Addition type organic silicon rubber and preparation method thereof

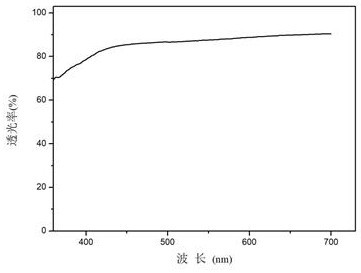

A technology of silicone rubber and addition type, which is applied in the field of silicone rubber and addition type silicone rubber, can solve the problems of high temperature reaction, influence of light transmission, increase of viscosity, etc., so as to reduce the preparation process and improve the mechanical properties , the effect of increasing the crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation of UV curing addition type silicone rubber, adopts following raw material:

[0026] 75 parts of vinyl-terminated silicone oil with a viscosity of 5000cst, 6 parts of 20cst hydrogen-containing silicone oil, 20 parts of 5000cst vinyl MQ silicone resin (vinyl content is 1.5%), mixed and stirred evenly, and then added 0.02 parts of trimethyl (methylcyclo Pentadienyl) platinum (IV), 0.01 part of diethyl fumarate are fully stirred and mixed evenly, then use vacuum to remove air bubbles, and then irradiate with ultraviolet light with a wavelength of 365nm for 5min to obtain the compound disclosed in Example 1. Silicone rubber.

Embodiment 2

[0028] A kind of preparation of UV curing addition type silicone rubber, adopts following raw material:

[0029] 60 parts of vinyl-terminated silicone oil with a viscosity of 5000cst, 8 parts of 20cst hydrogen-containing silicone oil, 30 parts of 5000cst vinyl MQ silicone resin (vinyl content is 1.5%), mixed and stirred evenly, and then added 0.02 parts of trimethyl (methylcyclo Pentadienyl) platinum (IV), 0.01 part of diethyl fumarate are fully stirred and mixed evenly, then use vacuum to remove air bubbles, and then irradiate with ultraviolet light with a wavelength of 365nm for 5min to obtain the compound disclosed in Example 2. Silicone rubber.

Embodiment 3

[0031] A kind of preparation of UV curing addition type silicone rubber, adopts following raw material:

[0032] 55 parts of vinyl-terminated silicone oil with a viscosity of 5000cst, 10 parts of 20cst hydrogen-containing silicone oil, 40 parts of 5000cst vinyl MQ silicone resin (vinyl content is 1.5%), mixed and stirred evenly, and then added 0.02 parts of trimethyl (methylcyclo Pentadienyl) platinum (IV), 0.01 part of diethyl fumarate are fully stirred and mixed evenly, then use vacuum to remove air bubbles, and then irradiate with ultraviolet light with a wavelength of 365nm for 5min to obtain the compound disclosed in Example 3. Silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com