A kind of preparation method and application of pitch-based nano carbon sheet

A nano-carbon and pitch-based technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of lack of sodium storage space and active sites, poor rate performance, and poor electrical conductivity of pitch-based carbon and other problems, to achieve the effect of simple synthesis process, improved rate performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

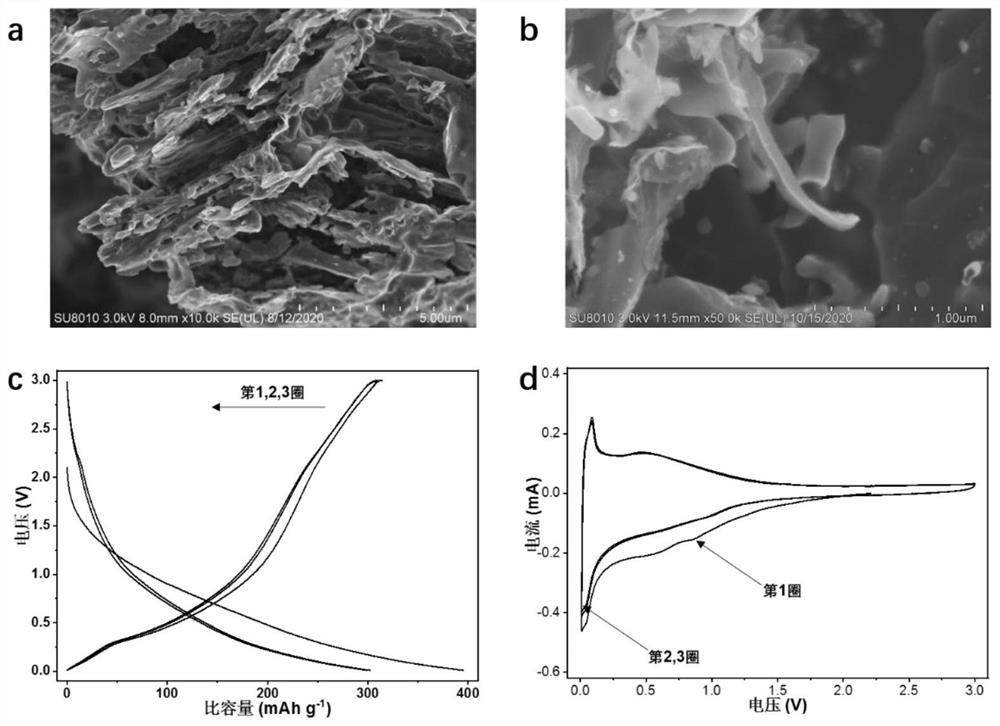

[0033] (1) Preparation of 80nm pitch carbon nanosheets: Dissolve 2g pitch in 20mL dichloromethane, disperse and mix with 1.6g sodium hypophosphite uniformly, dry and remove dichloromethane to obtain a mixture of pitch and sodium hypophosphite; Under an argon atmosphere, the mixture of pitch and sodium hypophosphite was heated in a tube furnace, and the heating program was 3 °C / min to 350 °C and held for 2 h; then heated to 800 °C at 5 °C / min and held for 4 h After being lowered to room temperature, the pitch carbon was mixed with a 1 mol / L hydrochloric acid solution at 60 °C for 2 h, followed by centrifugation, washing and drying to obtain the pitch nano-carbon sheet sodium ion battery negative electrode material (pitch-based nano-carbon sheet).

[0034] (2) Sodium ion assembly and performance test: Weigh 0.8g of pitch carbon prepared above, 0.1g of super carbon black, and 0.1g of polyvinylidene fluoride, disperse in N-methylpyrrolidone and homogenize, and apply the slurry even...

