Regular hexagonal micron chip capacitor material formed by interwoven NiCoP-CoP porous nanowires and preparation method

A technology of regular hexagons and nanowires, which is applied in the field of preparation of supercapacitor electrode materials, can solve the problems of low hydroxide conductivity, high specific capacitance, and unreachability, and achieve good repeatability, strong applicability, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

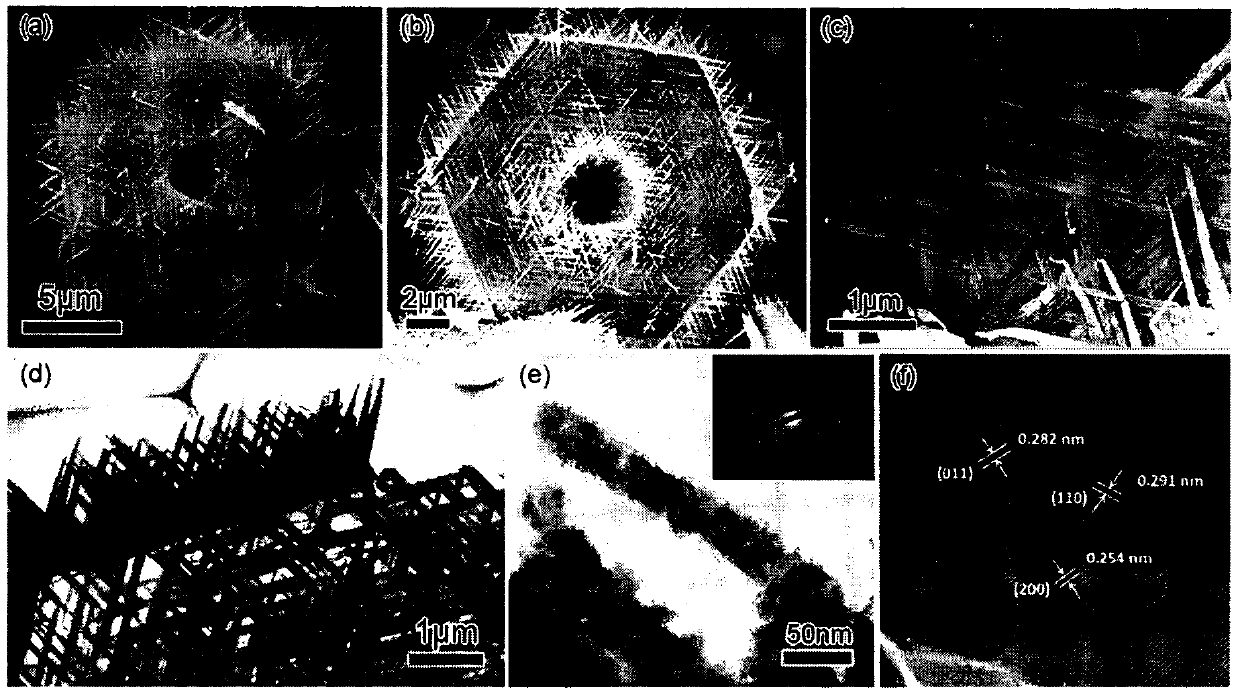

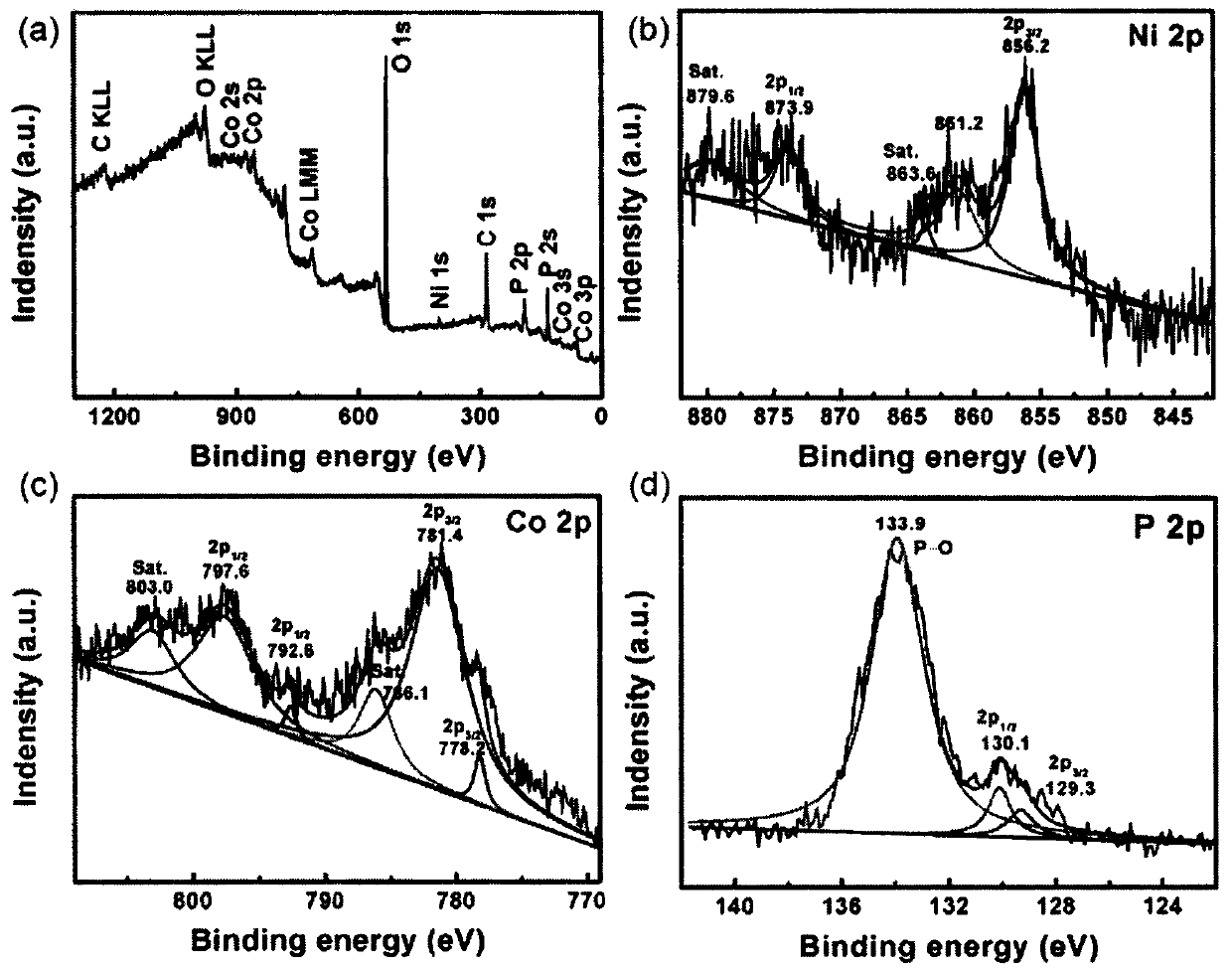

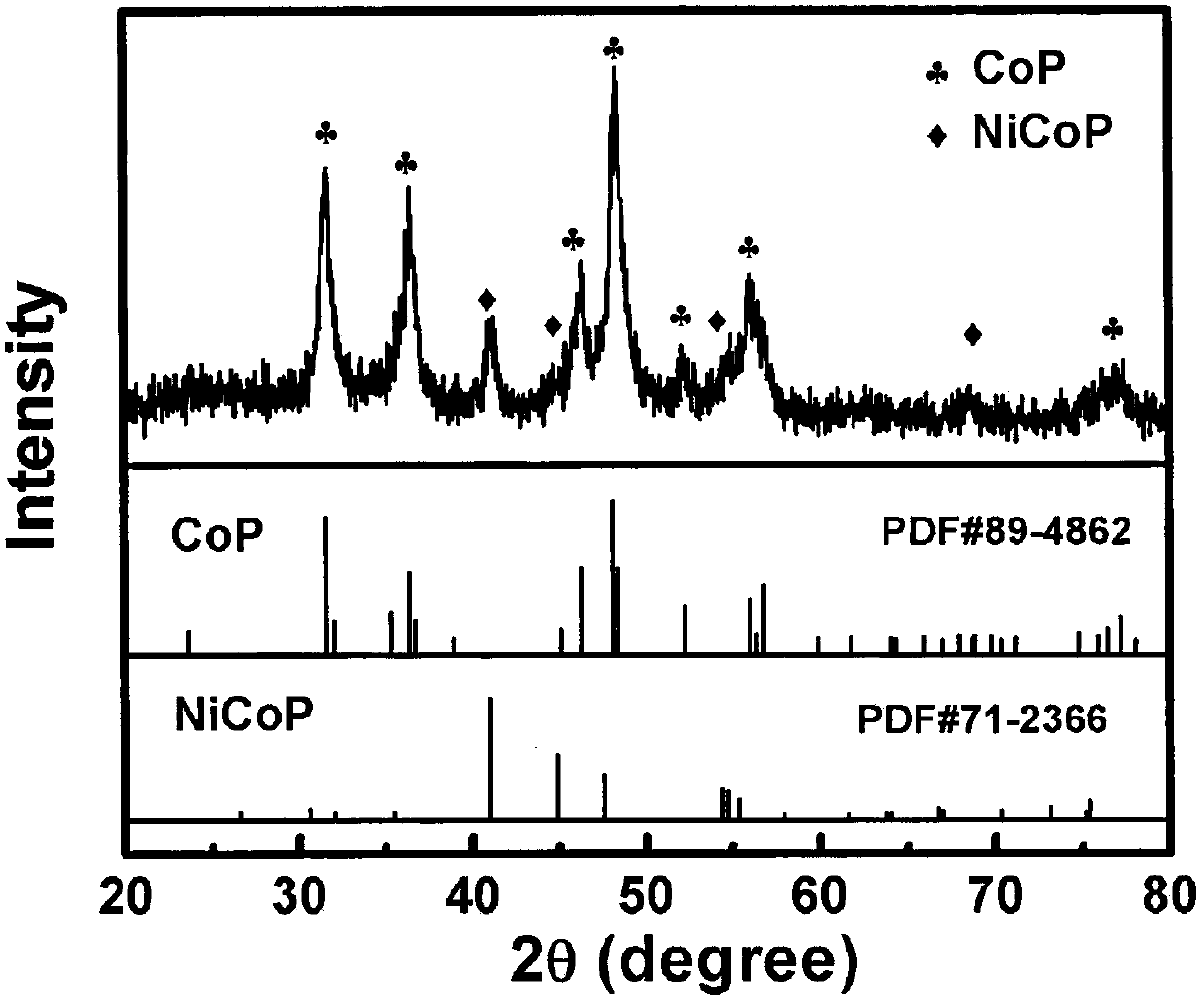

