Method for preparing nanometer copper oxide

A technology of nano-copper oxide and copper powder, which is applied in the direction of copper oxide/copper hydroxide, nanotechnology, etc., can solve problems such as difficult control, and achieve the effect of simple operation, high equipment requirements, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

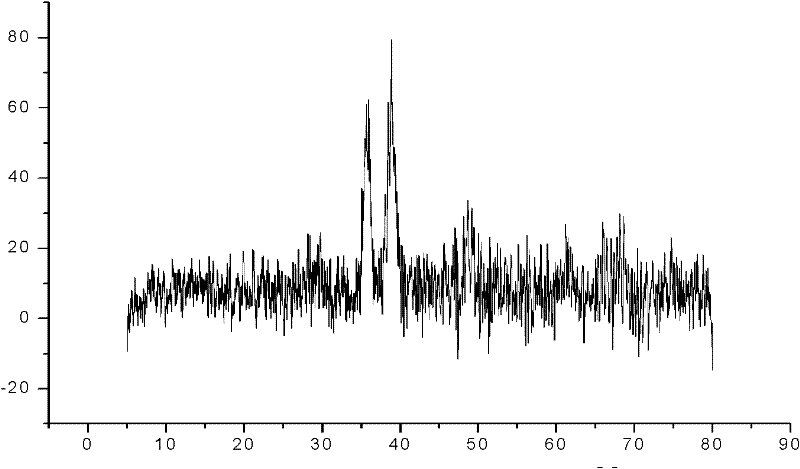

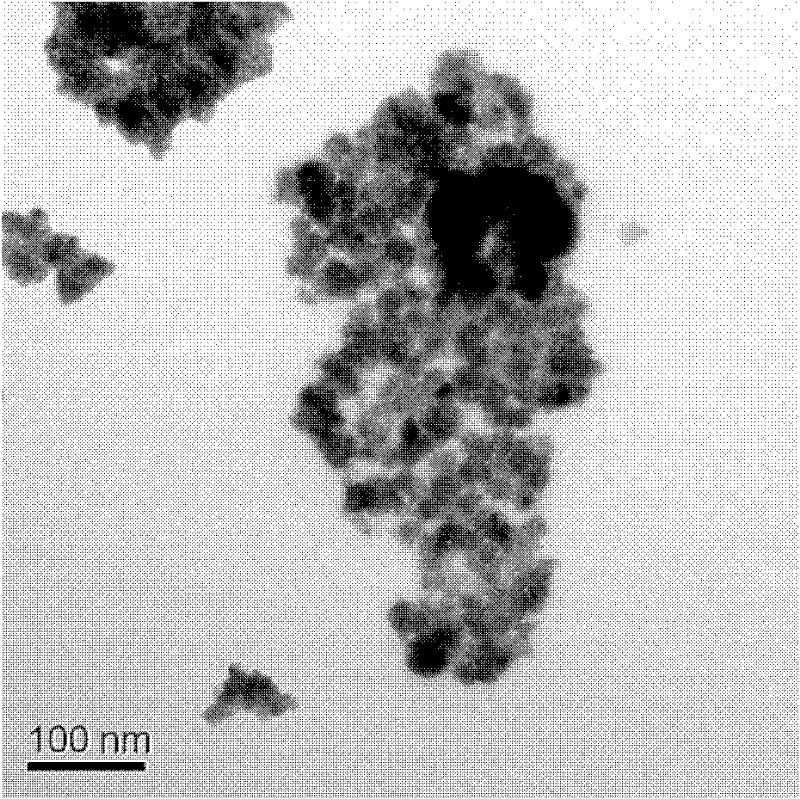

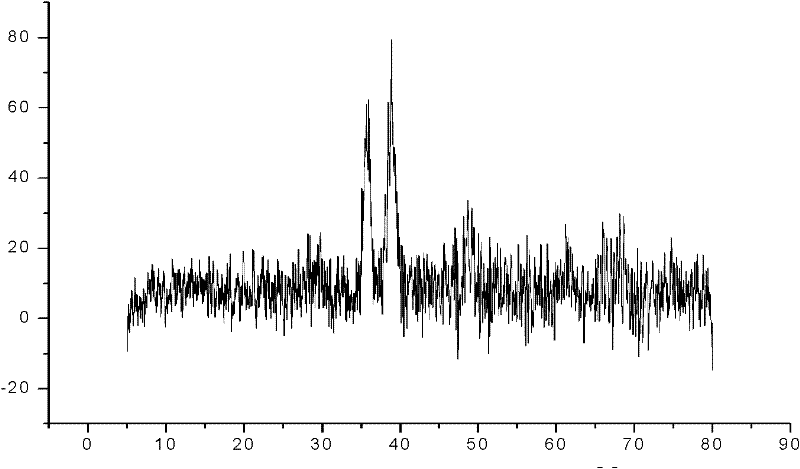

Image

Examples

Embodiment 1

[0014] Embodiment one: a kind of preparation method of nano-copper oxide material, the steps are as follows:

[0015] 1) Soak the copper powder in hydrochloric acid with a mass concentration of 25% for 3 minutes, then take out the copper powder, put it in acetone and clean it ultrasonically to obtain purified copper powder;

[0016] 2) Add iodine elemental substance into acetonitrile, heat and dissolve to obtain iodine in acetonitrile solution; the solubility of iodine in acetonitrile solution is 3g / L;

[0017] 3) Add the purified copper powder into the acetonitrile solution of iodine, heat and stir, and the heating temperature is 50°C;

[0018] 4) A black substance was obtained in the solution, precipitated and filtered, and it was nano-copper oxide powder.

Embodiment 2

[0019] Embodiment two: a kind of preparation method of nano-copper oxide material, the steps are as follows:

[0020] 1) Soak the copper powder in hydrochloric acid with a mass concentration of 28% for 3.5 minutes, then take out the copper powder, put it in acetone and clean it ultrasonically to obtain purified copper powder;

[0021] 2) Add iodine elemental substance into acetonitrile, heat and dissolve to obtain iodine in acetonitrile solution; the solubility of iodine in acetonitrile solution is 5g / L;

[0022] 3) Add the purified copper powder into the acetonitrile solution of iodine, heat and stir, and the heating temperature is 55°C;

[0023] 4) A black substance was obtained in the solution, precipitated and filtered, and it was nano-copper oxide powder.

Embodiment 3

[0024] Embodiment three: a kind of preparation method of nano-copper oxide material, the steps are as follows:

[0025] 1) Soak the copper powder in hydrochloric acid with a mass concentration of 30% for 4 minutes, then take out the copper powder, put it in acetone and clean it ultrasonically to obtain purified copper powder;

[0026] 2) Add iodine elemental substance into acetonitrile, heat and dissolve to obtain iodine in acetonitrile solution; the solubility of iodine in acetonitrile solution is 8g / L;

[0027] 3) Add the purified copper powder into the acetonitrile solution of iodine, heat and stir, and the heating temperature is 60°C;

[0028] 4) A black substance was obtained in the solution, precipitated and filtered, and it was nano-copper oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com