Airflow type leaf thread drying plant

A kind of drying equipment and air-flow technology, which is applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of obvious moisture difference, complex leaf silk production process, and ineffective effect, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

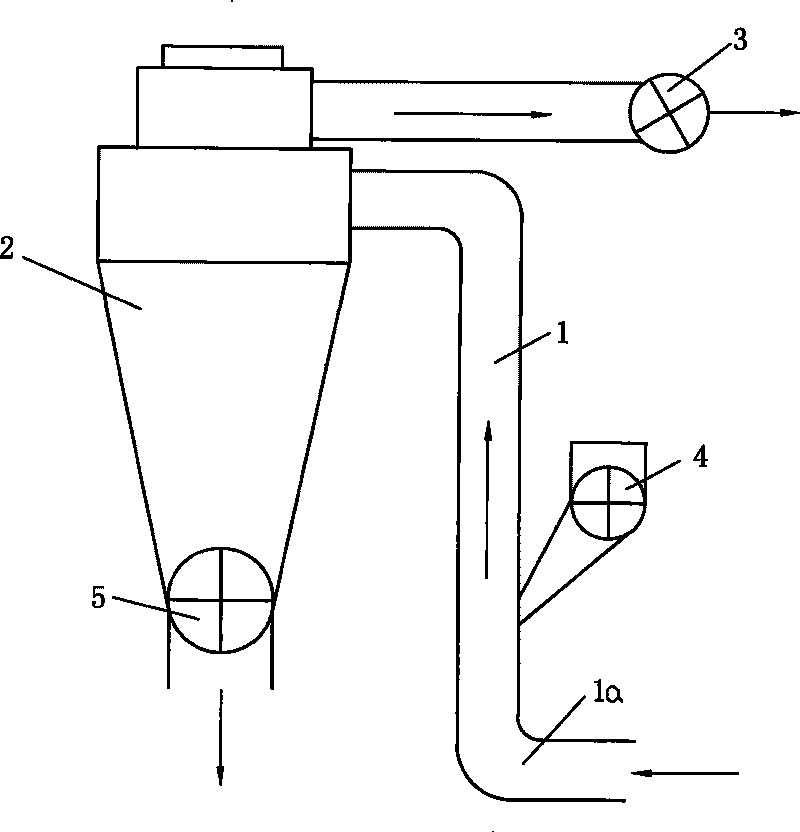

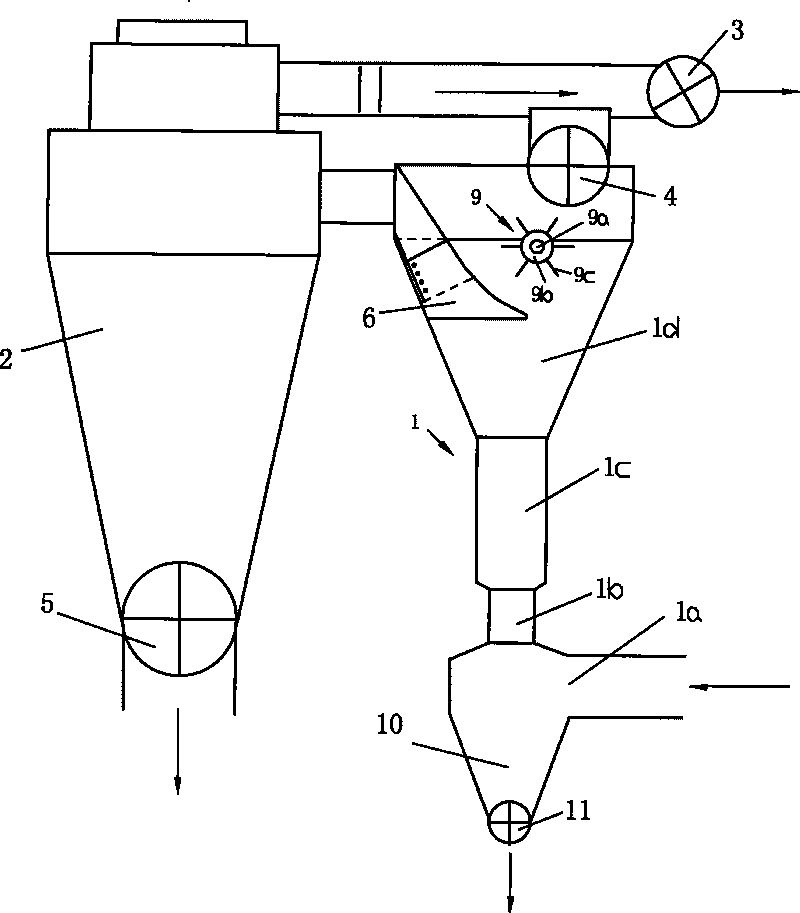

[0034] Such as figure 2 As shown, a kind of air-flow type leaf shred drying equipment described in this embodiment, a kind of air-flow type leaf shred drying equipment, comprises a vertical drying pipe 1, a cyclone separator 2 and a steam circulation system connected with a main fan 3, Wherein drying pipe 1 is provided with air inlet 1a, and air inlet 1a is positioned at the side of drying pipe 1 lower end, and links to each other with the main blower fan 3 in the steam cycle system through horizontal pipeline, and drying pipe 1 begins from air inlet 1a, upwards Divided into the first drying pipe 1b, the second drying pipe 1c and the bucket-shaped third drying pipe 1d successively; the diameter of the second drying pipe 1c is larger than that of the first drying pipe 1b, and the diameter of the third drying pipe 1d is smaller The end is connected with the second drying pipe 1c. The feed port closed by the feed air lock 4 is arranged on the top of the drying pipe 1, and the t...

