Method for preparing nanometer copper oxide by using copper scrap

A technology of nano-copper oxide and copper waste, applied in the direction of copper oxide/copper hydroxide, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of low cost, less pollution, simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Immerse copper scrap with a copper content of 20wt% in a chloric acid solution with a concentration of 15%, and the weight ratio of solid to liquid is 1:5, whichever is used to clarify copper chloride CuCl 2 supernatant;

[0015] (2) Copper chloride CuCl 2 Solution copper content is adjusted and controlled at 0.5wt%, and copper chloride CuCl 2 The acid-base value of the solution is controlled at pH=2;

[0016] (3) Copper chloride CuCl obtained in step (2) 2 The solution is placed in a reaction tank containing sodium hydroxide NaOH reaction solution, the pH value of sodium hydroxide NaOH is adjusted, so that the final reaction pH value is 9, the temperature in the reaction tank is controlled at 60 ° C, and the stirring time in the reaction tank is 0.5 hours;

[0017] (4) The black precipitate obtained in step (3) was filtered and washed with water to remove sodium Na and chlorine Cl in the reactant to obtain black nano-sized copper oxide.

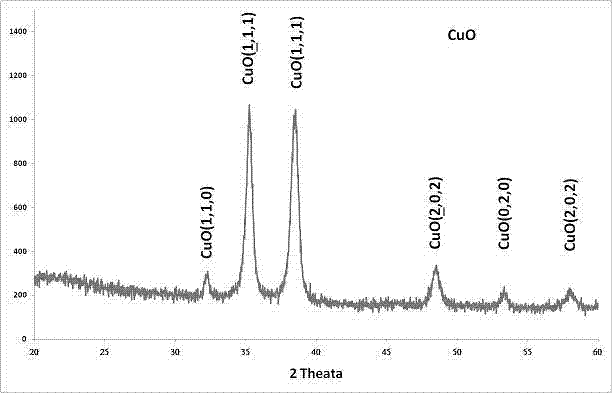

[0018] figure 1 It i...

Embodiment 2

[0020] (1) Immerse the copper scrap with a copper content of 40wt% in a chloric acid solution with a concentration of 30%, and the weight ratio of solid to liquid is 1:4, whichever is used to clarify copper chloride CuCl 2 supernatant;

[0021] (2) Copper chloride CuCl 2 Solution copper content is adjusted and controlled at 10wt%, and copper chloride CuCl 2 The acid-base value of the solution is controlled at pH=0;

[0022] (3) Copper chloride CuCl obtained in step (2) 2 The solution is placed in a reaction tank containing sodium hydroxide NaOH reaction solution, the pH value of sodium hydroxide NaOH is adjusted to make the final reaction pH value 11, the temperature in the reaction tank is controlled at 90 ° C, and the stirring time in the reaction tank is 2 hours;

[0023] (4) The black precipitate obtained in step (3) was filtered and washed with water to remove sodium Na and chlorine Cl in the reactant to obtain black nano-sized copper oxide.

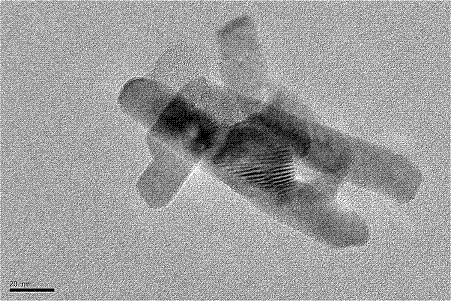

[0024] figure 2 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com