High-temperature resisting heat conductive oil

A technology of heat-conducting oil and high-temperature resistance, which is applied in the petroleum industry, heat exchange materials, chemical instruments and methods, etc. It can solve the problems of high equipment consumption, low life of high-temperature-resistant heat-conducting oil, and inability to recycle for a long time, so as to achieve the service life Prolonged, not easy to coke, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

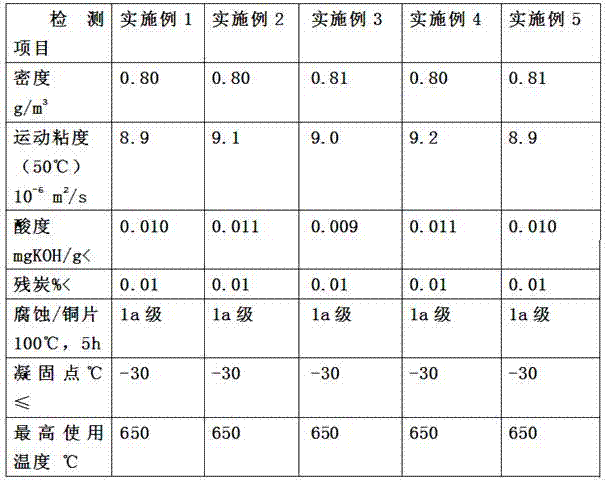

Examples

Embodiment 1

[0025] 1) Weigh 80 parts of base oil, 1 part of detergent, 5 parts of dispersant, 5 parts of high temperature antioxidant, 1 part of coking inhibitor, 1 part of pour point depressant, 1 part of viscosity reducer, metal deactivator 1 part; wherein, the base oil is a refined hydrogenated base oil, the acid value of the refined hydrogenated base oil is 340°C.

[0026] Wherein, the detergent includes high alkali value linear alkylbenzene synthetic calcium sulfonate and high alkali value sulfurized calcium phenate calcium. The dispersant is a mixture of high molecular weight succinimide and boronated high molecular weight polyisobutenyl succinimide, and the mass ratio of high molecular weight succinimide to boronated high molecular weight polyisobutenyl succinimide is 1:5. High temperature antioxidants include 2,6-di-tert-butyl-α-dimethylamino-p-cresol. The pour point depressants include polyoxyethylene sorbitan monolauryl, alkyl acrylate polymers, blends of alpha-olefins and m...

Embodiment 2

[0030] 1) Weigh 95 parts of base oil, 1.1 parts of detergent, 5.3 parts of dispersant, 6.8 parts of high temperature antioxidant, 1.3 parts of scorch inhibitor, 1.3 parts of pour point depressant, 1.3 parts of viscosity reducer, metal deactivator 1.1 parts; Among them, the base oil is a refined hydrogenated base oil, the acid value of the refined hydrogenated base oil is 340°C.

[0031] Among them, the detergent is calcium sulfate alkylphenate with high alkali value. The dispersant is a mixture of high molecular weight succinimide and boronated high molecular weight polyisobutenyl succinimide, and the mass ratio of high molecular weight succinimide to boronated high molecular weight polyisobutenyl succinimide is 1:5. The high-temperature antioxidant is a mixture of thionyl octyl zinc salt, zinc sulfide carbamate, and alkyl diphenylamine. The pour point depressant is a mixture of polyoxyethylene sorbitan monolauryl ester, polymethacrylate, and ethylene-vinyl acetate copolym...

Embodiment 3

[0035] 1) Weigh 98 parts of base oil, 1.3 parts of detergent, 5.5 parts of dispersant, 8.9 parts of high temperature antioxidant, 1.5 parts of coking inhibitor, 1.6 parts of pour point depressant, 1.5 parts of viscosity reducer, metal deactivator 1.3 servings. ; Among them, the base oil is refined hydrogenated base oil, the acid value of the refined hydrogenated base oil is 340°C .

[0036] Wherein, the detergent includes magnesium overbase value sulfonate. The dispersant is a mixture of high molecular weight succinimide and boronated high molecular weight polyisobutenyl succinimide, and the mass ratio of high molecular weight succinimide to boronated high molecular weight polyisobutenyl succinimide is 1:5. The high-temperature antioxidant is a mixture of 2,6-di-tert-butyl-α-dimethylamino-p-cresol and thionyl octyl zinc salt. The pour point depressant is a mixture of polyoxyethylene sorbitan monolauryl ester, alkyl acrylate polymer, α-olefin and maleic anhydride copolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com