A cooling system for cooling the circulating air in the feeding part of a cigarette machine

A technology of cooling system and cigarette making machine, which is applied in the fields of application, tobacco, and paper cigarette manufacturing. It can solve the problems of large moisture fluctuations in shredded tobacco and loss of aroma, and achieve the effects of low cost, improved stability, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

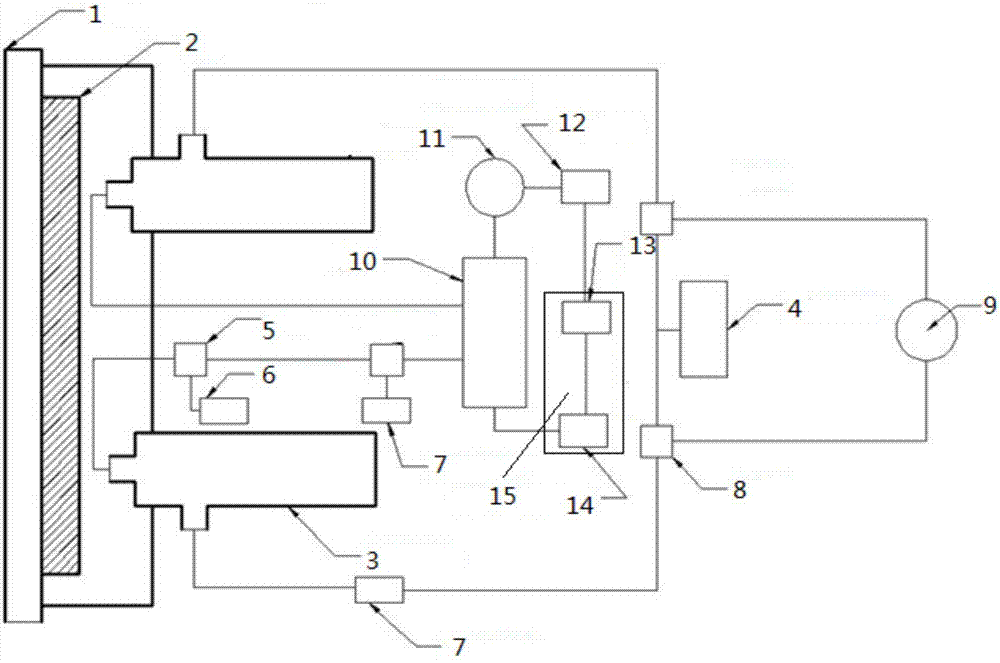

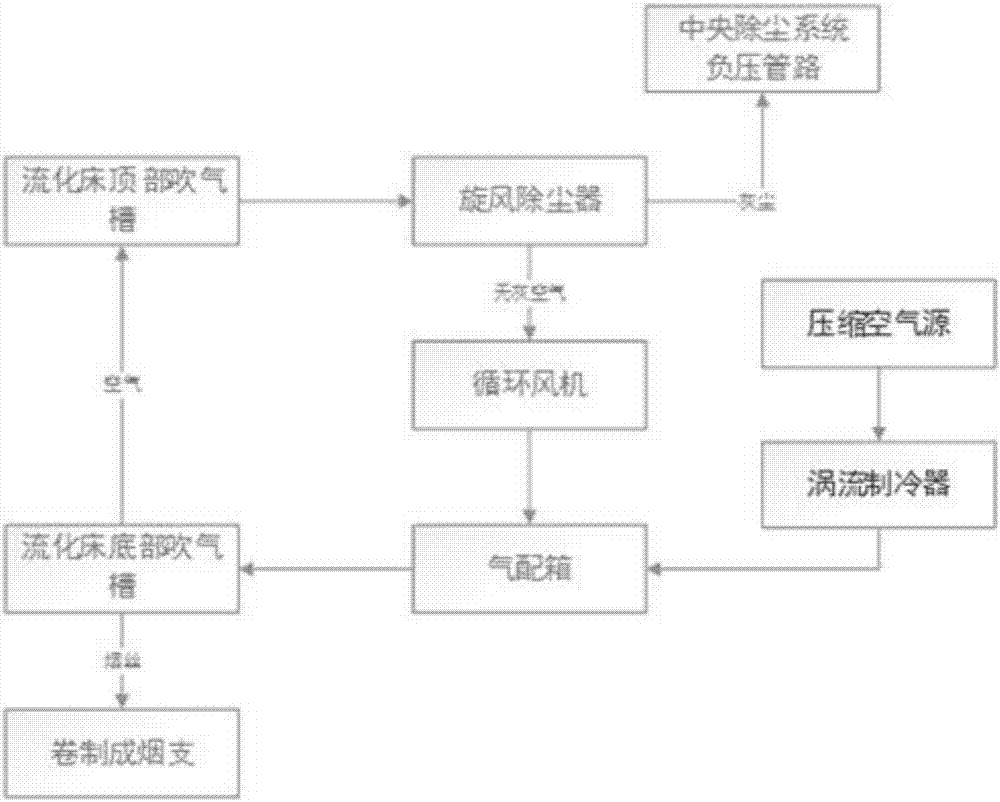

[0017] Such as Figure 1~2 A cooling system for cooling the circulating air in the feeding part of the cigarette machine is shown, the system includes two vortex refrigeration pipes 3, a pressure transmitter 6, a temperature transmitter, a fluidized bed 15, an air distribution box 10 and Compressed air source 4, the top board 1 of the feeding part of the cigarette machine is installed with a fan 2, and the two eddy current cooling pipes 3 are respectively installed through a bracket and the top board of the feeding part of the cigarette machine 1 connection, the fan 2 is located directly below the two vortex cooling tubes 3, and the air outlets of the two vortex cooling tubes 3 are respectively connected to the air distribution box 10 by setting the first hose connector, the said Both ends of the first hose connector ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com