Patents

Literature

50results about How to "Process clean and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beneficiation method for separating fluorite and tungsten through flotation

ActiveCN104084315AAvoid the problem of poor floatability and difficult flotation recoveryAvoid lostFlotationSulfidationTungsten

The invention discloses a beneficiation method for separating fluorite, white tungsten (black tungsten) and gangue minerals in complex polymetallic ore through flotation. Non-magnetic products of tailings subjected to sulphide ore flotation or tailings subjected to sulphide ore flotation and then subjected to strong magnetic separation for recycling black tungsten serve as two kinds of samples. The pH value is controlled by adding regulators, white tungsten, black tungsten, other gangue combined inhibitors and collectors are added, fluorite is subjected to differential flotation, then, tungsten minerals are subjected to flotation, and therefore fluorite and tungsten can be efficiently recycled. Loss of fluorite in tungsten flotation concentrate is avoided when tungsten minerals are subjected to differential flotation, and the defect that when tungsten flotation is performed, fluorite is difficult to recycle through flotation because the inhibitors have strong inhibition on fluorite, and beneficiation efficiency is low is avoided. Compared with a current beneficiation situation, the fluorite recycling rates of tests on the two different samples are increased by 39% to 48 % and 9% respectively, and the tungsten recycling efficiency is improved by 3%.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

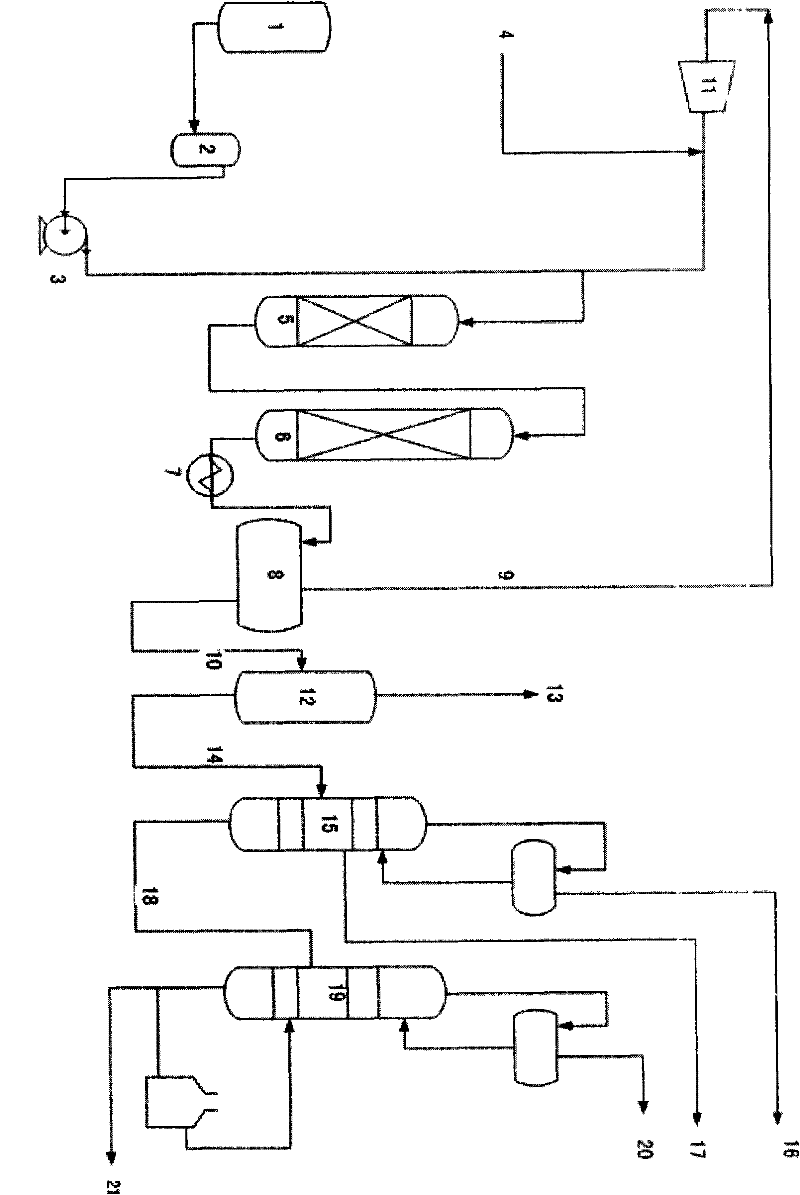

Hydrofining technology of heavy benzol

ActiveCN101712888ANot easy to cokeExtended operating cycleDistillation purification/separationTreatment with hydrotreatment processesBenzeneHydrogen

The invention discloses a hydrofining technology of heavy benzol, which is characterized in that heavy benzol is filtered and is mixed with hydrogen to successively enter a fixed bed pre-hydrogenation reactor and a fixed bed main hydrogenation reactor for selective hydrofining; the obtained hydrogenated oil is converted into solvent oil and industrial naphthalene after cooling, gas stripping, distillation, rectification and the like. The heavy benzol has favourable quality, high additional value and small pollution to environment when the heavy benzol is used, the device has long operation period, and the invention provides a new path for effectively using heavy benzol.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

