Drossing mud scraper

A mud scraper and mud scraper technology, which is applied to chemical instruments and methods, separation methods, sedimentation separation, etc., can solve the problems of destroying the sedimentation effect and the non-working state of the mud scraper, so as to avoid being agitated and improve sewage treatment Effect of quality, improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

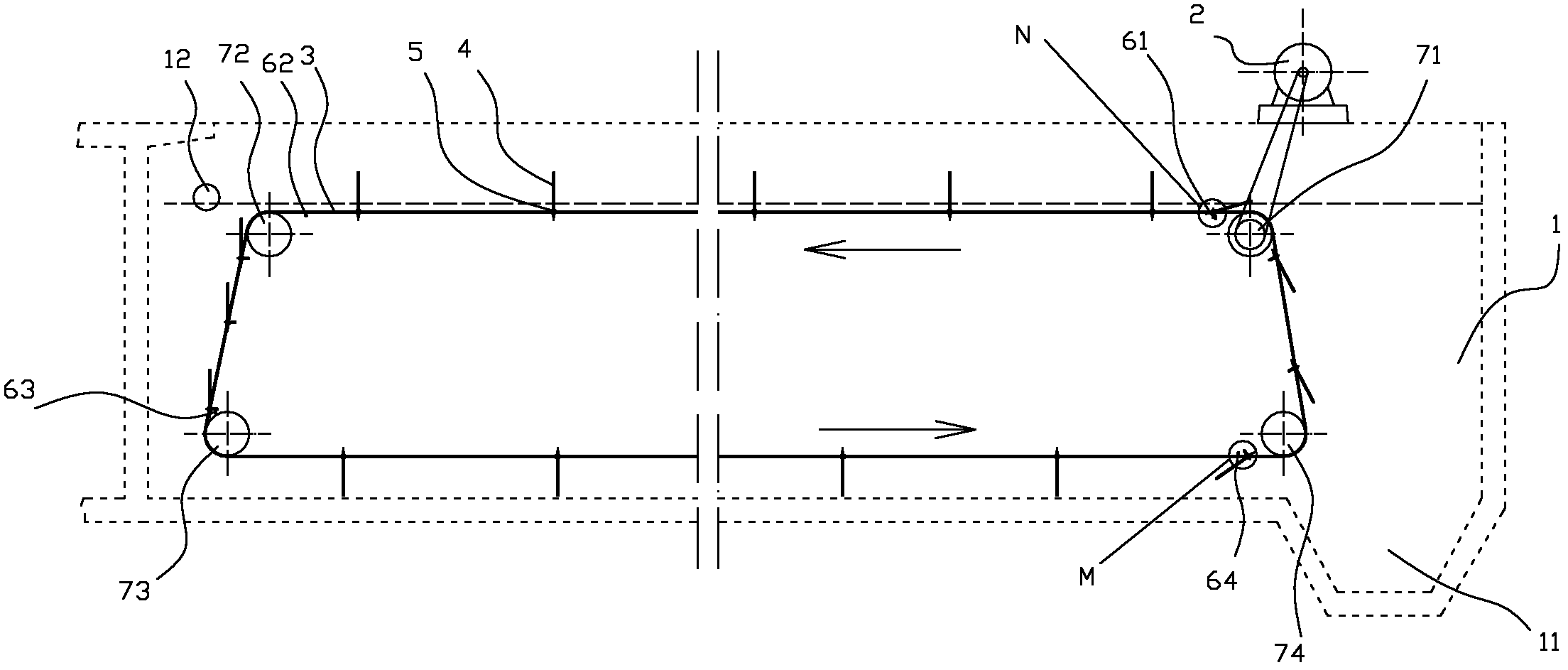

[0032] The present invention as Figure 1-4 As shown, it is arranged in the sedimentation tank 1, including the driving motor 2, the first pulley 71 and the second pulley 72 arranged at both ends below the liquid level in the sedimentation tank 1 (wherein the second pulley 72 is located near the slag outlet 12 , which is convenient for the scraper 4 to run in the upper horizontal section, and scrape the froth to this point); the pulley three 73 and the pulley four 74 located at both ends of the bottom surface of the sedimentation tank 1 (the pulley four 74 is located at the pulley one 71 Below, at the position close to the sludge tank 11, it is convenient to push the sludge scraped here by the scraper 4 into the sludge tank 11), a pair of running belts 3, several pieces connected between the pair of running belts 3 scraper 4,

