Variable displacement gerotor pump

a gerotor pump and variable displacement technology, applied in the field of oil pumps, can solve the problems of narrow tolerance design, excessive oil pressure at higher engine speeds, and hinder the operation of the valve or destroy the valve, so as to reduce the amount of oil pumped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described as being implemented for use in an engine to, for example, pump oil; however, it is clearly contemplated that the present invention may be incorporated into other systems and may be used to pump other fluids as known to one of ordinary skill in the art. The present invention advantageously responds to increasing fluid pressure by reducing output flow. For example, the higher the oil pressure, the lower the rate of pumping of the fluid of the present invention.

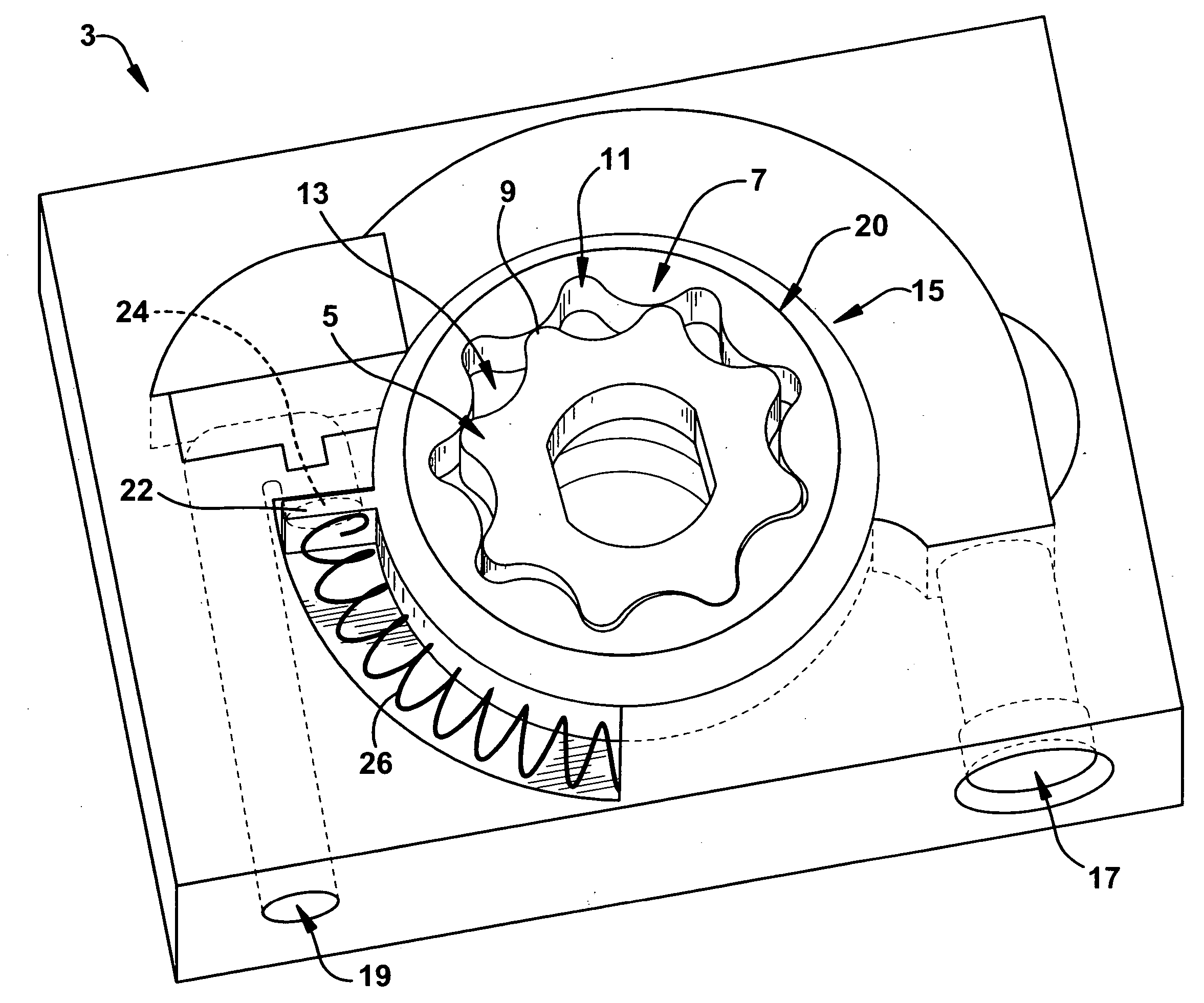

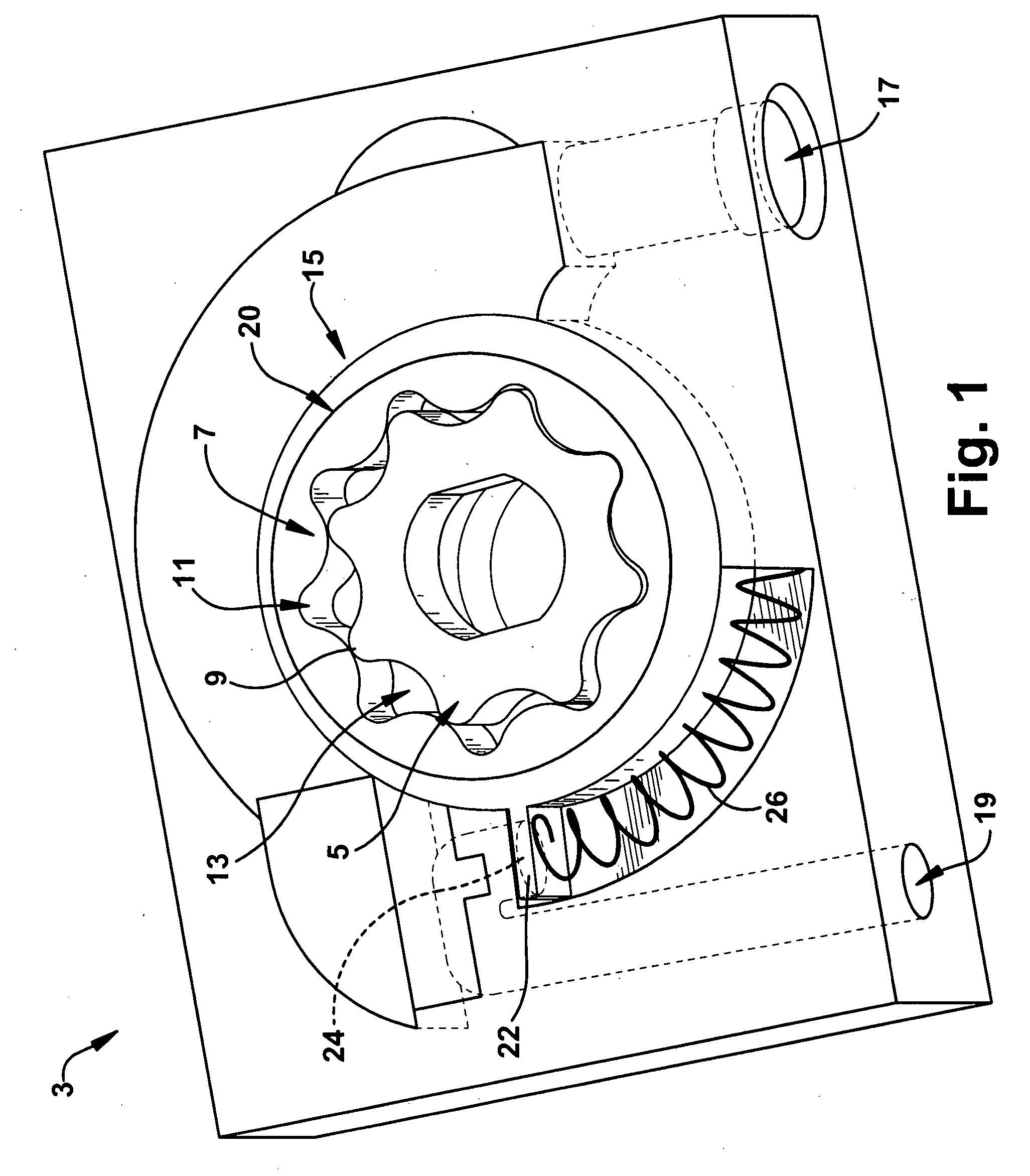

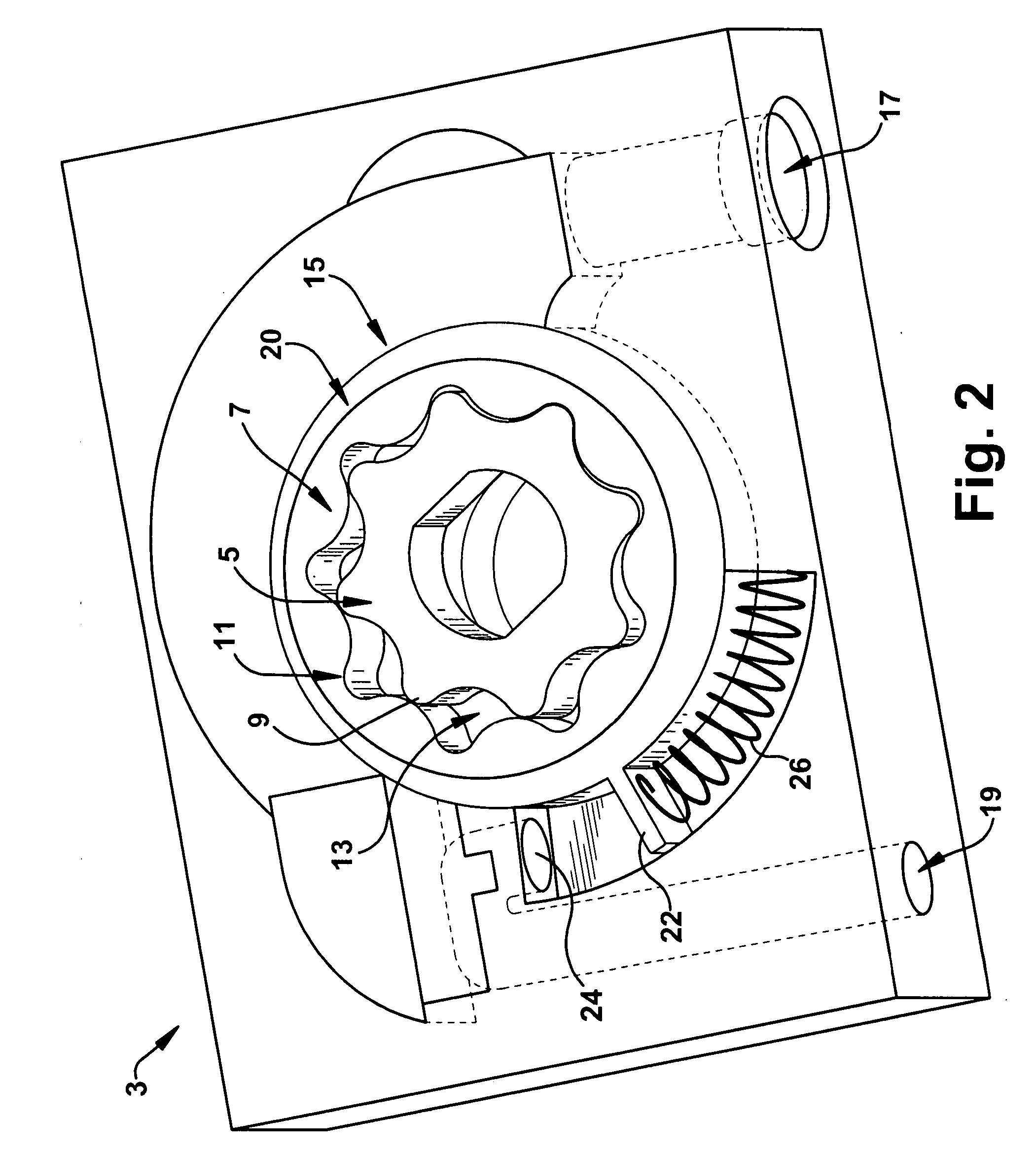

[0022] As illustrated in FIGS. 1 and 2, a variable displacement pump 3, such as a gerotor pump, may have an inner rotor 5 (or gerotor) in meshed engagement with an outer rotor 7. The inner rotor 5 may rotate with respect to the outer rotor 7. For example, the inner rotor 5 may rotate in a counterclockwise direction. Of course, the present invention could be implemented such that the gerotor 5 rotates in a counterclockwise direction or other direction as will be appreciated by one of or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com