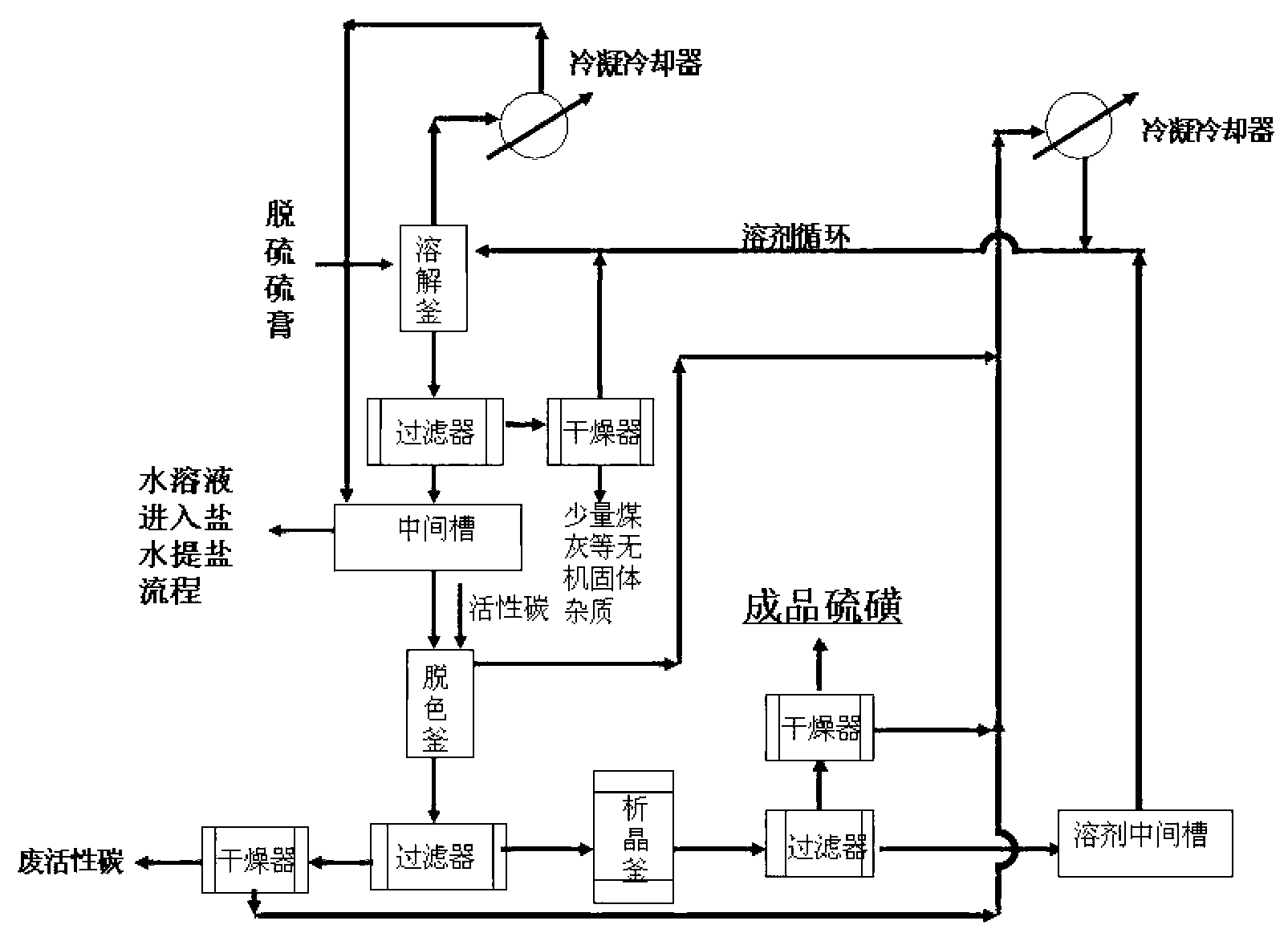

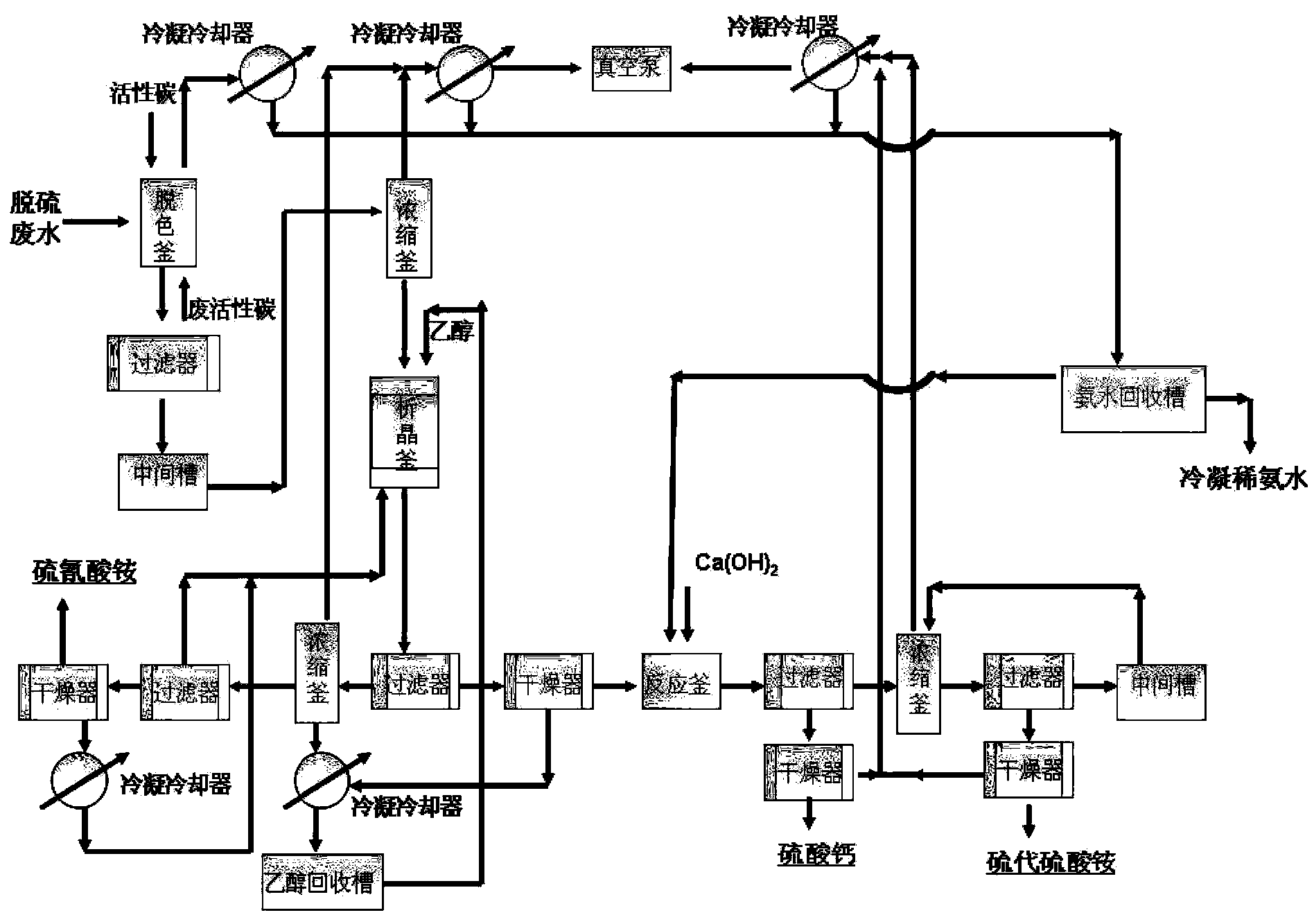

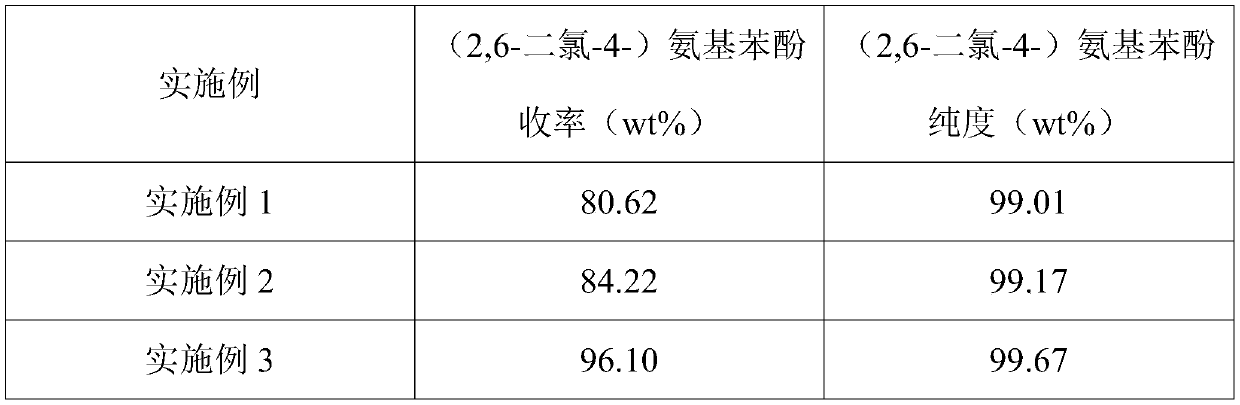

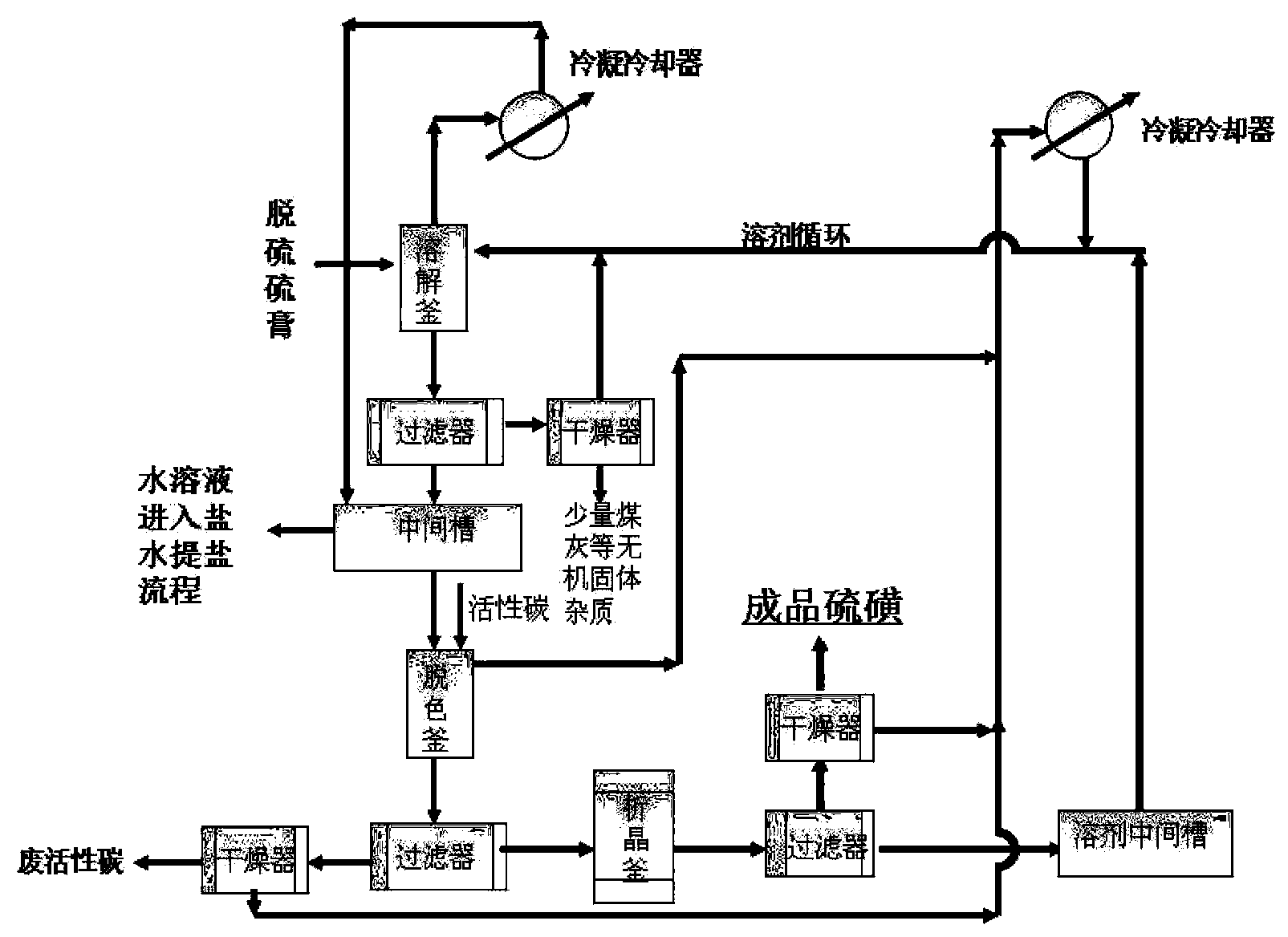

Method for processing sulfur paste as coke oven gas desulfuration by-product

ActiveCN103264991AThorough treatmentNo secondary pollutionCalcium/strontium/barium sulfatesThiosulfates/dithionites/polythionitesResource utilizationImpurity

The invention relates to a method for processing sulfur paste as a coke oven gas desulfuration by-product. The method is characterized in that a sulfur paste processing procedure comprises the steps of dissolving sulfur and removing impurities, decoloring and removing impurities, lowering temperature and crystallizing, drying the product and the like; and a waste liquid treatment procedure comprises the steps of decoloring and removing impurities, carrying out vacuum concentration on filtrate containing salt, separating ammonium thiocyanate, concentrating the ammonium thiocyanate ethyl alcohol filtrate for crystallization, drying an ammonium thiocyanate product, separating ammonium sulfate, concentrating the ammonium thiosulfate filtrate for crystallization, drying the ammonium thiosulfate product, and the like. The method can be used for thoroughly processing the sulfur paste and the waste liquid containing sulfur, the recycling rate of the product is high, no mixed salt and waste water are discharged without cause secondary pollution, so that the method is clean and environment-friendly. The method also has the outstanding characteristics of strong adaptive capacity, large production elasticity, high resource utilization ratio and the like.

Owner:张建利

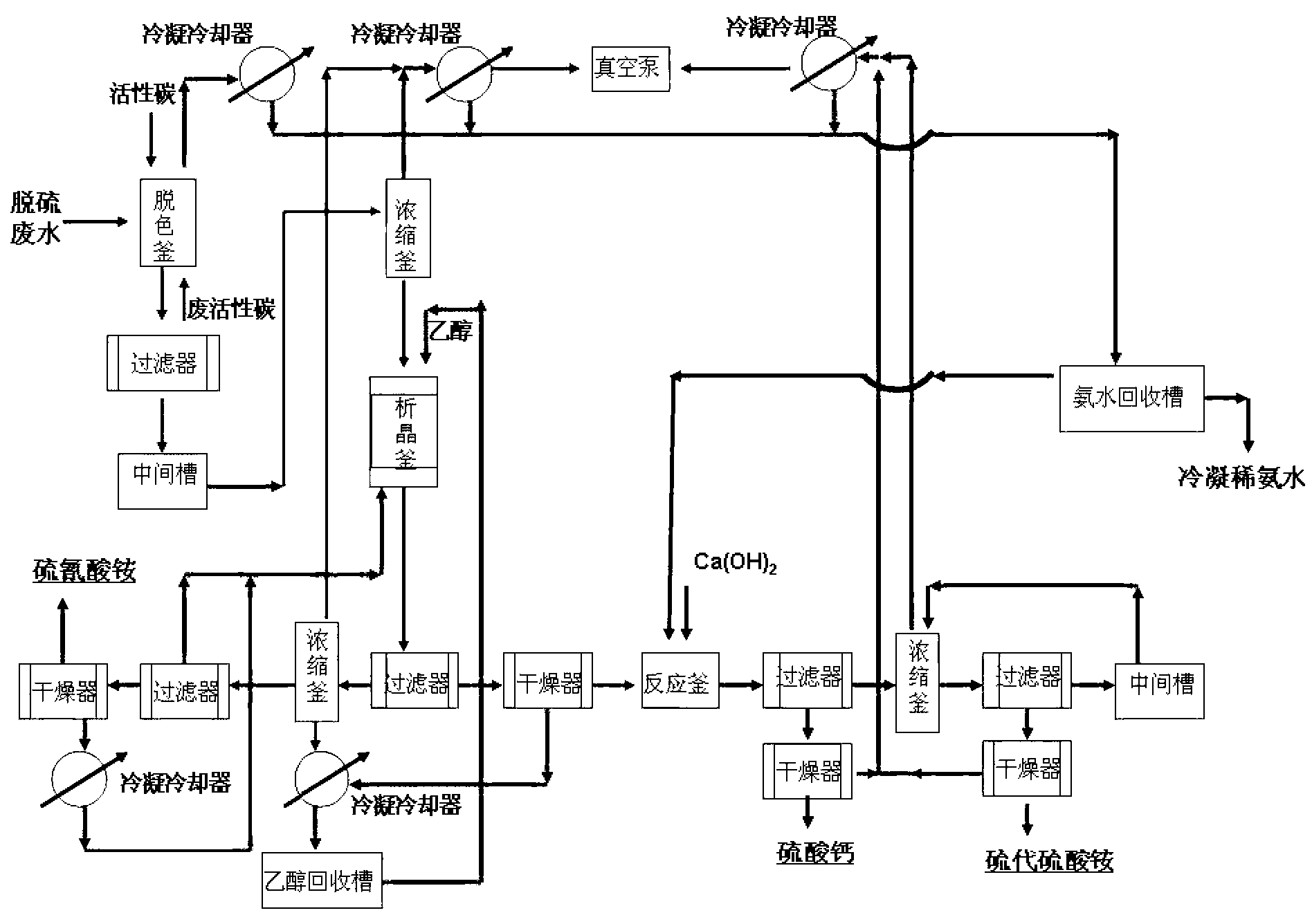

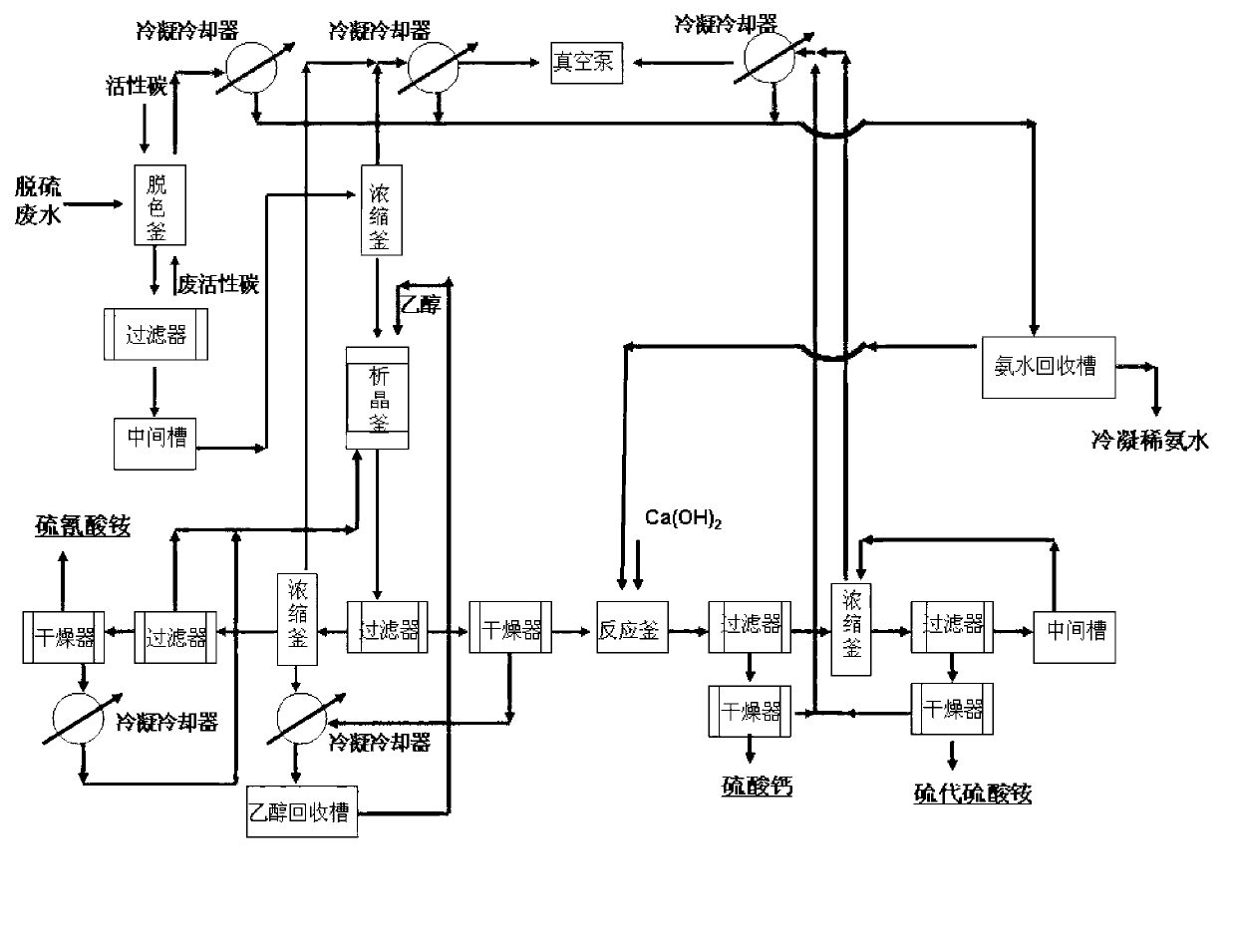

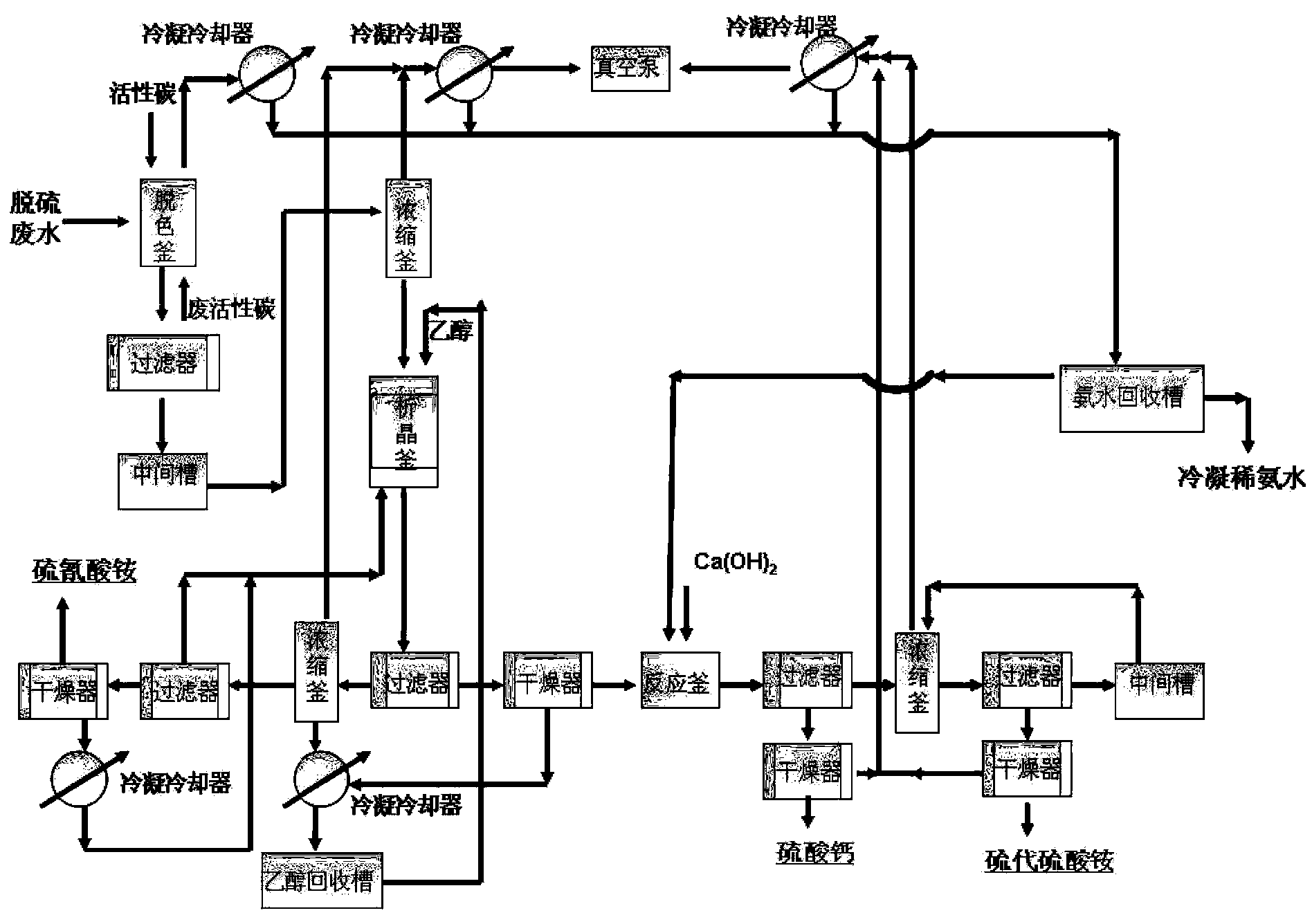

Method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas

ActiveCN103274367AThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteResource utilization

The invention relates to a method for extracting two secondary salts from a desulfurized salt-containing waste liquid of coke oven gas. The waste liquid treatment and secondary salt extraction process comprises the following steps: decolorizing, removing impurities, performing reduced pressure concentration on the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, drying the ammonium thiosulfate product and the like. According to the invention, the desulfurized waste liquid is thoroughly treated, the products are high in recovery rate, no mixed salts or waste water is discharged, no secondary pollution is caused, and the process is clean and environment-friendly. Meanwhile, the invention also has the remarkable characteristics of high adaptability, high production elasticity, high resource utilization rate and the like.

