Sludge scraping assembly

An assembly and mud scraper technology, applied in the field of sewage treatment, can solve problems such as potential safety hazards, waste of manpower, and influence on sedimentation effects, and achieve the effects of increasing resistance, avoiding agitation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

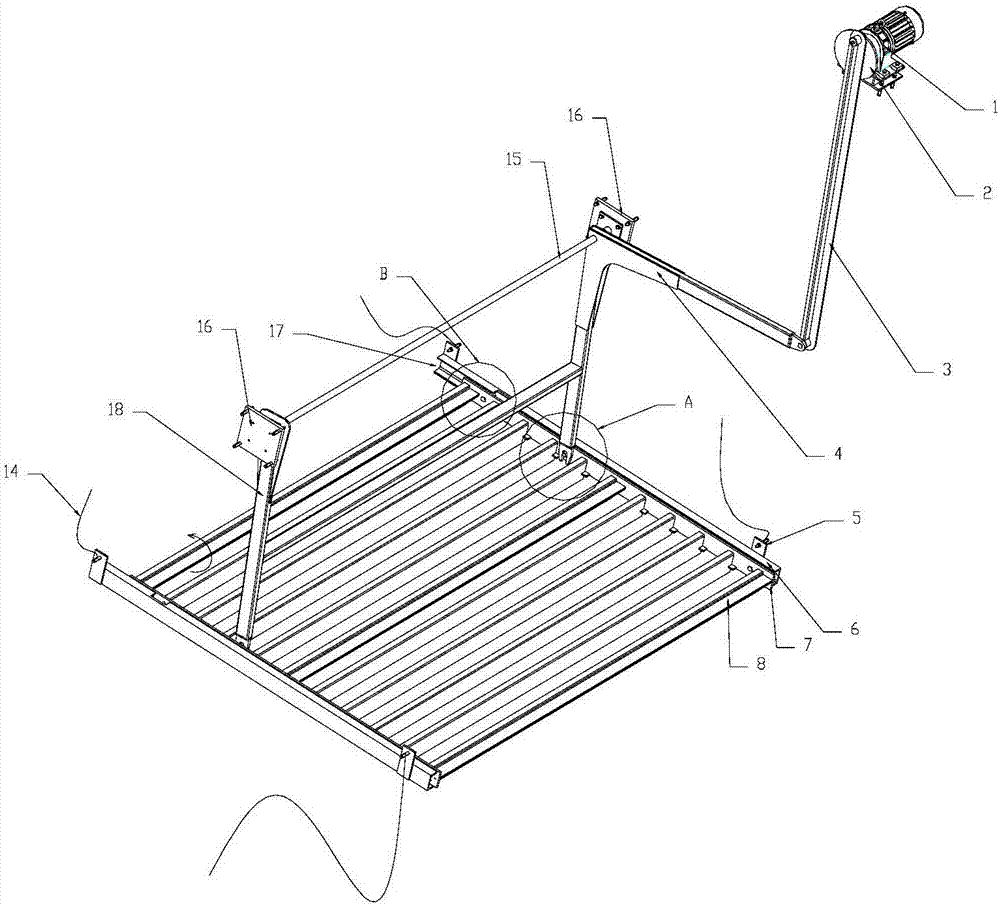

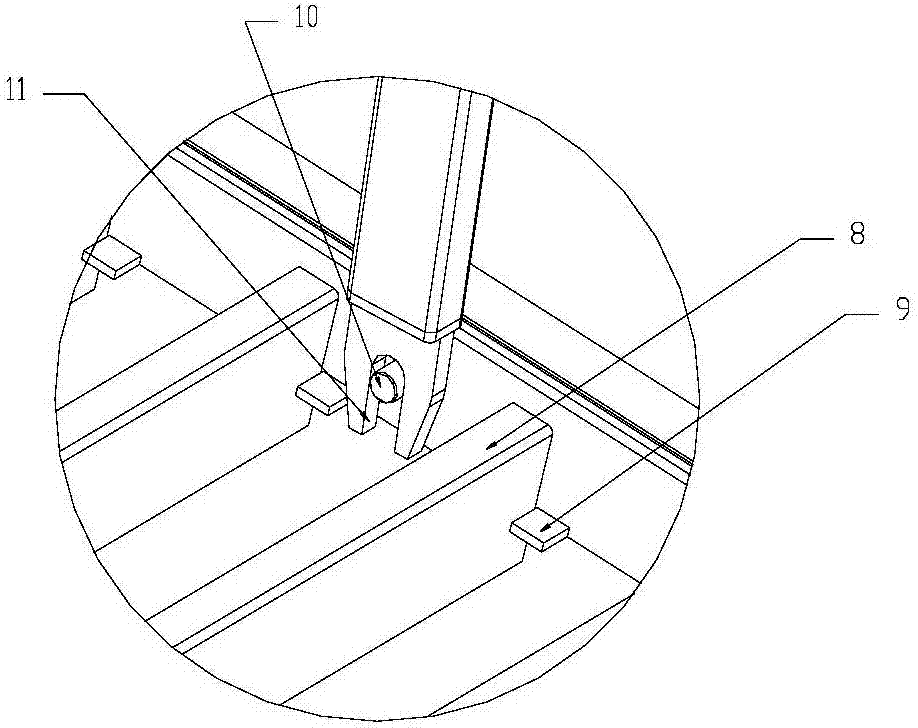

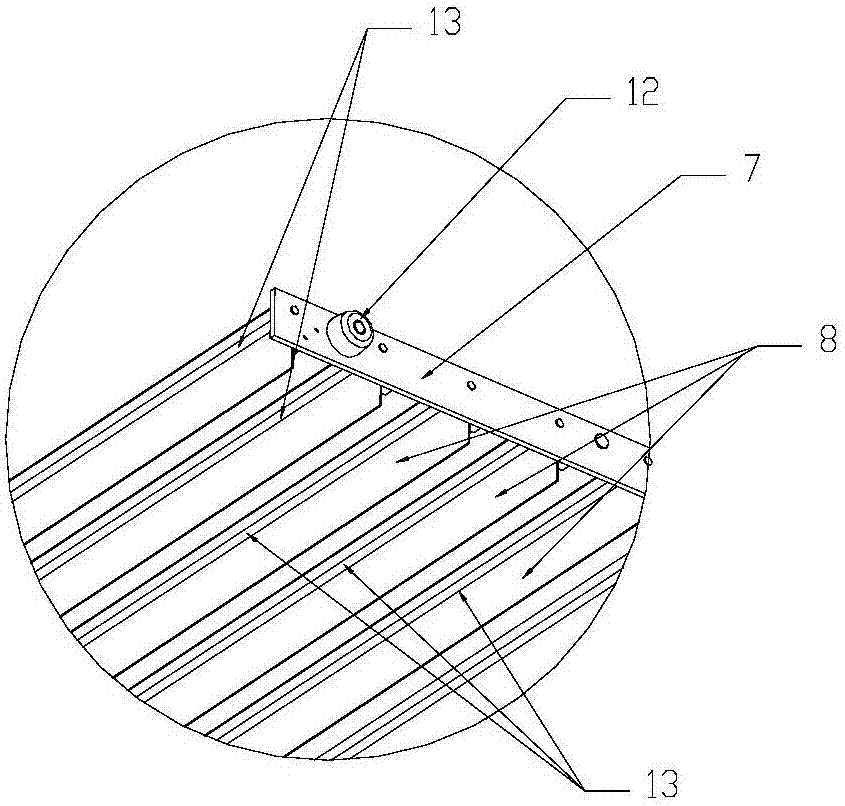

[0018] As shown in the figure: the mud scraping assembly in this embodiment includes a mud scraping assembly for scraping the sludge at the bottom of the sedimentation tank and a drive assembly for driving the mud scraping assembly to reciprocate back and forth; the mud scraping assembly includes a mud scraper 8 and the sliding plate 7 arranged at both ends of the mud scraper 8, the two ends of the mud scraper 8 are respectively connected to the sliding plate 8 with a single degree of freedom of rotation, and the sliding plate 7 is provided with a Carry out the spacer 9 of space-limiting during the state. The single-degree-of-freedom rotational connection can be realized as follows: the support shaft 13 is fixed on the mud scraper 8 , and a round hole for containing the support shaft 13 is provided on the sliding plate 7 . Of course, it can also be set in reverse, and a round hole is set on the mud scraper 8, and a support shaft 13 is set on the slide plate 7. When sliding pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com