Embodiment 2

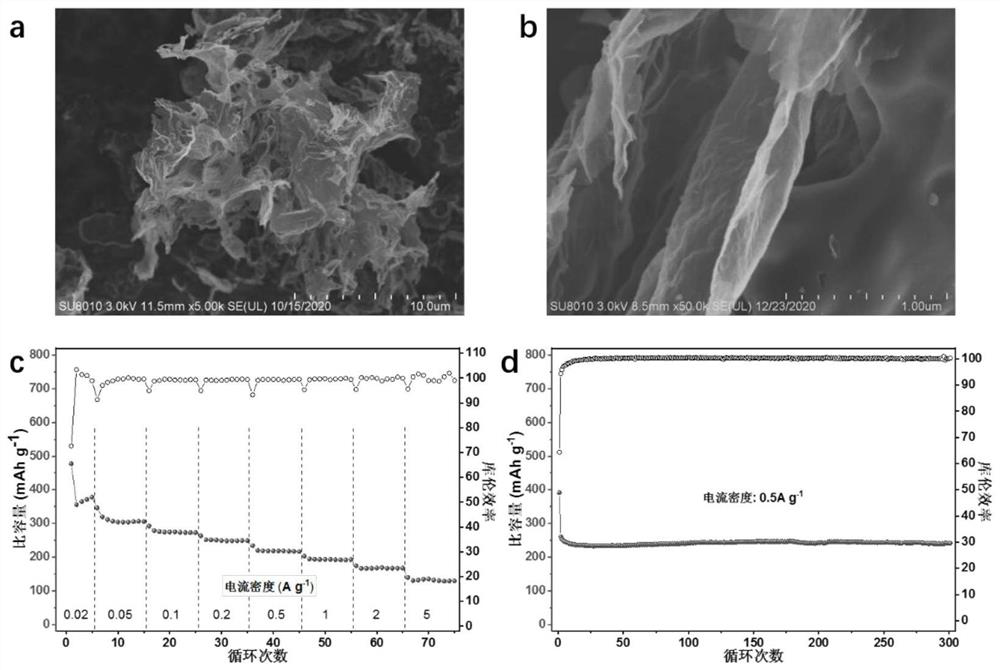

[0036] (1) Preparation of 10 nm pitch carbon nanosheets: Dissolve 2 g pitch in 40 mL of dichloromethane, mix with 10 g of sodium hypophosphite, dry and remove the dichloromethane to obtain a mixture of pitch and sodium hypophosphite; Under the atmosphere, put the mixture of pitch and sodium hypophosphite into a tube furnace for heating, and the heating program is 3 °C / min to 350 °C, and stay for 4 h; After dropping to room temperature, the pitch carbon was mixed with 1 mol / L hydrochloric acid solution at 60 °C and stirred for 4 h, followed by centrifugation, washing, and drying to obtain the pitch nano-carbon sheet sodium ion battery anode material (pitch-based nano-carbon sheet).

[0037](2) Sodium ion assembly and performance test: Weigh 0.8 g of pitch carbon prepared above, 0.1 g of super carbon black, and 0.1 g of polyvinylidene fluoride, disperse in N-methylpyrrolidone and homogenize, and apply the slurry evenly to the On the copper foil, vacuum-drying at 80 °C for 12 h, ...

Embodiment 3

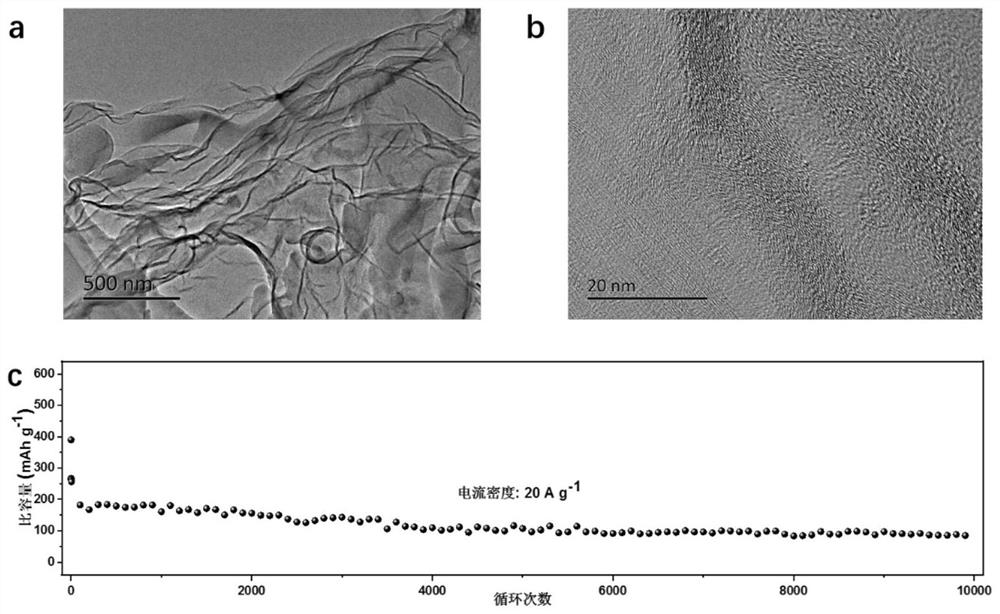

[0039] (1) Preparation of high-current-adapted pitch carbon nanosheets: Dissolve 2 g pitch in 80 mL of carbon tetrachloride, mix with 12 g of disodium hydrogen phosphate, and dry to remove dichloromethane to obtain a mixture of pitch and disodium hydrogen phosphate. Mixture; under argon atmosphere, put the mixture of pitch and disodium hydrogen phosphate in a tube furnace for heating, the heating program is 3°C / min to 350°C and stay for 4h; then the temperature is raised to 900°C at 5°C / min , and stayed for 8 h; after being lowered to room temperature, the pitch carbon was mixed with a 1 mol / L hydrochloric acid solution at 60 °C and stirred for 4 h, followed by centrifugation, washing and drying to obtain pitch nano carbon sheets as a negative electrode material for sodium ion batteries (pitch-based nano carbon). piece).

[0040] (2) Sodium ion assembly and performance test: Weigh 0.8g of the above-prepared pitch nano-carbon sheets, 0.1g of super carbon black, and 0.1g of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com