Owner:张建利

Vegetable seed protein feed and preparation method thereof

InactiveCN101433270AWide variety of sourcesLow priceAnimal feeding stuffAccessory food factorsRapeseedHydrolysis

The invention provides rapeseed protein feed which is solid powder or particulate matter. The content of protein is between 35 and 50 percent (N * 6.25, dry basis); the content of water-soluble nitrogen is between 25 and 35 percent; the content of small peptide is between 10 and 25 percent; the content is counted by weight percentage; and thioglycoside accounts for 5 to 15 micromole per gram of rapeseed protein feed. The invention also provides a method for preparing the rapeseed protein feed; one of bacillus subtilis, lactobacillus or candida utilis and actinomucor elegans or aspergillus usamii are compounded to prepare a fermenting agent; the fermenting agent is added to pulverized rapeseed dreg for solid fermentation; and a culturing substrate is sterilized, dried and pulverized to obtain the rapeseed protein feed rich in small peptide. The preparation method is environment-friendly, has mild reaction condition, can fully exert the functions of protease hydrolysis and thioglycoside degradation of microbe and is a method which has low cost and is suitable for the industrialized large-batch preparation of the rapeseed protein feed.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

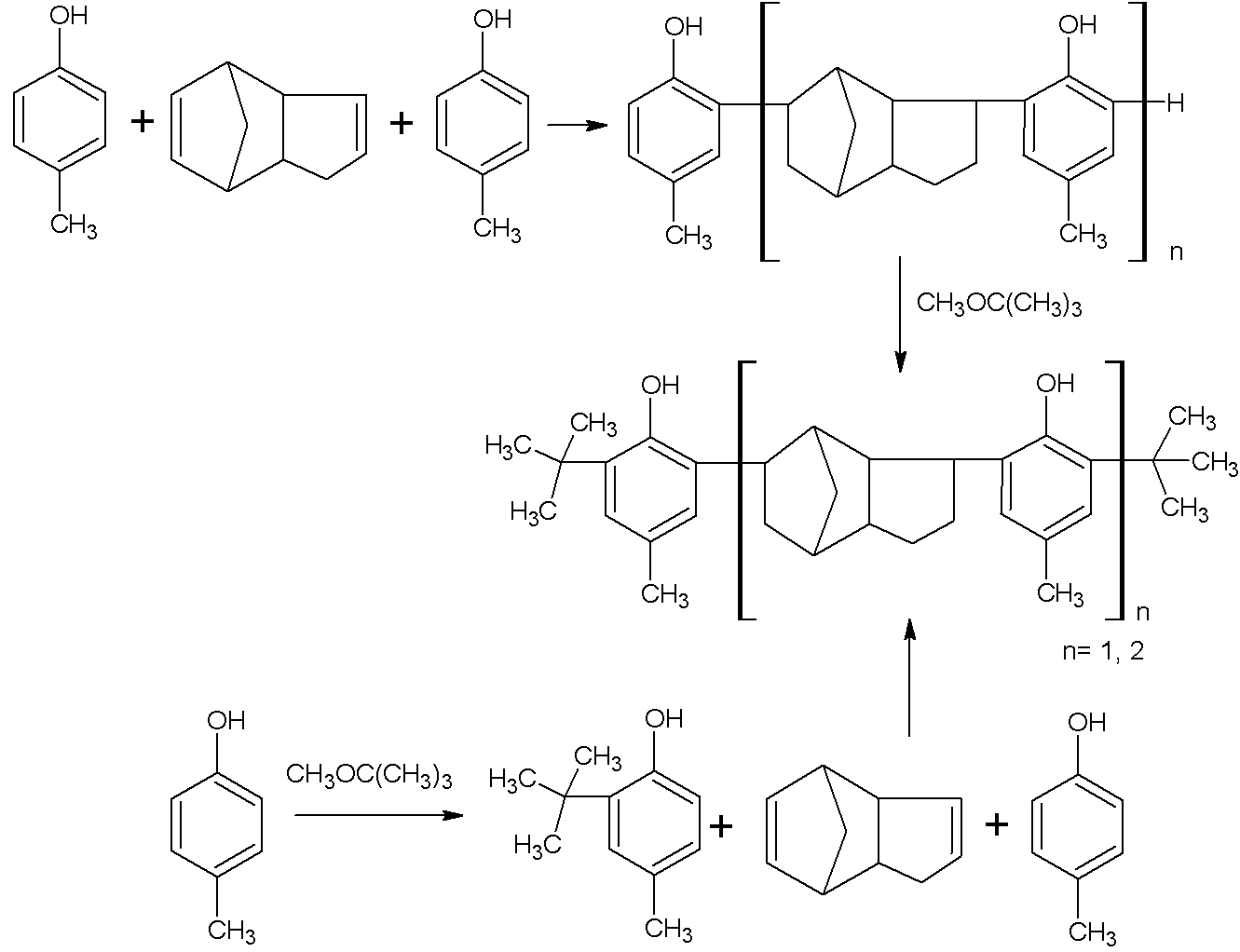

Method for producing aggregate-type hindered phenol antioxidant

InactiveCN103319315AReduce usageImprove efficiencyOrganic chemistryOrganic compound preparationSolubilityWater vapor

The invention provides a method for producing aggregate-type hindered phenol antioxidant. The method comprises the following steps of: firstly reacting p-cresol with dicyclopentadiene and a non-water-solubility solvent through an organic composite sulfonic acid catalyst under the anhydrous condition to obtain p-cresol-dicyclopentadiene resin; then adding tert-Butyl methyl ether so as to produce a p-cresol-dicyclopentadiene-isobutylated resin crude product, or firstly reacting the p-cresol with the tert-Butyl methyl ether and the non-water-solubility solvent through the organic composite sulfonic acid catalyst under the anhydrous condition to obtain an o-tert-butyl p-cresol; then adding the dicyclopentadiene so as to produce the p-cresol-dicyclopentadiene-isobutylated resin crude product; washing the crude product by water, and carrying out steam distillation on the crude product to obtain the aggregate-type hindered phenol antioxidant, wherein the final yield reaches more than 95%. The method has the advantages that the adopted organic composite sulfonic acid catalyst is low in cost, common and easy to wash by water and separate, water can be recycled, the product has good color and luster, low ash content and high purity, the treatment process is simple, equipment is free of being corroded, the technology is clean and environmentally-friendly, and the product yield reaches more than 95%.

Owner:HUBEI UNIV OF TECH

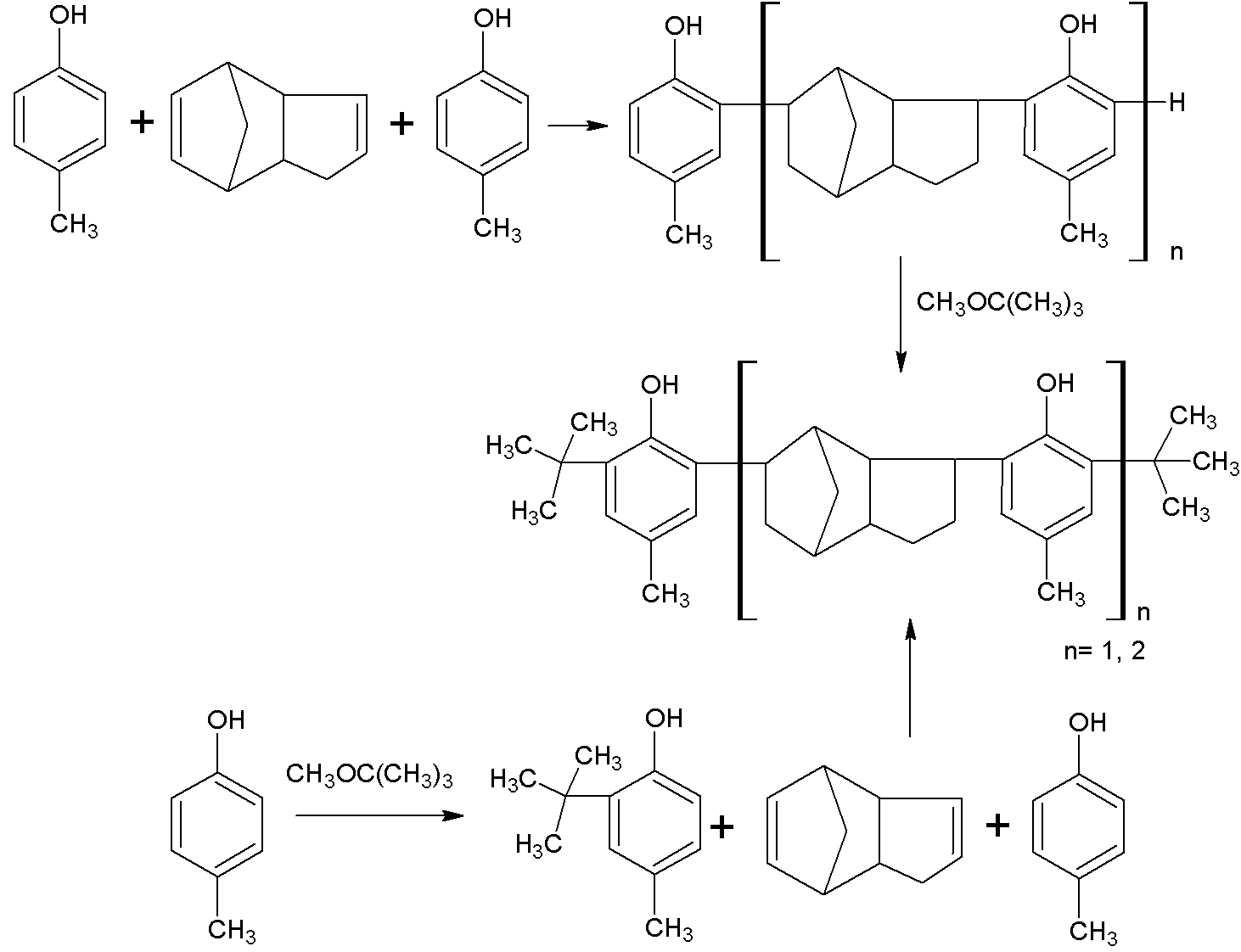

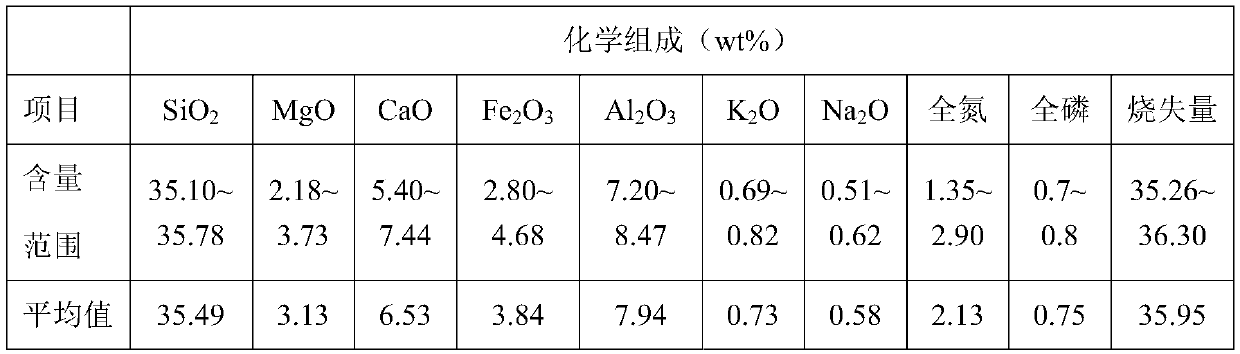

Ceramsites containing municipal sewage treatment sludge and ceramic polishing slag and preparation methods of ceramsites

ActiveCN109704725AIncrease profitWide variety of sourcesCeramic materials productionCeramicwareFoaming agentSlag

The invention discloses ceramsites containing municipal sewage treatment sludge and ceramic polishing slag and preparation methods of the ceramsites. A foamed ceramsite containing municipal sewage treatment sludge and ceramic polishing slag is composed of the following raw materials: municipal sewage treatment sludge, ceramic polishing slag, an admixture and a foaming agent. A sintered ceramsite containing municipal sewage treatment sludge and ceramic polishing slag is composed of the following raw materials: municipal sewage treatment sludge, ceramic polishing slag and an admixture. Meanwhile, the invention further discloses the preparation methods of the ceramsites containing municipal sewage treatment sludge and ceramic polishing slag. The municipal sewage treatment sludge and ceramic industrial solid waste ceramic polishing slag powder are comprehensively utilized, a novel solid waste recycling technology is provided, and the technology provides an effective approach for avoiding secondary pollution of the municipal sewage treatment sludge with relatively high treatment difficulty. The preparation methods have the advantages such as high waste slag utilization ratio, wide raw material source, clean and environment-friendly process, simple step, shortened production period and energy saving.

