Hydrofining technology of heavy benzol

A technology of hydrofining and heavy benzene, which is applied in the fields of hydrotreating process, petroleum industry, organic chemistry, etc. It can solve the problems of waste of aromatic resources, low added value, environmental pollution, etc., and achieve good product quality, high added value, The effect of not easy to coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

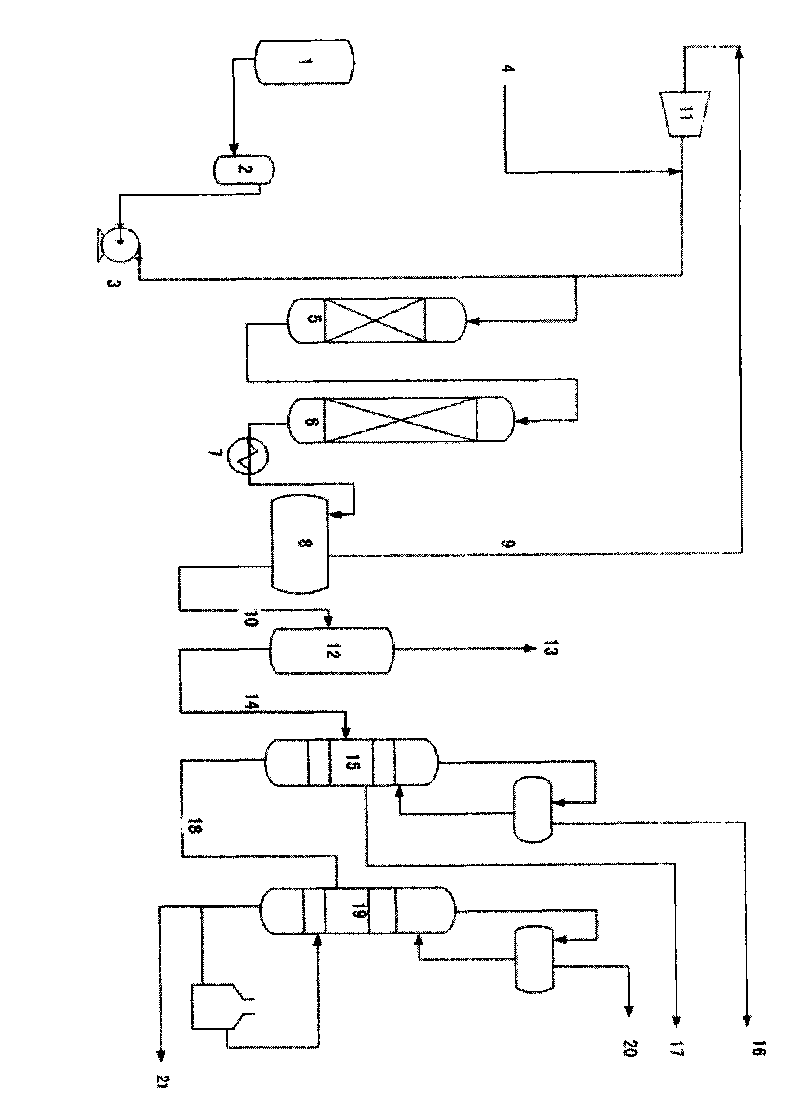

Image

Examples

Embodiment 1

[0020] A pickled heavy benzene is used as raw material 1, its properties are shown in Table 1, the reaction conditions of the pre-hydrogenation reactor are reaction temperature 180°C, reaction hydrogen partial pressure 2.0MPa, reaction hydrogen-oil ratio 200:1, reaction liquid hourly space velocity 0.5 h -1 ; The reaction conditions of the main hydrogenation reactor are reaction temperature 300°C, reaction hydrogen partial pressure 2.0MPa, reaction hydrogen oil ratio 200:1, reaction liquid hourly space velocity 0.5h -1 , see Table 1 for the properties of hydrogenated oil, Table 2 for the properties of solvent oil products, and Table 3 for the properties of industrial naphthalene products.

[0021] Table 1

[0022] Analysis Project

Heavy benzene raw material 1

Hydrogenated oil

Exterior

dark brown liquid

Colorless and transparent

Density at 20°C, kg / m 3 ,

971

968

Distillation range, ℃

96~266

95~265

Total...

Embodiment 2

[0029] A hydrogenated heavy benzene is used as raw material 2, its properties are shown in Table 4, the reaction conditions of the pre-hydrogenation reactor are reaction temperature 205°C, reaction hydrogen partial pressure 3.5MPa, reaction hydrogen-oil ratio 350:1, reaction liquid hourly space velocity 2.75 h -1 ; The reaction conditions of the main hydrogenation reactor are reaction temperature 330°C, reaction hydrogen partial pressure 3.5MPa, reaction hydrogen oil ratio 350:1, reaction liquid hourly space velocity 2.75h -1 , see Table 4 for the properties of hydrogenated oil, see Table 5 for the properties of solvent oil products, and see Table 6 for the properties of industrial naphthalene products.

[0030] Table 4

[0031] Analysis Project

[0032] Analysis Project

[0033] table 5

[0034] project

[0035] Table 6

[0036] project

[0037] project

Embodiment 3

[0039] A mixed heavy benzene prepared by acid-washed heavy benzene and hydrogenated heavy benzene in a weight ratio of 1:1 is used as raw material 3, its properties are shown in Table 7, and the reaction conditions of the pre-hydrogenation reactor are reaction temperature 230 ° C, reaction hydrogen partial pressure 5.0MPa, reaction hydrogen oil ratio 500:1, reaction liquid hourly space velocity 5.0h - ;The reaction conditions of the main hydrogenation reactor are reaction temperature 360°C, reaction hydrogen partial pressure 5.0MPa, reaction hydrogen oil ratio 500:1, reaction liquid hourly space velocity 5.0h -1 , see Table 7 for the properties of hydrogenated oil, see Table 8 for the properties of solvent oil products, and see Table 9 for the properties of industrial naphthalene products.

[0040] Table 7

[0041] Analysis Project

Heavy benzene raw material 3

Hydrogenated oil

Exterior

dark brown liquid

Colorless and transparent

Density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com