Screw type efficient oil pumping device

A spiral, oil pumping technology, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc., can solve the problem that the oil pumping efficiency cannot meet the demand, and the vibration caused by hitting the sliding sleeve; at the same time, the reverse check valve part , waste of time and other issues, to achieve the effect of saving working time, saving working time, and enhancing pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to to limit the present invention.

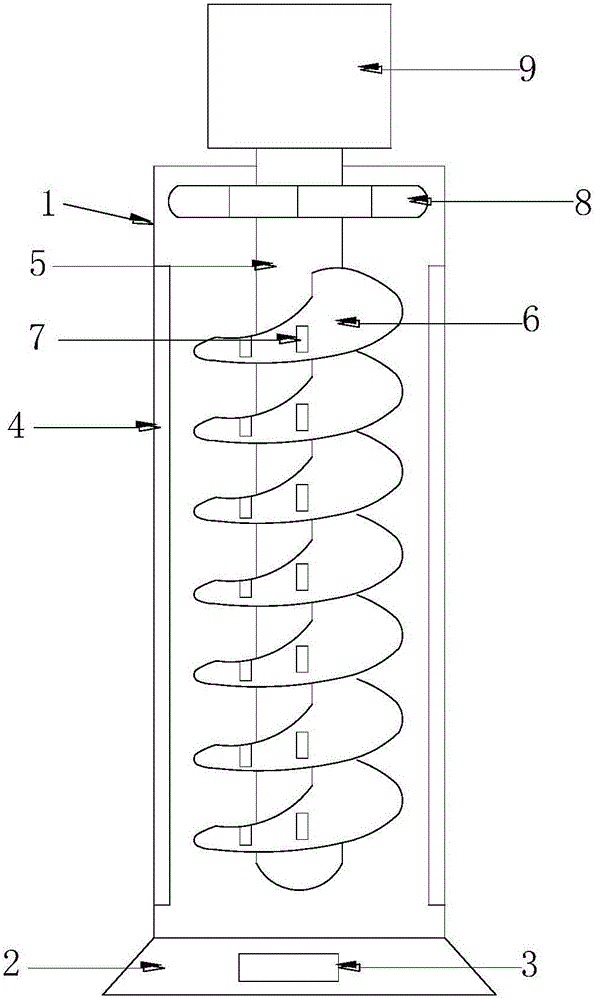

[0021] see figure 1 , a spiral type synergistic oil pumping device, including a casing 1, an oil collecting cover 2, a detection sensor 3, a main shaft 5, a spiral blade 6, an air plate 7, an air suction device 8 and a rotating motor 9;

[0022] The shell 1 is a cylindrical structure, and the bottom of the shell 1 is equipped with an oil collecting cover 2. The section of the oil collecting cover 2 is a symmetrical trapezoidal structure whose top is narrower than the bottom. It is a patch type temperature sensor, a rotating motor 9 is installed on the top of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com