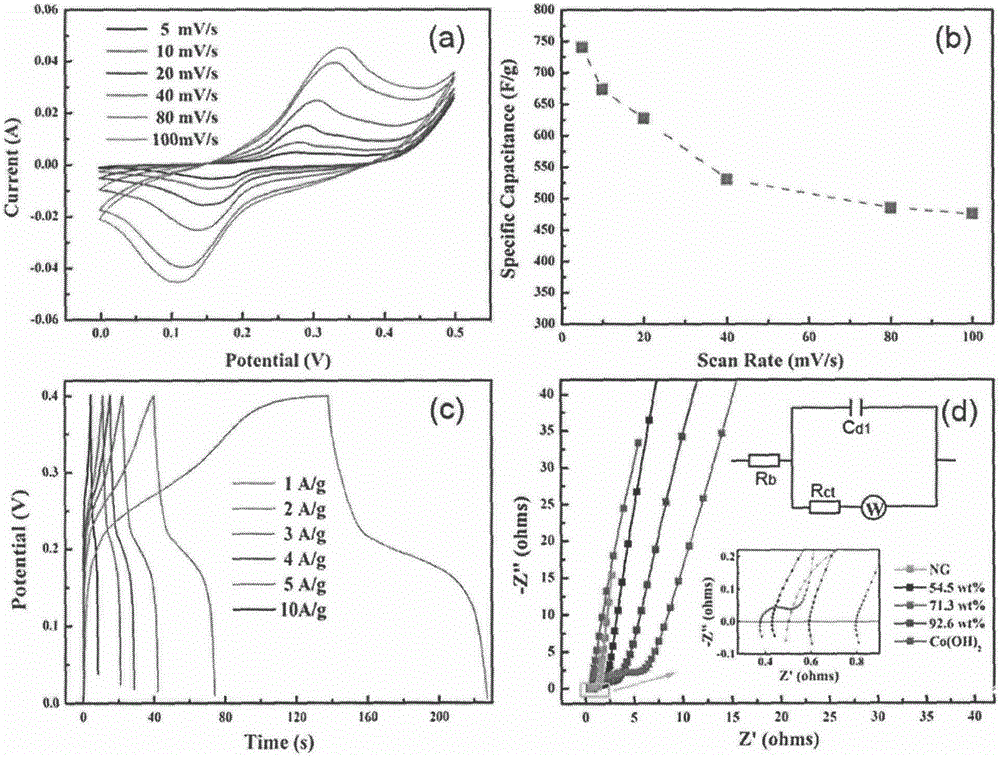

Preparation method for three-dimensional reticular nitrogen-doped graphene composite cobalt hydroxide hexagonal nano-sheet electrode material

InactiveCN105118693AGuaranteed specific surface areaHigh specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneCobalt hydroxide

The invention discloses a preparation method for a three-dimensional reticular nitrogen-doped graphene composite cobalt hydroxide hexagonal nano-sheet electrode material. In order to overcome the problem that the pseudocapacitance material is poor in electrical conductivity and low in specific surface area, the simple and economical one-step hydrothermal route is conducted. During the formation process of three-dimensional reticular nitrogen-doped graphene, the graphene three-dimensional network skeleton-supported Co(OH)2 composite electrode material is prepared through the in-situ growth of Co(OH)2 hexagonal nano-sheets. Each edge of one hexagonal nano-sheet is about 100-300 nm, and the thickness of the hexagonal nano-sheet is 10-15 nm. The material is good in capacitive performance, wherein the capacitive value of the material is 740.4F / g at the scanning speed of 5mV / s and is up to 952.4F / g at the current density of 1.0A / g. therefore, the method has a considerable advantage in preparing electrode materials for super capacitors.

