Application of nano copper oxide/carbon nitride composite material in water bloom control

A technology of nano-copper oxide and composite materials, which is applied in the field of water pollution treatment, can solve unknown problems and achieve good reusability, stable performance, and low algae inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

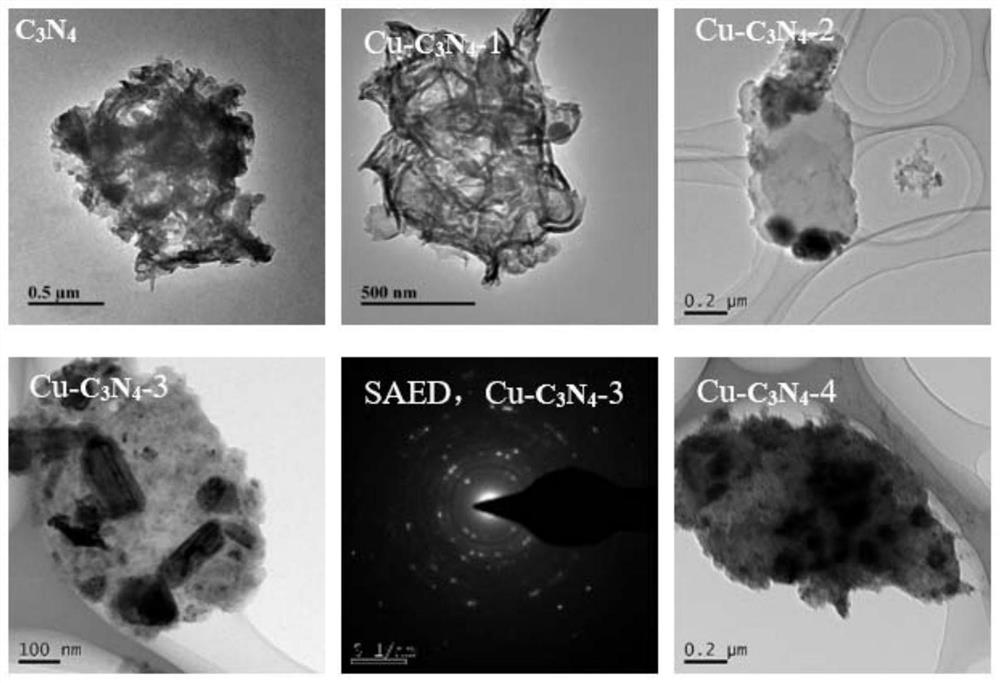

[0045] 1. Preparation of copper-loaded carbon nitride with different copper mass ratios:

[0046] Put 15g of urea in a muffle furnace, heat up to 550°C at a heating rate of 2°C / min, and keep heating at 550°C for 4 hours; then cool down to room temperature naturally, and wash the obtained white product three times with ethanol and distilled water, Remove unreacted urea. Subsequently, 1 g of the white product was dispersed in 400 mL of distilled water, ultrasonicated at 500 W for 8 h, centrifuged at 3000 rpm for 10 min to remove unstripped large particles, and the completely stripped product was freeze-dried to obtain purified C 3 N 4 , the freeze-drying method is: put the obtained reactant in a -20°C refrigerator for 12h, and then put it into a vacuum freeze-drying box, freeze-drying conditions: temperature -80°C, vacuum degree 8.5Pa, freeze-drying for 48h.

[0047] Take 64mg of purified C 3 N 4 Disperse into 0.00, 0.05, 0.10, 0.20, 0.50mM copper acetate solution, shake the...

Embodiment 2

[0051] Nano-copper oxide / carbon nitride composites for inhibiting algae growth:

[0052] Take the suspension of Microcystis aeruginosa, the initial density of Microcystis aeruginosa: 1.8×10 6 cells / mL, algae cells were cultured in 1 / 2 BG11 medium.

