A slurrying method of a mixed cathode material

A technology of mixing positive electrode materials and pulping, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problem of not meeting the requirements of battery energy density and cycle life, affecting the uniformity of the active material layer, and affecting the performance of the positive electrode of the coating process and other problems, to achieve the effect of avoiding slurry settlement, avoiding settlement, good dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

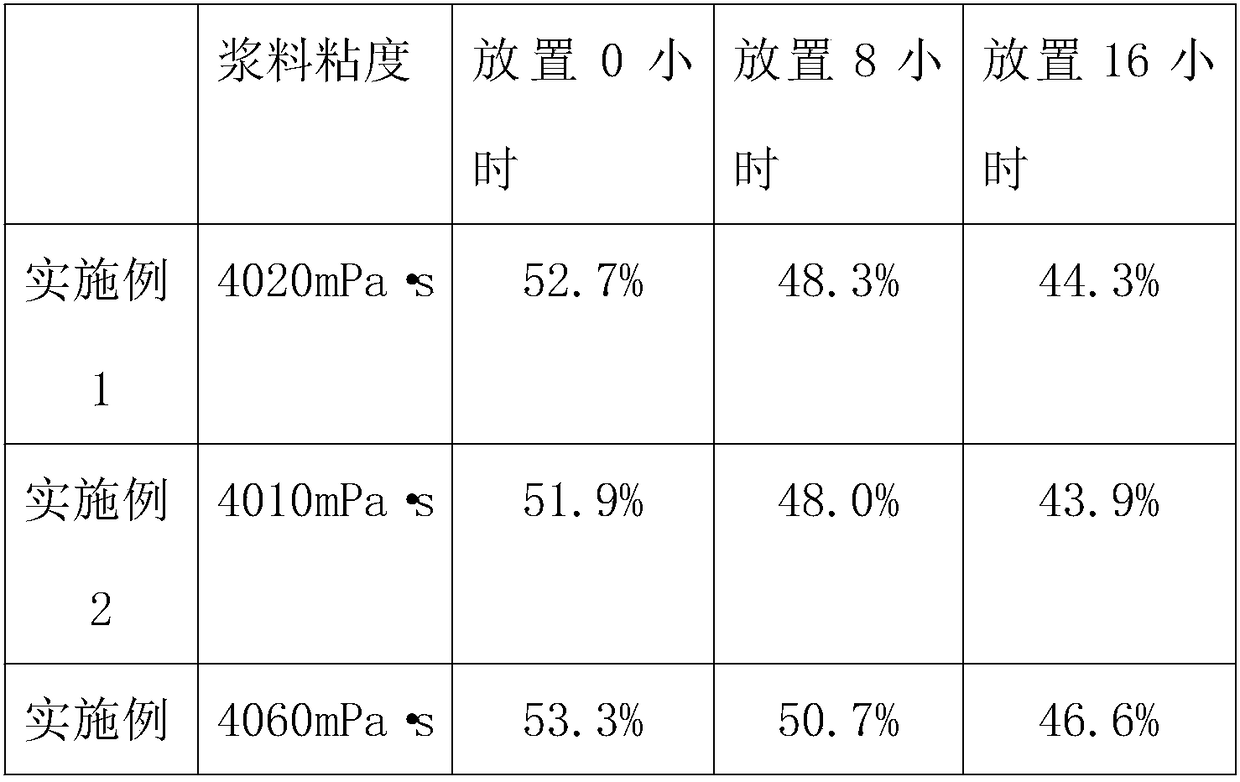

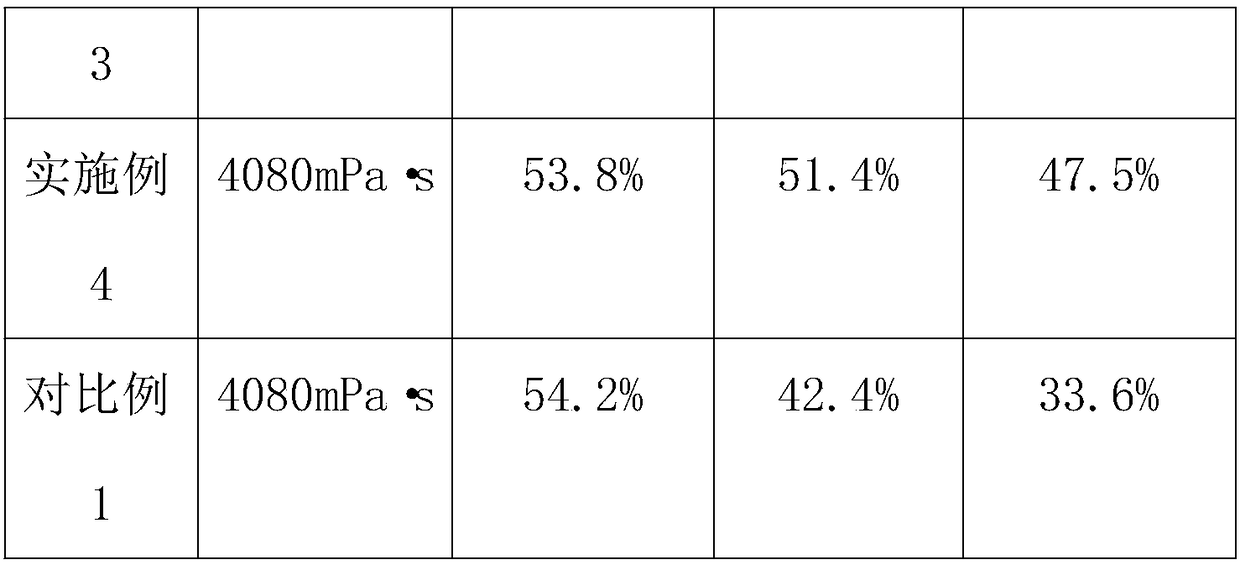

Examples

Embodiment 1

[0025] 1), providing lithium iron phosphate with a first particle size, the first particle size is 50nm; mixing lithium iron phosphate and Super P according to a mass ratio of 100:5, and ball milling for 6 hours; the ball-to-material ratio of ball milling is 4:1 , the rotating speed of the ball mill is 150r / min;

[0026] 2), add the solvent into the first stirred tank, keep the temperature in the stirred tank at 45°C, add carboxymethyl cellulose sodium into the first stirred tank, stir for 5h, then add carboxymethyl cellulose Sodium, stir for 2h, add the product of step 1, stir for 2h, then vacuumize and stir for 4h to obtain the first slurry, wherein the mass ratio, the lithium iron phosphate: Super P: PVDF: sodium carboxymethylcellulose=100: 5:5:4;

[0027] 3) Provide lithium cobaltate with a second particle size of 0.5 μm; add the solvent to the second stirred tank, keep the temperature in the stirred tank at 30°C, and add PVDF to the second stirred tank In the second sti...

Embodiment 2

[0031] 1), providing lithium iron phosphate with a first particle size, the first particle size being 150nm; mixing lithium iron phosphate and Super P according to a mass ratio of 100:3, and ball milling for 4 hours; the ball-to-material ratio of ball milling is 3:1 , the rotating speed of the ball mill is 100r / min;

