Method for nondestructively detecting and evaluating mass defect level of high-voltage ceramic capacitors

A high-voltage ceramic, quality defect technology, applied in the direction of material resistance, can solve the problems of high-voltage ceramic capacitor damage, long test cycle, unable to meet test requirements and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

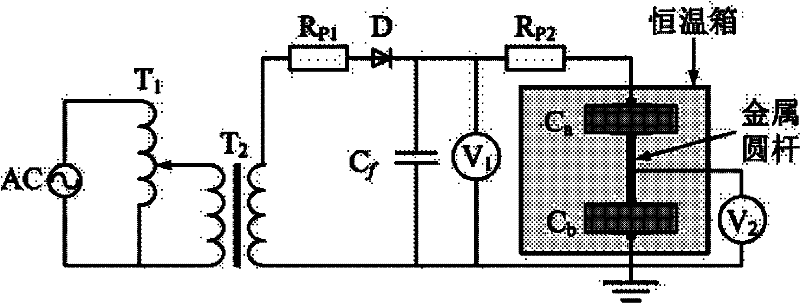

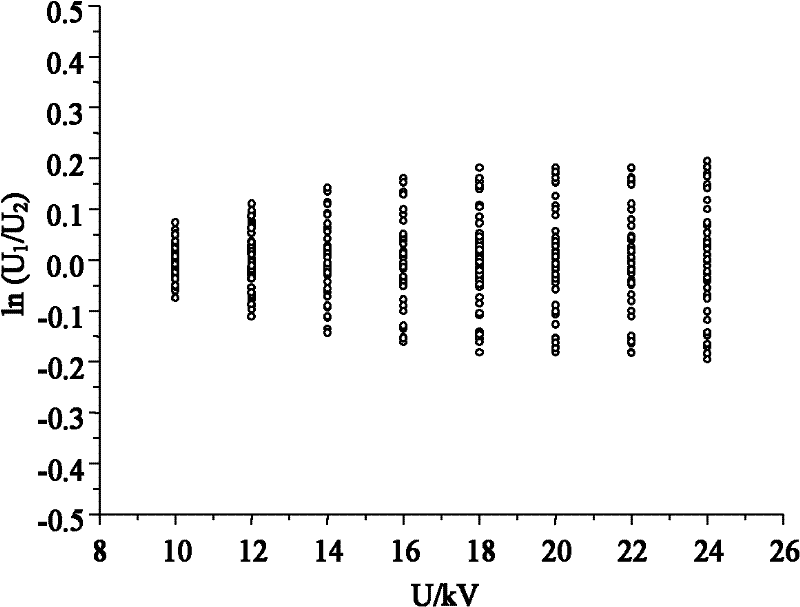

[0050] A method for non-destructive detection and evaluation of the quality defect level of a high-voltage ceramic capacitor according to the present invention, the method includes the following steps:

[0051] (1) Sample selection method and numbering method

[0052] Samples were drawn from the same batch of high-voltage ceramic capacitors. For the selection of continuous batches of high-voltage ceramic capacitor samples, the simple random sampling method (see 5.7 of GB / T3358.1-1993 for details) or the method of multiple sampling (see 8.1 of GB-T 2828.1-2003 for details), for isolated batches The sample selection of high-voltage ceramic capacitors should adopt the mode A in 4.1 of GB-T2828.2-2008 for sampling, and the randomly selected samples should be numbered in the order of No. 1 to No. n. The insulation resistance of the high-voltage ceramic capacitors in the randomly selected samples are respectively R 1 ,...R n .

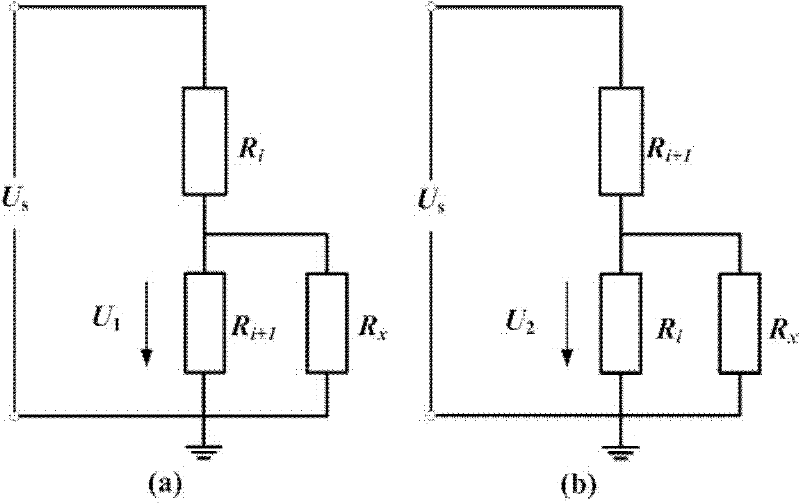

[0053] (2) Combination of samples

[0054] The hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com