Silver-loaded copper oxide nano composite material preparation method

A nano-composite material, copper oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. areas, the need for roasting, etc., to achieve the effects of low cost, good industrial application prospects, and reduced labor intensity and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

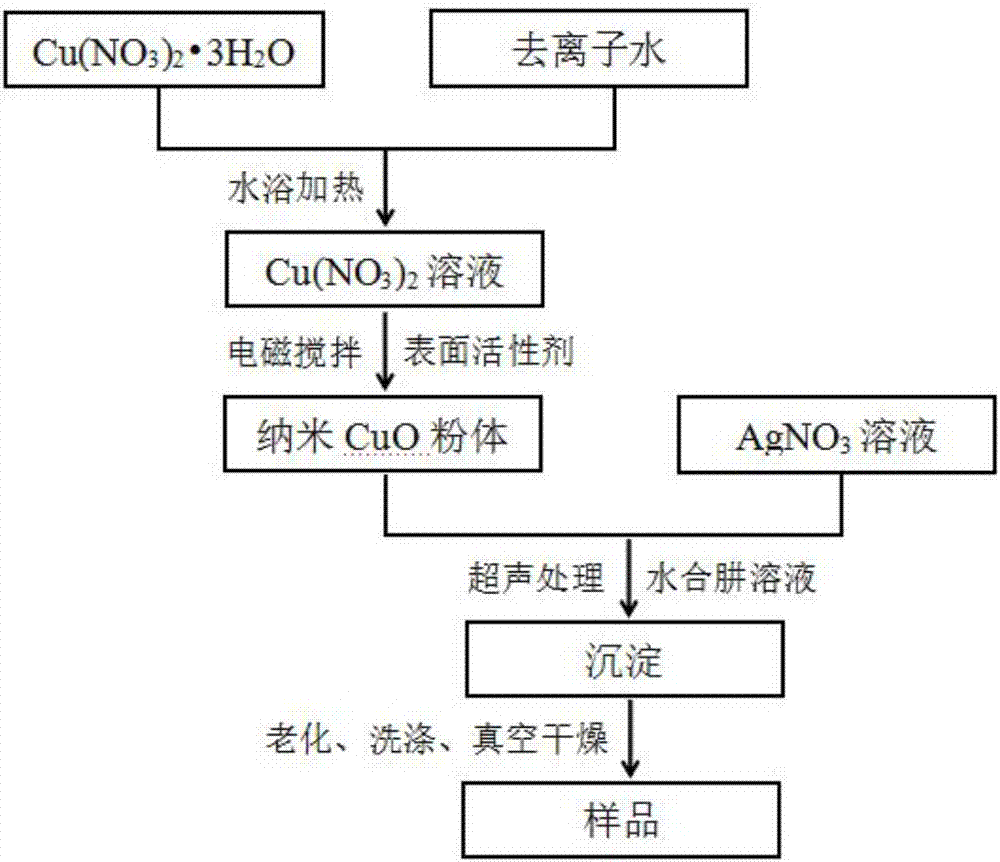

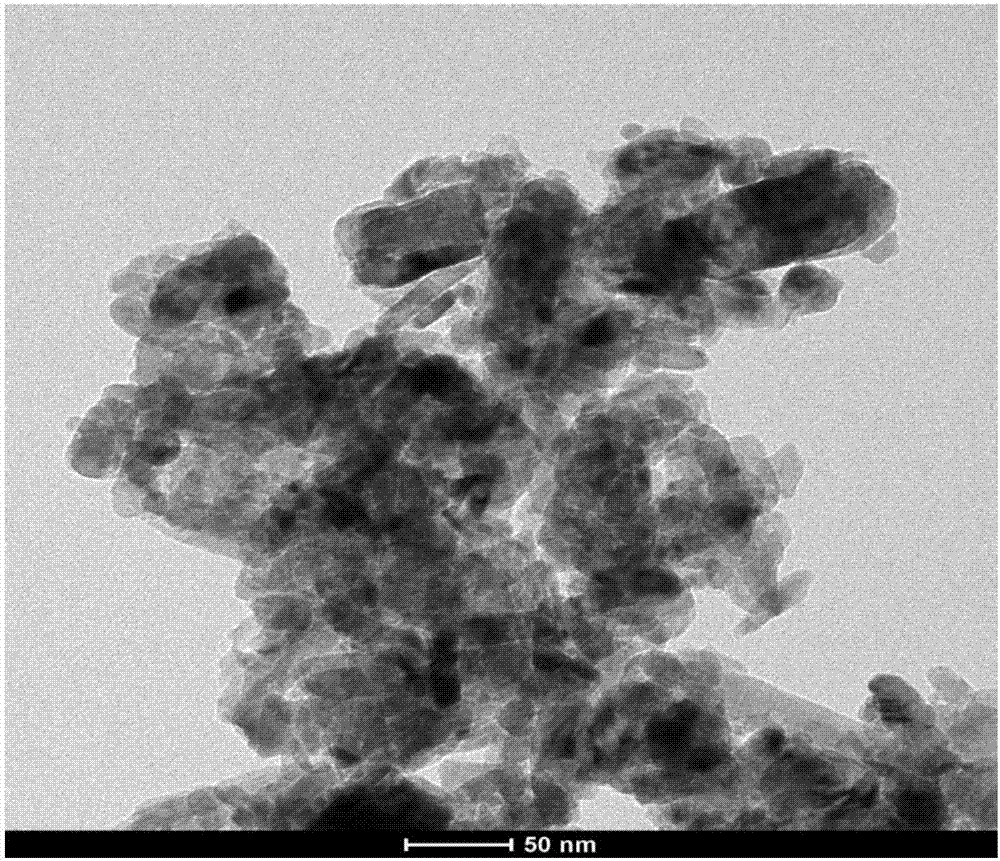

[0048] The preparation method of a copper oxide composite material loaded with nano-silver described in this embodiment, the specific steps are as follows figure 1 As shown in the process flow, 32.01gCu(NO 3 ) 2 ·3H 2 O was added to 1000ml of deionized water, and 2.3g of sodium dodecylbenzenesulfonate was added, and stirred evenly. Add 300 ml of 1 mol / L sodium hydroxide solution dropwise, stir electromagnetically for 40 minutes, wash and dry to obtain nano copper oxide. The obtained nano-copper oxide powder is dispersed in 400ml0.2mol / L AgNO 3 In the aqueous solution, sonicate at 60°C for 15 minutes to disperse evenly, and then add 100ml of 1.2mol / L hydrazine hydrate solution dropwise to the above aqueous solution under the condition of sonication. After 15 minutes of reaction, the precipitate is aged and washed. And vacuum drying at 100° C. for 8 h to prepare silver-loaded copper oxide nanomaterials. Its average particle size is about 50nm.

Embodiment 2

[0051] The preparation method of a copper oxide composite material loaded with nano-silver described in this embodiment, the specific steps are as follows figure 1 As shown in the process flow, 21.1gCu(NO 3 ) 2 ·3H 2 O was added to 1000ml of deionized water, and 2.2g of sodium