Turbine generator set oil pipeline half-outside oil circulation system

A turbogenerator and circulation system technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as filter clogging, bearing damage, and rapid deterioration of oil quality, and meet the needs of large flushing flow, The effect of saving construction period cost and washing thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

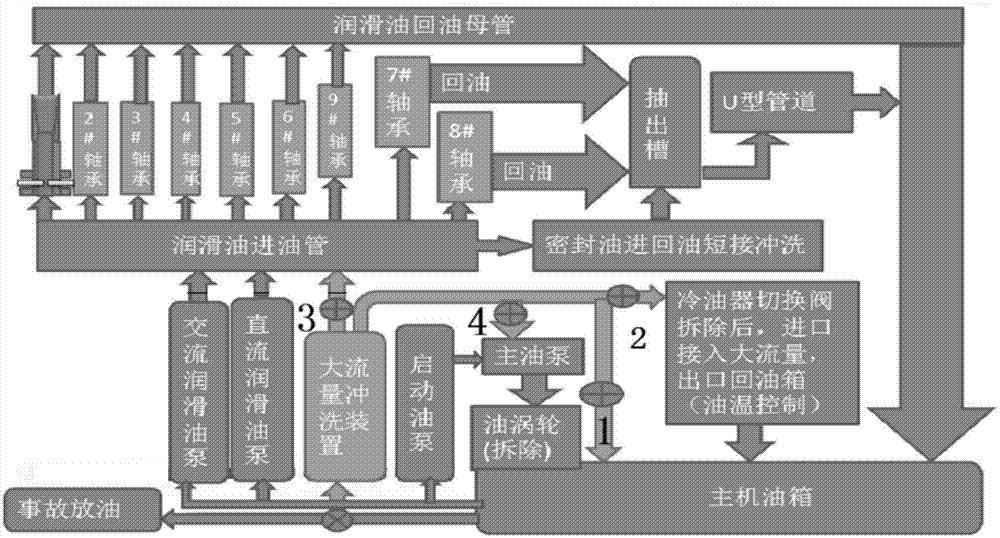

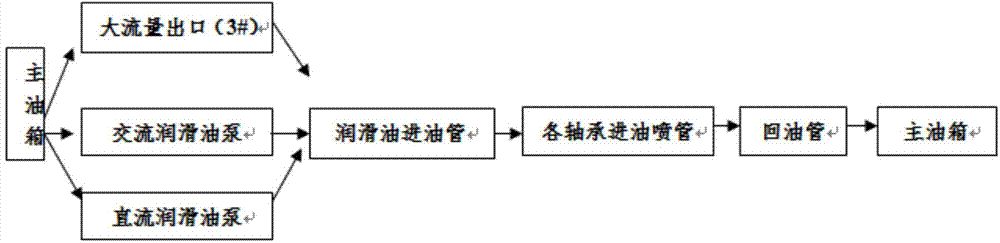

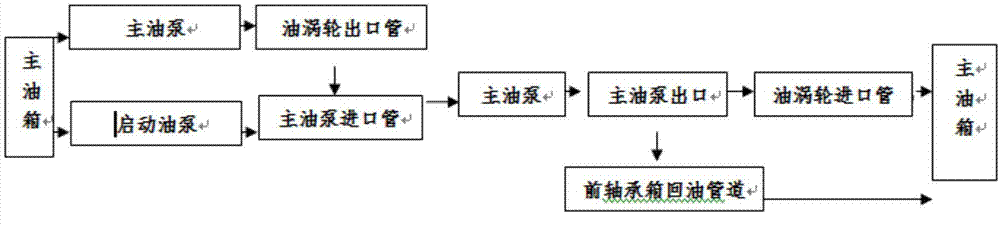

[0015] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a semi-external oil circulation system of a steam turbine generator set oil pipeline, which comprises a main engine oil tank, an engine oil delivery part connected with the main engine oil tank, and a lubricating part connected with the engine oil delivery part. The lubricating part includes the lubricating oil inlet pipe, the parts to be lubricated connected with the lubricating oil inlet pipe, the lubricating oil return main pipe connected to the lubricating parts, and the lubricating oil return main pipe connected to the oil tank of the main engine. The oil delivery part includes 4 temporary oil passages for oil delivery and a large-flow flushing device. The large-flow flushing device is connected to the main engine oil tank through the emergency oil discharge pipeline. Temporary oil passage for oil delivery I is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com