Copper oxide and titanium oxide heterojunction composite catalyst as well as preparation method and application thereof

A composite catalyst and titanium dioxide technology, which is applied in the field of composite materials and photocatalysis technology, and can solve problems such as limiting reaction activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation of embodiment 1 cupric oxide and titania heterojunction composite catalyst:

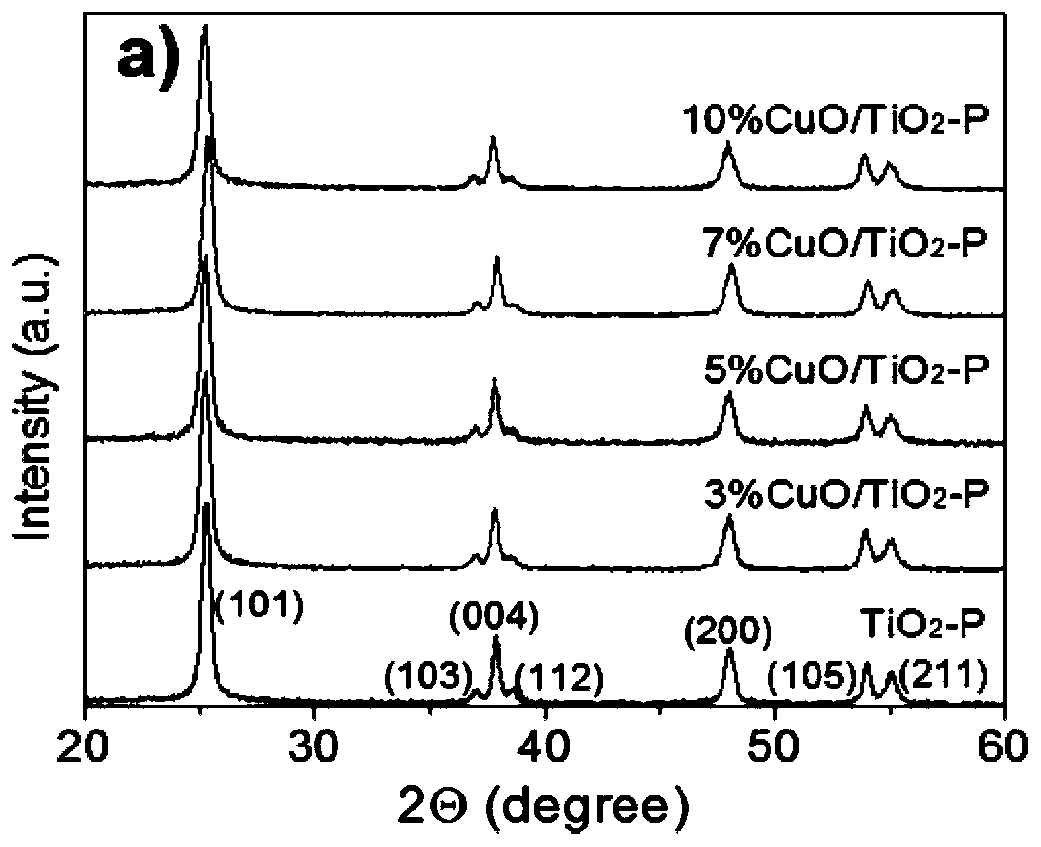

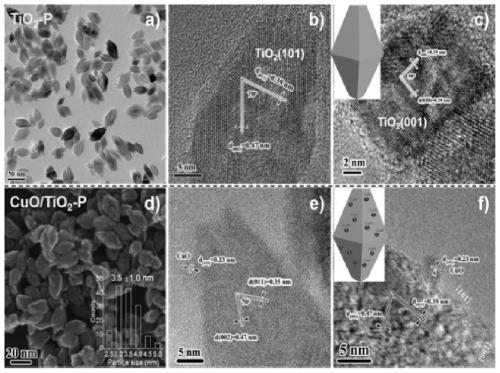

[0020] At room temperature, 5 mL of butyl titanate was added to 20 mL of acetic acid, stirred vigorously for 10 min, the mixed solution became colorless and transparent, and then the mixed solution was transferred to a hydrothermal reactor lined with polytetrafluoroethylene and placed in an oven In the process, the temperature was raised to 200°C at a heating rate of 5°C / min, kept at a constant temperature of 200°C, reacted for 24 hours, and then cooled naturally to room temperature. The obtained product was centrifugally filtered, and the precipitate was washed three times with deionized water and once with absolute ethanol, and then dried at 80°C for 12 hours to obtain anatase TiO 2 spindle, labeled TiO 2 -P; 37.71mL, 62.86mL, 88.00mL, 125.71mL of 0.01mol·L - 1 Cu(NO 3 ) 2 The solution was added to a 500 mL round bottom beaker, followed by 100 mL of deionized water, and ...

