A kind of niobium pentoxide nanorod material with regular hollow square box shape and its preparation method and application

A niobium pentoxide and nanorod technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as slow diffusion of sodium ions, and achieve improved electrochemical performance, material The effect of stabilizing and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

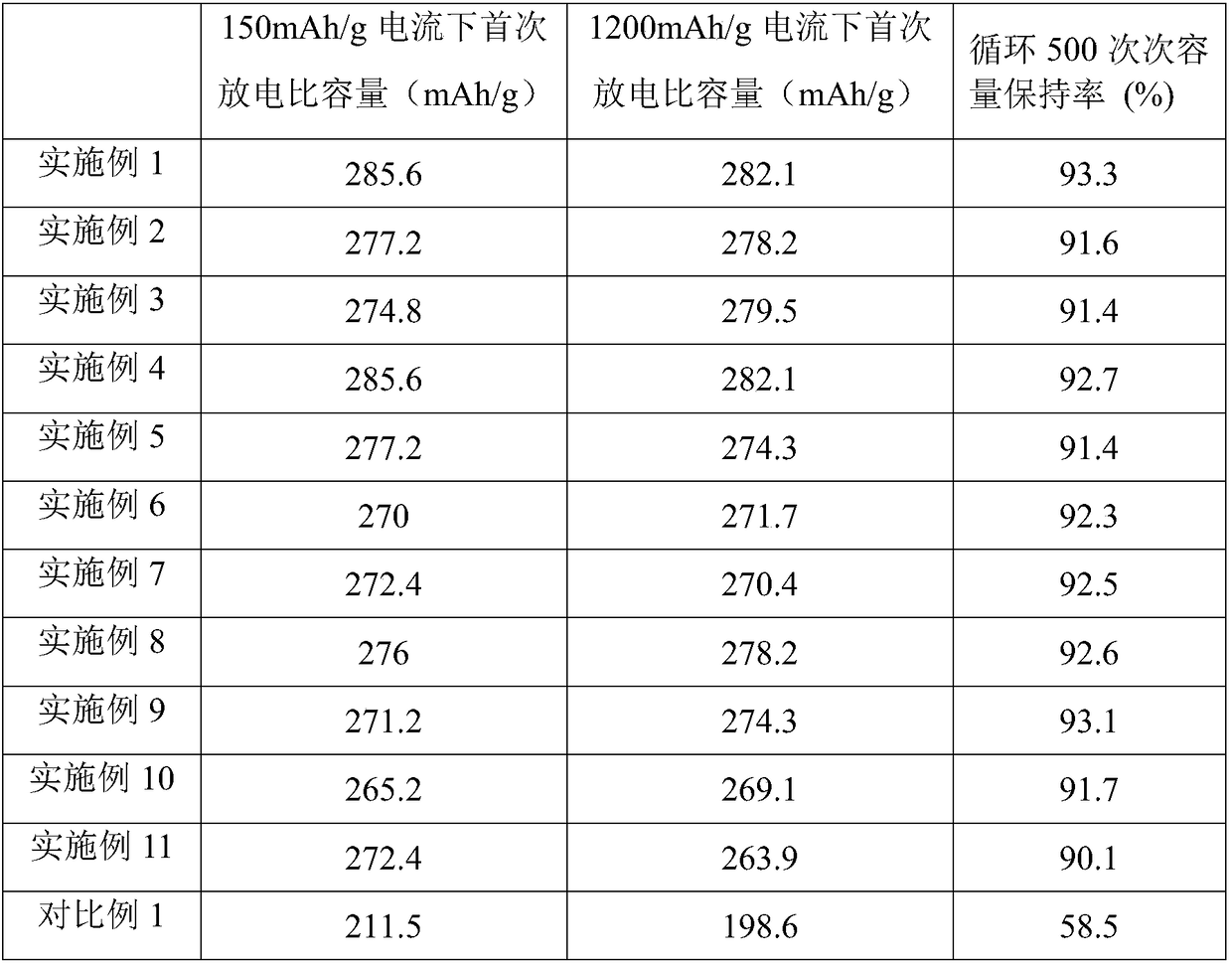

Embodiment 1

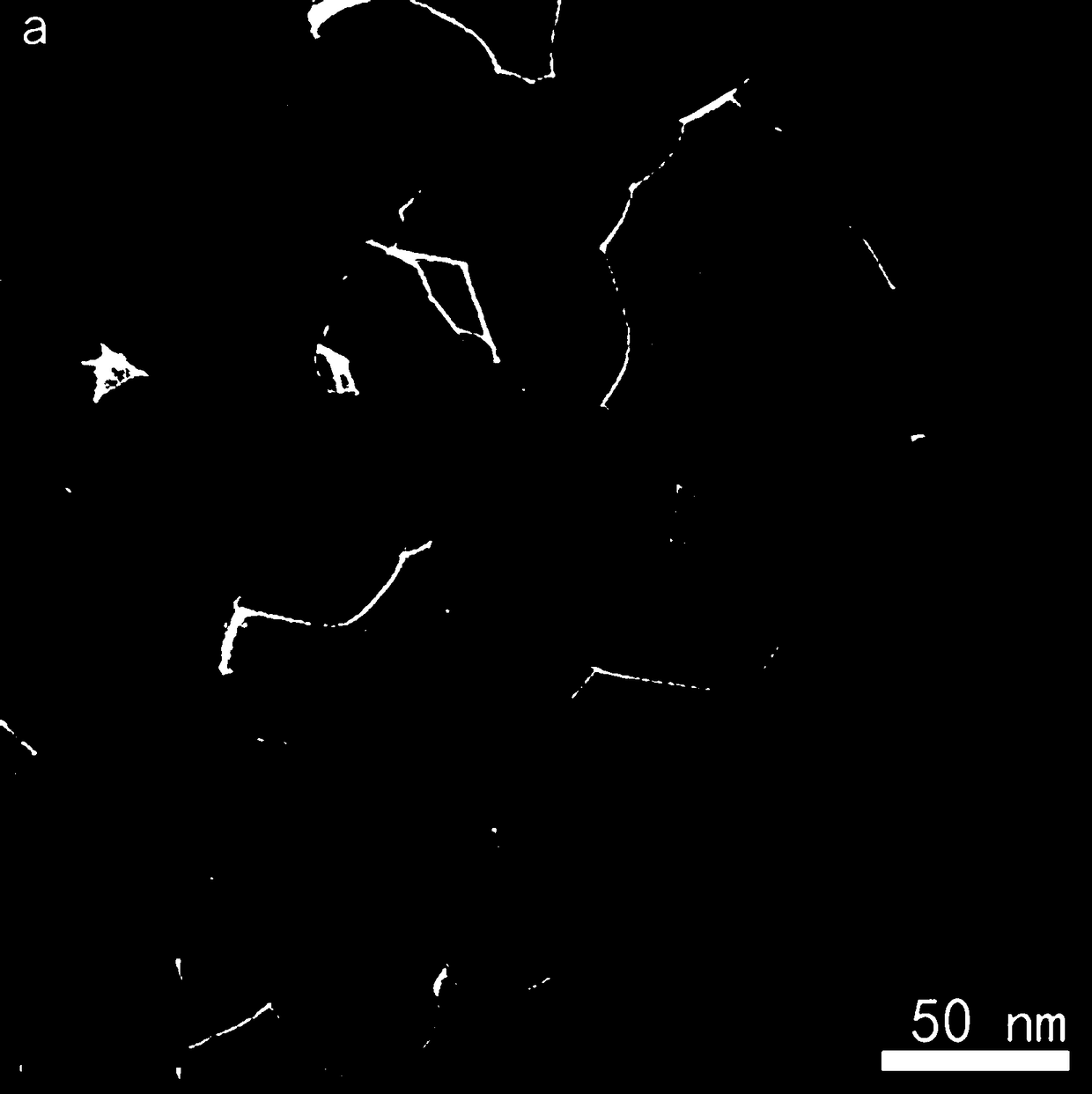

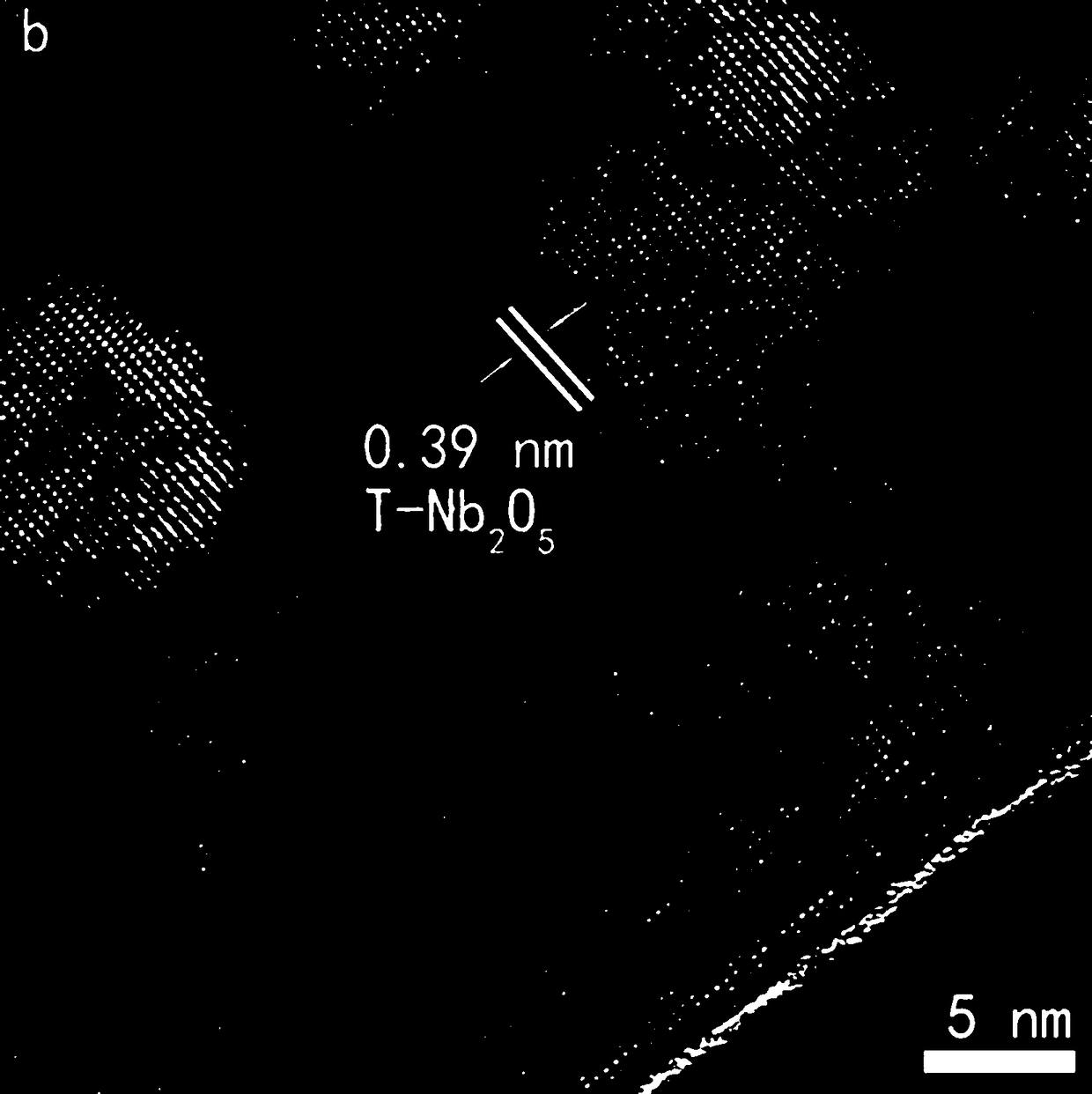

[0031] The preparation method of niobium pentoxide nanorod material with regular hollow square box shape comprises the following steps: taking niobium oxalate as niobium source, under normal temperature, niobium oxalate is dissolved in 20ml deionized water to form solution A1; select mass ratio as 10:1 P123 and cetyltrimethylammonium bromide were dissolved in 40ml deionized water respectively to form solution B1; after the first stirring for 4 hours respectively; the stirred solution A1 and solution B1 were mixed to obtain niobium Mixed solution C1 with an ion concentration of 1.8mmol / L; continue to stir for 20 minutes, then transfer the mixed solution