Owner:NANJING UNIV

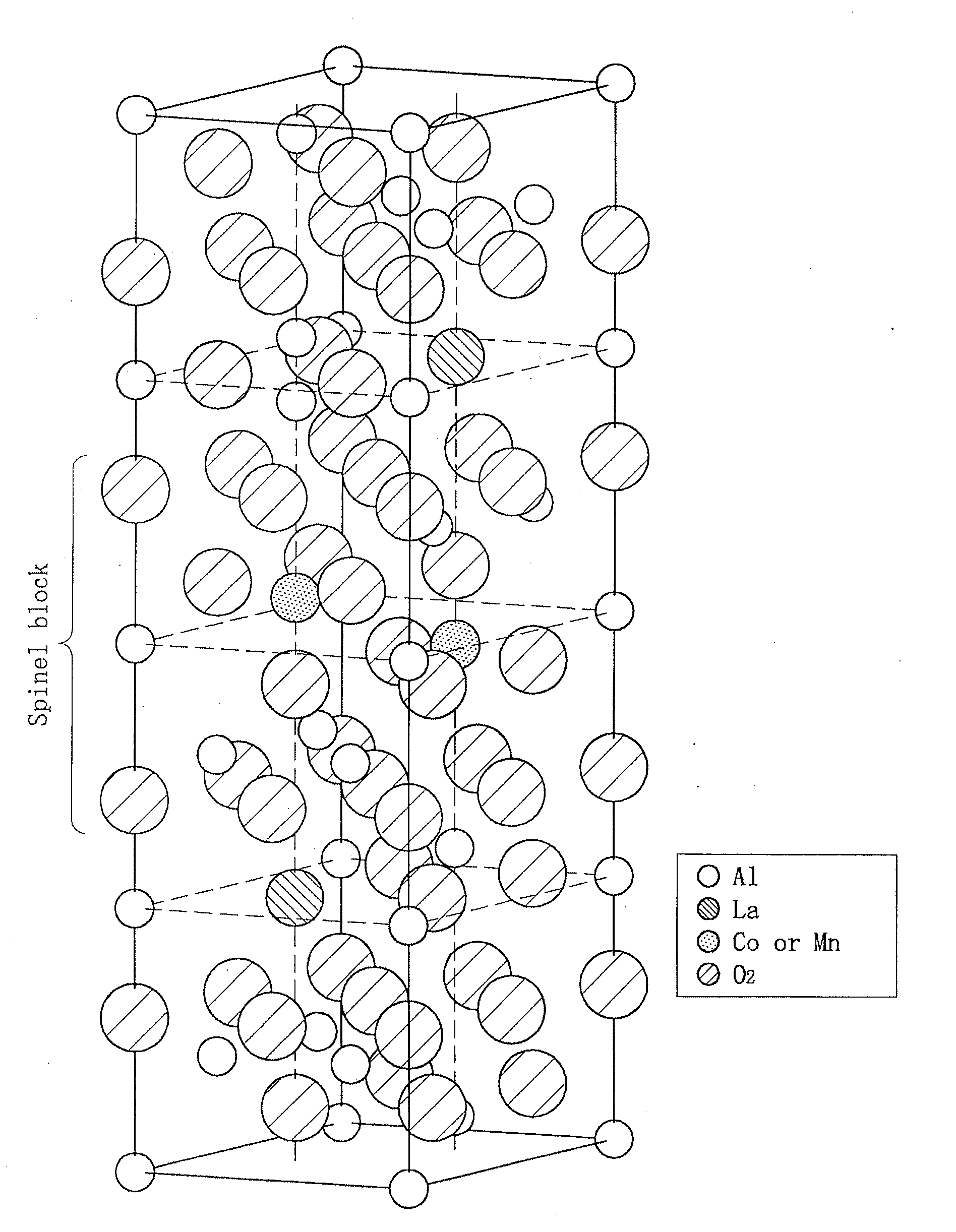

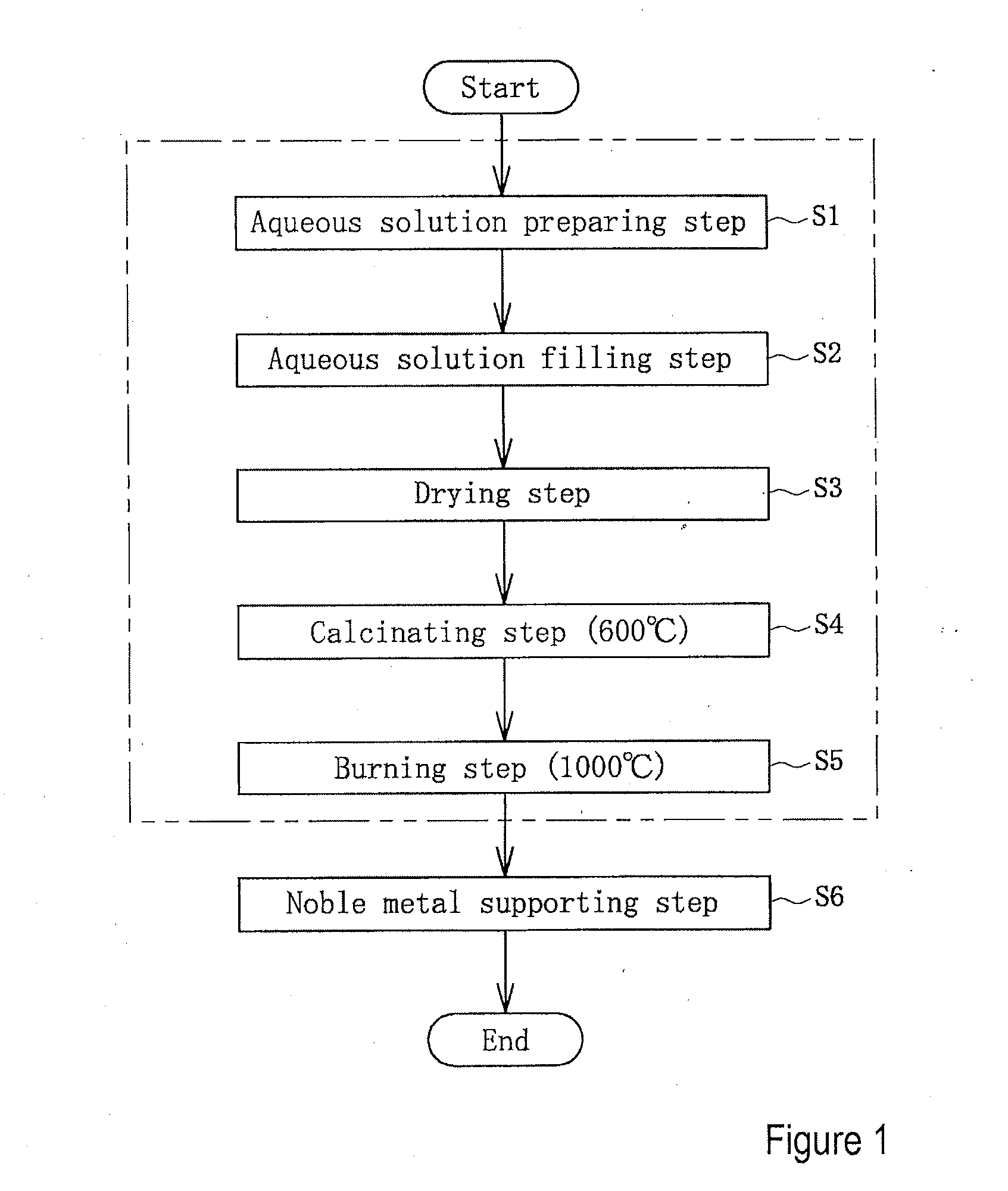

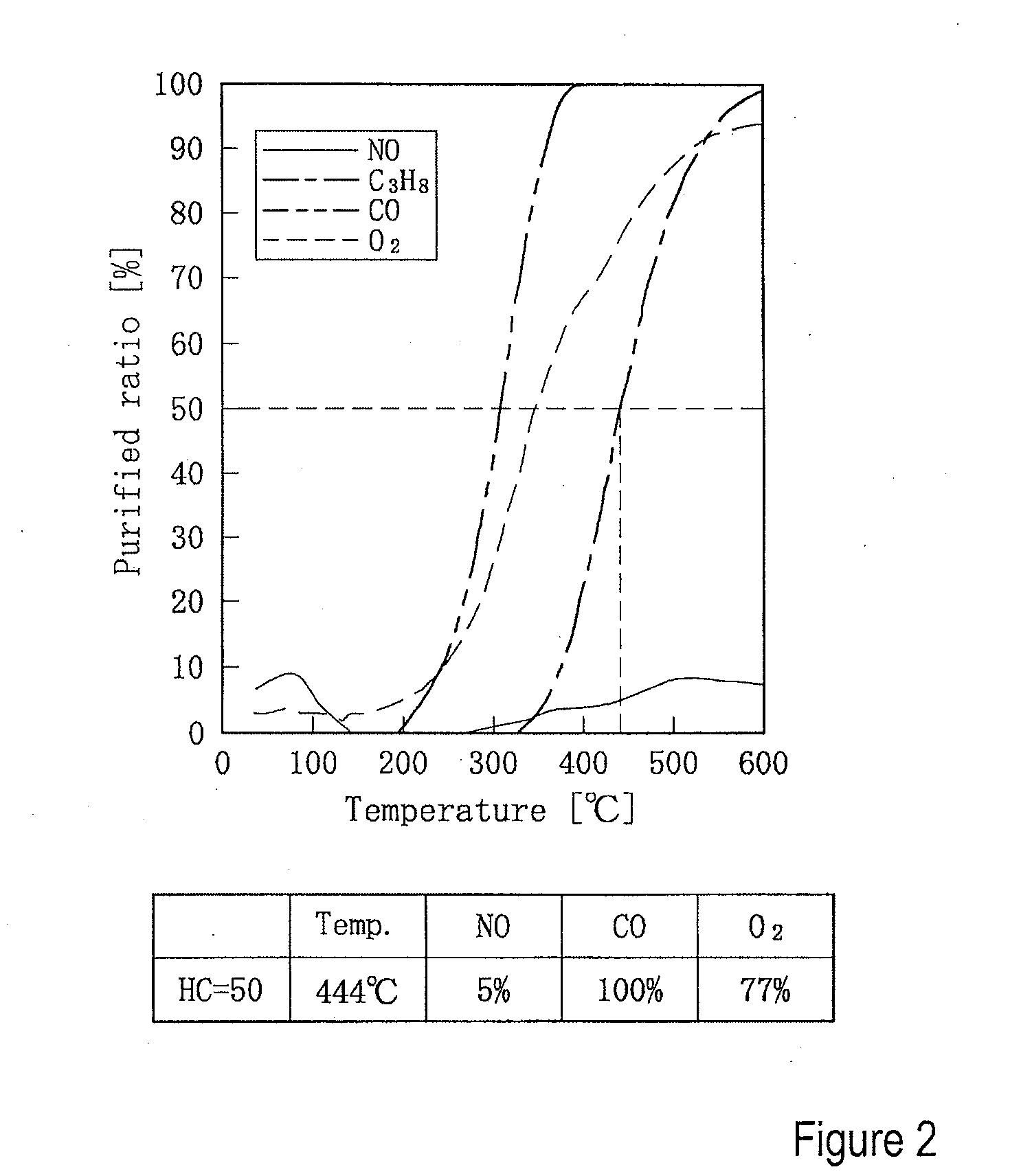

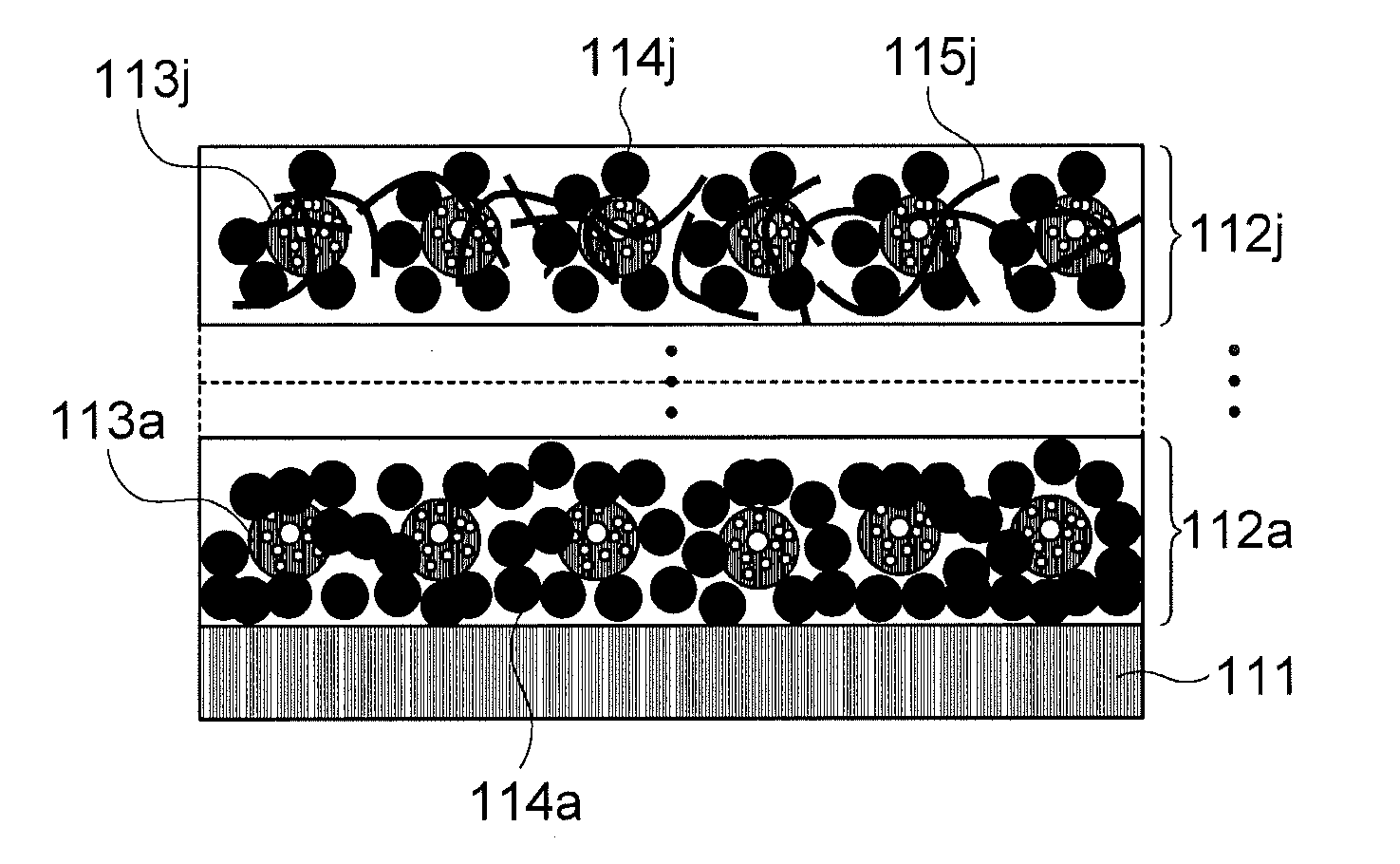

Catalyst support and method of producing same

InactiveUS20110039691A1Easy to produceImprove low temperature combustion activityAluminium compoundsInternal combustion piston enginesAqueous solutionLanthanum Ion

An object of the present invention is to provide a catalyst support which can maintain the purifying ability of HC, CO and NO even after being exposed to a high temperature atmosphere such as about 1000° C. for a long term and a method which can easily produce the catalyst support. According to the present invention there is provided a method for producing a catalyst support of porous alumina formed with pores within which magneto-plumbite type complex oxide ((La.M) Al11O19 (wherein M is Mn or Fe)) is formed and a noble metal is supported on the magneto-plumbite type complex oxide comprising an aqueous solution preparing step for preparing aqueous solution containing lanthanum ions and either manganese ions or iron ions; an aqueous solution filling step for filling the pores of porous alumina with the aqueous solution obtained in the aqueous solution preparing step by a pore-filling method using the capillarity caused in the pores; a drying step for drying the porous alumina of which pores are filled with aqueous solution in the aqueous solution filling step, and a burning step for forming the magneto-plumbite type complex oxide by burning the porous alumina obtained in the drying step.

