Preparation method of nano-copper oxide catalyst for degrading organic dye wastewater

A technology of nano-copper oxide and organic dyes, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

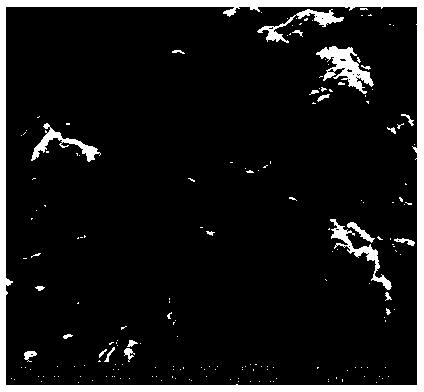

[0036] Weigh 1.20g (1.0mol / L) of sodium hydroxide and 1.7048g (1.0mol / L) of copper chloride dihydrate, dissolve them in 30mL of 30wt% hydrogen peroxide and 10mL of deionized water respectively, and add the copper ion solution under magnetic stirring into the sodium hydroxide / hydrogen peroxide mixed solution, and continue to stir for 30 minutes to obtain a black precipitate. After washing the precipitate with deionized water for 2-3 times, the precipitate was dispersed in 80 mL of deionized water to obtain a suspension, and then the suspension Add it into a 100mL autoclave with a polytetrafluoroethylene liner, seal the autoclave, put it in an oven, react at 60°C for 4h, then cool it, wash it with deionized water and ethanol for 2-3 times, and then put it in an oven at 60°C Dry at ℃ to obtain a chrysanthemum-shaped nano-copper oxide catalyst with an average particle diameter of about 600nm.

[0037] The morphology of the samples was characterized by a Nova Nano SEM 230 scanning ...

Embodiment 2

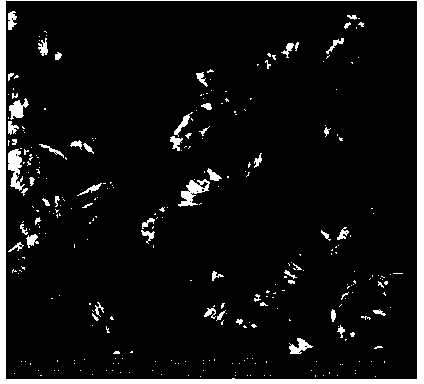

[0039] Weigh 1.20g (1.0mol / L) of sodium hydroxide and 1.7048g (1.0mol / L) of copper chloride dihydrate, dissolve them in 40mL of 25wt% hydrogen peroxide and 10mL of deionized water respectively, and dissolve the copper ion solution under magnetic stirring Add it into the sodium hydroxide / hydrogen peroxide mixed solution and continue to stir for 30 minutes to obtain a black precipitate. After washing the precipitate with deionized water for 2-3 times, disperse the precipitate in 80mL of deionized water to obtain a suspension, and then suspend Add the solution into a 100mL autoclave with a polytetrafluoroethylene liner, seal the autoclave, put it in an oven, react at 100°C for 10h, then cool it, wash it with deionized water and ethanol for 2-3 times, and then put it in an oven Dry at 60°C to obtain a chrysanthemum-shaped nano-copper oxide catalyst with an average particle diameter of about 600nm.

[0040] The morphology of the samples was characterized by a Nova Nano SEM 230 scan...

Embodiment 3

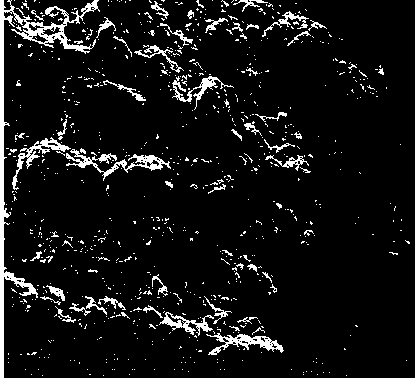

[0044] Catalytic Performance Evaluation of Nano Copper Oxide Catalyst Prepared by the Method of the Invention and Common Commercial Nano Copper Oxide

[0045] The nano-copper oxide catalyst prepared by the method of the present invention degrades rhodamine B under the condition of hydrogen peroxide as an oxidizing agent, the dosage of the catalyst is 10 mg, and the concentration of rhodamine B is 1.0×10 -5 mol / L, the volume is 100mL, the concentration of hydrogen peroxide is 30wt%, the volume is 2mL, and the temperature of the water bath is 50°C. The absorbance of the degradation process was measured with a 721 UV-Vis spectrophotometer. A sample was taken every 5 minutes, and after centrifugation, the supernatant was taken for measurement. Figure 7 The degradation curve of the nano-copper oxide catalyzed oxidation of rhodamine B prepared by the method of the present invention. Depend on Figure 7 It can be seen that under the action of a catalyst, the degradation rate of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com