Cooler for hot plate-type wind generating set

A technology for wind power generating sets and generating sets, applied in the direction of electric components, indirect heat exchangers, cooling/ventilation devices, etc., can solve the problems of reduced heat exchange efficiency, complex structure, heavy weight, etc., and achieve low cost, small size, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

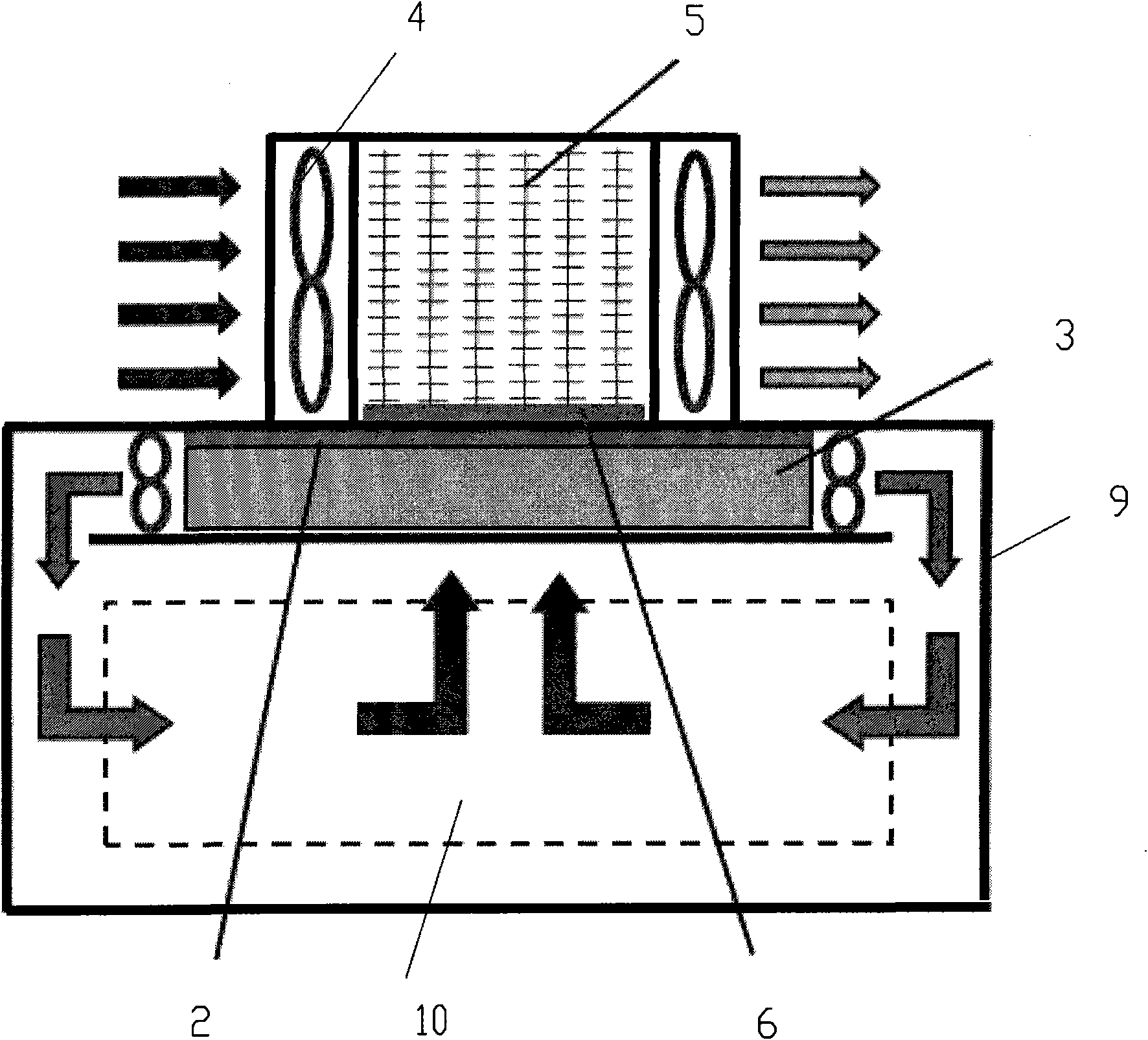

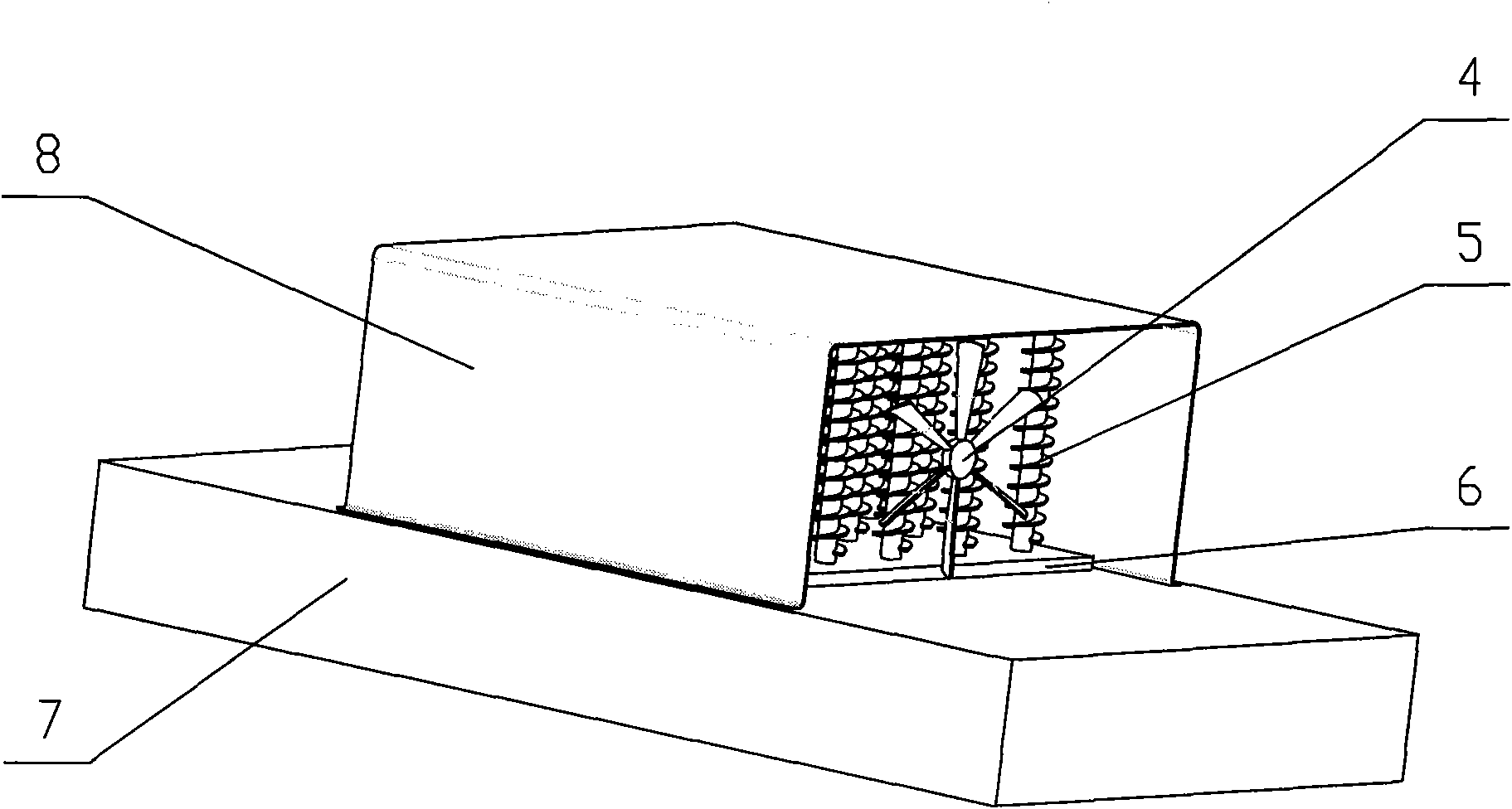

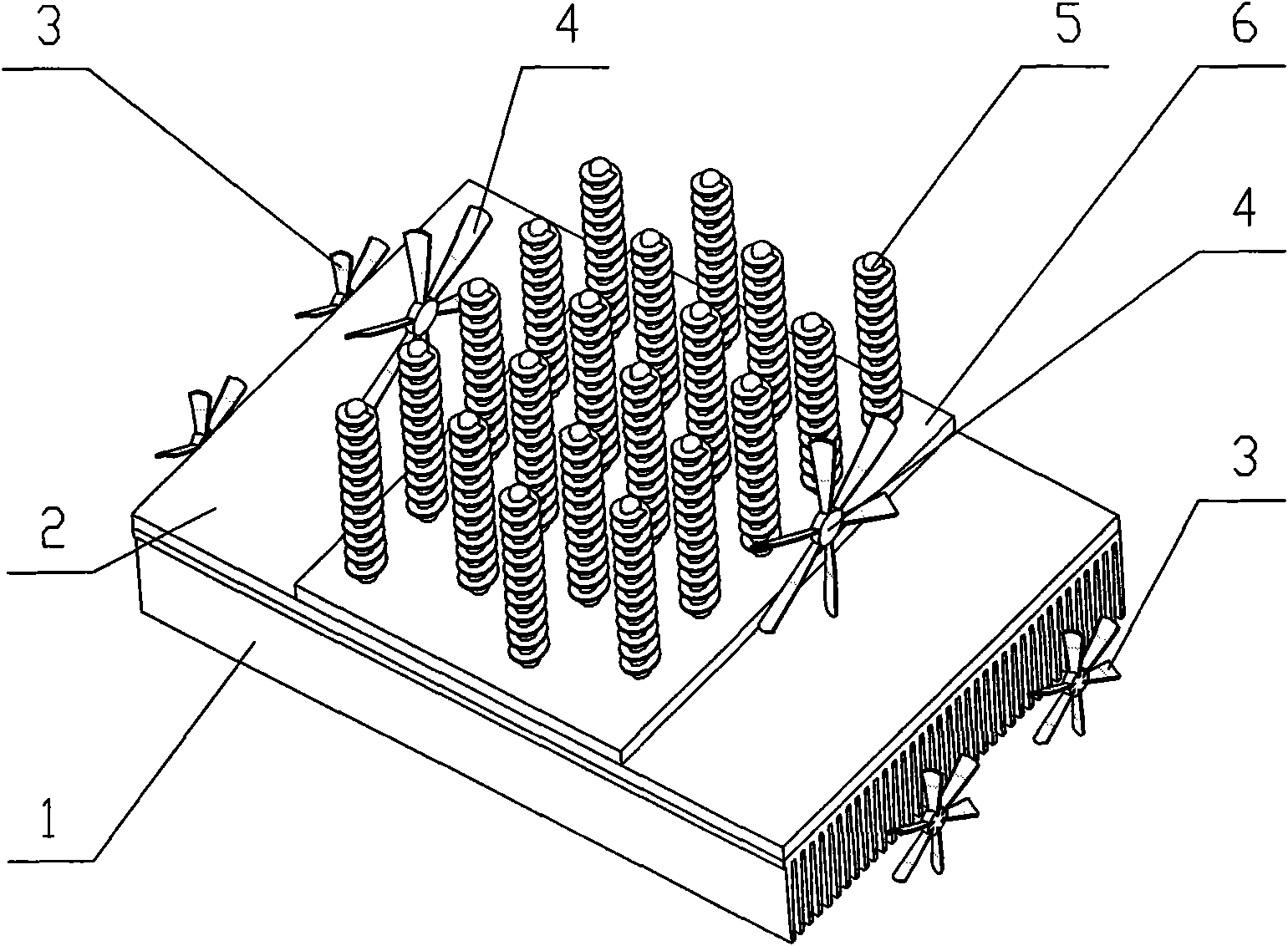

[0022] Referring to the accompanying drawings, a hot-plate cooler for wind turbines includes a hot-side part and a cold-side part. 2 and hot-side circulation fan 3; the cold-side part includes an upper hot plate 6, a heat pipe bundle 5, a cold-side fan 4 and a cold-side wind guide hood 8, and the upper hot plate 6 is arranged on the lower heat plate 2, and communicate with the cavity of the heat pipe bundle 5.

[0023] The heat-absorbing fins 1 and the lower heat plate 2 are fixed on the upper top plate of the generator case 9 by bolts, and form a closed cavity together with the generator case 9 .

[0024] The upper hot plate 6 is in direct contact with the lower hot plate 2 and fixed by screws. The upper hot plate 6 and the lower hot plate 2 are combined with copper water, and a certain amount of 60-80 mesh water mist copper powder is added. There is a high flatness between the upper heating plate 6 and the lower heating plate 2, and between the lower heating plate 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com