Owner:FCC KK

Electrodes, and electrochemical capacitors including the same

InactiveUS20130050903A1Improve fill rateImprove conductivityElectrolytic capacitorsHybrid capacitor electrodesCapacitanceElectrical resistance and conductance

Electrodes and electrochemical capacitors including the same including an electrode active material layer having two layers or more formed on a current collector, wherein the electrode active material layer has a gradient of the specific surface area value to the electric conductivity along a thickness direction of a current collector. Exemplary embodiments manufacture the electrodes having the gradient of the specific surface area value to the electricity conductivity along the thickness direction of the current collector by forming the electrode active material layer having compositions in which a kind of electrode active materials and conductive materials are different along the thickness direction of the current collector. The exemplary embodiments can increase the capacitance of the electrochemical capacitor including the electrode and lower the electric resistance thereof, by appropriately controlling the resistance and capacitance value of the electrode.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

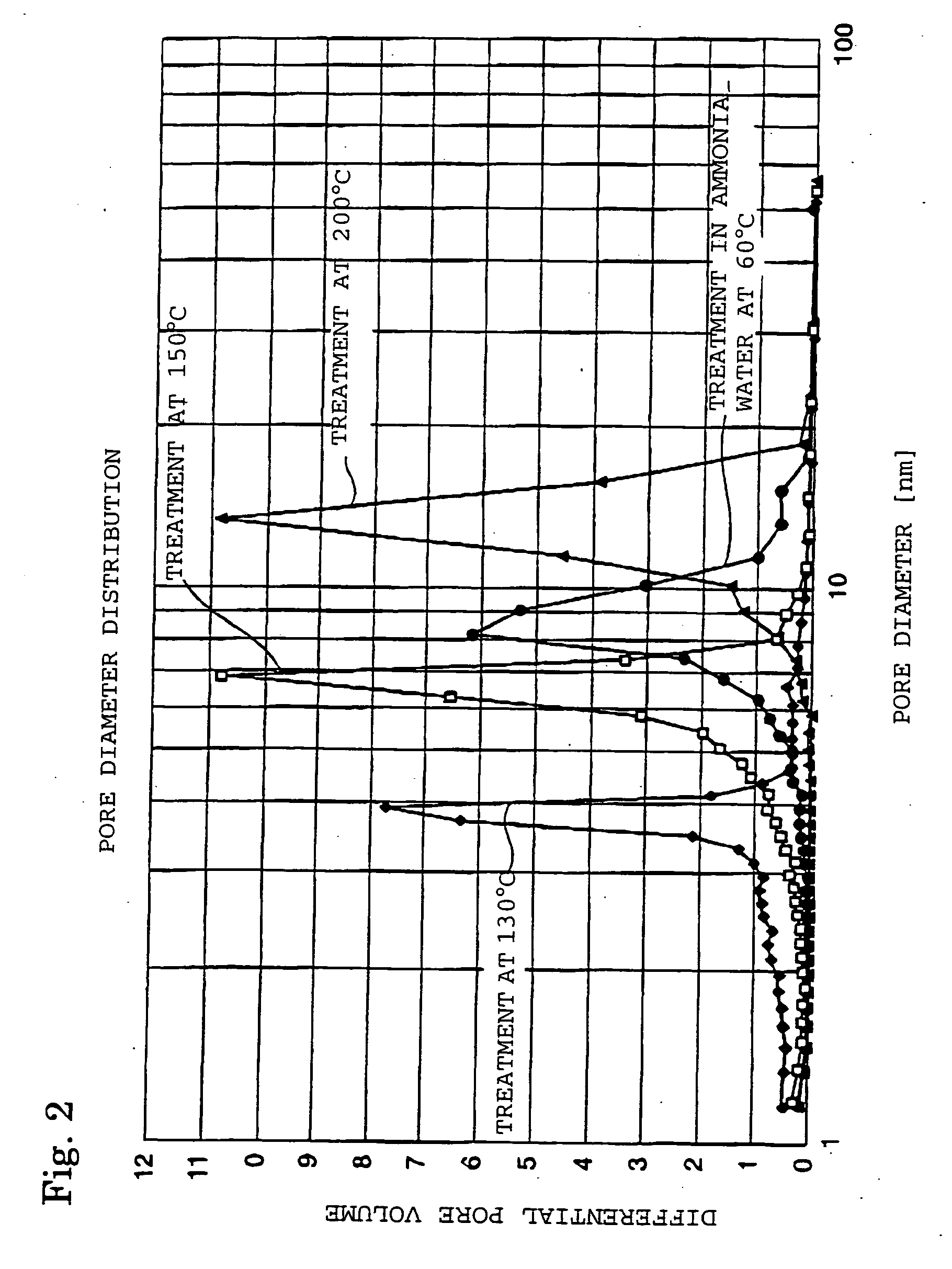

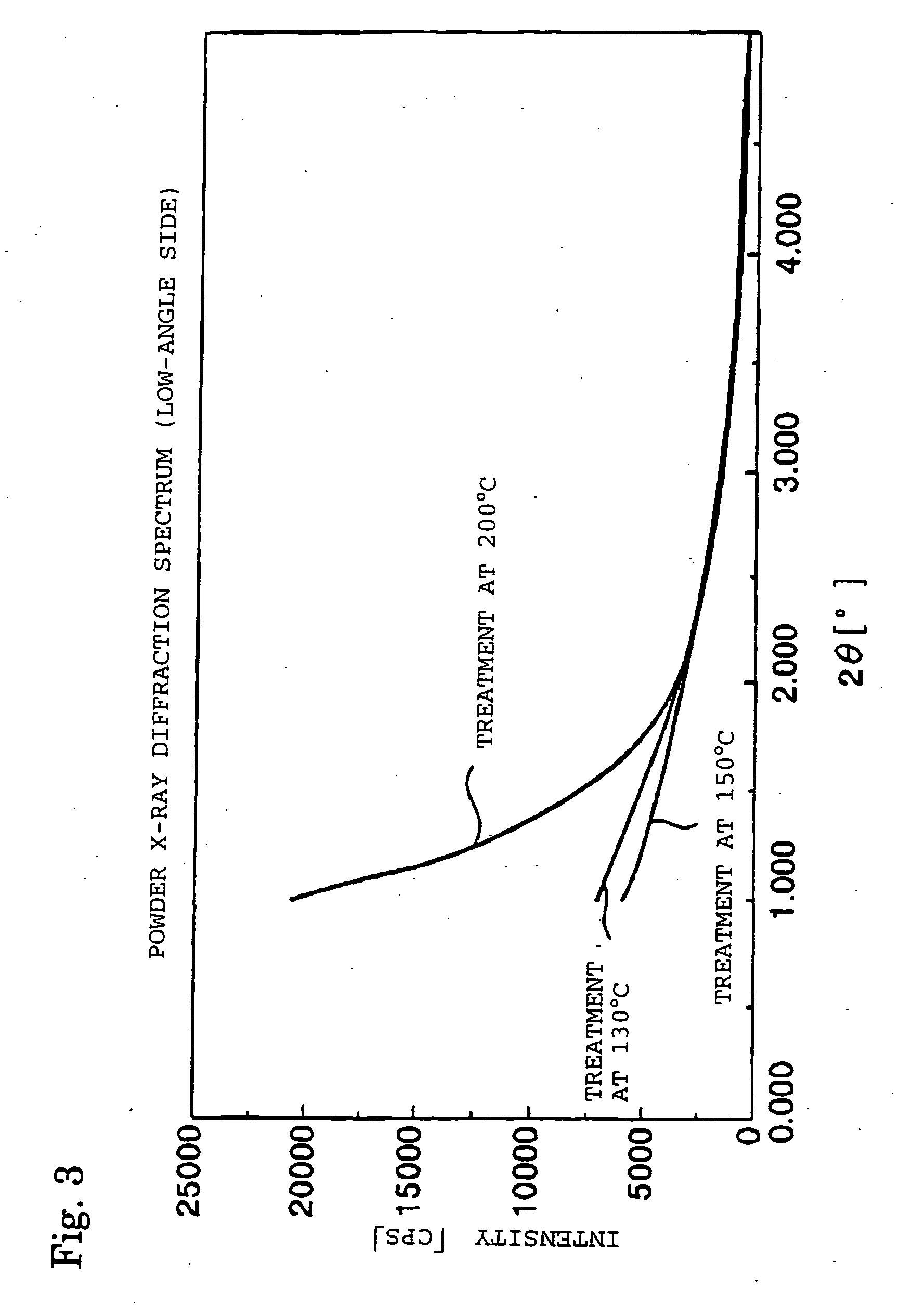

Silica gel

