Desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time

A technology of desulfurization agent and hydrogen sulfide, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of easy loss of active components and low mechanical strength, and achieve better impregnation effect, uniform distribution, and economical Cost and Energy Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

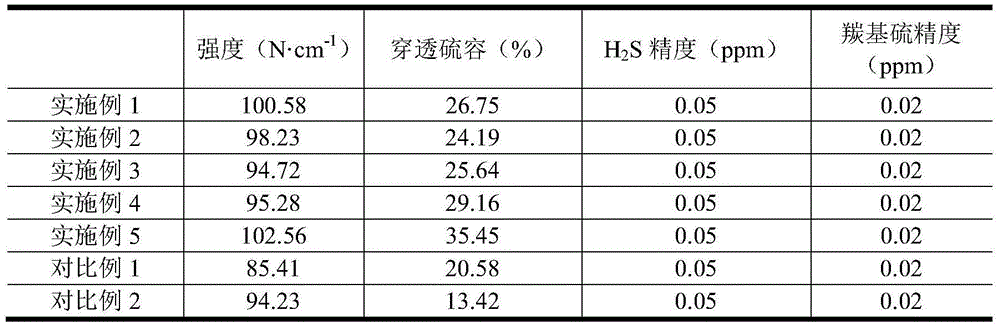

Examples

Embodiment 1

[0025] This embodiment provides a desulfurizer for simultaneously removing hydrogen sulfide and carbonyl sulfide, which is prepared by the following steps:

[0026] S1, mixing 80 parts by weight of nano-zinc oxide, 15 parts by weight of attapulgite and 5 parts by weight of manganese carbonate uniformly and then kneading and forming;

[0027] S2, drying the mixture formed by kneading in step S1 at 120° C. for 2 hours to obtain a dry desulfurization carrier precursor;

[0028] S3. Calcining the desulfurization support precursor obtained in step S2 at 380° C. for 2 hours to obtain a desulfurization agent support;

[0029] S4. Dissolve 1 part by weight of basic copper carbonate in 10 parts by weight of ammonia water with a mass concentration of 15%, mix uniformly, and prepare the first copper salt solution; impregnate the desulfurizer carrier obtained in step S3 in the In the first copper salt solution for 2 hours, the volume ratio of the desulfurizing agent carrier to the first ...

Embodiment 2

[0032] This embodiment provides a desulfurizer for simultaneously removing hydrogen sulfide and carbonyl sulfide, which is prepared by the following steps:

[0033] S1. After mixing 85 parts by weight of basic zinc carbonate, 10 parts by weight of carboxymethyl cellulose and 5 parts by weight of manganese oxide, kneading and molding;

[0034] S2, drying the mixture formed by kneading in step S1 at 140° C. for 3 hours to obtain a dry desulfurization carrier precursor;

[0035] S3. Calcining the desulfurization support precursor obtained in step S2 at 450° C. for 3 hours to obtain a desulfurization agent support;

[0036] S4. Dissolve 1 part by weight of basic copper carbonate in 20 parts by weight of ammonia water with a mass concentration of 25%, mix uniformly, and prepare the first copper salt solution; impregnate the desulfurizer carrier obtained in step S3 in the In the first copper salt solution for 3 hours, the volume ratio of the desulfurizing agent carrier to the first...

Embodiment 3

[0039] This embodiment provides a desulfurizer for simultaneously removing hydrogen sulfide and carbonyl sulfide, which is prepared by the following steps:

[0040] S1, 95 parts by weight of zinc hydroxide, 3 parts by weight of silica sol and 2 parts by weight of cerium oxide are mixed uniformly and then kneaded and formed;

[0041] S2, drying the mixture formed by kneading in step S1 at 140° C. for 2 hours to obtain a dry desulfurization carrier precursor;

[0042] S3. Calcining the desulfurization support precursor obtained in step S2 at 450° C. for 2 hours to obtain a desulfurization agent support;

[0043] S4. Dissolve 1 part by weight of basic copper carbonate in 10 parts by weight of ammonia water with a mass concentration of 25%, mix uniformly, and prepare the first copper salt solution; impregnate the desulfurizer carrier obtained in step S3 in the In the first copper salt solution for 2 hours, the volume ratio of the desulfurizing agent carrier to the first copper sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com