[0027] Preparation of regular hexagonal microsheets composed of NiCoP-CoP microporous nanowires interlaced: 320mg nickel nitrate hexahydrate, 640mg cobalt nitrate hexahydrate, 245mg ammonium fluoride and 991mg urea were dissolved in 40mL deionized water in sequence, and magnetically stirred for 20min ; The mixed solution was transferred to a 50mL reactor, reacted at 120°C for 8h, the reaction product was washed by centrifugation, and dried at 60°C for 12h to obtain a Ni-Co precursor. Then, take 100 mg of precursor and 1000 mg of sodium hypophosphite and place them on both ends of the porcelain boat and place them in a tube furnace. Under the protection of inert gas N2, set the temperature rise program at 2°C / min to 300°C, and react at high temperature for 2 hours. Then the temperature was naturally lowered, and finally the reaction product was centrifugally cleaned, and dried at 60° C. for 12 hours to obtain the final product (composite material of nickel cobalt phosphide and c...

Embodiment 2

[0032] The molar ratio of the reagents nickel nitrate hexahydrate and cobalt nitrate hexahydrate used to prepare the Ni-Co precursor was adjusted to 2:3, and other conditions were the same as in Example 1.

Embodiment 3

[0034] The molar ratio of the reagents nickel nitrate hexahydrate and cobalt nitrate hexahydrate used to prepare the Ni-Co precursor was adjusted to 1:1, and other conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com