A method of producing a silica gel by hydrolyzing a silicon alkoxide and subjecting the resulting hydrogel to a hydrothermal treatment substantially without aging it is described. Also described in a silica gel produced by such a method and a silica gel which has the following characteristics: (a) the pore volume is from 0.6 to 1.6 ml / g, (b) the specific surface area is from 300 to 900 m2 / g, (c) the mode diameter (Dmax) of pores is less than 20 nm, (d) the volume of pores having diameters within ±20% of Dmax is at least 50% of the total pore volume, (e) it is amorphous, and (f) the content of metal impurities is at most 500 ppm.

Owner:MITSUBISHI CHEM CORP

Stacks of internally connected surface-mediated cells and methods of operating same

ActiveUS9349542B2Increase electrode areaHigh currentPrimary cell to battery groupingBatteries circuit arrangementsChemical physicsSupercapacitor

An energy storage stack of at least two surface-mediated cells (SMCs) internally connected in parallel or in series. The stack includes: (A) At least two SMC cells, each consisting of (i) a cathode comprising a porous cathode current collector and a cathode active material; (ii) a porous anode current collector; and (iii) a porous separator disposed between the cathode and the anode; (B) A lithium-containing electrolyte in physical contact with all the electrodes, wherein the cathode active material has a specific surface area no less than 100 m2 / g in direct physical contact with the electrolyte to receive lithium ions therefrom or to provide lithium ions thereto; and (C) A lithium source. This new-generation energy storage device exhibits the highest power densities of all energy storage devices, much higher than those of all the lithium ion batteries, lithium ion capacitors, and supercapacitors.

