Preparation method for durable antibacterial cellulose fibres

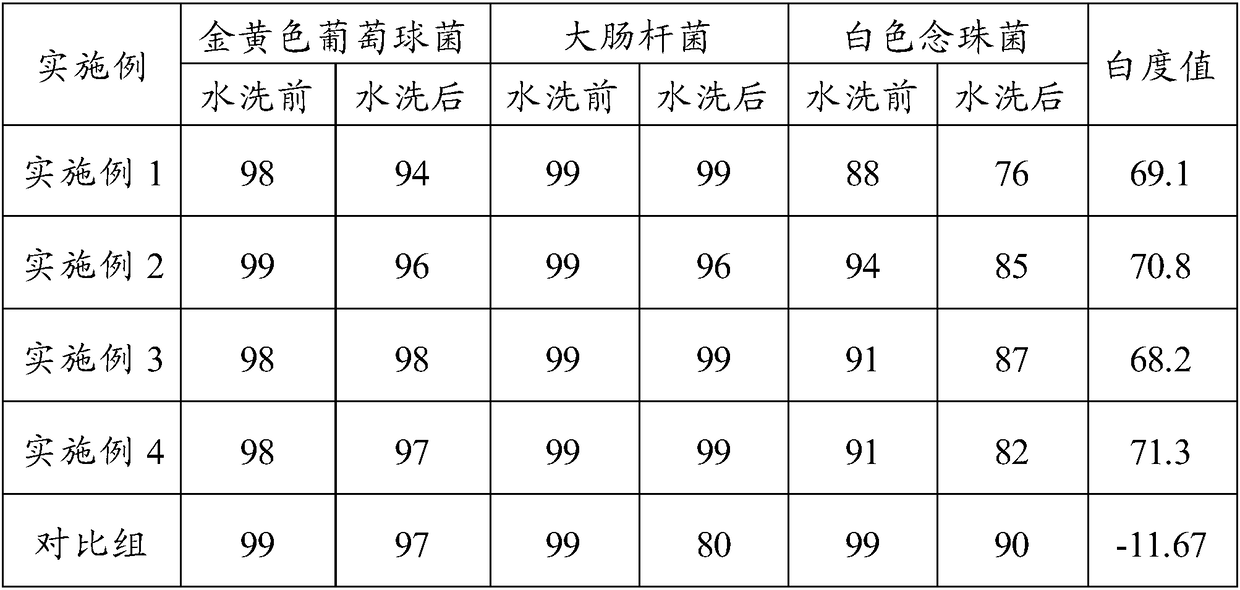

A cellulose fiber and fiber technology, applied in the field of functional preparation, can solve the problems of affecting the antibacterial effect of fibers, affecting the printing and dyeing processing of light-colored products, etc., and achieve the effect of high whiteness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of durable antibacterial cellulose fiber, comprising the following steps:

[0022] S1. Removing impurities from the cellulose fibers through physical and mechanical means to obtain fibers after removal of impurities;

[0023] S2. Pretreating the fibers after the removal of impurities, the pretreatment includes a cleaning process and / or a scouring and bleaching process, and dehydration to obtain dehydrated fibers;

[0024] S3, using an antibacterial working solution, performing antibacterial finishing on the dehydrated fibers to obtain durable antibacterial cellulose fibers;

[0025] The antibacterial working solution includes antibacterial agent, alkaline auxiliary agent and penetrating agent, and the antibacterial agent is magnesium carbonate, copper nitrate, copper chloride, copper hydroxide, copper carbonate, basic copper carbonate, zinc chloride, zinc sulfate One or more of zinc hydroxide and zinc carbonate; the a...

Embodiment 1

[0054] (1) Carding the long-staple cotton fibers to remove impurities in the fibers;

[0055] (2) Place 100kg of cotton fiber after cleaning in the cake making machine evenly, the basket pressure is 4MPa, the foot pressure is 2MPa, and the beating density is 0.2g / cm 3 A uniform cotton cake, put the cotton fiber cake into the dyeing vat;

[0056] (3) Pretreat the cotton fiber cake in the dye vat: add hydrogen peroxide 3-5g / L, caustic soda 2-3g / L, iron ion chelating agent 726 2-3g / L, hydrogen peroxide stabilizer P-CBB 1- 2g / L, scouring agent SA-3E3-5g / L, bath ratio 1:5, circulate for 10min, then heat up to 98-100℃ at 3°C / min, keep warm for 40min, discharge; add water, bath ratio 1:5, then Heat up to 98-100°C at 3°C / min, keep warm for 20 minutes, and drain; add water, the bath ratio is 1:5, then raise the temperature to 98-100°C at 3°C / min, keep warm for 20 minutes, and drain.

[0057] It should be noted that the concentration of hydrogen peroxide is calculated as 100%, and the...

Embodiment 2

[0063] (1) Carding the long-staple cotton fibers to remove impurities in the fibers;

[0064] (2) Place 200kg of cotton fiber after cleaning evenly in the cake making machine, the basket pressure is 4MPa, the foot pressure is 2MPa, and the beating density is 0.22g / cm 3 A uniform cotton cake, put the cotton fiber cake into the dyeing vat;

[0065] (3) Pretreat the cotton fiber cake in the dye vat: add caustic soda 40g / L, scouring agent SA-3E2-4g / L, bath ratio 1:5, circulate for 10min, then heat up to 100- 102°C, keep warm for 60min, discharge; add water, bath ratio 1:5, then heat up to 98-100°C at 3°C / min, keep warm for 20min, drain; add water, bath ratio 1:5, then heat up to 98°C / min -100℃, keep warm for 20min, drain; add hydrogen peroxide 3-5g / L, caustic soda 2-3g / L, iron ion chelating agent 726 2-3g / L, hydrogen peroxide stabilizer P-CBB1-2g / L, scouring agent SA- 3E 3-5g / L, bath ratio 1:3, cycle for 10min, then heat up to 98-100°C at 3°C / min, keep warm for 40min, discharge;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com