Flexible electrochromic device and preparing method thereof

A color-changing, flexible electricity technology, applied in the direction of instruments, photovoltaic power generation, nonlinear optics, etc., can solve the problems of poor stability, low penetration rate, and low color-changing efficiency of electrochromic devices, and achieve stable cyclic color change and high color-changing efficiency , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

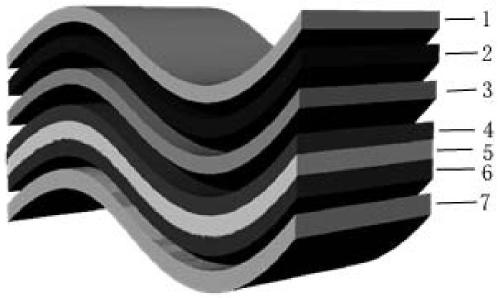

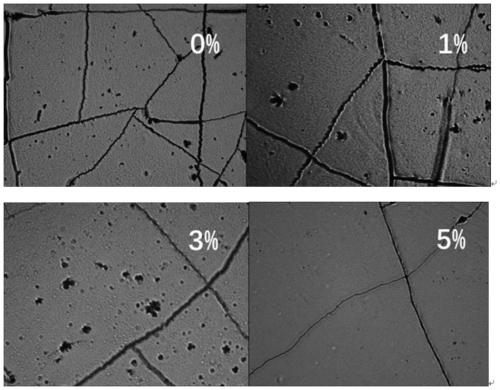

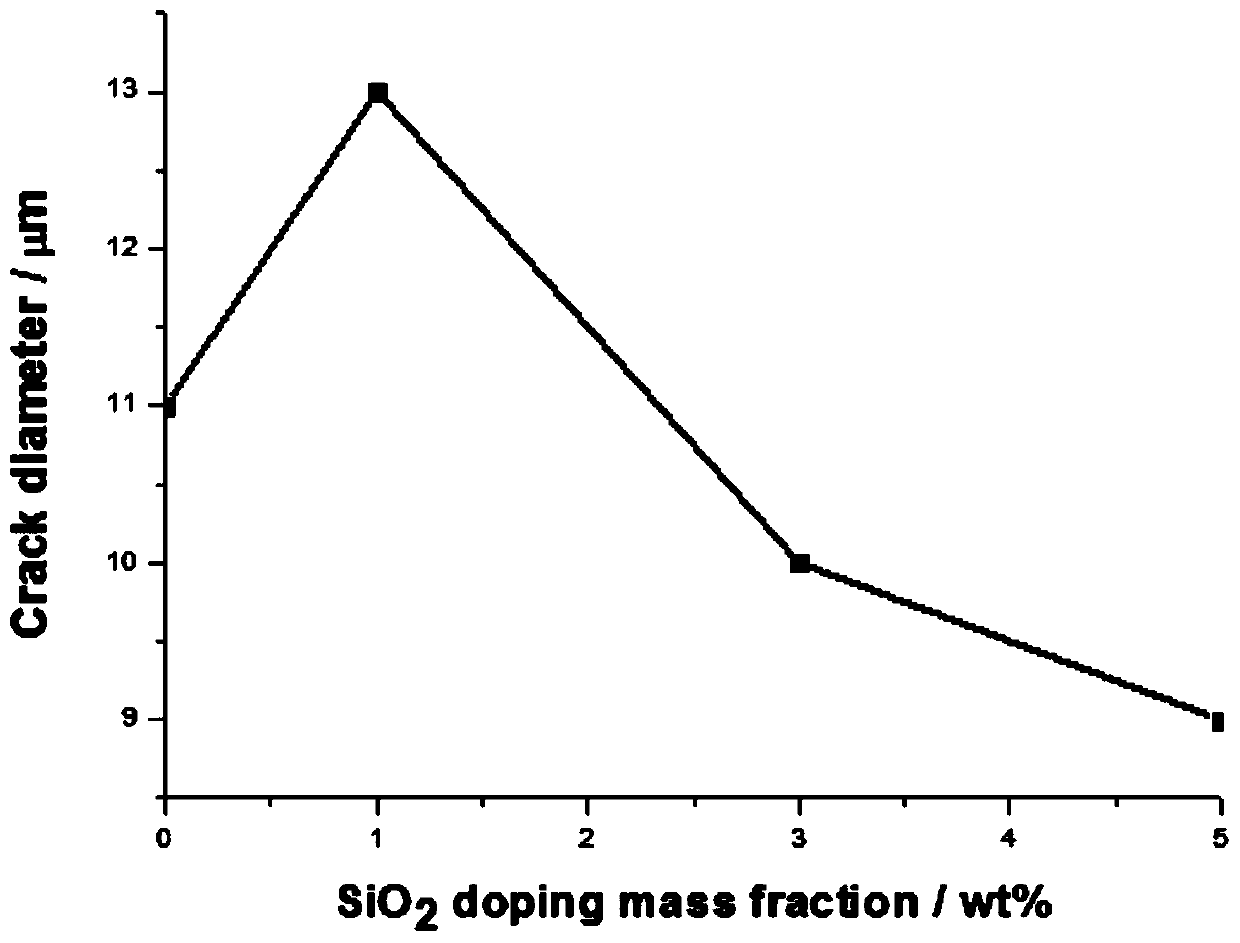

[0030]Step 1. Preparation of flexible and stretchable polydimethylsiloxane (PDMS) substrate: PDMS, mesoporous silica nanoparticles and curing agent are placed in a 3cm*5cm plastic box at a ratio of 20:1:2 Mix and stir for 2-5 minutes, then put the mixture in a vacuum drying oven to ventilate and dry until no bubbles can be seen, put it on a heating plate and cure it at 80°C for 2 hours to prepare a PDMS substrate with uniform thickness. The particle size of mesoporous silica is 7-40nm.

[0031] Step 2. Put the PDMS substrate into a magnetron sputtering target coating machine, and use plasma to clean and activate the PDMS surface.

[0032] Step 3. At 200W RF power, Ar / O 2 The flow rate is 20sccm, the proportion of oxygen is 80%, and the working pressure is 2.9mTorr. The pure tungsten target is sputtered by radio frequency magnetron sputtering, and WO with a thickness of 50nm is deposited on the surface of PDMS. 3 layer.

[0033] Step 4. Under the parameters of DC power 60W, ...

Embodiment 2

