Cleaning device for plane glass

A cleaning device and glass technology, applied to the cleaning method using tools, the cleaning method using liquid, the arrangement of dry gas, etc., can solve the problems of no detection device, hidden safety hazards, high labor costs, etc., and achieve simple structure , easy maintenance, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

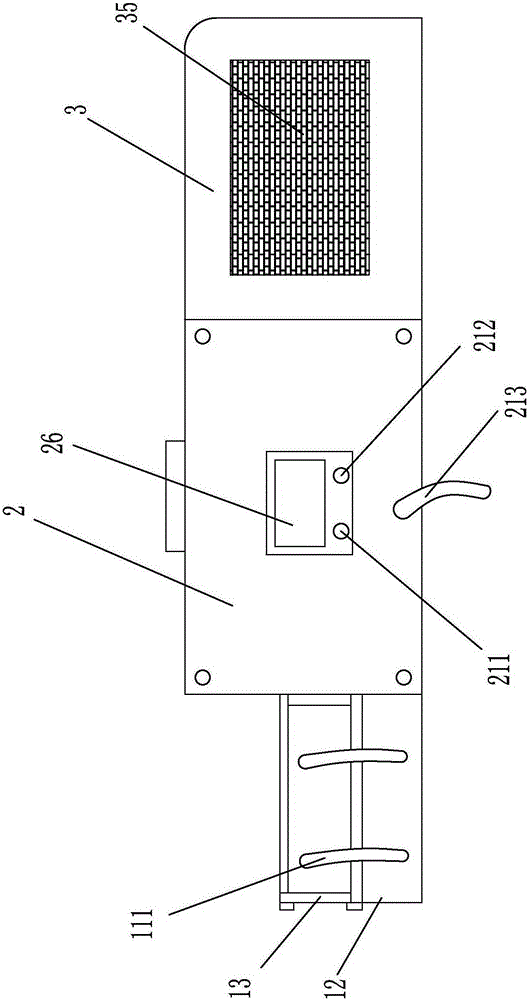

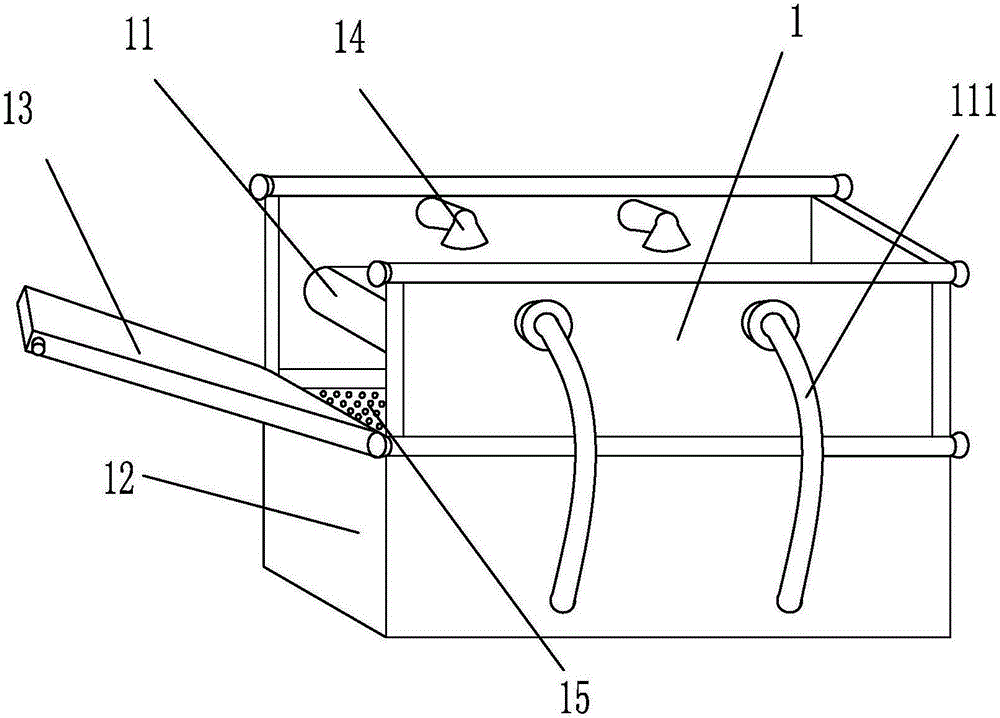

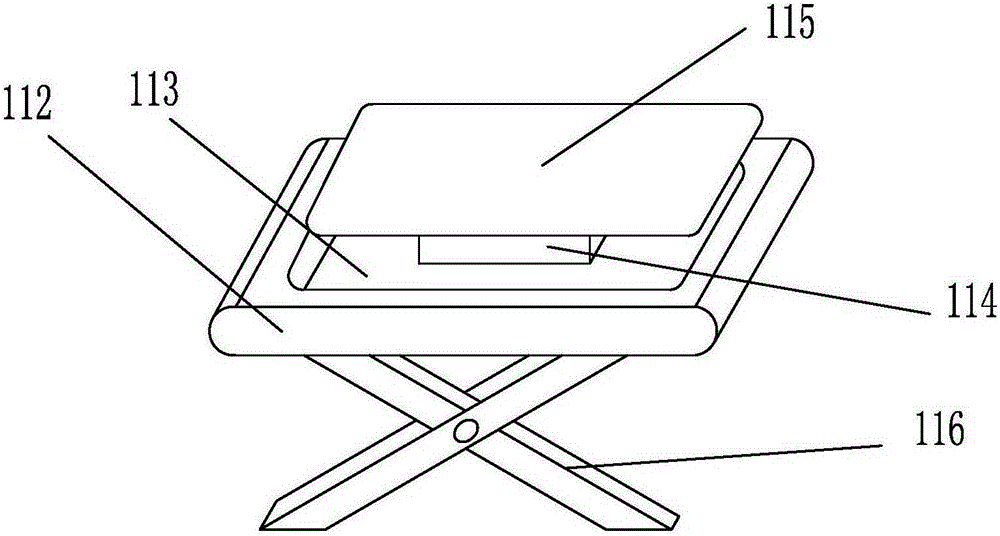

[0029] Such as Figure 1 to Figure 5As shown, a cleaning device for flat glass includes a water immersion mechanism, a flushing chamber 2 and a drying chamber 3. The flushing chamber 2 is located between the water immersion mechanism and the drying chamber 3. The water immersion mechanism includes a water immersion tank 1 and a cleaning base 11. And cleaning liquid collection box 12, be provided with cleaning base 11 in the immersion tank 1, the lower end of immersion tank 1 is connected with cleaning solution collection box 12, and the left side of immersion tank 1 is provided with opening door 13, can open and open door 13 to immersion tank 1 for adjustment and maintenance of the components, which facilitates the maintenance of the device by the operator. The inner side of the water immersion tank 1 is provided with a liquid spray head 14, and the number of the liquid spray head 14 is at least 4, and the liquid spray head 14 is fan-shaped and arranged obliquely. The materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com