Owner:GLOBAL GRAPHENE GRP INC +1

Thermochemical gas sensor using chalcogenide-based nanowires and method for manufacturing the same

InactiveUS20160013389A1Maximized thermoelectric propertyCharacteristic electricalNanostructure manufactureThermoelectric device with peltier/seeback effectElectricityNanowire

The present invention relates to a thermochemical gas sensor using chalcogenide-based nanowires and a method for same, comprising: a porous alumina template comprising a front surface, a rear surface, and side surfaces and provided with a plurality of pores which penetrate the front surface and the rear surface; a seed layer provided on the rear surface of the porous alumina template for covering the plurality of pores and having electric conductivity; a plurality of chalcogenide-based nanowires provided inside the plurality of pores and coming into contact with the seed layer, which is exposed through the plurality of pores; an electrode provided on the front surface of the porous alumina template and coming into contact with the chalcogenide-based nanowires; an electrode wire for electrically connecting with the electrode; and a porous white gold-alumina composite or a porous palladium-alumina composite provided above the electrode for causing a heat-emitting reaction by coming into contact with a gas to be detected, wherein the chalcogenide-based nanowires comprise BixTey(1.5≦x≦2.5, 2.4≦y≦3.6), SbxTey(1.5≦x≦2.5, 2.4≦y≦3.6) or (Bi1-xSbx)Te3(0<x<1). According to the present invention, a variety of gases can be detected through a change in the porous white gold-alumina composite or the porous palladium-alumina composite, and temperature and minute changes in electromotive force can be confirmed by detecting the gases, and thus the present invention can be utilized for evaluating a thermochemistry performance by using gas.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Method of surface treatment of aluminum foil and its alloy and method of producing immobilized nanocatalyst of transition metal oxides and their alloys

InactiveUS8540826B2Guaranteed specific surface areaSmall surface areaMaterial nanotechnologyCatalyst activation/preparationNano catalystAlloy

A process for surface treatment of aluminium foils includes steps of applying an etching solution to chemically etch at least one surface of the foil to form an etched surface, and forming an aluminium oxidized coating on the etched surface. The etching solution comprises an aqueous solution which includes hydrogen peroxide as an oxidant and sulfuric, orthophosphoric or nitric acid.

Owner:UNIVERSITY OF WINDSOR

High specific surface area mixed oxide of cerium and of another rare earth, preparation method and use in catalysis

ActiveUS8435919B2Reduce the risk of contaminationGuaranteed specific surface areaNitrogen compoundsInternal combustion piston enginesMixed oxideLiquid medium

The mixed oxide of the invention mainly consists of cerium oxide and of at least one oxide of another rare earth. It has a specific surface area of at least 20 m2 / g after calcining at 1000° C. for 5 hours. It is obtained by forming a liquid medium comprising a cerium compound; by heating this medium; by adding to the precipitate obtained a compound of the other rare earth, by heating the medium thus obtained and by bringing its pH to a basic value and by calcining the precipitate. The mixed oxide may be used as a catalyst support.

Owner:ANAN KASEI CO LTD

Graphene powder, electrode paste for lithium ion battery and electrode for lithium ion battery

ActiveUS20170346098A1Good dispersionImprove discharge performanceMaterial nanotechnologyGrapheneX-rayGraphene

The present invention relates to preparation of a highly dispersible graphene powder. Further, the present invention includes providing an electrode for a lithium ion battery having good output characteristics and cycle characteristics by utilizing a highly dispersible graphene powder. The present invention also includes providing a graphene powder having a specific surface area of 80 m2 / g or more to 250 m2 / g or less as measured by BET measurement, and an oxygen-to-carbon element ratio of 0.09 or more to 0.30 or less as measured by X-ray photoelectron spectroscopy.

Owner:TORAY IND INC

Preparation method for petal-like magnesium aluminum hydrotalcite used for phosphorous removal by adsorption

InactiveCN109603735AEasy to operateClear direction of useOther chemical processesWater contaminantsWater bathsPetal

The invention discloses a preparation method for petal-like magnesium aluminum hydrotalcite used for phosphorous removal by adsorption. The preparation method comprises the following steps that 1, a sodium carbonate solution is prepared; 2, magnesium nitrate hexahydrate and aluminum chloride hexahydrate are obtained and used for preparing a magnesium aluminum mixed solution; 3, the magnesium aluminum mixed solution is dropwise added into the sodium carbonate solution, in a constant temperature water bath, stirring is conducted for a reaction, and the pH value is adjusted with sodium hydroxide;4, a reaction liquid obtained after crystallization of a turbid liquid is filtered, washed, dried and ground, and magnesium aluminum hydrotalcite is obtained; 5, the magnesium aluminum hydrotalcite obtained in the fourth step is calcined for 3-5 hours at the temperature of 450-500 DEG C, and then the petal-like magnesium aluminum hydrotalcite is obtained. When the magnesium aluminum hydrotalciteis prepared by using the method, the process is simple, the problem of agglomeration is solved, and the petal-like magnesium aluminum hydrotalcite material is large in specific surface area, good in morphology and high in degree of crystallinity, the two kinds of metal have a lot of net positive charges, a good environment is provided for physical electrostatic adsorption, the adsorption effect isgood, the application range is wide, and the petal-like magnesium aluminum hydrotalcite has a wide application prospect in the field of phosphorous-containing water treatment and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Adsorbent and method for producing the same