Owner:GUANGZHOU UNIVERSITY

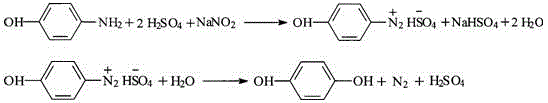

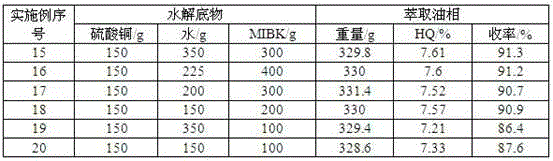

Hydrolysis process for hydroquinone

InactiveCN102746122AMake up for the disadvantage of high priceRealize cleaner productionOrganic chemistryOrganic compound preparationP-AminophenolReaction temperature

The invention discloses a hydrolysis process for hydroquinone and relates to a hydrolysis process during hydroquinone synthesis by subjecting p-aminophenol to diazotization and hydrolysis processes. The process includes: adding basic cupric carbonate, cupric sulfate and solvents into a hydrolysis reaction kettle, dropwise adding diazonium solution of 0+ / -0.5 DEG C obtained by subjecting sodium nitrite and dilute sulfuric acid to diazotization and performing hydrolysis reaction at a reaction temperature of 85 DEG C-88 DEG C. Raffinate phase does not generate waste acid, and the copper recovery rate reaches to more than 99.5%, so that a disadvantage of high copper price is made up; and sodium sulfate is obtained by means of concentration and crystallization of filtrate, concentrated water is used for preparing acid for diazo reaction, and crystallized mother solution of the sodium sulfate is used for preparing cupric sulfate solution for hydrolysis, so that clean production is realized.

Owner:JIANGSU YANGNONG CHEM GROUP +1

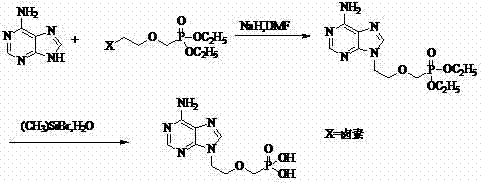

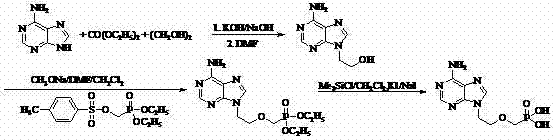

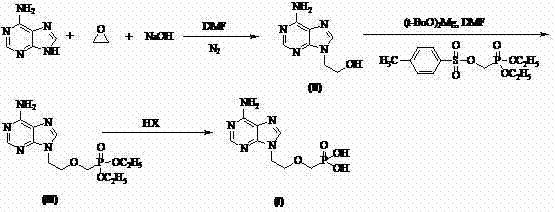

Method for synthesizing adefovir serving as anti-hepatitis B virus medicine

InactiveCN102250146AEmission reductionGood choiceGroup 5/15 element organic compoundsHepatitis B virusPharmaceutical Substances

The invention discloses a method for synthesizing adefovir serving as anti-hepatitis B virus medicine, which belongs to the field of antiviral chemical medicines. In the method, adefovir is obtained by using adenine as a starting raw material and by three nucleophilic substitution reactions. In the invention, the reaction conditions are mild, the method is simple, easy to implement, efficient and high in selectivity, fewer byproducts are produced, and the yield and purity of the product are high.

Owner:扬州三友合成化工有限公司

Method for preparing monophenol compounds through microwave depolymerization of lignin

ActiveCN107337585ADepolymerization is fast and efficientIncrease profitOrganic chemistryOrganic compound preparationDepolymerizationMicrowave

The invention discloses a method for preparing monophenol compounds through microwave depolymerization of lignin. The method comprises the following steps: uniformly mixing, by mass, 10 parts of lignin and 5-10 parts of silicon carbide particles, and placing the obtained mixture in a microwave depolymerization reaction environment; continuously introducing a carrier gas and reaction gas mixed gas into the microwave depolymerization reaction environment to start a microwave depolymerization reaction; cooling pyrolysis gas generated during the microwave depolymerization reaction to obtain a solvent-based pyrolysis liquid; and carrying out reduced pressure distillation on the solvent-based pyrolysis liquid until no distillate is distilled off in order to obtain an undistilled component which is the monophenol compounds. The method greatly improves the yield of the monophenol compounds by changing the reaction atmosphere, and provides an important technical support for the high-efficiency conversion of the lignin into the monophenol compounds.

Owner:SHAANXI UNIV OF SCI & TECH

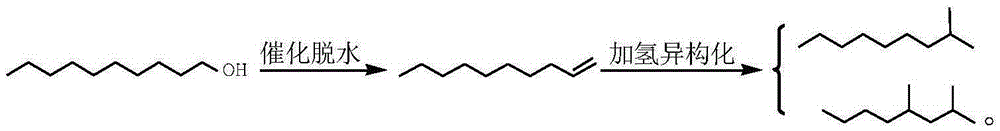

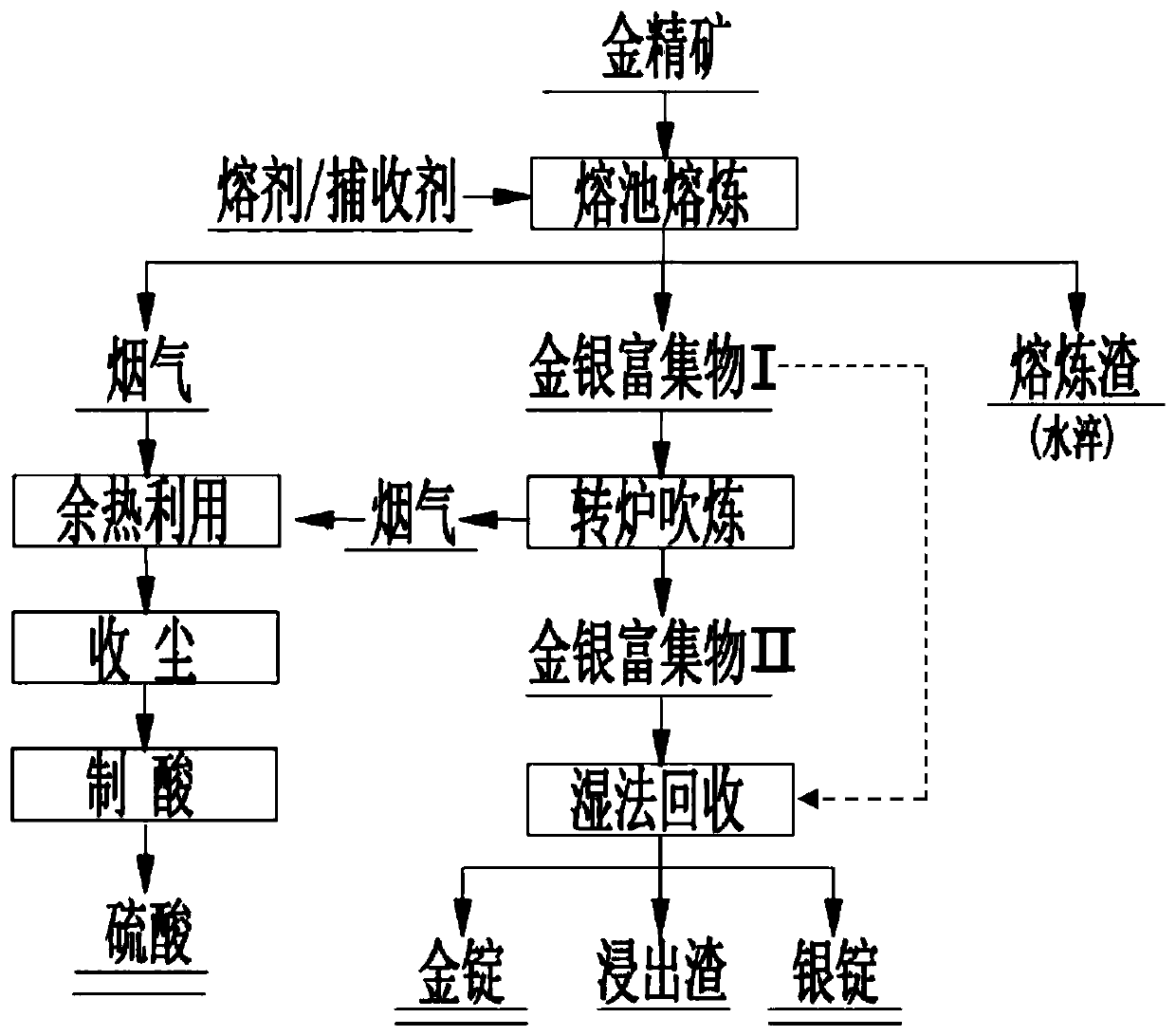

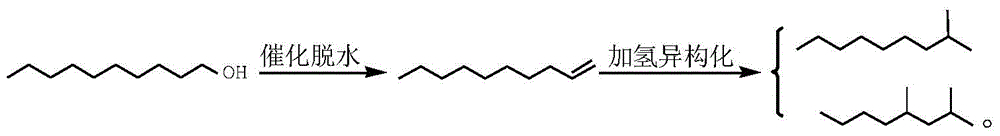

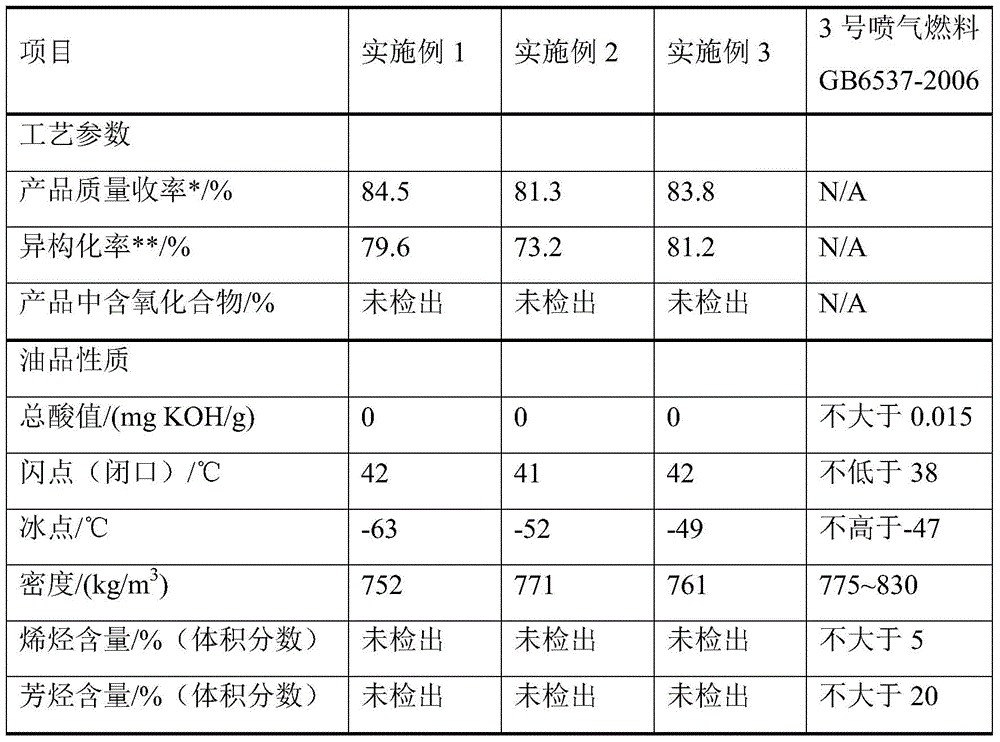

Method for producing aviation fuel from fatty alcohols

ActiveCN105400540AHigh product yieldGood qualityLiquid hydrocarbon mixture productionBio-feedstockEnvironmentally friendlyAlkane

The invention relates to a method for producing an aviation fuel from fatty alcohols, and belongs to the technical field of aviation fuels. The method comprises the following steps: 1, converting the fatty alcohols into C8-C16 n-alkenes under catalytic dehydration conditions; and 2, preparing C8-C16 isoalkanes from the n-alkenes obtained in step 1 under hydrogenation isomerization conditions. The C8-C16 isoalkanes obtained through the method can be mixed with traditional petroleum base aviation fuels according to arbitrary proportions. The method has the advantages of renewable raw material, high yield and high quality of the above product, and environmentally friendly and clean process.

Owner:BEIJING UNIV OF CHEM TECH

Method for separating and enriching < 7 > Li isotope through extraction-electromigration coupling

PendingCN113262636ASeparation effect is obviousEasy to operate continuouslyIsotope separationProcess efficiency improvementLithiumDiluent

The invention discloses a method for separating and enriching < 7 > Li isotope through extraction-electromigration coupling. The method comprises the following steps: uniformly mixing an ionic liquid, a diluent and a crown ether compound to form an extraction organic phase; uniformly mixing the extracted organic phase with a lithium salt solution, extracting, and collecting a lithium-loaded organic phase; the anode, the cathode, the anolyte, the catholyte and the isolating membrane jointly form an electromigration system, wherein the anolyte is the obtained lithium-loaded organic phase, and the isolating membrane is arranged between the anolyte and the catholyte; and finally, electrifying the electromigration system to obtain the cathode solution rich in < 7 > Li. According to the method, under the action of an electric field, the lithium isotope separation effect continuously exists, the enrichment limitation of the front end and the tail end of an ion migration flow does not exist, the isolation membrane is not subjected to saturation capacity limitation, meanwhile, all solution phases can be recycled, and the process is clean and environment-friendly; in addition, the process has no special requirements on temperature, humidity, air and the like, and sealing is not needed.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