Embodiment 2

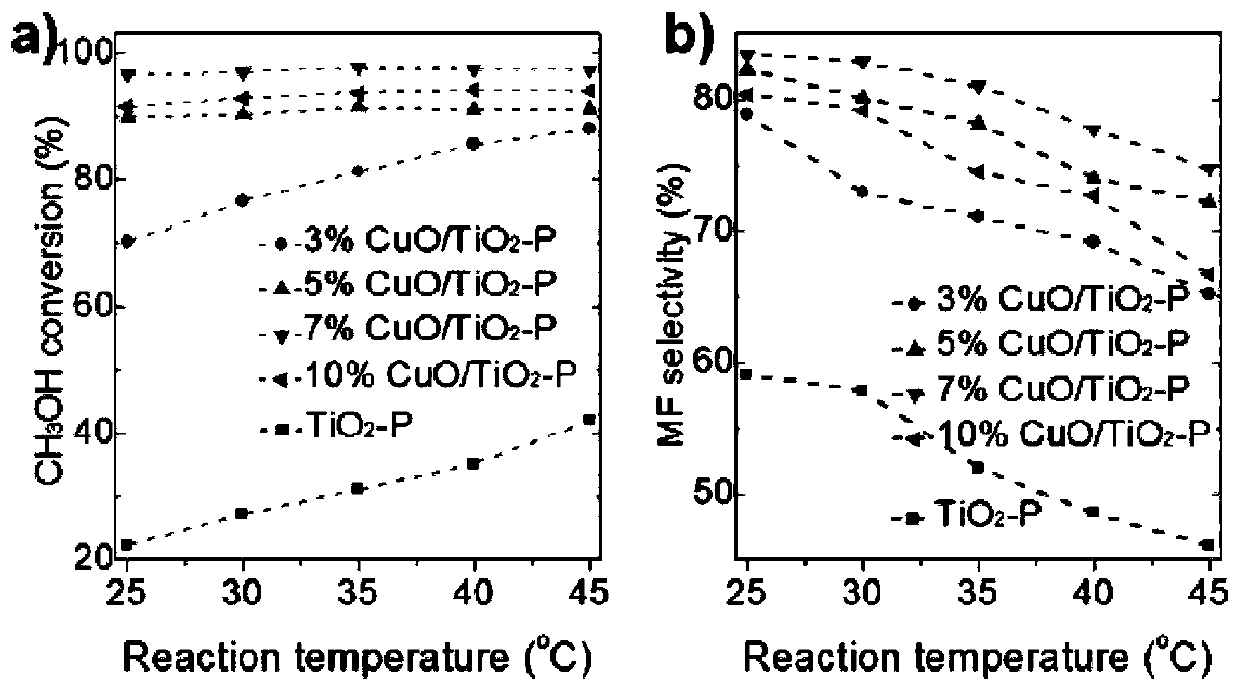

[0024] Embodiment 2 Copper oxide and titanium dioxide composite catalyst photocatalytic methanol prepare methyl formate reaction:

[0025]Photocatalytic oxidation of methanol to formic acid was carried out in a continuous flow aluminum alloy reactor. Apply the catalyst evenly on three rectangular glass slides of appropriate size, then place the slides in the reaction tank, and then place a piece of quartz glass on the reaction tank to seal the reaction tank. Install a 500W high-pressure mercury lamp above the quartz glass, so that the glass slide coated with the catalyst side is completely exposed to the mercury lamp. The entire reaction uses cooling water circulation to control the reaction temperature at 25-45°C. The mixture of methanol / oxygen / nitrogen was introduced from above the catalyst for reaction. The mixed gas is made of nitrogen bubbling through the low-temperature methanol bubbler and mixed with the other two measured nitrogen and oxygen. The volume percentage of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com