Embodiment 2

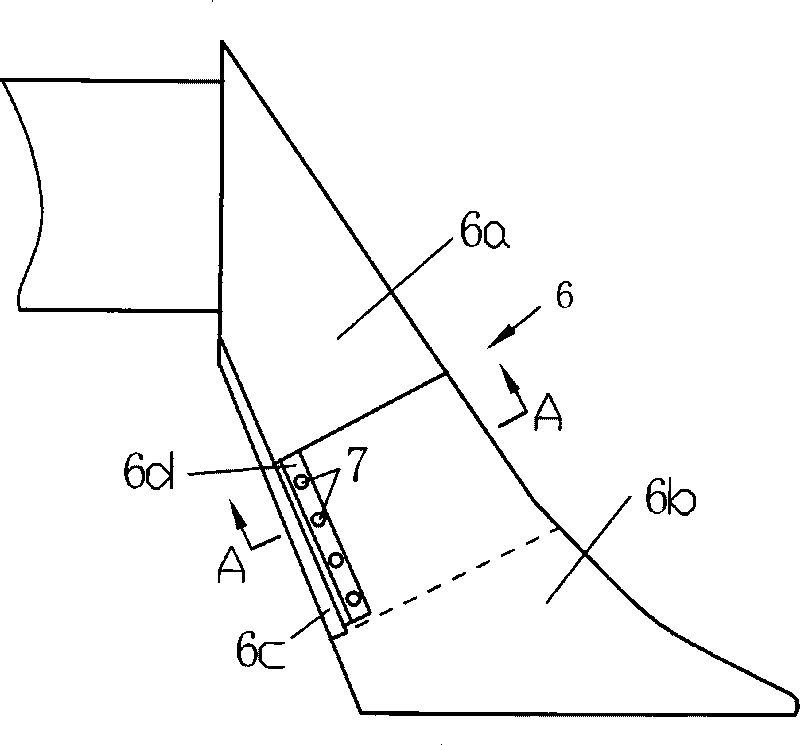

[0038] Such as figure 2 , Figure 5 and Figure 6 As shown, the airflow drying equipment described in this embodiment is basically the same as that in Embodiment 1, the difference is that the movable cover 6b of the separate receiving cover 6 in this embodiment is fixed to the fixed cover 6a by bolts 8 . Both longitudinal edges of the fixed cover 6a and the movable cover 6b are bent outwards, and a slide bar 6e is fixed on the bending plate of the fixed cover 6a, and five equidistant screw holes are provided on the slide bar 6e; A through hole opposite to the screw hole is provided on the bent plate of 6b, and three bolts 8 pass through the through hole and are fixed in the screw holes of the fixed cover 6a. When adjusting the up and down position of the movable cover 6b, the bolt 8 is withdrawn, the movable cover 6b is moved up and down, and the bolt 8 is screwed into the screw hole of the fixed cover 6a at an appropriate position.

[0039] The invention works like this: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com