Method for quickly preparing large-area graphene foam/polymer fiber three-dimensional network composite foam film

A technology of graphene foam and three-dimensional network, applied in the direction of graphene, chemical instruments and methods, synthetic resin layered products, etc., can solve the difficulty of obtaining large-area high-mechanical-strength graphene composite films, control problems of equipment and conditions Relatively harsh, difficult to control film thickness and other issues, to achieve the effect of short preparation cycle, good mechanical properties and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

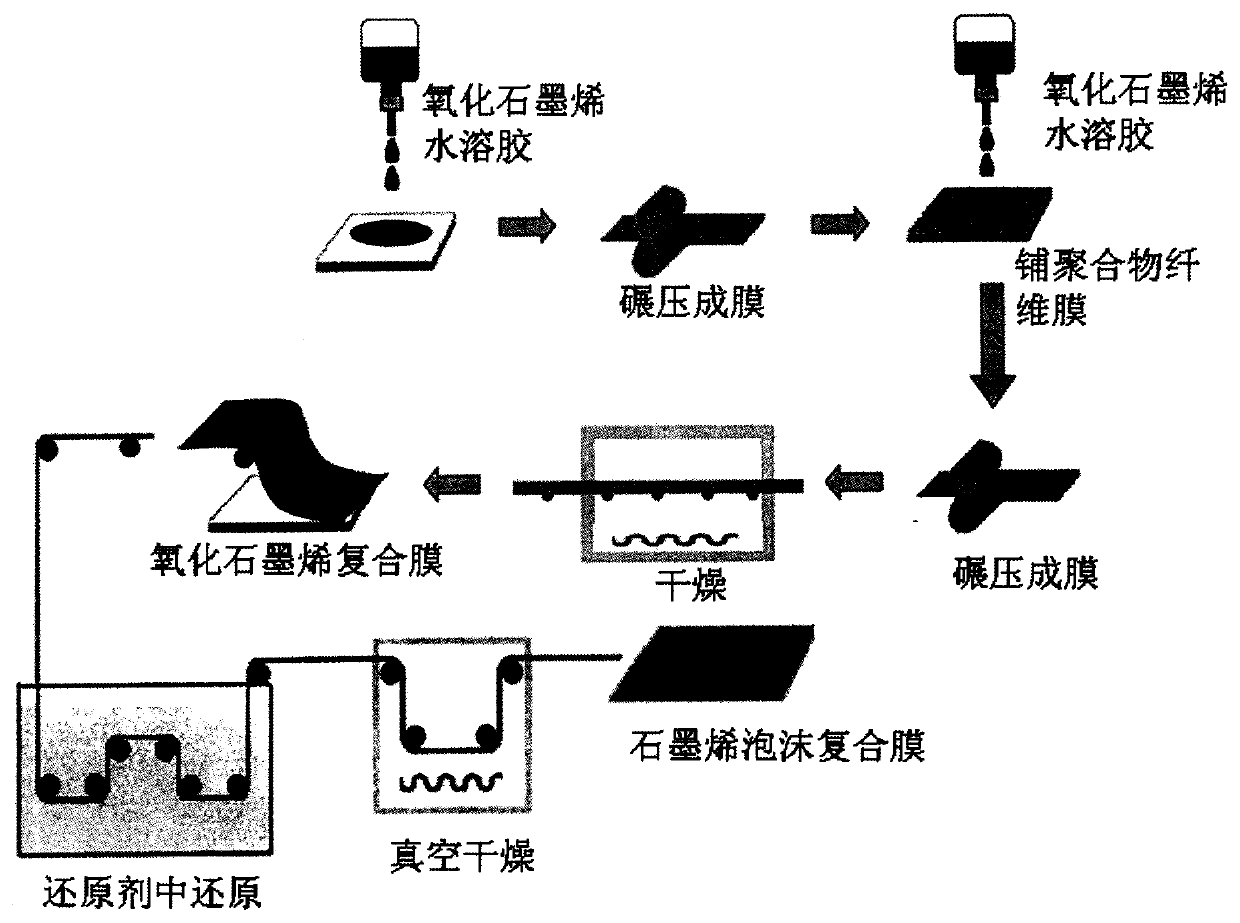

[0021] like figure 1 Shown:

[0022] The first step is the preparation of graphene oxide hydrosol, and the specific steps are:

[0023] Step (1). Add 2g flake graphite powder in four-necked flask, 20mL concentrated H 2 SO 4 , 2g K 2 S 2 o 8 , and 1g P 2 o 5 ;Stir for 4 hours at a temperature of 65°C, dilute the mixture with deionized water, filter and wash, and dry the filter cake at 50°C;

[0024] Step (2). 30mL concentrated H 2 SO 4 , 40 mL concentrated H 3 PO 4 , 2g of dry filter cake was added to a four-necked flask, and mechanically stirred; when the temperature of the mixture in the four-necked flask was lower than 20°C, 3g of NaNO was added under stirring 3 and 5g KMnO 4 , stirred for 10 min; heated to 30 ° C, stirred for 3 h; slowly added 100 mL of deionized water; and 10 mL of 30% H 2 o 2 , to obtain bright yellow solution, continue to stir for 2h;

[0025] Step (3). After the reaction, the bright yellow solution is centrifuged and washed 6 times with ...

Embodiment 2

[0039] The first step is the preparation of graphene oxide hydrosol, and the specific steps are:

[0040] Step (1). Dissolve 30mL of concentrated H under ice bath conditions 2 SO 4 , 40 mL concentrated H 3 PO 4 , Add 2g flake graphite powder into the four-necked flask and stir mechanically; when the temperature of the mixture in the four-necked flask is lower than 20°C, add 3g NaNO 3 and 5g KMnO 4 , stirred for 10 min; warmed up to 40 ° C, stirred for 2 h; slowly added 200 mL of deionized water; heated to 75 ° C, continued to stir for 60 min; added 15 mL of 30% H 2 o 2 , to obtain bright yellow solution, continue to stir for 1.5h;

[0041]Step (2). After the reaction, the bright yellow solution is centrifuged and washed 8 times with 5% HCl solution by mass fraction, and then centrifuged and washed with deionized water until the supernatant is neutral, and the centrifuge speed is 10000 rpm , and then concentrate the graphene oxide aqueous solution to finally obtain a gra...

Embodiment 3

[0054] The first step is the preparation of graphene oxide hydrosol, and the specific steps are:

[0055] Step (1). Add 2g flake graphite powder in four-necked flask, 20mL concentrated H 2 SO 4 , 2g K 2 S 2 o 8 , and 1g P 2 o 5 ;Stir for 3 hours at a temperature of 70°C, dilute the mixture with deionized water, filter and wash, and dry the filter cake at 60°C;

[0056] Step (2). 30mL concentrated H 2 SO 4 , 40 mL concentrated H 3 PO 4 , 2g of dry filter cake was added to a four-necked flask, and mechanically stirred; when the temperature of the mixture in the four-necked flask was lower than 20°C, 3g of NaNO was added under stirring 3 and 5g KMnO 4 , stirred for 10 min; heated to 45 ° C, stirred for 1 h; slowly added 150 mL of deionized water; heated to 80 ° C, continued to stir for 50 min; added 20 mL of 30% H 2 o 2 , to obtain bright yellow solution, continue to stir for 1h;

[0057] Step (3). After the reaction, the bright yellow solution is centrifuged and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com