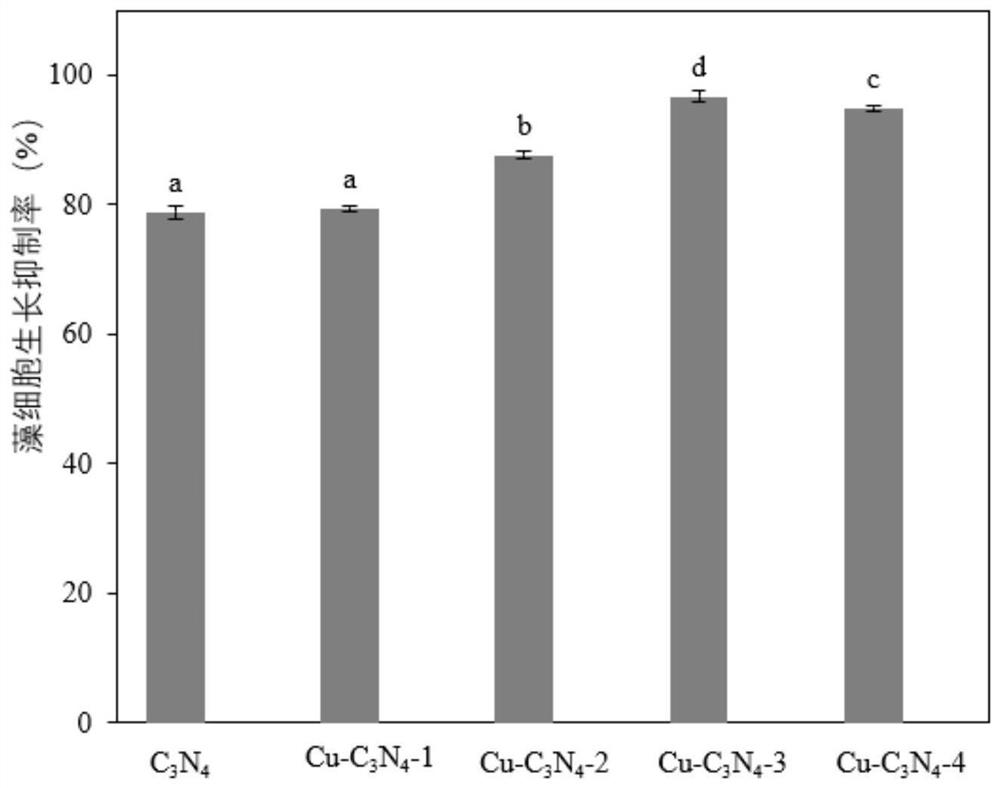

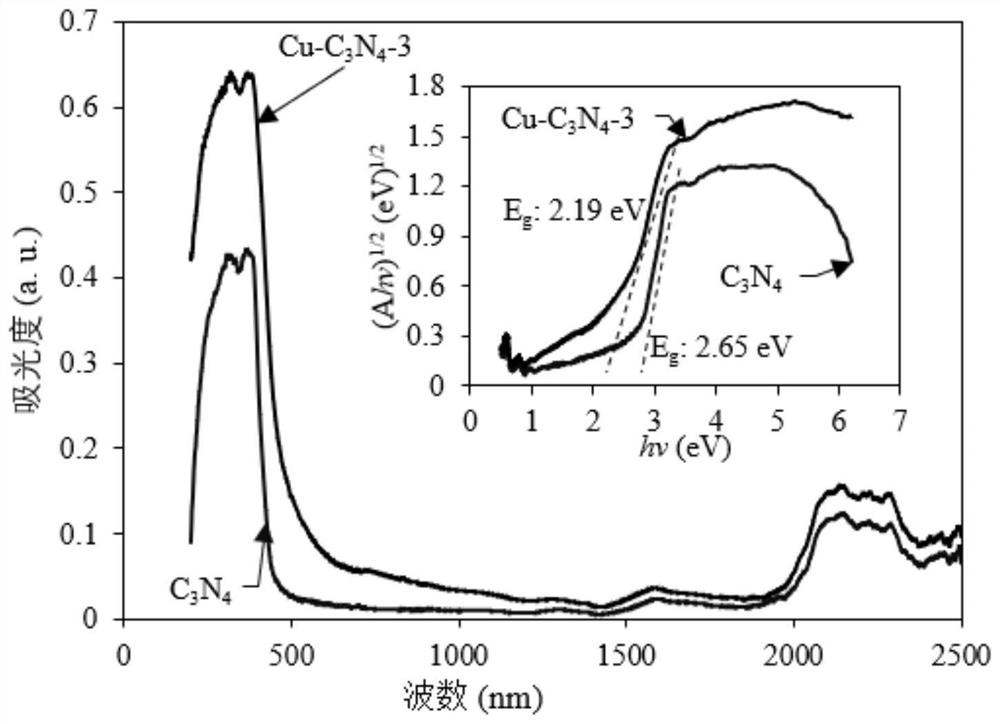

[0053] Make 10mL concentration 100mg / LC 3 N 4 , Cu-C 3 N 4 -1, Cu-C 3 N 4 -2, Cu-C 3 N 4 -3, Cu-C 3 N 4 -4 suspension was added to 90mL of algae cell culture medium, and kept shaking at 200rpm / min during the cultivation process. The daily light time and dark time are: 14h and 10h respectively, and the light intensity is 312μmol / m 2 / s. After 96 hours of exposure, use a hemocytometer to count the number of algae cells to determine the inhibition rate of various materials on the growth of algae cells. figure 2 for C 3 N 4 and different proportions of copper loading C 3 N 4 The comparison chart of anti-algae performance shows that the loading of copper significantly increases the C 3 N 4 Algae inhibitory performanc...

Embodiment 3

[0055] C at different concentrations and different exposure times 3 N 4 and Cu-C 3 N 4 -3's anti-algae performance:

[0056] The suspension of Microcystis aeruginosa and the conditions of exposure are all the same as in Example 2.

[0057] Calculation method of half effect concentration:

[0058]

[0059] with C 3 N 4 or Cu-C 3 N 4 -3 The logarithm of 10 for the treatment concentration is taken as the abscissa, and the algal cell inhibition rate of different treatment concentrations is used as the ordinate to calculate the regression equation and correlation coefficient of each treatment concentration. The corresponding treatment concentration when the inhibition rate is 50% is The median effect concentration.

[0060] Different concentrations (0, 1, 5, 10, 20, 50, 100mg / L) of C 3 N 4 and Cu-C 3 N 4 -3 was added to the suspension of Microcystis aeruginosa, and after exposure for 24, 48, 72, and 96 hours respectively, the number of algae cells was counted with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com