dodecylbenzenesulfonate was added, and stirred evenly. Add 200 ml of 1 mol / L sodium hydroxide solution dropwise, stir electromagnetically for 35 minutes, wash and dry to obtain nano copper oxide. The obtained nano-copper oxide powder is dispersed in 400ml0.2mol / L AgNO 3 In the aqueous solution, sonicate at 60°C for 15 minutes to disperse evenly, and then add 100ml of 1.2mol / L hydrazine hydrate solution dropwise to the above aqueous solution under the condition of sonication. After 15 minutes of reaction, the precipitate is aged and washed. And vacuum drying at 100° C. for 6 h to prepare silver-loaded copper oxide nanomaterials. Its average particle size is about 40nm.

Embodiment 3

[0053] The preparation method of a copper oxide composite material loaded with nano-silver described in this embodiment, the specific steps are as follows figure 1 As shown in the process flow, 12.37gCu(NO 3 ) 2 ·3H 2 O was added to 1000ml of deionized water, and 2.3g of sodium dodecylbenzenesulfonate was added, and stirred evenly. Add 150 ml of 1 mol / L sodium hydroxide solution dropwise, stir electromagnetically for 30 minutes, wash and dry to obtain nano copper oxide. The obtained nano-copper oxide powder is dispersed in 400ml0.2mol / L AgNO 3 In the aqueous solution, sonicate at 60°C for 15 minutes to disperse evenly, and then add 100ml of 1.2mol / L hydrazine hydrate solution dropwise to the above aqueous solution under the condition of sonication. After 15 minutes of reaction, the precipitate is aged and washed. And vacuum drying at 100° C. for 5 h to prepare silver-loaded copper oxide nanomaterials. Its average particle size is about 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com