Waterborne building heat-insulation environment-friendly coating and preparation method thereof

An environmentally friendly coating, water-based technology, applied in coatings and other directions, can solve the problems of the reflection effect of functional fillers, the complex processing technology of heat-insulating coatings, and the impact on the scope of application of products, so as to avoid the decline of coating performance, overcome the problem of VOC emissions, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

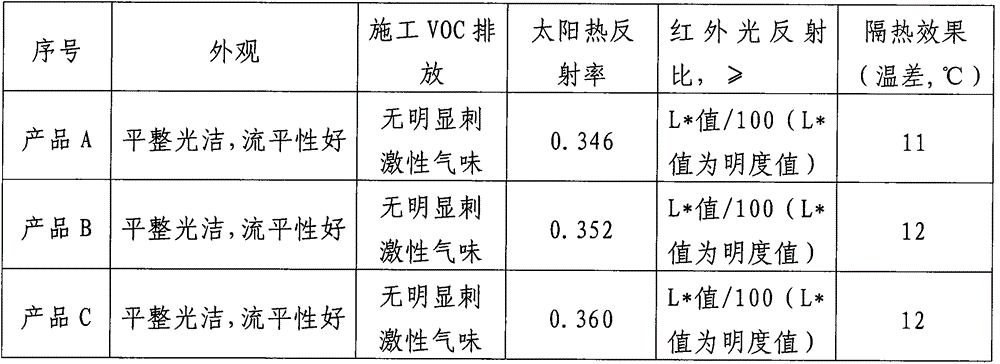

Examples

Embodiment 1

[0044] In parts by weight, add 20 parts of hexafluorobutyl methacrylate, 22 parts of methyl methacrylate, and 250 parts of styrene-acrylic emulsion into 200 parts of water, and disperse with a mixer at a speed of 1500 rpm. Add 1 part of organic ammonia antiseptic and fungicide, 1 part of carboxylic acid soap anionic surface wetting agent, 2 parts of organic siloxane defoamer and 2 parts of polyethylene wax in sequence, and continue to disperse for 30 minutes; Add 200 parts of deer marsh soil, 100 parts of fly ash, 150 parts of titanium dioxide, 80 parts of talcum powder, and 50 parts of expanded perlite in the obtained mixed solution, and the control speed is 2000 rpm, and the dispersion time is 40 minutes; Add 30 parts of n-dodecanethiol, 20 parts of ethylene glycol butyl ether, and 1 part of tributyl phosphate in the mixture obtained in the first step, adjust the rotating speed to 1600 rpm, and disperse for 30 minutes; add the obtained mixed solution Grind in a grinder. When...

Embodiment 2

[0047] In parts by weight, add 25 parts of hexafluorobutyl methacrylate, 26 parts of methyl methacrylate, and 270 parts of styrene-acrylic emulsion into 200 parts of water, and disperse with a mixer at a speed of 1700 rpm to keep constant Add 1.5 parts of organic chloride antiseptic and fungicide, 1.5 parts of hydroxysulfate anionic surface wetting agent, 2 parts of polyether defoamer and 2 parts of polyethylene wax in sequence, and continue to disperse for 35 minutes; Add 220 parts of deer marsh soil, 120 parts of fly ash, 170 parts of titanium dioxide, 100 parts of talcum powder, and 55 parts of expanded perlite in the mixed solution, and the control speed is 2200 rpm, and the dispersion time is 50 minutes; Add 35 parts of n-dodecanethiol, 25 parts of ethylene glycol butyl ether, and 1.5 parts of tributyl phosphate successively in the mixture obtained, adjust the rotating speed to be 1700 rpm, and the dispersion time is 35 minutes; the mixed solution obtained is added to Gri...

Embodiment 3

[0050]In parts by weight, add 30 parts of hexafluorobutyl methacrylate, 30 parts of methyl methacrylate, and 280 parts of styrene-acrylic emulsion into 220 parts of water, and disperse with a mixer at a speed of 1800 rpm to keep constant Add 2 parts of organic chloride antiseptic and fungicide, 2 parts of hydroxysulfate anionic surface wetting agent, 4 parts of polyether defoamer and 4 parts of polyethylene wax in sequence, and continue to disperse for 40 minutes; Add 240 parts of deer marsh soil, 160 parts of fly ash, 180 parts of titanium dioxide, 120 parts of talcum powder, and 60 parts of expanded perlite in the mixed solution in turn. The control speed is 2400 rpm, and the dispersion time is 60 minutes; In the obtained mixture, add 40 parts of n-dodecanethiol, 30 parts of ethylene glycol butyl ether, and 2 parts of tributyl phosphate successively, adjust the rotating speed to be 1800 rpm, and the dispersion time is 40 minutes; the mixed solution obtained is added to Grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com