[0032] 2) Add the solvent into the first stirred tank, keep the temperature in the stirred tank at 35°C, add carboxymethyl cellulose sodium into the first stirred tank, stir for 3 hours, then add carboxymethyl cellulose Sodium, stir for 1h, add the product of step 1, stir for 1h, then vacuumize and stir for 3h to obtain the first slurry, wherein the mass ratio, the lithium iron phosphate: Super P: PVDF: sodium carboxymethylcellulose=100: 3:3:2;

[0033] 3) Provide lithium cobaltate with a second particle size of 2 μm; add the solvent to the second stirred tank, keep the temperature in the stirred tank at 20°C, and add PVDF to the second stirred tank In the stir...

Embodiment 3

[0037] 1), providing lithium iron phosphate with a first particle size, the first particle size is 100nm; mixing lithium iron phosphate and Super P according to a mass ratio of 100:4, and ball milling for 5 hours; the ball-to-material ratio of ball milling is 4:1 , the rotating speed of the ball mill is 120r / min;

[0038]2) Add the solvent into the first stirred tank, keep the temperature in the stirred tank at 40°C, add sodium carboxymethyl cellulose into the first stirred tank, stir for 4 hours, then add carboxymethyl cellulose Sodium, stir for 2h, add the product of step 1, stir for 2h, then vacuumize and stir for 3h to obtain the first slurry, wherein the mass ratio, the lithium iron phosphate: Super P: PVDF: sodium carboxymethylcellulose=100: 4:4:3;

[0039] 3) Provide lithium cobalt oxide with a second particle size, the second particle size is 1 μm; add the solvent into the second stirred tank, keep the temperature in the stirred tank at 25°C, and add PVDF into the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com