Preparation method of nano copper oxide and application of nano copper oxide in photocatalytic degradation of organic matters

A nano-copper oxide and organic technology, which is applied in copper oxide/copper hydroxide, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high preparation cost and complicated preparation process of nano-copper oxide. and other problems, to achieve the effect of regular morphology, good crystallinity and high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

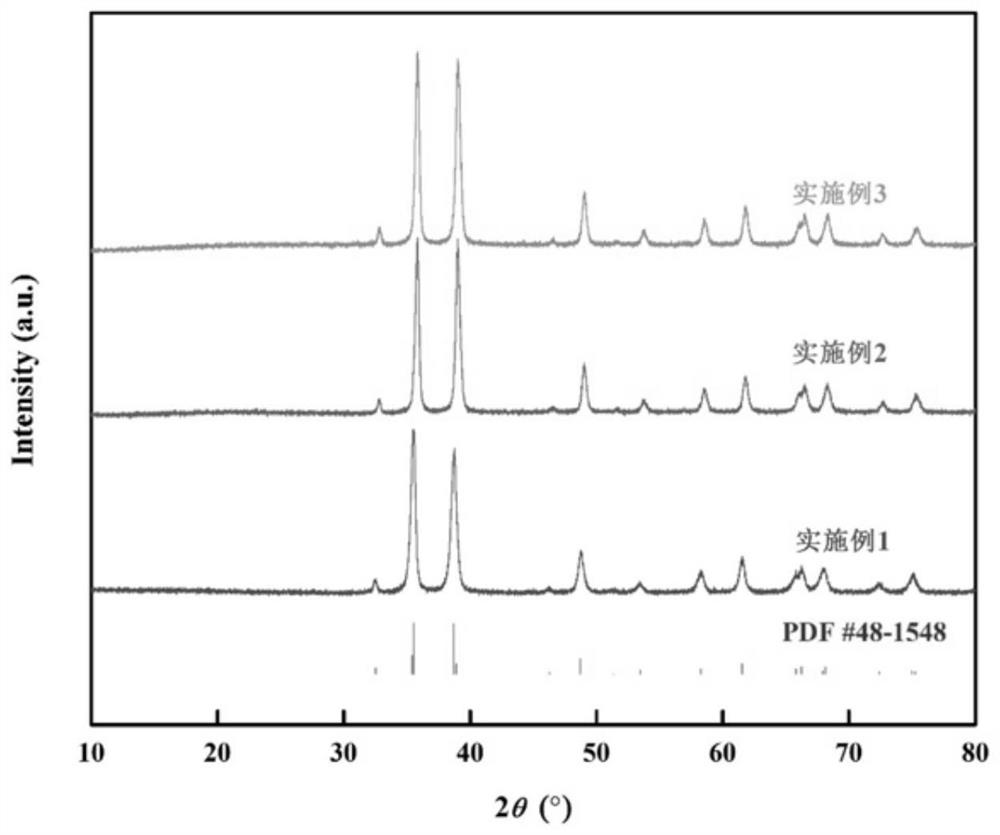

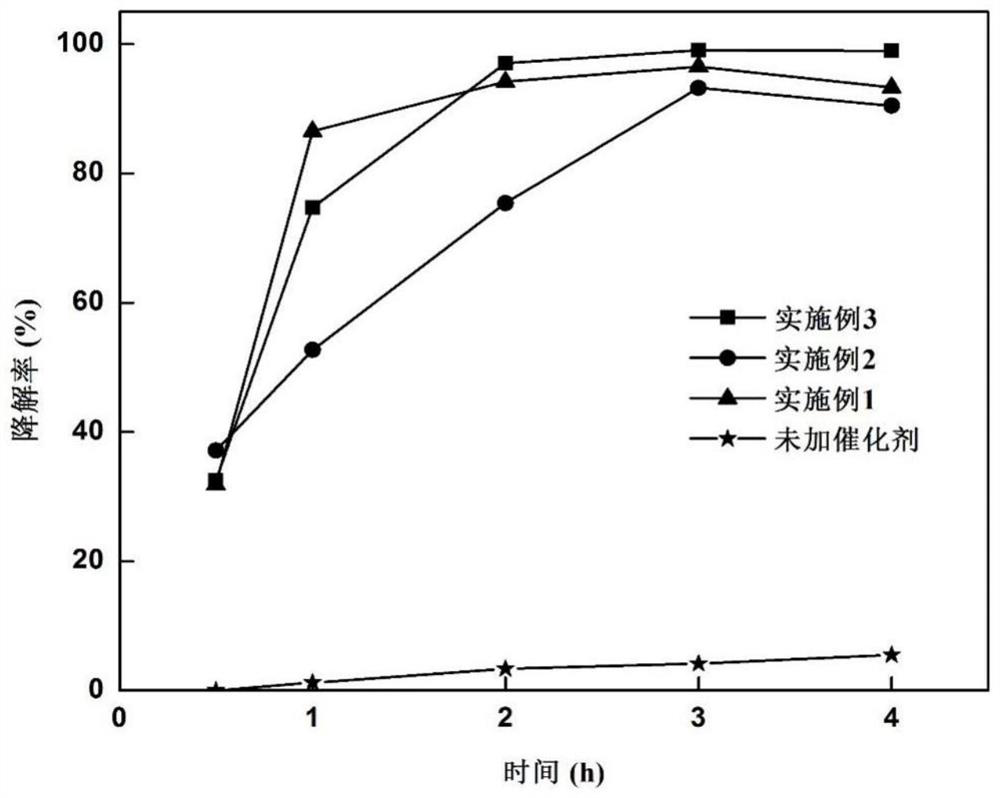

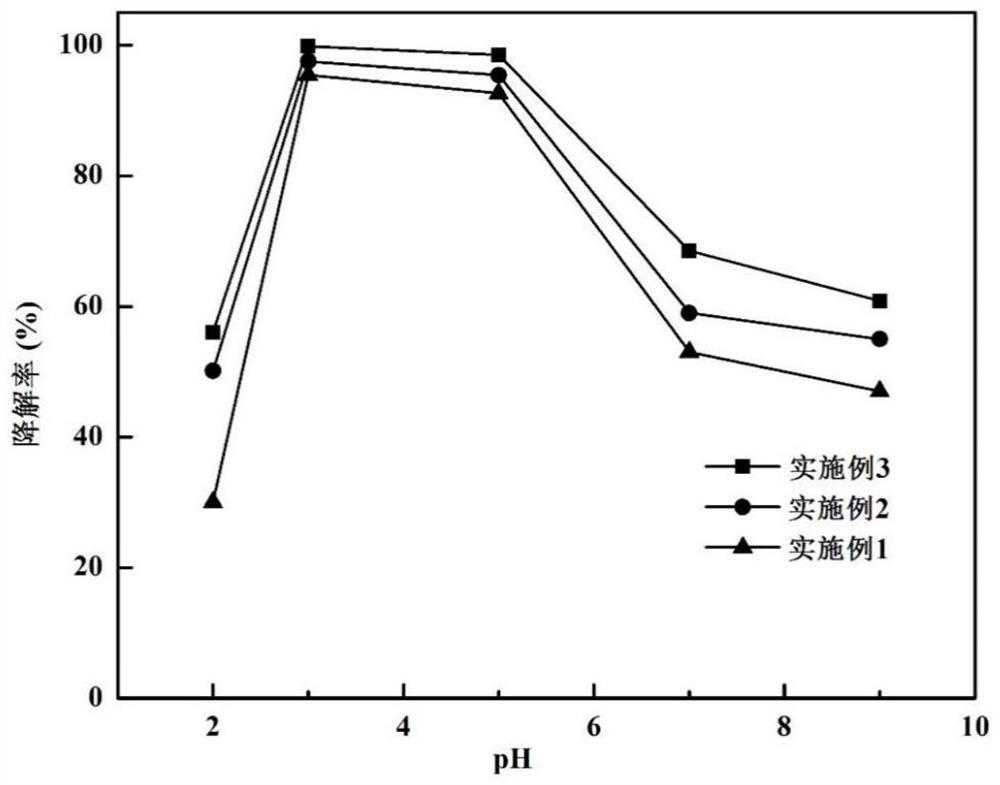

Embodiment 1

[0029] A preparation method of nano-copper oxide, comprising the steps of:

[0030] Accurately weigh 3g of Cu(NO 3 ) 2 ·3H 2 O and 4.92g of NaOH solids were placed in a small beaker respectively, and were completely dissolved with 5mL of deionized water. Under stirring, the NaOH solution was slowly added dropwise to the copper nitrate aqueous solution, and reacted for 2h;

[0031]Then transfer it into a microwave hydrothermal reaction kettle, set the pressure of the microwave hydrothermal reaction to 3MPa, the microwave power to 800W, and conduct the microwave hydrothermal reaction at 120°C for 48min, and naturally cool to room temperature after the reaction;

[0032] The product was isolated, washed three times with deionized water and ethanol, dried at 80°C, ground, and roasted in a tube furnace under a nitrogen atmosphere. After rising to 500°C, heat-preserve and roast for 3 hours, and then lower to room temperature to obtain nano-copper oxide.

Embodiment 2

[0034] A preparation method of nano-copper oxide, comprising the steps of:

