Ultrahigh cleaning process for semiconductor parts

A technology for parts and semiconductors, which is applied in the field of ultra-high cleaning process of semiconductor parts, can solve the problems of labor-intensive and time-consuming, complicated and time-consuming operation, and the cleaning effect is not obvious, so as to achieve the effect of improving cleaning efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

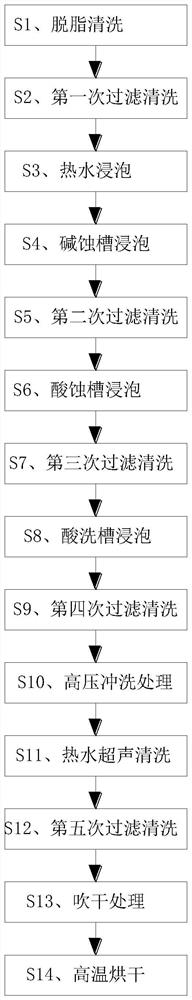

[0034] Example 1: Please refer to figure 1 As shown, the present invention discloses an ultra-high cleaning process for semiconductor parts, comprising the following steps:

[0035] S1. Degreasing cleaning: Put the required semiconductor aluminum alloy parts into the degreasing agent tank equipped with ultrasonic for degreasing cleaning. The temperature of the cleaning agent in the degreasing agent tank is 45°C, the cleaning time is 3min, and the concentration It is ISOPREP49L 10% v / v, after the cleaning is completed, take it out and spray it with a water gun;

[0036] S2, the first filter cleaning: put the semi-conductor aluminum alloy parts after spray cleaning in step S1 into the clear water pool for filter cleaning, and spray the products taken out after cleaning with a water gun;

[0037] S3. Soaking in hot water: Soak the semiconductor aluminum alloy parts cleaned in step S2 in hot water for 30 minutes and 60° C.;

[0038] S4, Soaking in Alkaline Etching Tank: The semi...

Embodiment 2

[0049] Example 2: Please refer to figure 1 As shown, the present invention discloses an ultra-high cleaning process for semiconductor parts, comprising the following steps:

[0050] S1. Degreasing and cleaning: Put the required semiconductor aluminum alloy parts into the degreasing agent tank equipped with ultrasonic for degreasing and cleaning. It is ISOPREP49L 10% v / v, after the cleaning is completed, take it out and spray it with a water gun;

[0051] S2, the first filter cleaning: put the semi-conductor aluminum alloy parts after spray cleaning in step S1 into the clear water pool for filter cleaning, and spray the products taken out after cleaning with a water gun;

[0052] S3. Soaking in hot water: Soak the semiconductor aluminum alloy parts cleaned in step S2 in hot water for 35 minutes and 65° C.;

[0053] S4, Soaking in Alkaline Etching Tank: Put the semi-conductor aluminum alloy parts soaked in step S3 into an alkali etching tank for immersion, the liquid concentra...

Embodiment 3

[0064] Example 3: Please refer to figure 1 As shown, the present invention discloses an ultra-high cleaning process for semiconductor parts, comprising the following steps:

[0065] S1. Degreasing and cleaning: Put the required semiconductor aluminum alloy parts into the degreasing agent tank equipped with ultrasonic for degreasing and cleaning. It is ISOPREP49L 10% v / v, after the cleaning is completed, take it out and spray it with a water gun;

[0066] S2, the first filter cleaning: put the semi-conductor aluminum alloy parts after spray cleaning in step S1 into the clear water pool for filter cleaning, and spray the products taken out after cleaning with a water gun;

[0067] S3. Soaking in hot water: Soak the semiconductor aluminum alloy parts cleaned in step S2 in hot water for 40 minutes and at a temperature of 70°C;

[0068] S4, Soaking in Alkaline Etching Tank: The semi-conductor aluminum alloy parts soaked in step S3 are put into an alkali etching tank for immersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com