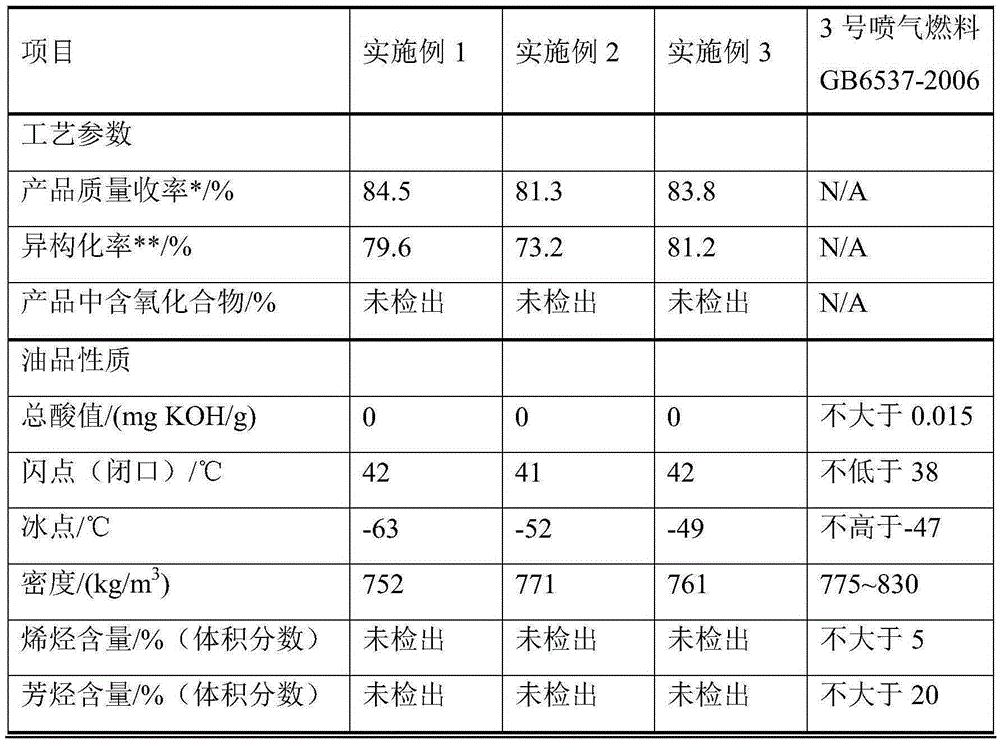

Method suitable for independent smelting of various types of complex gold concentrate

InactiveCN110777264AWide adaptabilityEfficient recyclingSulfur compoundsEnergy inputSocial benefitsCyanide

The invention relates to a method suitable for independent smelting of various types of complex gold concentrate, and belongs to the technical field of gold smelting. The method comprises the following steps that (1) gold concentrate raw materials are matched with flux for smelting, so that the gold and silver are enriched in matte, the matte is oxidized into smelting flue gas, the gold and silverconcentrate I, smelting slag and smelting flue gas are obtained; (2) the gold and silver concentrate I is recovered through the wet process to obtain gold products, silver products and leached slag;and (3) sulfuric acid is produced from smelting flue gas after waste heat utilization and dust collection, when the copper content of the gold and silver concentrate I is high, the gold and silver concentrate I is subjected to blow secondary enrichment of gold and silver to obtain a gold and silver concentrate II, and then the gold and silver concentrate II can enter the step (2) for wet process recovery treatment. The method suitable for independent smelting of various types of the complex gold concentrate can process various types of complex gold ores, the complex gold concentrate and secondary materials, the process technology and equipment are mature, industrial application is easy to realize, the smoke and dust rate is effectively reduced, cyanide slag or cyanide containing waste water do not be produced, and the economic and social benefits are remarkable.

Owner:蒋开喜

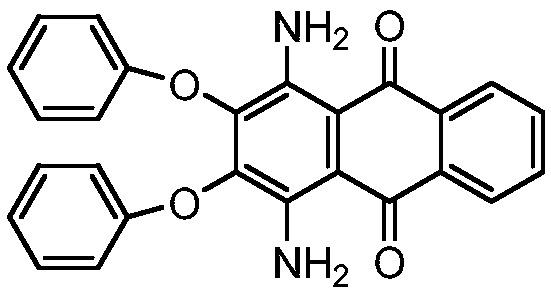

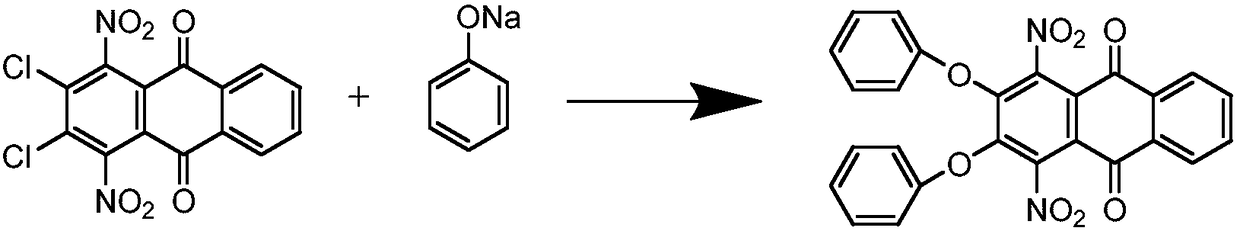

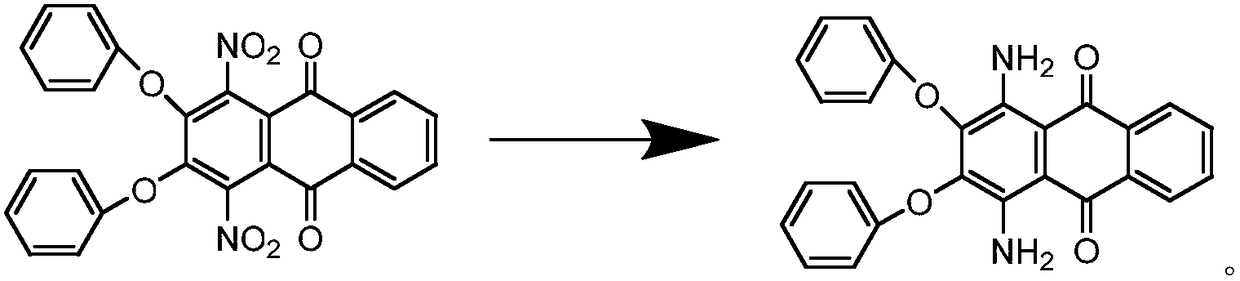

Synthesis process of solvent violet 59

The invention discloses a synthesis process of solvent violet 59. The synthesis process of the solvent violet 59 comprises the following steps: taking 1,4-binitro-2,3-dichloroanthraquinone and sodiumphenoxide as raw materials, performing condensation reaction under the existence of an organic solvent orthodichlorobenzene to generate 1,4-binitro-2,3-diphenoxyanthraquinone, and reducing the 1,4-binitro-2,3-diphenoxyanthraquinone to generate 1,4-diamido-2,3-diphenoxyanthraquinone. The activity of the 1,4-binitro-2,3-dichloroanthraquinone is higher than the activity of the 1,4-diamido-2,3-dichloroanthraquinone, and the reaction is easier to conduct, so the reaction time is greatly shortened; furthermore, the reaction has little side reactions, the yield is high and undissolved substances aregreatly reduced; moreover, the synthesis route avoids generation of a large amount of salt-containing waste water, and the process is relatively clean and environment-friendly.

Owner:JIANGSU DAOBO CHEM

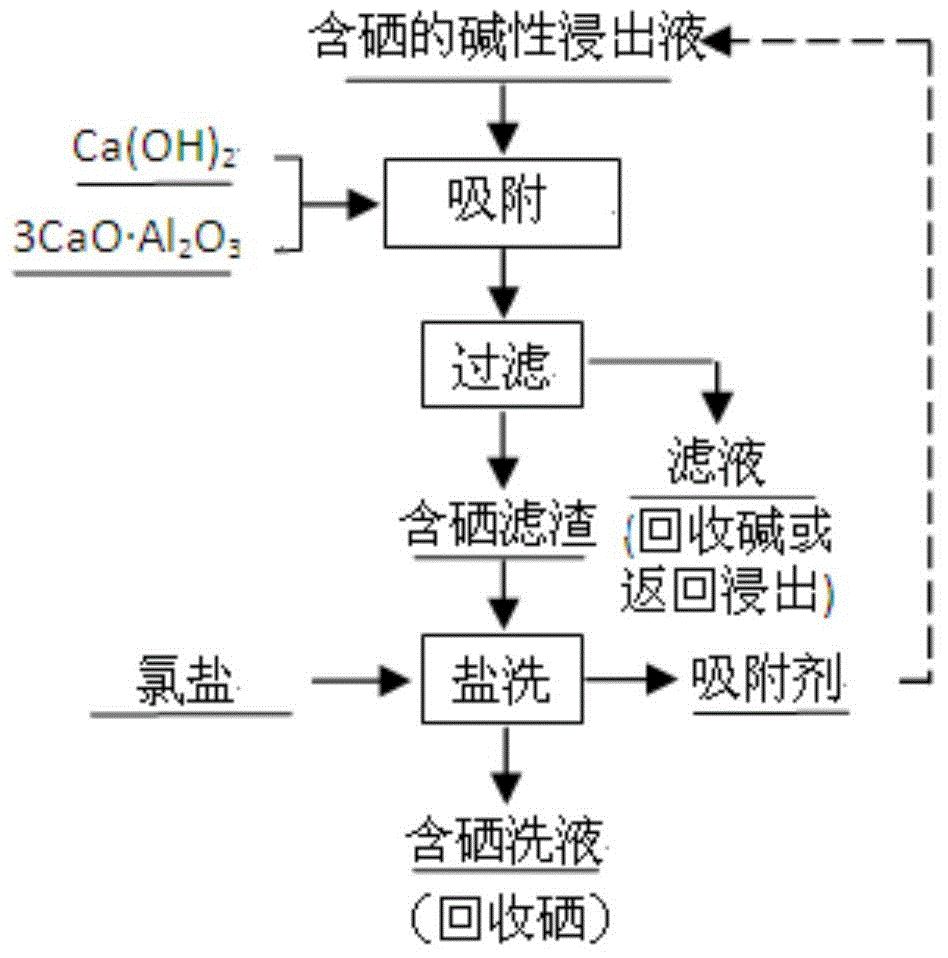

Method for separating selenium in alkaline leachate

ActiveCN105000537AImprove adsorption capacityAchieve reuseElemental selenium/telluriumPregnant leach solutionSorbent

The invention discloses a method for separating selenium in alkaline leachate. The method comprises 1, slowly adding Ca(OH)2 and 3CaO.Al2O3 into an alkaline leaching liquid containing SeO3<2-> and / or SeO4<2->, and carrying out stirring for a reaction at a temperature of 40-80 DEG C to produce precipitates, 2, filtering the mixed solution obtained by the step 1 to obtain selenium-containing filter residue and filtrate, 3, washing the selenium-containing filter residue by deionized water many times, carrying out drying, mixing the dried selenium-containing filter residue and a chlorine salt solution, carrying out stirring, and carrying out liquid-solid separation after the reaction to obtain a selenium-containing washing lotion and a Ca-Al-Cl adsorbent which mainly comprises 3CaO. Al2O3. CaCl2. 10H2O, and 4, recovering selenium from the selenium-containing washing lotion obtained by the step 3. The method realizes adsorbent cyclic utilization and recovery of alkali in the leachate and has environmentally friendly processes.

Owner:CENT SOUTH UNIV

A method for producing aviation fuel from fatty alcohol

ActiveCN105400540BHigh yieldImprove qualityLiquid hydrocarbon mixture productionBio-feedstockIsomerizationAlkene

The invention relates to a method for producing an aviation fuel from fatty alcohols, and belongs to the technical field of aviation fuels. The method comprises the following steps: 1, converting the fatty alcohols into C8-C16 n-alkenes under catalytic dehydration conditions; and 2, preparing C8-C16 isoalkanes from the n-alkenes obtained in step 1 under hydrogenation isomerization conditions. The C8-C16 isoalkanes obtained through the method can be mixed with traditional petroleum base aviation fuels according to arbitrary proportions. The method has the advantages of renewable raw material, high yield and high quality of the above product, and environmentally friendly and clean process.

Owner:BEIJING UNIV OF CHEM TECH

A method for extracting two secondary salts from coke oven gas desulfurization salty waste liquid

ActiveCN103274367BThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteWater discharge

A method for extracting two secondary salts from desulfurized salt-containing waste liquid of coke oven gas. Waste liquid treatment and secondary salt extraction techniques comprise decoloring and decontaminating, decompressing and concentrating the salt-containing filtrate, separating ammonium thiocyanate, concentrating and crystallizing the ammonium thiocyanate ethanol filtrate, drying the ammonium thiocyanate product, separating ammonium sulfate, concentrating and crystallizing the ammonium thiosulfate filtrate, and drying the ammonium thiosulfate product. The invention completely treats desulfurized waste liquid, has high product recycling rate, and produces no mixed salt. The waste water discharge contains no secondary pollution. The technique is clean and environmentally friendly. The invention also has substantial advantages such as high adaptability, scalability, and resource utility rate.