[0035] Accurately weigh 3g of Cu(NO 3 ) 2 ·3H 2 O and 4.92g of NaOH solids were placed in a small beaker respectively, and were completely dissolved with 5mL of deionized water. With stirring, the NaOH solution was slowly added dropwise to the copper nitrate aqueous solution, and reacted for 2h;

[0036] Then transfer it into a microwave hydrothermal reaction kettle, set the pressure of the microwave hydrothermal reaction to 3MPa, the microwave power to 800W, and conduct the microwave hydrothermal reaction at 150°C for 48 minutes, and naturally cool to room temperature after the reaction;

[0037] The product was isolated, washed three times with deionized water and ethanol, dried at 80°C, ground, and roasted in a tube furnace under a nitrogen atmosphere. After rising to 500°C, heat-preserve and roast for 3 hours, and then lower to room temperature to obtain nano-copper oxide.

Embodiment 3

[0039] A preparation method of nano-copper oxide, comprising the steps of:

[0040] Accurately weigh 3g of Cu(NO 3 ) 2 ·3H 2 O and 4.92g of NaOH solids were placed in a small beaker respectively, and were completely dissolved with 5mL of deionized water. With stirring, the NaOH solution was slowly added dropwise to the copper nitrate aqueous solution, and reacted for 2h;

[0041] Then transfer it into a microwave hydrothermal reaction kettle, set the pressure of the microwave hydrothermal reaction to 3MPa, the microwave power to 800W, and conduct the microwave hydrothermal reaction at 180°C for 48 minutes, and naturally cool to room temperature after the reaction;

[0042] The product was isolated, washed three times with deionized water and ethanol, dried at 80°C, ground, and roasted in a tube furnace under a nitrogen atmosphere. After rising to 500°C, heat-preserve and roast for 3 hours, and then lower to room temperature to obtain nano-copper oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com