ActiveUS20170182478A1Guaranteed specific surface areaEasy to controlSerum immunoglobulinsOther chemical processesCalcium biphosphateSorbent

An adsorbent, which can be produced by a method in which a particle size, a pore size, a specific surface area or the like can be easily controlled, and is suitable for isolation of biomolecules. The adsorbent contains aggregates of calcium phosphate-based particles, and has an average pore size of 15 to 36 nanometers and a specific surface area of 40 to 90 m2 / mL when measurement is carried out by mercury porosimetry.

Owner:JNC CORP +1

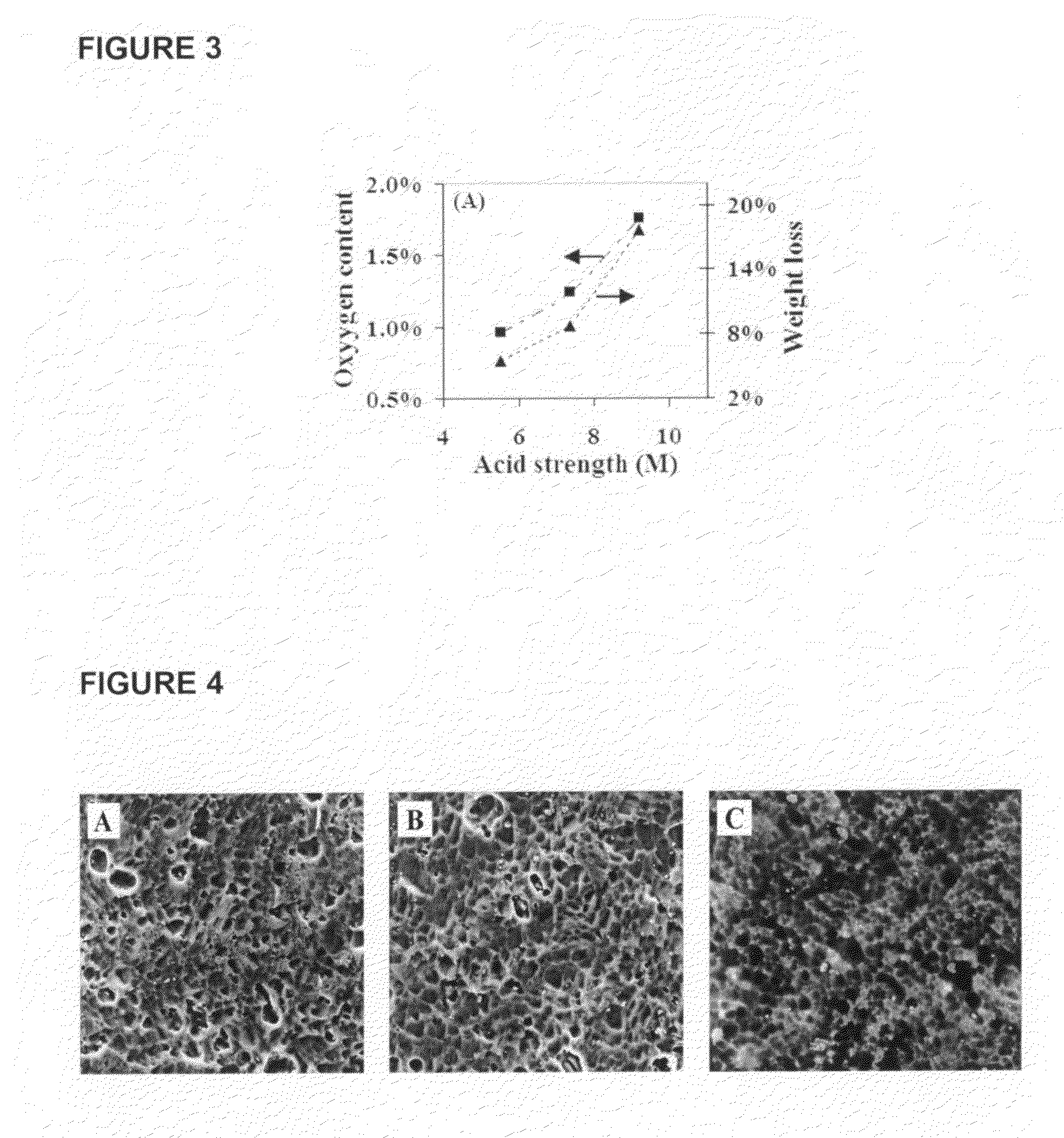

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS8124227B2Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com