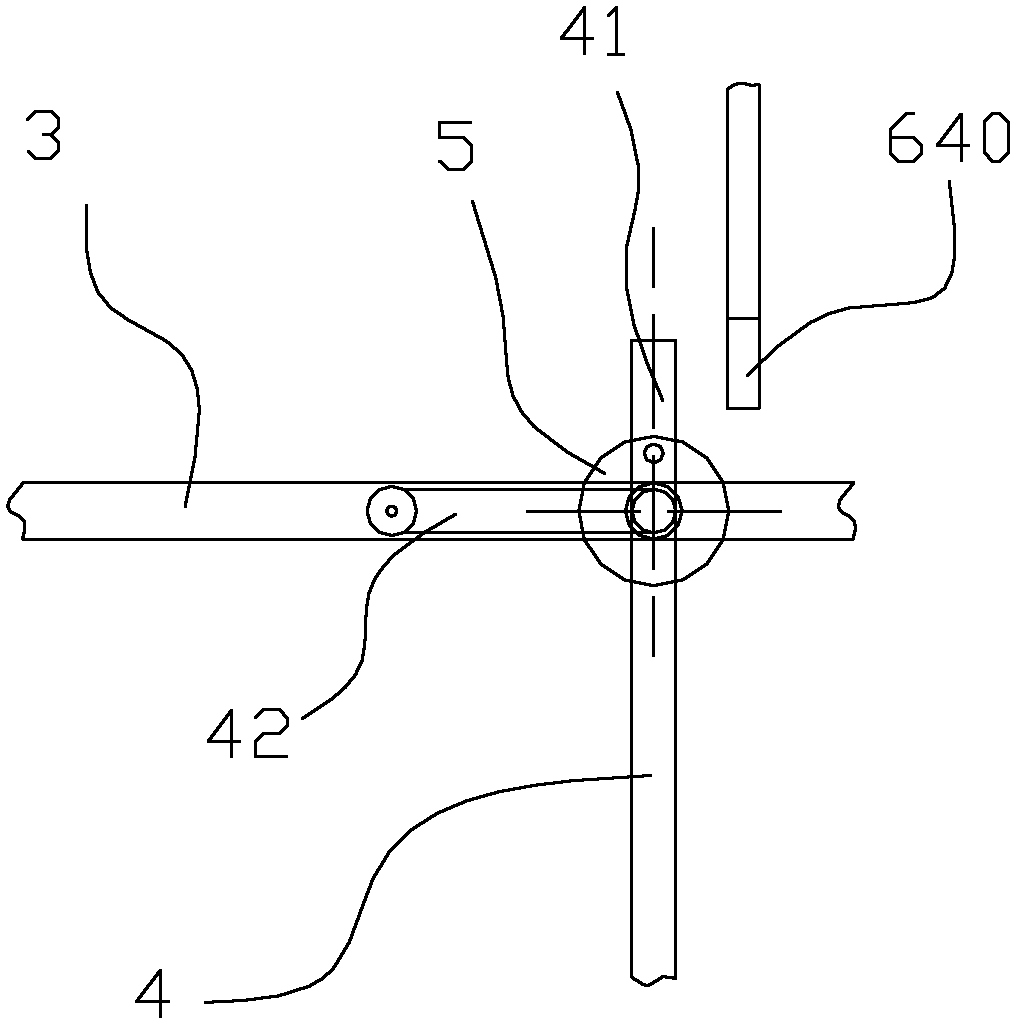

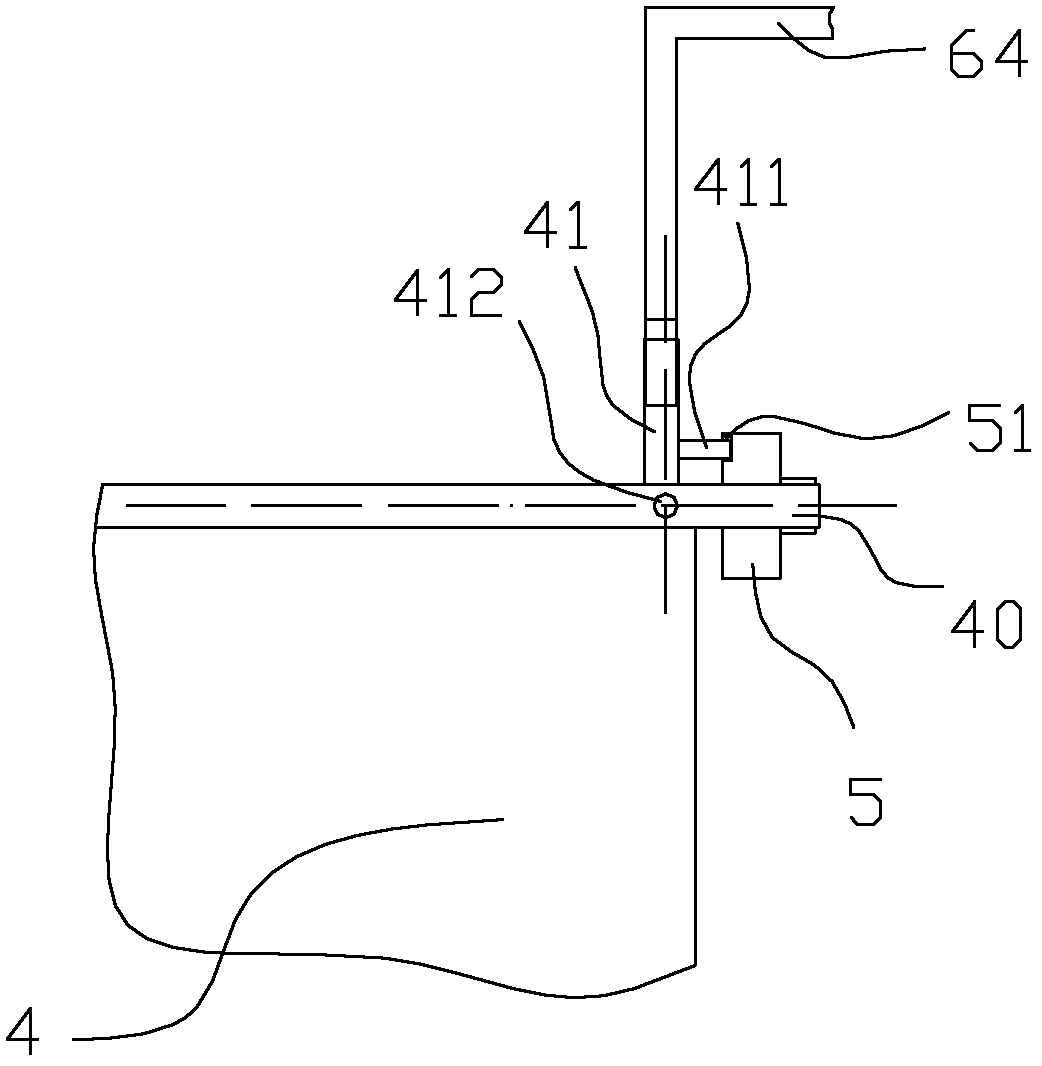

[0033] The mud scraper 4 is connected to the running belt 3 through an opening and closing device, and a plywood block is arranged at the front end or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com