Spicy non-slag hotpot oil with sauce aroma and preparation method thereof

A technology of hot pot oil and spicy, which is applied in the field of sauce-flavored, spicy and residue-free hot pot oil and its preparation. It can solve the problems that the spices have not been pretreated, the flavor of the spices cannot be fully revealed, and the frying temperature is low, so as to increase the frying stability. , high antioxidant stability, soft taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

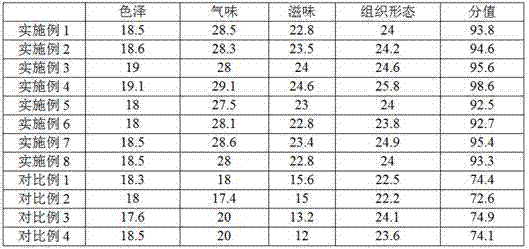

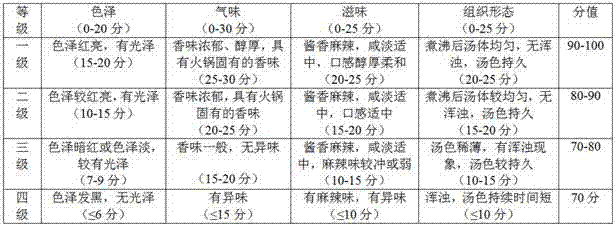

Examples

Embodiment 1

[0028] A sauce-flavored, spicy and residue-free hot pot oil is made from the following raw materials in parts by weight: 3400 parts of soybean oil, 110 parts of palm oil, 190 parts of butter, 965 parts of rapeseed oil, 240 parts of green onion, 240 parts of ginger, onion 25 parts, 45 parts of parsley, 70 parts of garlic, 3 parts of rock sugar, 12 parts of cumin, 15 parts of cinnamon, 18 parts of star anise, 18 parts of cumin, 7 parts of cloves, 9 parts of black pepper, 9 parts of Angelica dahurica, 8 parts of Chinese pepper , 240 parts of pickled ginger, 210 parts of two vitex peppers, 240 parts of new generation peppers, 110 parts of Indian peppers, 190 parts of bean paste, 25 parts of tempeh, 5 parts of nutmeg, 12 parts of fragrant fruit, 6 parts of grass fruit, 65 parts of table salt , 35 parts of white sugar, 65 parts of monosodium glutamate, 75 parts of chicken essence, 145 parts of concentrated pork bone soup and 45 parts of white wine.

[0029] A preparation method of s...

Embodiment 2

[0035] A sauce-flavored, spicy and residue-free hot pot oil is made from the following raw materials in parts by weight: 3450 parts of soybean oil, 105 parts of palm oil, 195 parts of butter, 960 parts of rapeseed oil, 245 parts of green onion, 245 parts of ginger, onion 22 parts, 48 parts of parsley, 68 parts of garlic, 4 parts of rock sugar, 13 parts of cumin, 14 parts of cinnamon, 19 parts of star anise, 17 parts of cumin, 8 parts of cloves, 10 parts of black pepper, 8 parts of Angelica dahurica, 9 parts of Chinese prickly ash , 245 parts of pickled ginger, 208 parts of two vitex peppers, 242 parts of new generation peppers, 105 parts of Indian peppers, 195 parts of bean paste, 26 parts of tempeh, 6 parts of nutmeg, 11 parts of fragrant fruit, 7 parts of grass fruit, 68 parts of table salt , 36 parts of white sugar, 62 parts of monosodium glutamate, 76 parts of chicken essence, 142 parts of concentrated pork bone soup and 46 parts of white wine.

[0036] A preparation met...

Embodiment 3

[0042] A sauce-flavored, spicy and residue-free hot pot oil is made from the following raw materials in parts by weight: 3480 parts of soybean oil, 100 parts of palm oil, 200 parts of butter, 960 parts of rapeseed oil, 248 parts of green onion, 248 parts of ginger, onion 24 parts, 50 parts of parsley, 65 parts of garlic, 5 parts of rock sugar, 14 parts of cumin, 13 parts of cinnamon, 20 parts of star anise, 16 parts of cumin, 8 parts of cloves, 11 parts of black pepper, 7 parts of Angelica dahurica, 10 parts of Chinese prickly ash , 248 parts of ginger, 205 parts of two vitex peppers, 245 parts of new generation peppers, 100 parts of Indian peppers, 200 parts of bean paste, 28 parts of tempeh, 7 parts of nutmeg, 10 parts of fragrant fruit, 7 parts of grass fruit, 70 parts of table salt , 38 parts of white sugar, 60 parts of monosodium glutamate, 78 parts of chicken essence, 40 parts of concentrated pork bone soup and 48 parts of white wine.

[0043] A preparation method of sau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com