Micro-nano copper oxide and preparation method thereof

A copper oxide, micro-nano technology, applied in the direction of copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of low sensitivity, difficulty in the synthesis of copper oxide gas-sensitive materials, and low specific surface area of materials, so as to increase sensitivity and response speed, beneficial to electron transfer, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The second aspect of the present invention provides a method for preparing micro-nano copper oxide, the steps comprising:

[0027] (1) dissolving the soluble copper salt in an organic solvent, sealing and stirring until the soluble copper salt is completely dissolved;

[0028] (2) dodecyltrimethylammonium bromide is dissolved in the solution obtained in step (1), so that the mass volume ratio of dodecyltrimethylammonium bromide and organic solvent is 0.002-0.04g / mL, Seal and stir for 1-4 hours;

[0029] (3) heat the solution obtained in step (2) at 120-200° C. for 2-12 hours, and cool;

[0030] (4) The reaction product is filtered, centrifuged, cleaned and dried;

[0031] (5) Calcining the dried product of step (4) at a high temperature of 400-600° C. for 1-5 hours to obtain micronano copper oxide.

[0032] Preferably, the soluble copper salt is copper nitrate, and the organic solvent is absolute ethanol.

[0033] More preferably, the copper nitrate in step (1) is d...

Embodiment 1

[0037] Prepare micro-nano copper oxide, the specific steps are as follows:

[0038] 1) Dissolve 20 grams of copper nitrate in 50-100 ml of absolute ethanol, seal and stir continuously for 3 hours until the copper nitrate is completely dissolved;

[0039] 2) Dissolve 0.5 gram of dodecyltrimethylammonium bromide in the solution of step (1), seal and stir continuously for 2 hours;

[0040] 3) Transfer the solution obtained in step (2) to an autoclave, heat it at 180°C for 2 hours, and cool it down to room temperature naturally;

[0041] 4) The reaction product was filtered, centrifuged, washed three times with absolute ethanol, and dried at 70°C for 12 hours;

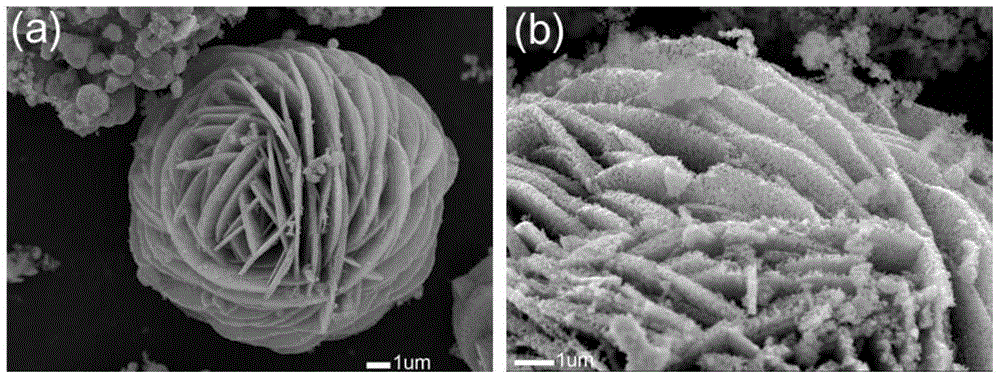

[0042] 5) Calcining the powder obtained in step (4) at a high temperature of 500° C. for 1.5 h to obtain micro-nano copper oxide with a three-dimensional hierarchical rose shape.