Owner:张建利

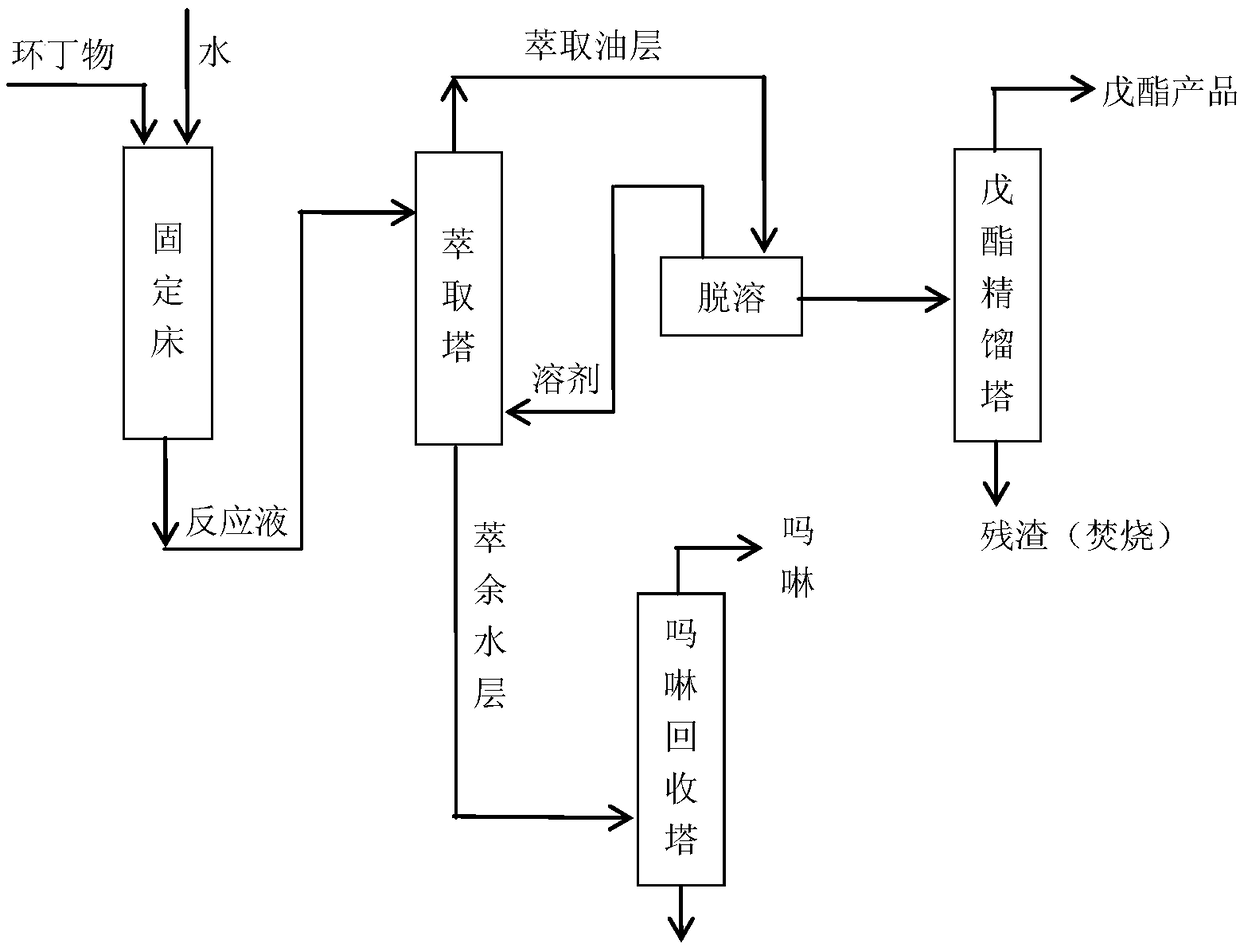

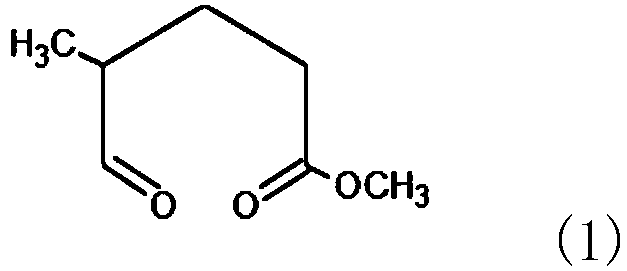

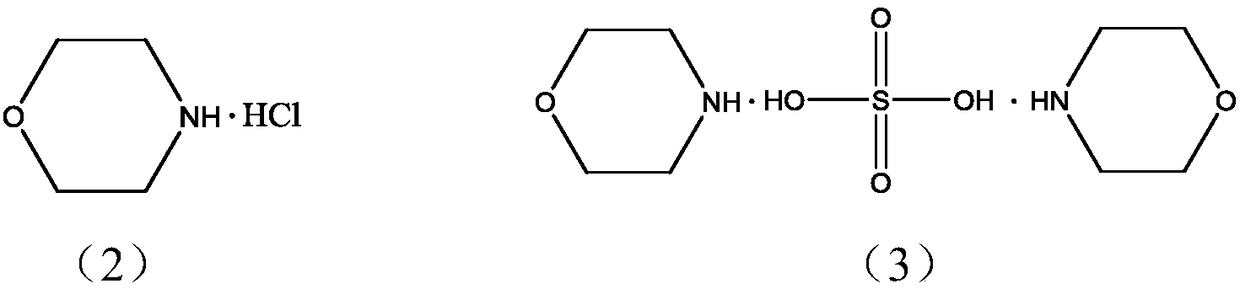

Synthesizing method for pesticide intermediate 4-formyl menthyl valerate

ActiveCN108129321ASolve recycling difficultiesAvoid disadvantagesOrganic compound preparationCarboxylic acid esters preparationMorpholineWastewater

The invention belongs to the technical field of organic chemicals, and relates to a synthesizing method for a pesticide intermediate 4-formyl menthyl valerate, more particularly to a method for synthesizing amyl ester by taking 3-methyl-2-(4-morpholinyl)methyl cyclobutyrate as a raw material and performing catalytic acidolysis by using highly acidic resin. The yield of the amyl ester is not less than 80 percent; a byproduct morpholine exists in a reaction liquid in a free state; the morpholine is recycled through a commonly used chemical operating unit. The synthesizing method for the pesticide intermediate 4-formyl menthyl valerate has the advantages of that an operation process is simple and continuous, morpholine serving as the raw material is convenient to recover, equipment is not corroded, the industrial wastewater amount is small, and the product yield is high.

Owner:JIANGSU YANGNONG CHEM GROUP +2

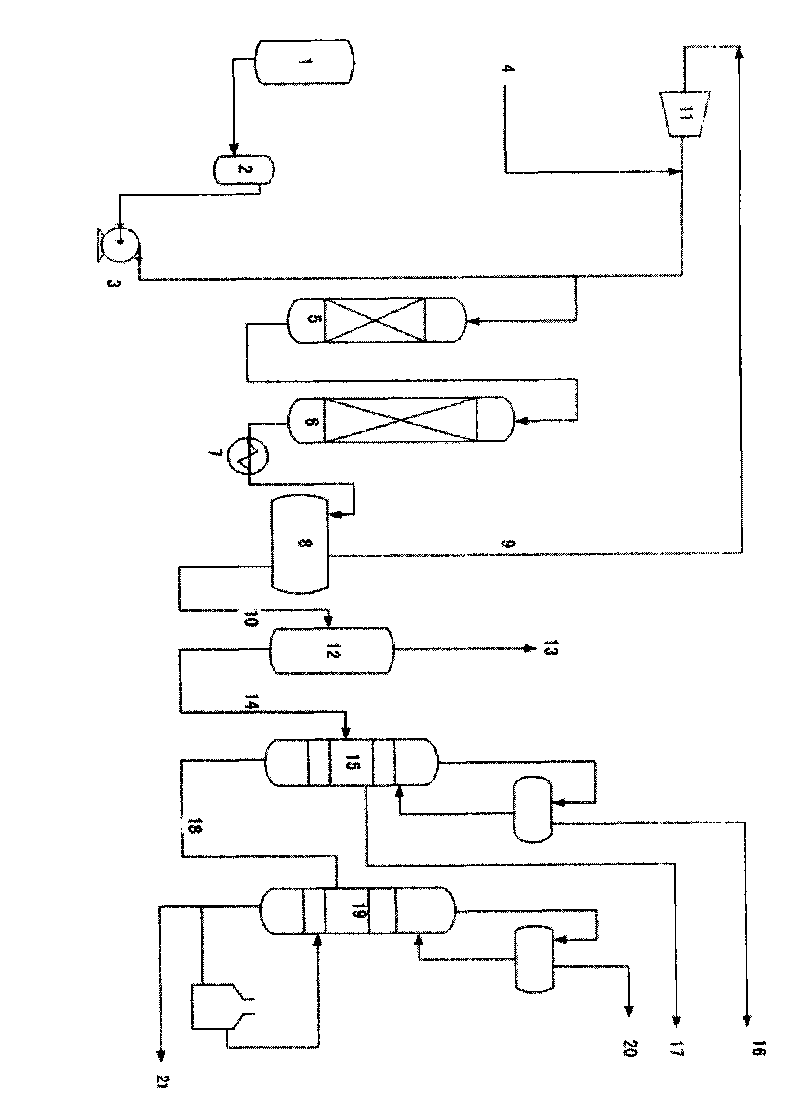

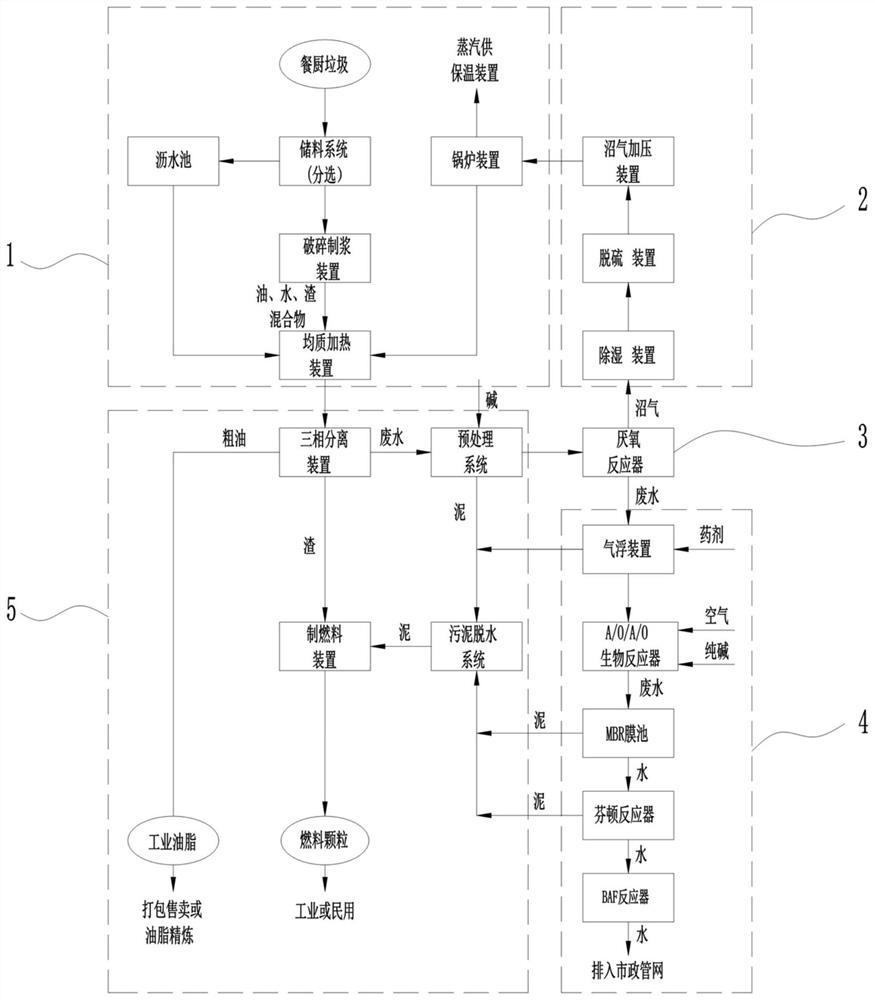

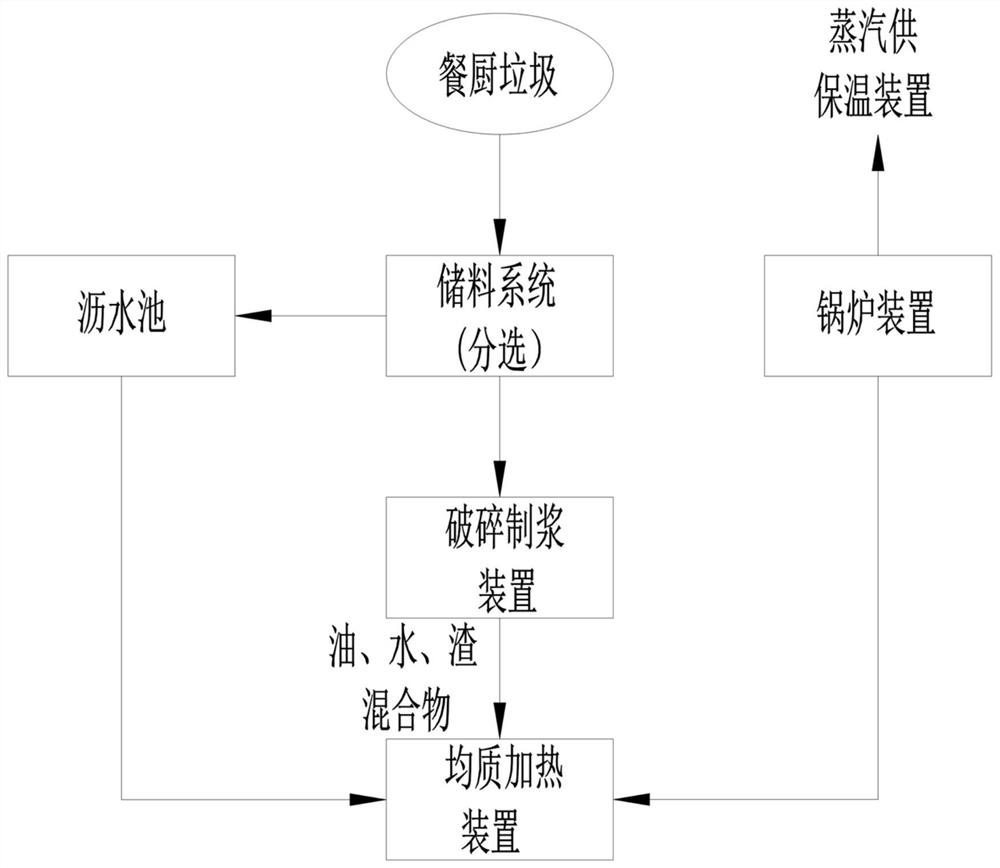

Kitchen waste treatment process

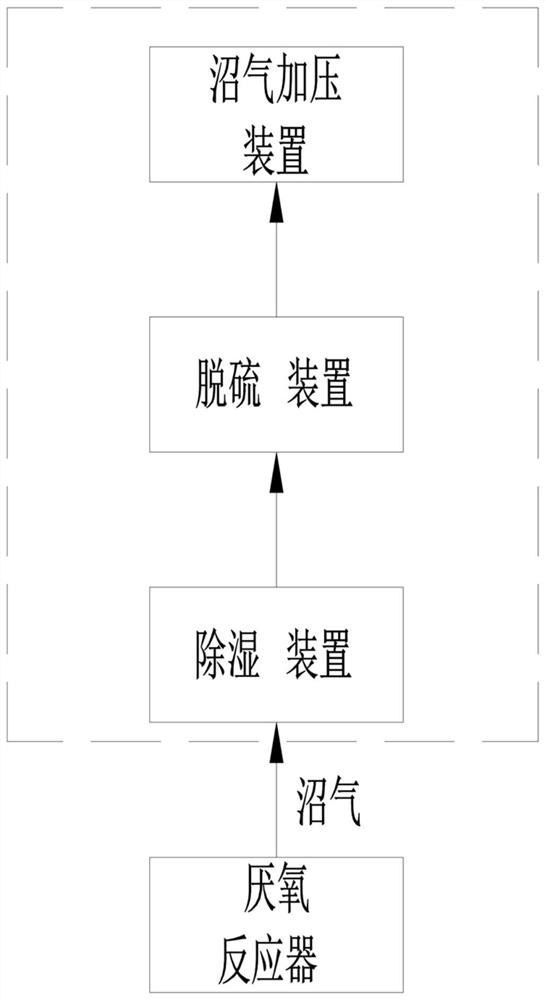

PendingCN113798308ATake advantage ofProcess clean and environmentally friendlyWaste processingSolid waste disposalActivated sludgeEnergy recovery

The invention discloses a kitchen waste treatment process. The kitchen waste treatment process comprises the following steps of conveying kitchen waste into a pre-treatment system for screening, pulping and heating; conveying the kitchen waste treated by the pre-treatment system to a recycling system for three-phase separation, to obtain crude oil, residues and waste water; processing and recycling the crude oil and residues in the recycling system, and leading wastewater to enter an anaerobic reactor through the pre-treatment system; conveying marsh gas generated by the anaerobic reactor to an energy recovery system, and conveying the wastewater and floating oil generated by the anaerobic reactor to a post-treatment system; and purifying and discharging the generated wastewater through the post-treatment system, and returning activated sludge generated by the post-treatment system to the recycling system. According to the kitchen waste treatment process, energy and resources in the waste can be fully utilized, the kitchen waste is harmlessly treated after the resources are utilized, and the whole process is environmentally friendly, clean and easy to use.

