Automatic forming combined firework barrel

A technology for automatic forming and firecracker barrels, applied in firecrackers and other directions, can solve the problems of easy falling of mud bottom, complicated assembly process, high labor intensity, etc., and achieve the effect of convenient automatic assembly line production, stable product performance and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

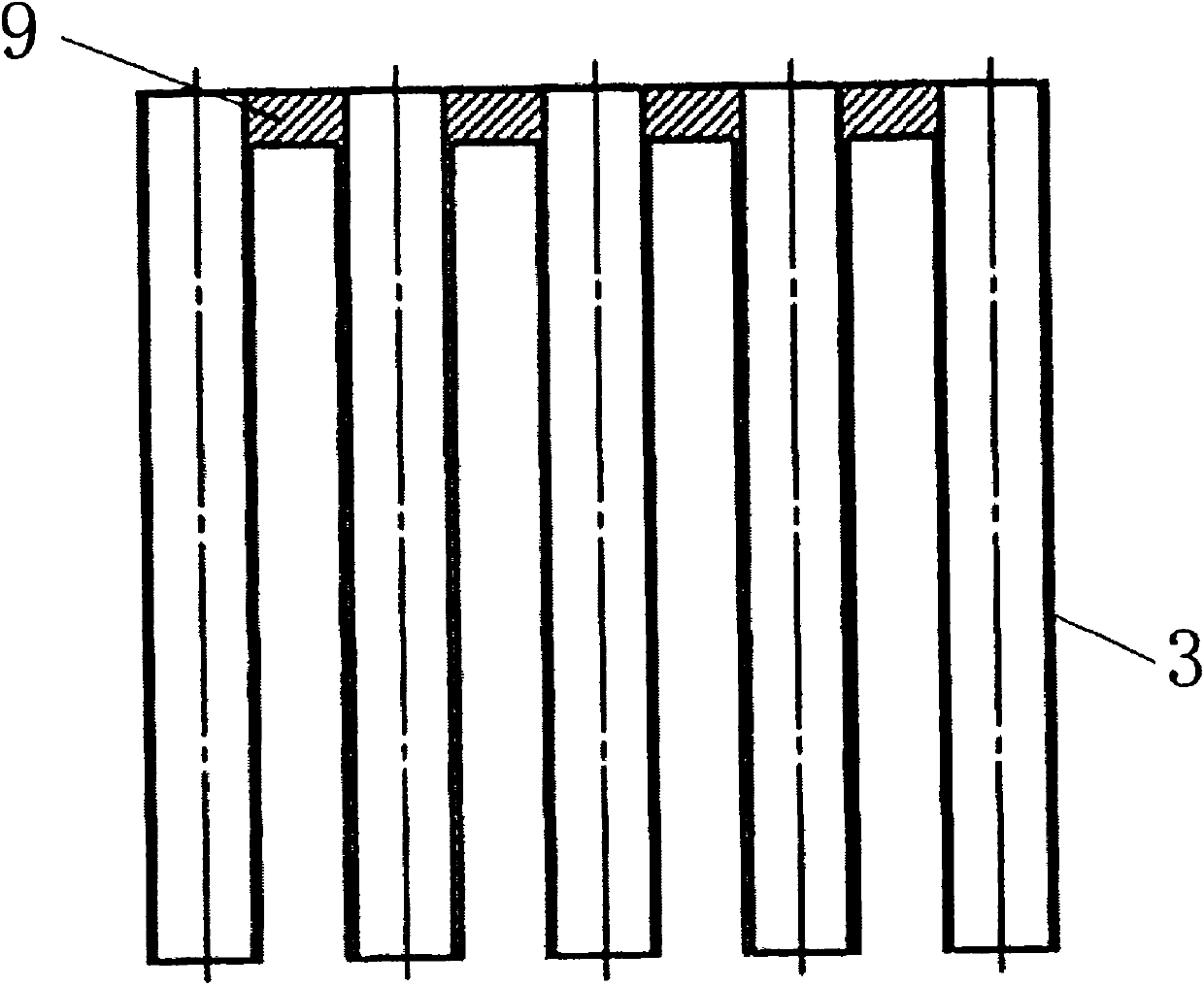

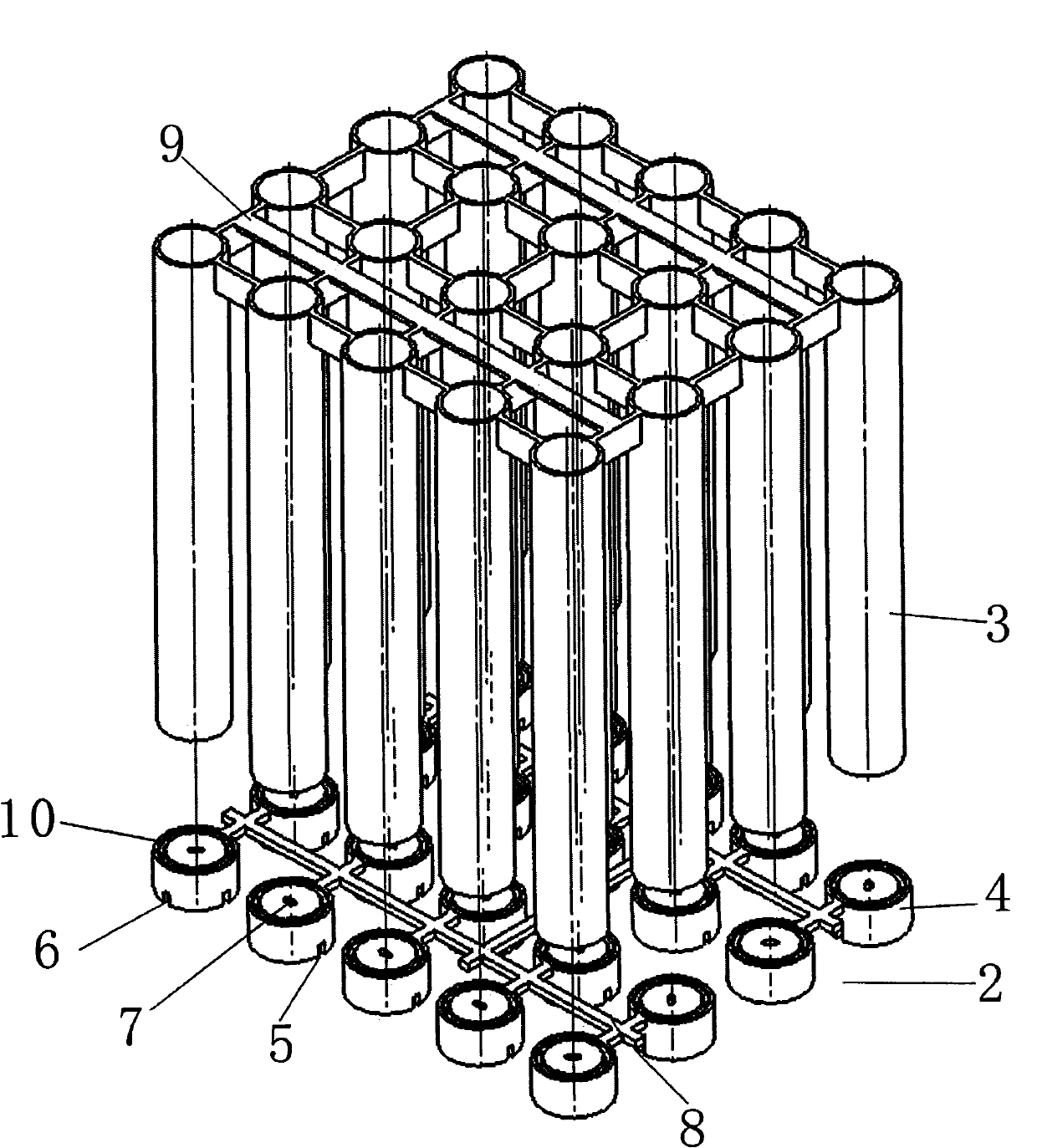

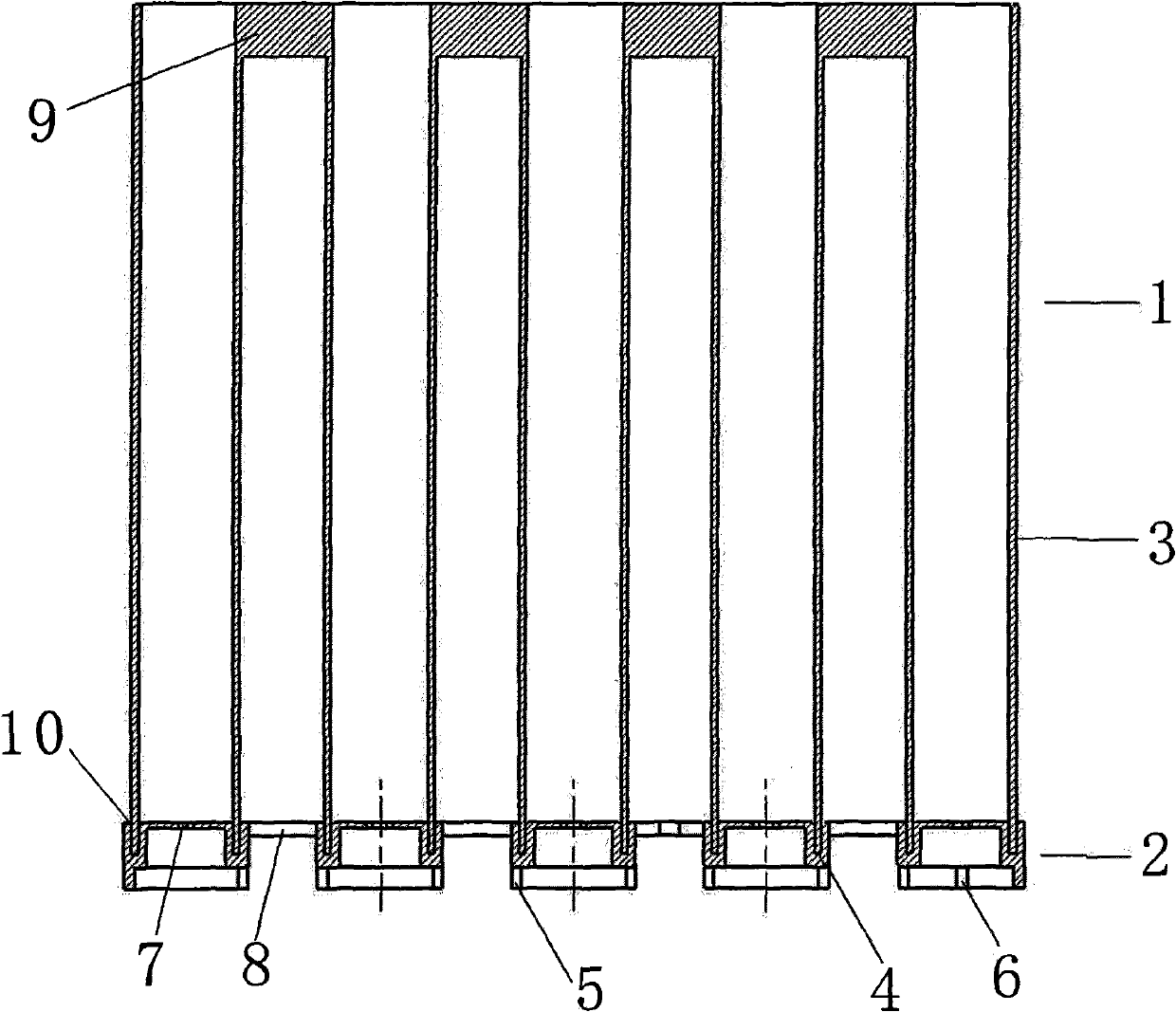

[0014] Such as figure 1 As shown: the automatic forming combined firecracker barrel of the present invention is mainly composed of a firecracker barrel 1, a string fire hole 7, and a fire string lead groove 5, and is characterized in that: the firecracker barrel 1 is mainly composed of a firecracker barrel seat 2 and a bobbin tube 3. Two independent components are inserted and connected. The firecracker barrel seat 2 is mainly composed of a bobbin socket 4 and a bobbin socket connector 8 for connecting each bobbin socket 4. The bobbin socket 4 is provided with a circle for Just plug into the groove 10 of the bobbin 3, a stringer hole 7 is provided in the center of the upper bottom of the bobbin socket 4, and the lower part of the tube wall of the bobbin socket 4 is provided with a stringer lead groove (5, 6). Tube connectors 9 are also used to connect the tubes 3 .

[0015] figure 2 and image 3 It is a structural schematic diagram of a firecracker barrel seat 2 for automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com