Method for controllably synthesizing different shapes of niobium pentoxide nanomaterials without template hydrothermal heat

A technology of niobium pentoxide and nanomaterials, applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., can solve the problems of expensive experimental drugs and complex synthetic routes, and achieve simple experimental conditions, wide application prospects, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Add 1.5 mmol of niobium pentachloride and 7.5 mmol of sodium carbonate powder into 30 mL of deionized water, put it in a 100 mL beaker, put it into an ultrasonic instrument for 15 minutes to make it evenly mixed, and then pour it into 50 mL of polytetrafluoroethylene Put it in a reaction kettle with vinyl fluoride substrate, seal it, put it in an oven, control the temperature of the oven at 200°C, and react for 12 hours. After washing several times and drying at 80°C for 3 hours, the nanorods of niobium pentoxide were obtained.

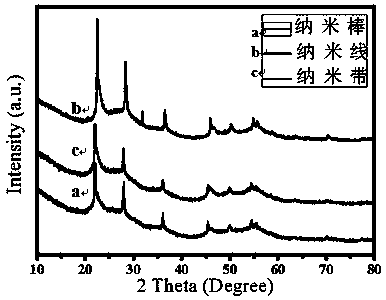

[0031] figure 1 Among them, there are no other miscellaneous peaks, and the positions and relative intensities of each diffraction peak are consistent with the JPCDS card (28-0317), indicating that the product is hexagonal-like niobium pentoxide.

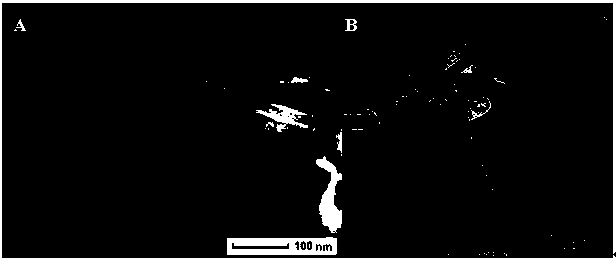

[0032] from figure 2 It can be seen that the prepared niobium pentoxide nanorods have a diameter of about 60 nanometers and a length of about 2 microns.

example 2

[0034] Add 1.5 mmol of niobium pentachloride and 7.5 mmol of sodium carbonate powder into 30 mL [deionized water: absolute ethanol (v / v) = 1:1], put it in a 100 mL beaker, and put it into an ultrasonic instrument Ultrasound for 15 minutes to make it evenly mixed, then pour it into a 50 mL polytetrafluoroethylene-lined reaction kettle, seal it, place it in an oven, control the temperature of the oven at 200°C, and react for 12 hours. After the reaction, cool with the oven to At room temperature, the precipitated product was separated by centrifugation, washed several times with deionized water and absolute ethanol, and dried at 80°C for 3 hours to obtain niobium pentoxide nanowires with a diameter of about 50 nanometers, such as image 3 shown.

example 3

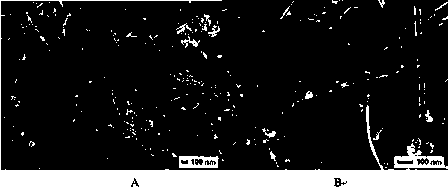

[0036] Add 1.5 mmol of niobium pentachloride and 7.5 mmol of sodium carbonate powder to 30 mL [deionized water: ethylene glycol (v / v) = 1:1], put it in a 100 mL beaker, and put it into the ultrasonic instrument Ultrasound for 15 minutes to make it evenly mixed, then pour it into a 50 mL polytetrafluoroethylene-lined reaction kettle, seal it, place it in an oven, control the temperature of the oven at 200°C, and react for 12 hours. After the reaction, cool with the oven to At room temperature, the precipitated product was separated by centrifugation, washed several times with deionized water and absolute ethanol, and dried at 80°C for 3 hours to obtain niobium pentoxide nanobelts. Figure 4 It can be seen that the bandwidth of the nanoribbon is about 150 nanometers, and the thickness is about 15 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com