Owner:河南玉霖致景环保科技有限公司

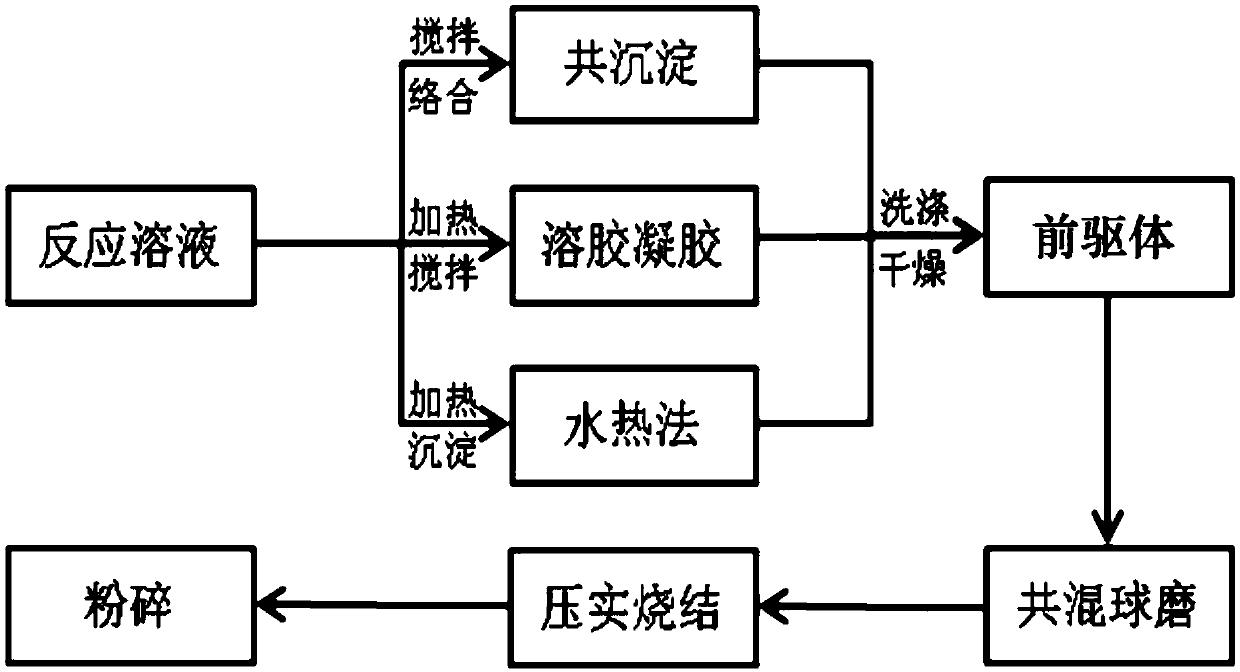

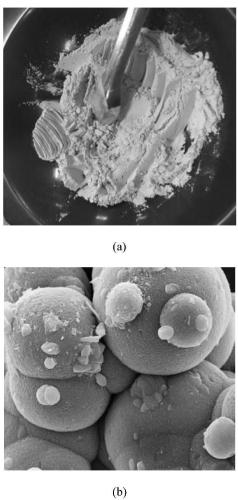

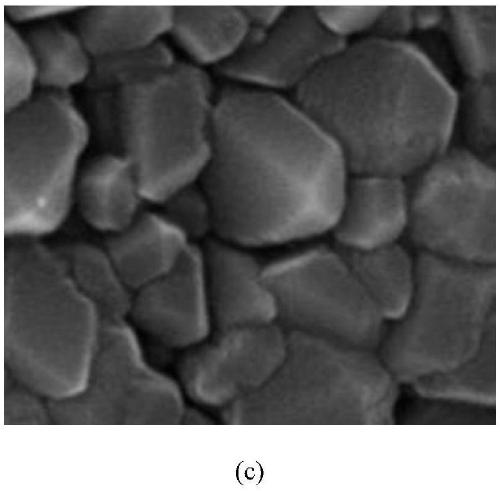

Method for preparing lithium battery positive electrode material based on in-situ composite and recombination

ActiveCN109659539AHigh crystallinityUniform and dense particle size distributionVacuum evaporation coatingSputtering coatingEnvironmental resistanceComposite film

The invention relates to a method for preparing a lithium battery positive electrode material based on in-situ composite and recombination, which belongs to the technical field of lithium battery positive electrode preparation. The method adopts a sputtering process to recombine and grow a pure-phase lithium-rich positive electrode material and a doping substance on a base to obtain a material serving as a lithium battery positive electrode, wherein the doping substance comprises any one or more of a conductive agent, a substance providing anion doping and a substance providing cation protection. The composite film prepared by adopting the method has the advantages of high purity, good crystallinity, stable structure, low catalytic activity of the surface of the material, can be directly used as the lithium battery positive electrode material, significantly improves the electrical conductivity and the coulombic efficiency of the material, stabilizes the voltage window, and protects thecatalytic decomposition of an electrolyte; and the process of the invention realizes one-step electrode plate forming, can avoid the cumbersome slurry and electrode plate preparation process, and simplifies the operation process while improving the material performance. The method disclosed by the invention has the advantages of clean and environmentally-friendly process, simple operation, low cost and high experimental repetition rate, and is favorable for realizing large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Hydrofining technology of heavy benzol

ActiveCN101712888BNot easy to cokeExtended operating cycleDistillation purification/separationTreatment with hydrotreatment processesBenzeneHydrogen

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

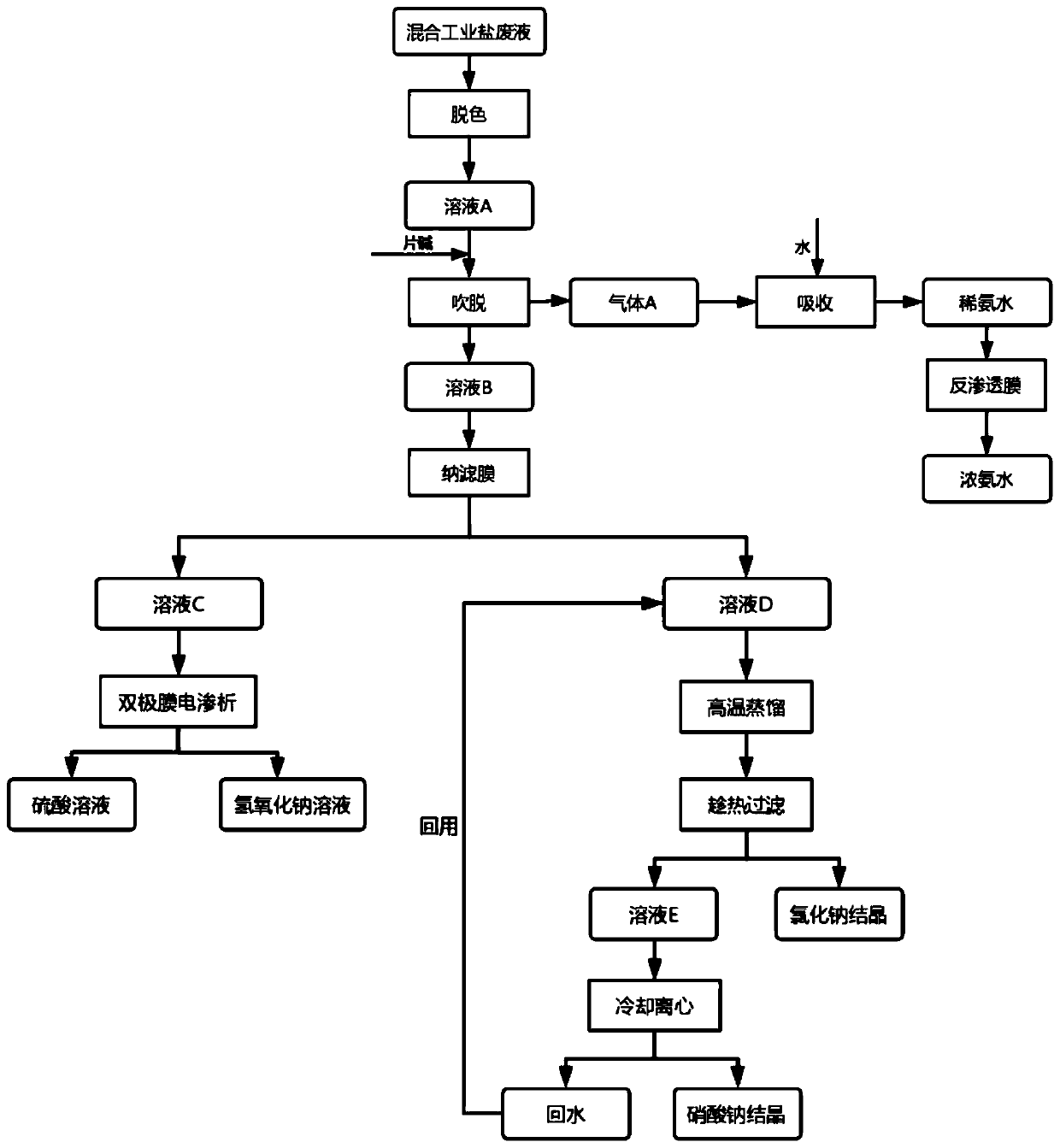

Method for using membrane technology for recycling mixed industrial salt waste solutions

InactiveCN109851107AProcess clean and environmentally friendlySimple processWater contaminantsAlkali metal nitrate purificationSalt-wastingChemical products

The invention discloses a method for using a membrane technology for recycling mixed industrial salt waste solutions. The method comprises the following steps of (1) adding a decolorising agent into the mixed industrial salt waste solutions, stirring a mixture for 2-3 h, and filtering the mixture to obtain a solution A; (2) using alkali for adjusting a pH of the solution A to be 7-9, and producinggas A and a solution B from the solution through an air stripping tower; (3) making the gas A run through a spray tower and then run through membrane 1 for concentration to produce stronger ammonia water; (4) producing a solution C and a solution D from the solution B through membrane 2; (5) producing a sulfuric acid solution and a sodium hydroxide solution from the solution C through action of membrane 3; (6) producing sodium chloride crystals and a solution E after conducting concentration and centrifugation on the solution D; and (7) obtaining sodium nitrate crystals after cooling the solution E, and recycling backwater. According to the method for using the membrane technology for recycling the mixed industrial salt waste solutions, the technology is clean and environmentally friendly, required equipment is simple, operation is easy, energy consumption is low, and the various chemical products can be obtained from the three kinds of mixed salt solutions at the same time, so that economic benefits and environmental benefits are well combined.

Owner:盛隆资源再生(无锡)有限公司

Method for separating and enriching < 6 > Li isotope through extraction-electromigration coupling

ActiveCN113265541AEasy and continuous operationProcess clean and environmentally friendlyPhotography auxillary processesIsotope separationElectromigrationAnode

The invention discloses a method for separating and enriching < 6 > Li isotope through extraction-electromigration coupling. The method comprises the following steps that ionic liquid, a diluent and a complexing agent are uniformly mixed to form an extraction organic phase; the extraction organic phase is uniformly mixed with a lithium salt solution, and a lithium-loaded organic phase is collected after extraction; an anode, a cathode, the anolyte, catholyte and an isolating membrane jointly form an electromigration system, wherein the anolyte is the obtained lithium-loaded organic phase, and the isolating membrane is arranged between the anolyte and the catholyte; and finally, the electromigration system is electrified to obtain < 6 > Li-enriched catholyte. According to the method, under the action of an electric field, the lithium isotope separation effect continuously exists, the enrichment limitation of the front end and the tail end of an ion migration flow does not exist, the isolation membrane is not subjected to saturation capacity limitation, meanwhile, all solution phases can be recycled, and the process is clean and environment-protecting; and in addition, the process has no special requirements on temperature, humidity, air and the like, and sealing is not needed.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

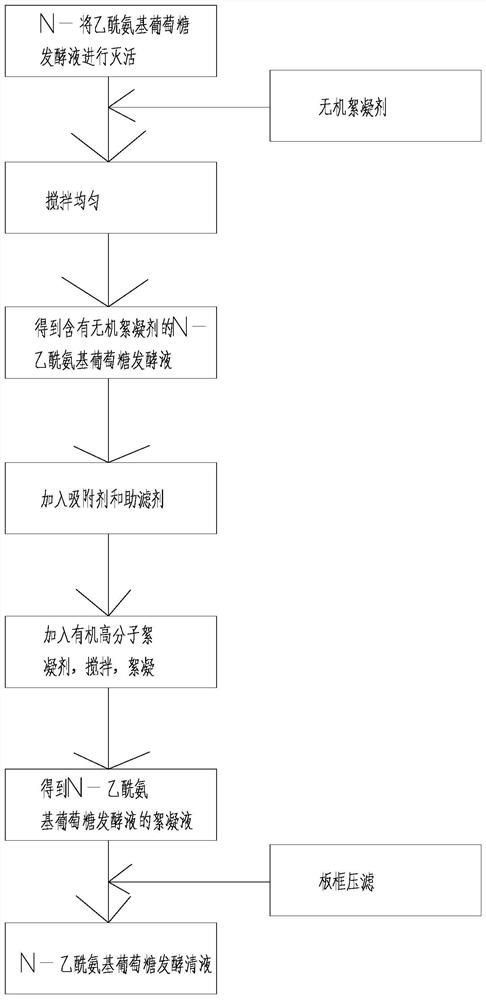

Method for preparing N-acetylglucosamine fermentation clear liquid by using composite flocculant

PendingCN113354698ADestabilizingGood flocculation effectSugar derivativesSugar derivatives preparationFlocculationSorbent

The invention relates to a method for preparing N-acetylglucosamine fermentation clear liquid by using a composite flocculant, and belongs to the field of bioengineering. The method comprises the following specific steps of: inactivating N-acetylglucosamine fermentation liquid; adding an inorganic flocculant, and stirring to obtain N-acetylglucosamine fermentation liquid containing the inorganic flocculant; adding an adsorbent and a filter aid, stirring, adding a prepared organic polymer flocculant, stirring uniformly, and standing for flocculation for 30-60 minutes to obtain a flocculation liquid of the N-acetylglucosamine fermentation liquid; and performing plate-frame pressure filtration to obtain the N-acetylglucosamine fermentation clear liquid. The flocculation impurity removal process has an obvious effect, the clear liquid obtained after plate-frame filtration has high yield, the water content of mushroom dregs is low, and the use amount of the flocculant is reduced by composite flocculation. The process is simple to operate, has no three-waste emission, and is an environment-friendly, simple and efficient method for preparing the acetylglucosamine fermentation clear liquid.

