Treatment method for reducing nitrosodimethylamine in water by catalyzing zero-valent iron through copper corrosion product

A nitrosodimethylamine, copper corrosion technology, applied in the direction of reducing water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of low removal rate, unsatisfactory standard, long reaction time And other problems, to achieve obvious catalytic effect, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

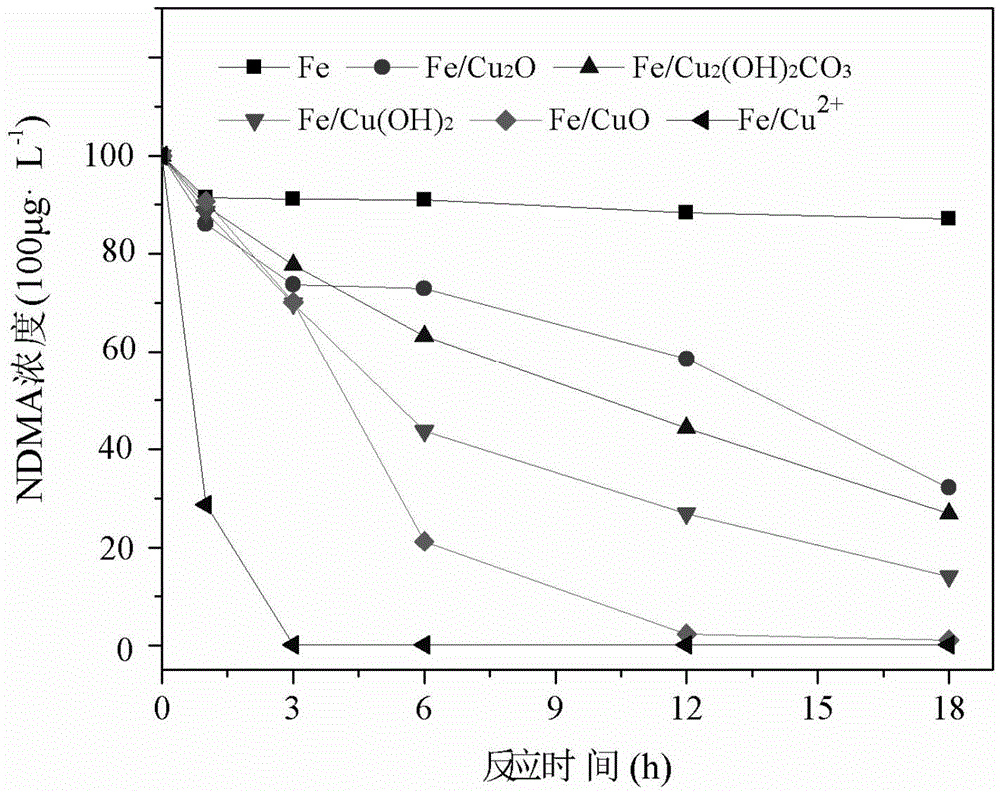

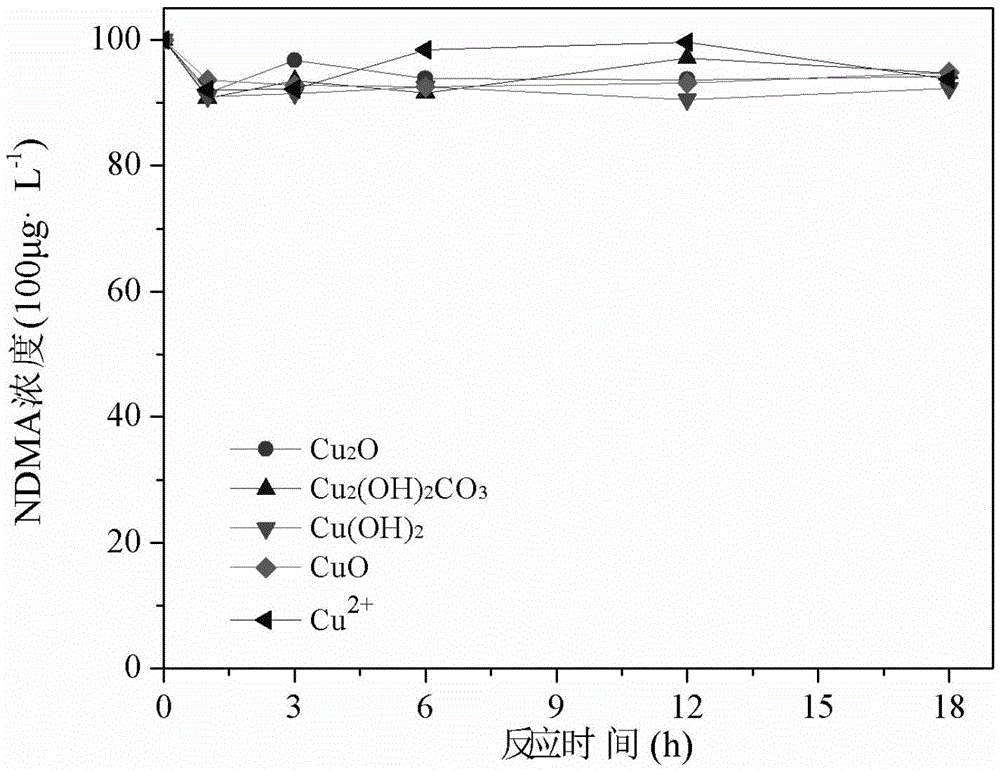

Embodiment 1

[0016] Add 40mL HEPES buffer solution (25mmol·L -1 , pH value is 7.0), add 10g·L -1 iron powder, then add 12.7mg, 28.6mg, 19.5mg, 44.2mg of copper oxide, cuprous oxide, copper hydroxide, basic copper carbonate (wherein the corrosion product content of copper is 5mmol L -1 ); for copper ions (Cu 2+ ), first add Cu to the buffer solution 2+ The mother liquor makes the Cu in solution 2+ up to 5mmol·L -1 , then add 10g·L -1 Iron powder; after the above steps, add NDMA mother liquor to make the initial concentration reach 100μg·L -1 , close the bottle cap tightly, and place it on the QB-328 rotary incubator (Qilinbeier Instrument Manufacturing Co., Ltd., Haimen City) at 45r min -1 Rotate at a high speed; take samples at regular intervals, and use a vacuum pump to filter the samples through a 0.22 μm filter membrane to separate unreacted iron powder and copper corrosion products to terminate the reaction. The obtained water samples are used for analysis and testing of NDMA con...

Embodiment 2

[0021] To contain nitrosodimethylamine (concentration 100μg·L -1 ) in water with 5mmol / L of copper ions (the anion is Cl - ) and 10g / L iron powder, adjust the pH value to 7.0, rotate and stir at a speed of 50r / min for 3h, and the removal rate of NDMA is above 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com