C1 to a reaction kettle, and conduct a hydrothermal reaction at a temperature of 160°C. After 20 hours of reaction, naturally cool to room temperature; The solution was moved to a centrifugal device for centrifugation, and the centrifuged solid matter was washed three times with deionized water and absolute ethanol, then put into...

Embodiment 2

[0034] The preparation method of niobium pentoxide nanorod material with regular hollow square box shape comprises the following steps: taking niobium chloride as niobium source, under normal temperature, niobium chloride is dissolved in 20ml deionized water to form solution A2; A mixture of P123 with cetyltrimethylammonium bromide and dodecyltrimethylammonium chloride in a ratio of 12:1, wherein cetyltrimethylammonium bromide and dodecyltrimethylammonium The mass ratio of methylammonium chloride is 1:1; respectively dissolved in 40ml deionized water to form solution B2; after the first stirring for 1 hour, the stirred solution A2 and solution B2 are mixed to obtain a niobium ion concentration of 1.01 mmol / L mixed solution C2; continue to stir for 60 minutes, then transfer the mixed solution C2 to the reaction kettle, carry out hydrothermal reaction at 120 ° C, react for 36 hours, and naturally cool to room temperature; move the reacted solution to the centrifuge Carry out cen...

Embodiment 3

[0036]The preparation method of niobium pentoxide nanorod material with regular hollow square box-like, comprises the following steps: take niobium acetate as niobium source, under normal temperature, niobium acetate is dissolved in 20ml deionized water, forms solution A3; Select mass ratio as A mixture of 20:1 P123 and cetyltrimethylammonium bromide, dodecyltrimethylammonium chloride and cetyltrimethylammonium chloride was dissolved in deionized water to obtain solution B3; Wherein, the mass ratio of cetyltrimethylammonium bromide, dodecyltrimethylammonium chloride and cetyltrimethylammonium chloride in solution B3 is 1:1:1; After stirring once for 24 hours, mix the stirred solution A3 and solution B3 to obtain a mixed solution C3 with a niobium ion concentration of 3.4mmol / L, continue to stir for 10min, then transfer the mixed solution C3 to the reaction kettle, and heat it at 200°C , carry out hydrothermal reaction, react for 12 hours, and naturally cool to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com