Device and method for separating and recovering cutting fluid and iron filings

A technology for separation and recovery of cutting fluid, applied in separation methods, precipitation separation, chemical instruments and methods, etc., can solve the problems of low recovery efficiency, polluted cutting fluid, and large cutting impact, achieve high utilization rate, reduce work intensity, The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

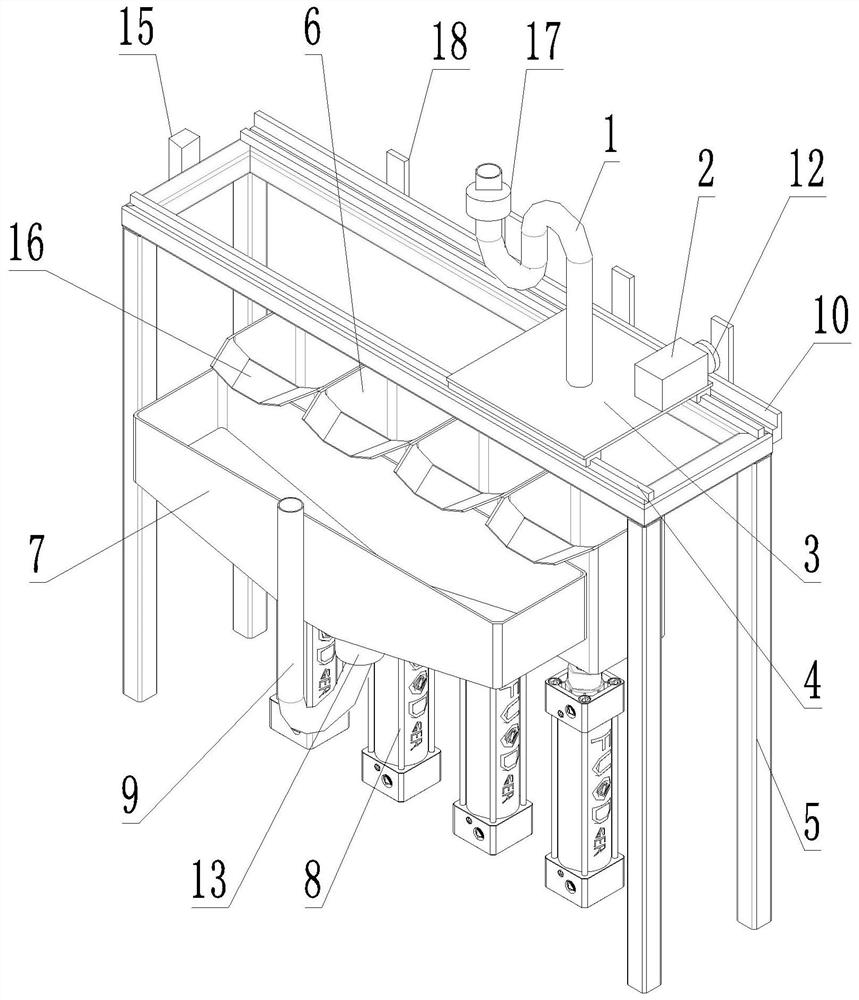

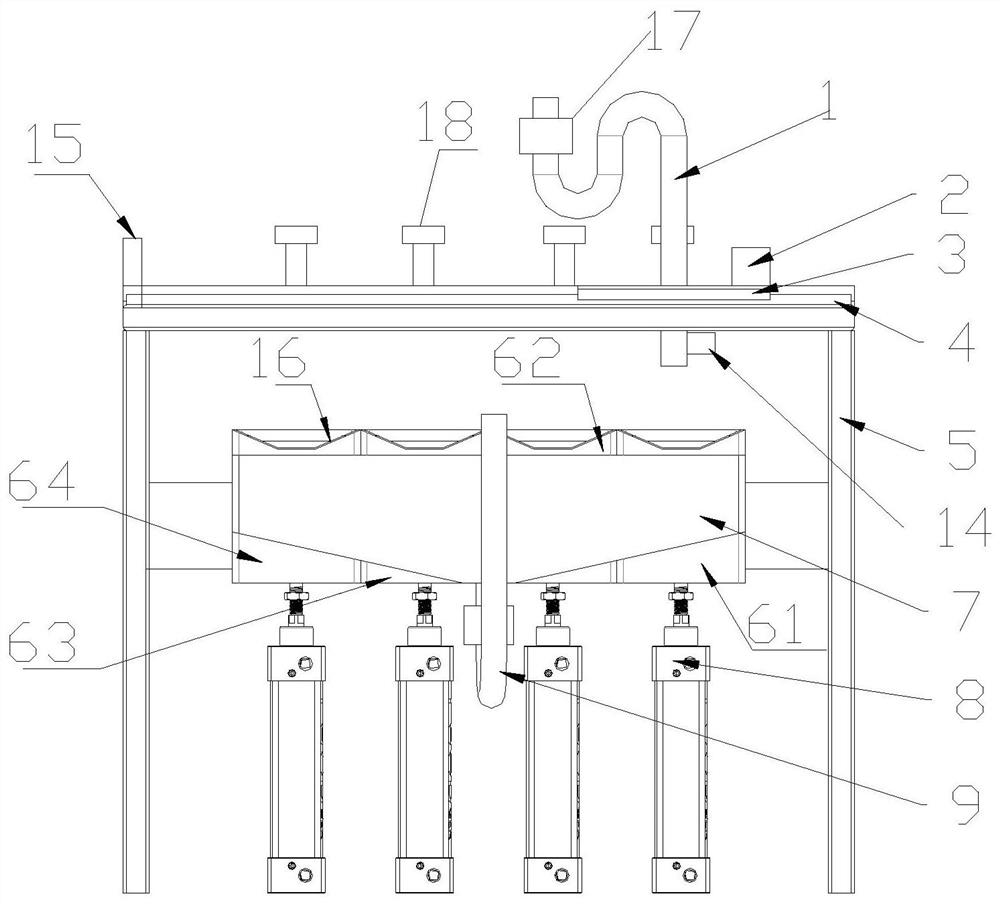

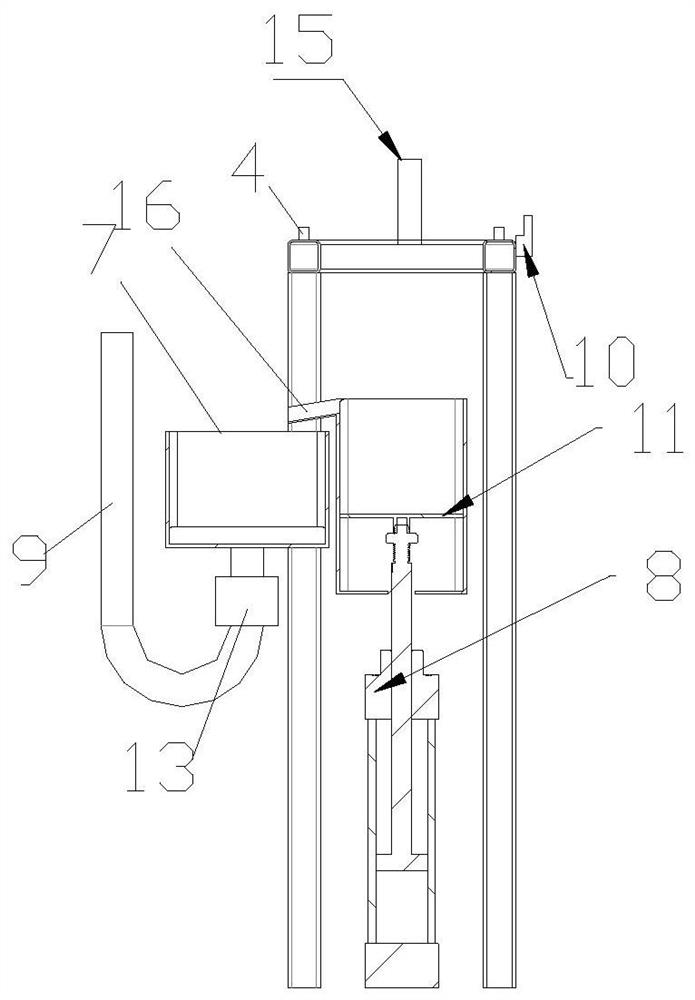

Embodiment 1

[0032] like Figure 1-3 As shown in the figure, a cutting fluid and iron filings separation and recovery device proposed in this embodiment includes a frame body 5, the top of the frame body 5 is provided with a slide rail 4, and the slide rail 4 is matched with a collection tube that moves along the slide rail 4. 1. A solenoid valve 17 is provided on the collecting pipe 1, and the collecting pipe 1 is connected with a driving mechanism for driving the moving of the collecting pipe 1; On the sliding plate 3, and the bottom end of the collecting pipe 1 penetrates the sliding plate 3; the sliding plate 3 is connected with the motor 2, the drive shaft of the motor 2 is connected with a gear 12, the gear 12 is meshed with a rack 10, and the rack 10 is fixedly connected to the frame At the top of the body 5, when in use, the motor 2 rotates to drive the gear 12 to rotate, and the rotation of the gear 12 will move along the rack 10, thereby driving the collection tube 1 to move left...

Embodiment 2

[0058] like Figure 4-5 As shown in the figure, other structures are the same as the first embodiment, the difference is that in this embodiment, the sedimentation tank 6 is not fixedly connected with the frame body 5, and the collection groove 7 can be directly connected with the frame body 5, or can be connected to the frame body 5 through a column or the like The structure is supported on the ground to realize the fixation of the collection tank 7, which is a conventional setting and will not be described again; a plurality of sedimentation tanks 6 arranged at intervals are arranged side by side below the bottom port of the collection pipe 1, and the outer wall of the sedimentation tank 6 is provided with The sliding column 21 is provided with an arc-shaped guide rail 19 on both sides of each sedimentation tank 6. The arc-shaped guide rail can be fixed on the ground or on the frame body. In the groove 20; the sedimentation groove 6 can slide along the arc guide 19.

[0059...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com