Owner:JIANGSU HEVI BIOTECH CO LTD

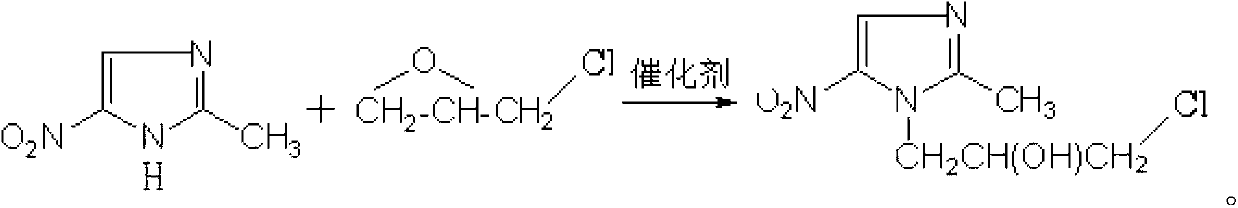

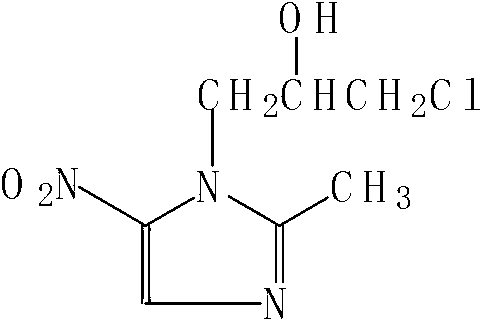

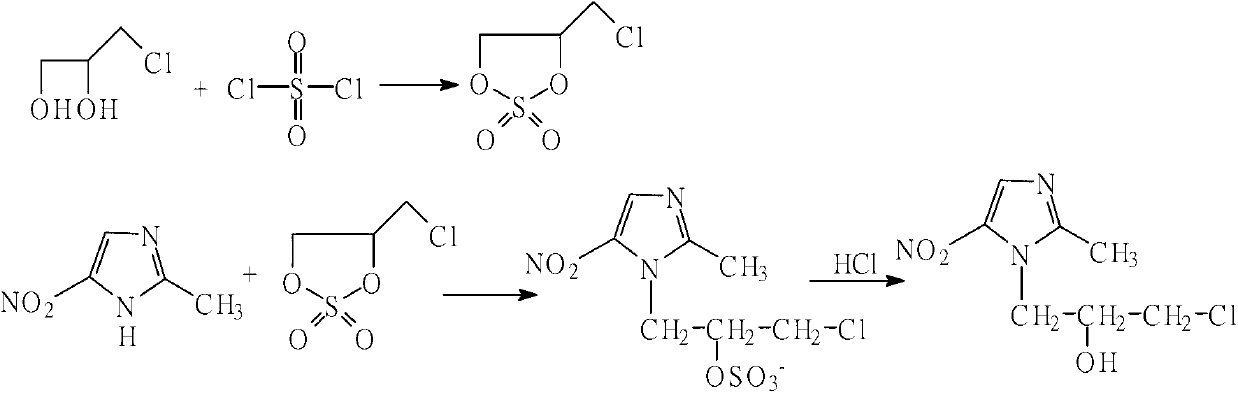

Ornidazole green synthetic method

InactiveCN103130721AHigh catalytic efficiencyLow costOrganic chemistryChemical recyclingNitroimidazoleDistillation

The invention discloses an ornidazole green synthetic method, which is characterized in that 2-methyl-5-nitroimidazole and chloropropylene oxide are taken as raw materials, ethyl acetate is taken as a solvent, macroporous acidic high-molecular resin is taken as a catalyst, chloropropylene oxide is catalyzed and is performed with ring opening, and is performed alkylation condensation with 2-methyl-5-nitroimidazole, the ornidazole crude product can be obtained by one step reaction, and a supernatant liquid obtained by centrifugal separation is an ornidazole condensation liquid; the supernatant liquid is separated to obtain a mother liquor containing a catalyst, the mother liquor containing the catalyst is activated, the catalyst can be reutilized; and the ornidazole condensation liquid is performed with the processes of distillation, residues decoloring, filtering crystallization and recentrifugation to obtain the ornidazole. The ornidazole green synthetic method has high catalytic efficiency, mild reaction and reduced cost, the preparation yield can be increased from 66% to 75%, and the environmental pollution of waste water containing aluminum salt can be avoided.

Owner:ZHEJIANG UNIV

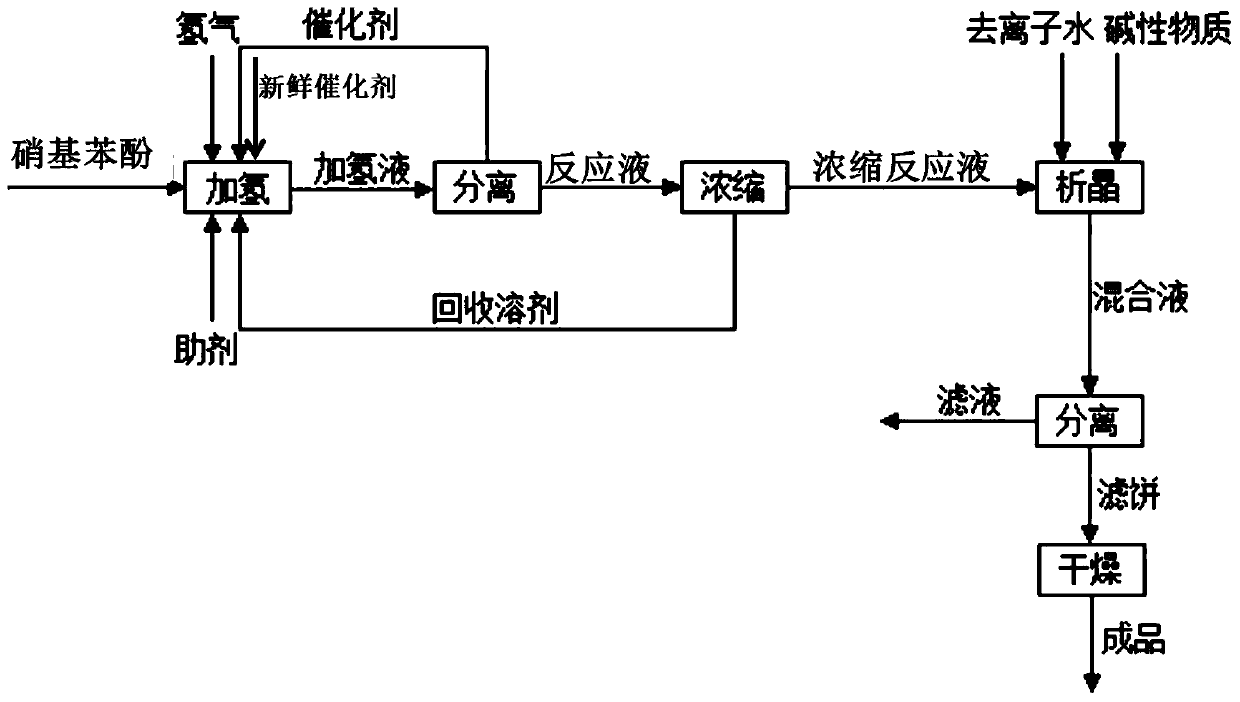

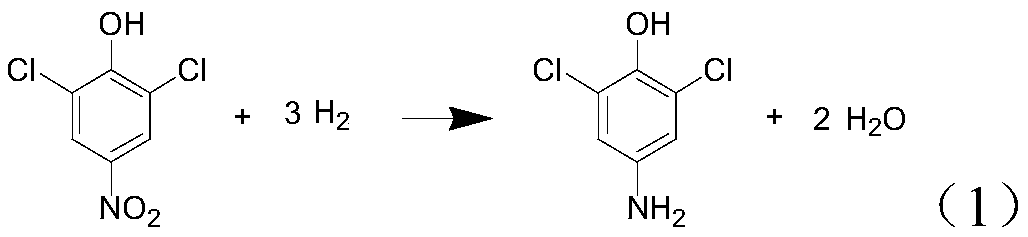

Synthesis method of aminophenol

PendingCN111302955ASimple post-processingLess side effectsOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolNitrobenzene

The invention provides a synthesis method of aminophenol. According to the method, by reacting nitrophenol with hydrogen under the conditions of an auxiliary agent and a solvent, an aminophenol product with high selectivity and yield can be prepared, the auxiliary agent can well control the reaction depth of nitrophenol and hydrogen, thereby inhibiting the side reaction, enhancing the purity of the final product, overcoming the problems of poor selectivity and high three-waste amount in the common hydrazine hydrate, sodium hydrosulfite and other reducing agents in the prior art, and having higher industrial application value.

Owner:JIANGSU YANGNONG CHEM GROUP +3

A method for treating coke oven gas desulfurization by-product sulfur paste

ActiveCN103264991BThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesCalcium/strontium/barium sulfatesResource utilizationImpurity

Owner:张建利

Beneficiation method for separating fluorite and tungsten through flotation

ActiveCN104084315BAvoid the problem of poor floatability and difficult flotation recoveryAvoid lostFlotationSulfidationTungsten

The invention discloses a beneficiation method for separating fluorite, white tungsten (black tungsten) and gangue minerals in complex polymetallic ore through flotation. Non-magnetic products of tailings subjected to sulphide ore flotation or tailings subjected to sulphide ore flotation and then subjected to strong magnetic separation for recycling black tungsten serve as two kinds of samples. The pH value is controlled by adding regulators, white tungsten, black tungsten, other gangue combined inhibitors and collectors are added, fluorite is subjected to differential flotation, then, tungsten minerals are subjected to flotation, and therefore fluorite and tungsten can be efficiently recycled. Loss of fluorite in tungsten flotation concentrate is avoided when tungsten minerals are subjected to differential flotation, and the defect that when tungsten flotation is performed, fluorite is difficult to recycle through flotation because the inhibitors have strong inhibition on fluorite, and beneficiation efficiency is low is avoided. Compared with a current beneficiation situation, the fluorite recycling rates of tests on the two different samples are increased by 39% to 48 % and 9% respectively, and the tungsten recycling efficiency is improved by 3%.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

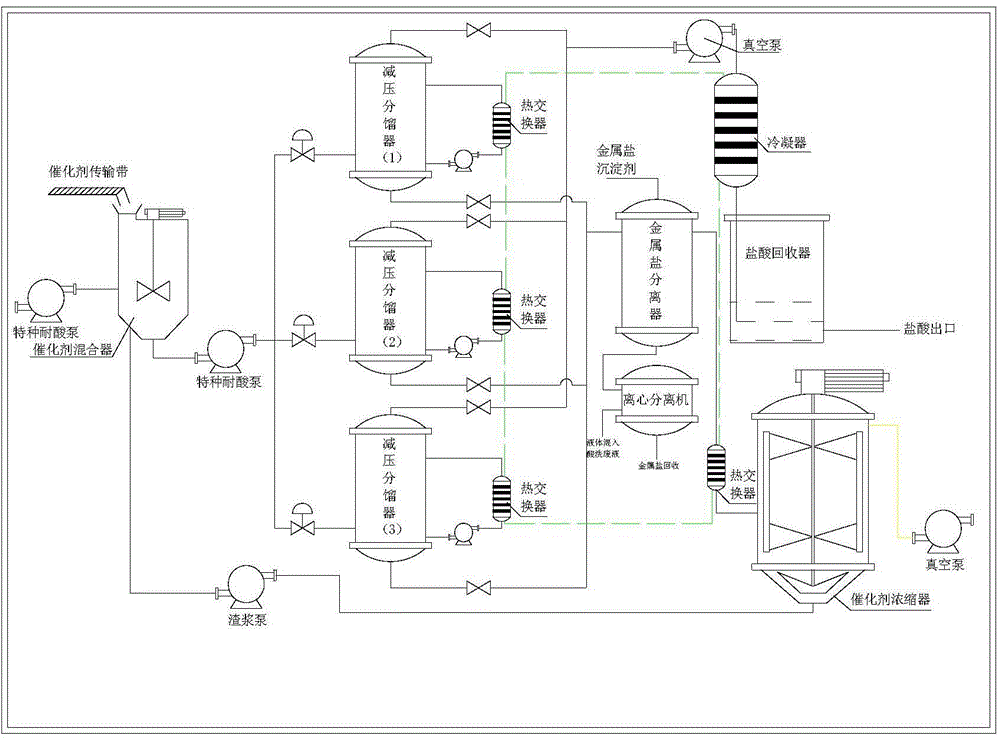

Method for treating pickling wastewater and recovering byproducts through reduced pressure and low temperature catalytic fractionation

InactiveCN105439362AIncrease profitIncrease added valueWaste water treatment from metallurgical processMultistage water/sewage treatmentTreatment costsCatalysis

The invention provides a method for treating pickling wastewater and recovering byproducts through reduced pressure and low temperature catalytic fractionation, belongs to the technical field of environmental protection, and especially relates to terminal treatment of wastewater containing hydrochloric acid and metal salts and recycling of wastes. The method comprises the following steps: 1, preparing a material: filtering the pickling wastewater to remove particles with large particle sizes, and fully mixing the filtered pickling wastewater with a catalyst in a mixing device until uniformity; 2, fractioning: pumping the obtained mixed solution to a low pressure fractioning device, and separating an acid solution at a low temperature under a low pressure; 3, separating metal salts: allowing the obtained residual liquid to enter a metal salt separation device, adjusting the pH value until the metal salts precipitate, and carrying out adsorbing separation by using a rotating magnetic disc; 5, carrying out solid-liquid separation: allowing slurry to enter a solid-liquid separation device, and dehydrating; and 5, carrying out catalyst concentration: allowing the obtained metal salt removed residual liquid to enter a concentration device, carrying out low temperature and low pressure concentration, and returning the obtained concentrated catalyst to make the catalyst participate in the reaction. The reduced pressure and low temperature catalysis method is adopted to treat the pickling wastewater, so the acid solution and metal salt recovery rate is improved, the treatment cost is reduced, and the present technological gaps in low-cost, high-efficiency and zero-pollution treatment of the pickling wastewater are filled.

Owner:TIANJIN TIANLIDA ENVIRONMENTAL PROTECTION TECH CO LTD

A method for preparing monophenolic compounds by microwave depolymerization of lignin

ActiveCN107337585BDepolymerization is fast and efficientIncrease profitOrganic chemistryOrganic compound preparationCarbide siliconDepolymerization

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com