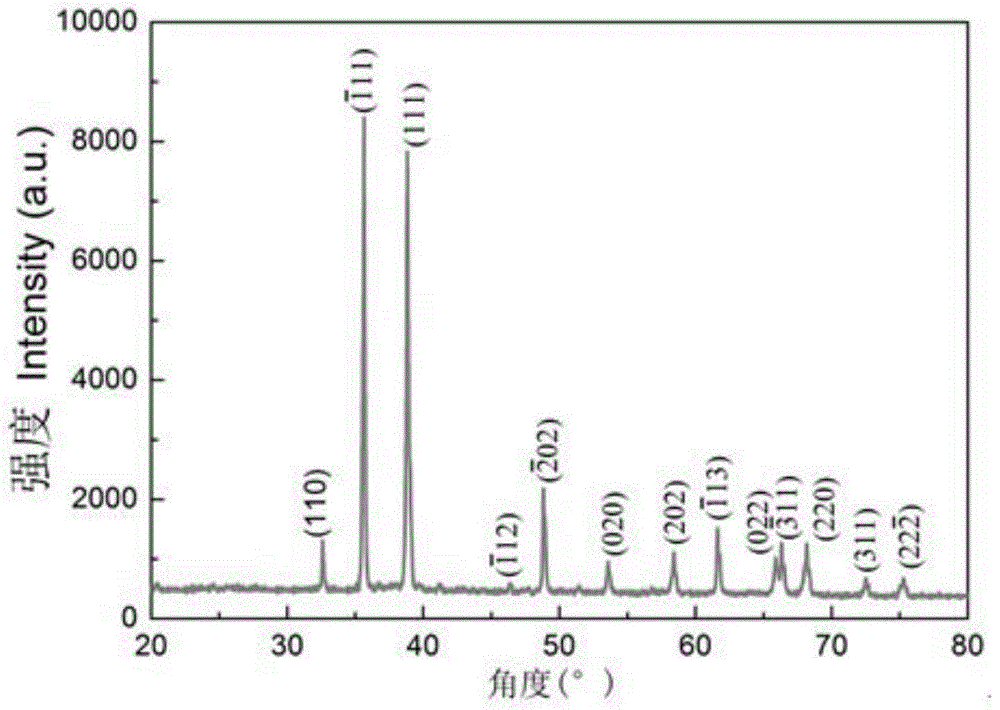

[0043] The micro-nano copper oxide prepared by the above method has good dispersion and regular shape, and it is subjected to XRD test to det...

Embodiment 2

[0046] Prepare micro-nano copper oxide, the specific steps are as follows:

[0047] (1) Dissolve 10 grams of copper nitrate in 50-100 milliliters of absolute ethanol, seal and stir continuously for 3 hours until the copper nitrate is completely dissolved;

[0048] (2) 0.5 gram of dodecyltrimethylammonium bromide is dissolved in the solution of step (1), sealed and continuously stirred for 2 hours;

[0049] (3) Transfer the solution obtained in step (2) to an autoclave, heat it at 180° C. for 2 hours, and cool to room temperature naturally;

[0050] (4) The reaction product was filtered, centrifuged, washed with absolute ethanol three times, and dried at 70° C. for 12 hours;

[0051] (5) Calcining the powder obtained in step (4) at a high temperature of 500° C. for 1.5 h to obtain micronano copper oxide.

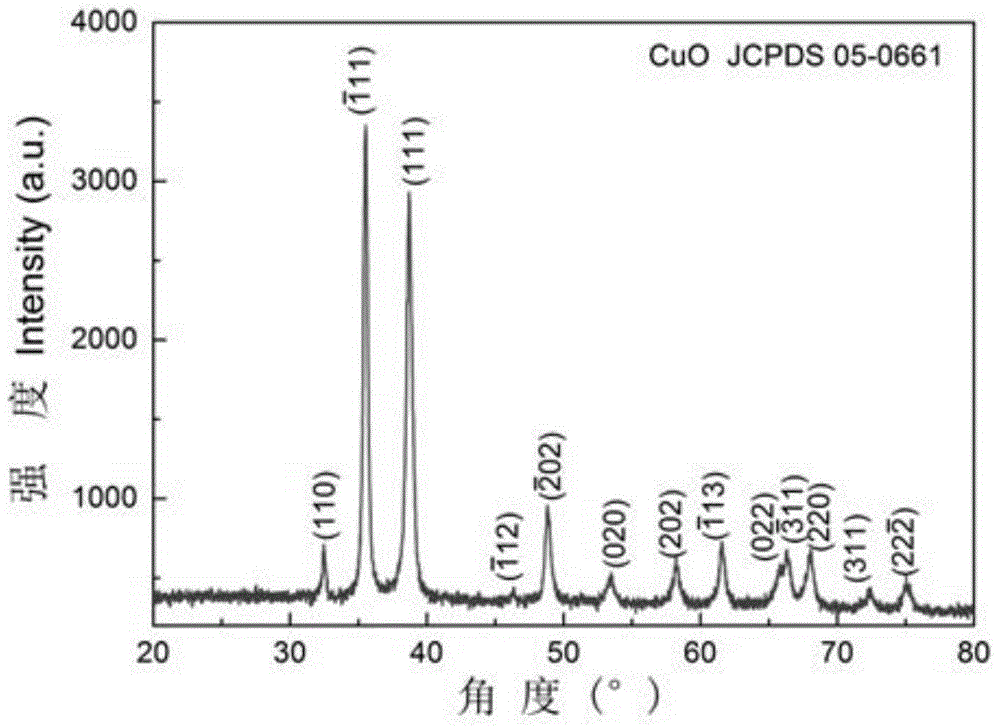

[0052] The micro-nano copper oxide prepared by the above method has good dispersion and regular shape, and it is subjected to XRD test to determine the crystal form of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com