[0040] Step 1. Preparation of flexible and stretchable polydimethylsiloxane (PDMS) substrate: PDMS, mesoporous silica nanoparticles and curing agent are placed in a 3cm*5cm plastic box at a ratio of 20:0.5:2 Mix and stir for 2-5 minutes, then put the mixture in a vacuum drying oven to exhaust and dry until no bubbles can be seen, put it on a heating plate and cure it at 70°C for 1 hour to prepare a PDMS substrate with uniform thickness. The particle size of mesoporous silica is 7-40nm.

[0041] Step 2. Put the PDMS substrate into a magnetron sputtering target coating machine, and use plasma to clean and activate the PDMS surface.

[0042] Step 3. At 120W RF power, Ar / O 2 The flow rate is 20sccm, the proportion of oxygen is 20%, and the working pressure is 2.9mTorr. The pure molybdenum target is sputtered by radio frequency magnetron sputtering, and MoO with a thickness of 60nm is deposited on the surface of PDMS. 3 layer.

[0043] Step 4. Under the parameters of DC power 60...

Embodiment 3

[0050] Step 1. Preparation of flexible and stretchable polydimethylsiloxane (PDMS) substrate: PDMS, mesoporous silica nanoparticles and curing agent are placed in a 3cm*5cm plastic box at a ratio of 100:1:10 Mix and stir for 2-5 minutes, then put the mixture in a vacuum drying oven to ventilate and dry until no bubbles can be seen, put it on a heating plate and cure it at 90°C for 2 hours to prepare a PDMS substrate with uniform thickness. The particle size of mesoporous silica is 7-40nm.

[0051] Step 2. Put the PDMS substrate into a magnetron sputtering target coating machine, and use plasma to clean and activate the PDMS surface.

[0052] Step 3. At 150W RF power, Ar / O 2 The flow rate is 20sccm, the proportion of oxygen is 50%, and the operating pressure is 2.9mTorr. The pure nickel target is sputtered by radio frequency magnetron sputtering, and a NiO layer with a thickness of 30nm is deposited on the PDMS surface.

[0053] Step 4. Under the parameters of DC power 60W, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com