Method for preparing nanometre copper oxide by solid-phase template method

A technology of nano-copper oxide and template method, which is applied in the fields of copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The solid-phase preparation of nano-copper oxide by lignin amine template method, the specific steps are as follows:

[0034] 1. Take 10g of lignin, add 30mL of deionized water, drop in a mixture of 1mL of concentrated hydrochloric acid and 7mL of dioxane while stirring, heat and reflux at 75°C for 5h, cool to room temperature, filter, wash the precipitate and filter, take Add 10g of lignin purified by the above steps, add 30mL of absolute ethanol, add 0.75mL of concentrated hydrochloric acid dropwise while stirring, heat and reflux at 75°C for 4h, filter, wash several times to obtain a tan fine powder, air-dry, and set aside .

[0035] 2. Weigh 8 g of the purified and degraded lignin prepared in step 1 at room temperature, add 184 mL of deionized water and 0.4 mol. L -1 NaOH solution 11mL, magnetically stirred for 10min, added 5mL of formaldehyde, stirred for 10min, then added 5.6mL of tetraethylenepentamine, continued to stir for 10min, the solution was heated to re...

Embodiment 2

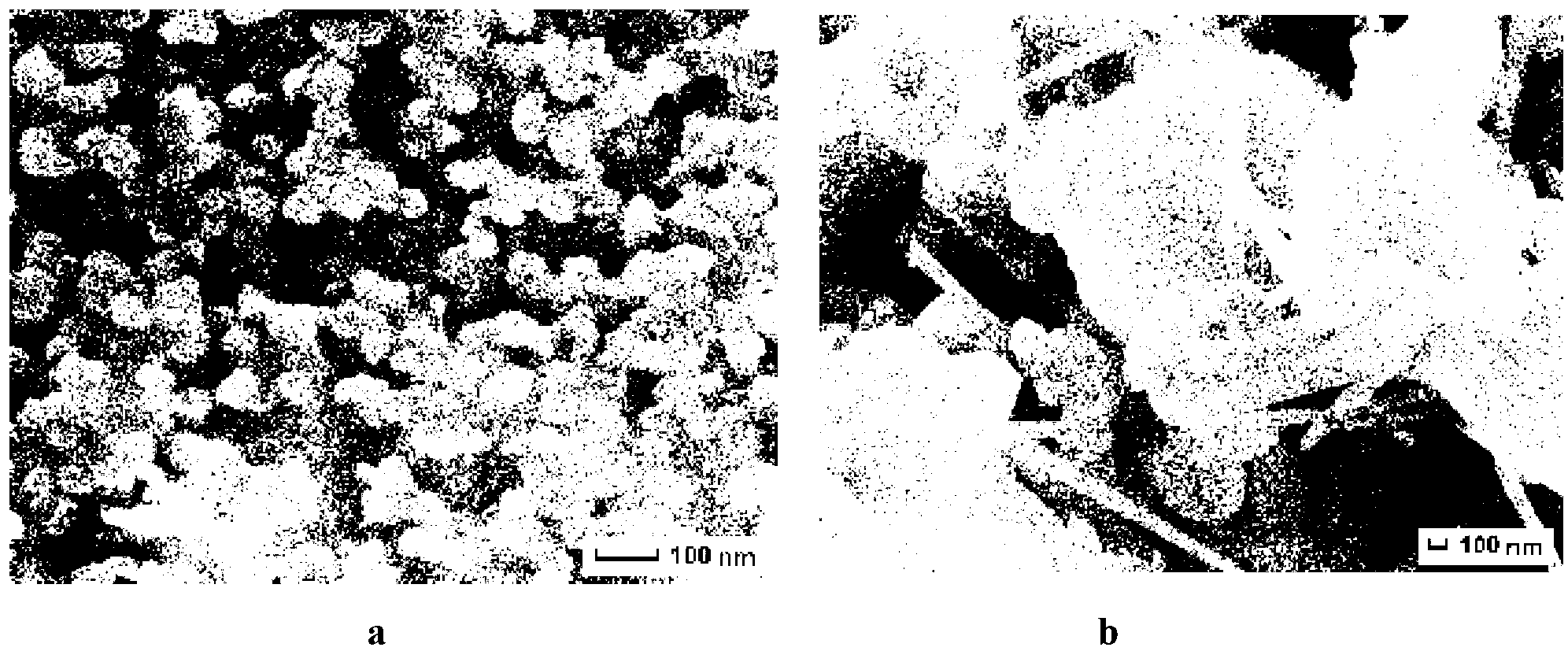

[0038] The solid-phase preparation of nano-copper oxide by ligninamine template method is the same as that of Example 1, except that in the third step, the dried solid is finally calcined at 700° C. for 2 hours. Sample SEM as figure 2 b.

Embodiment 3

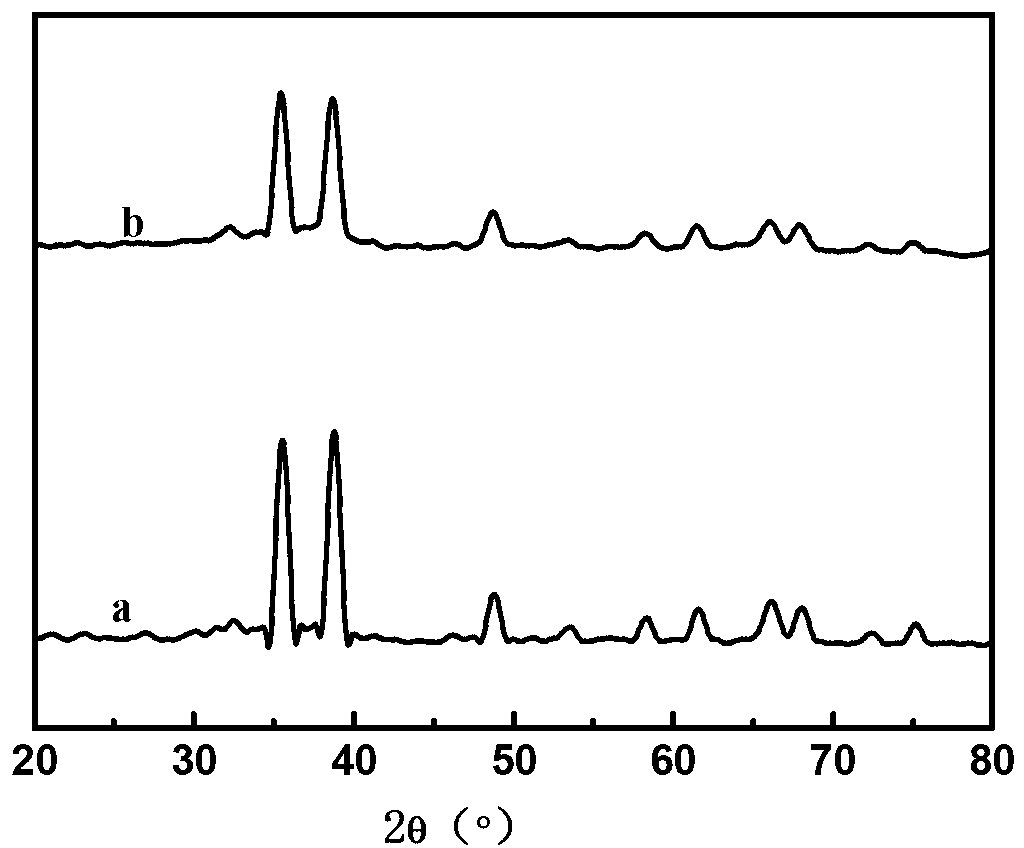

[0040] Preparation of nano-copper oxide in solid phase by lignin amine template method is the same as in Example 1, except that in the second step, 4 g of the purified and degraded lignin prepared in step 1 is weighed, and 92 mL of deionized water and 0.4 mol ﹒ L -1 NaOH solution was 5.5 mL, the added formaldehyde was 2.5 mL, and the added tetraethylenepentamine was 2.8 mL. In the third step, the dried solid is finally calcined at 300° C. for 2 hours. Sample XRD as figure 1 b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com