Cabin cabinet energy-saving system heat exchange box and ship fuel oil preheating system

A technology of energy-saving system and heat exchange box, which is applied in the direction of charging system, ship construction, ship parts, etc., can solve the problems of cold start pumping difficulty of delivery pump and low oil temperature, so as to reduce resistance loss, increase oil temperature, The effect of reducing the operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

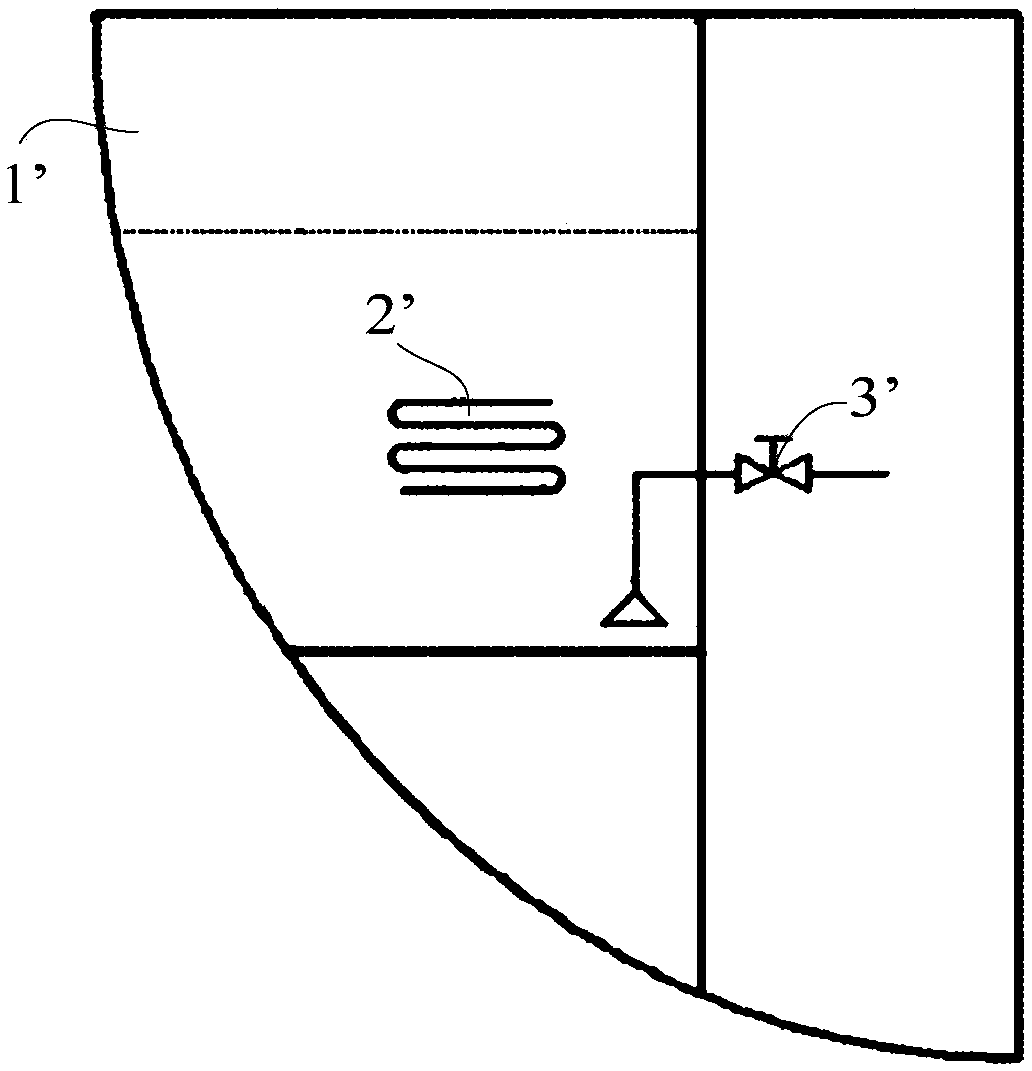

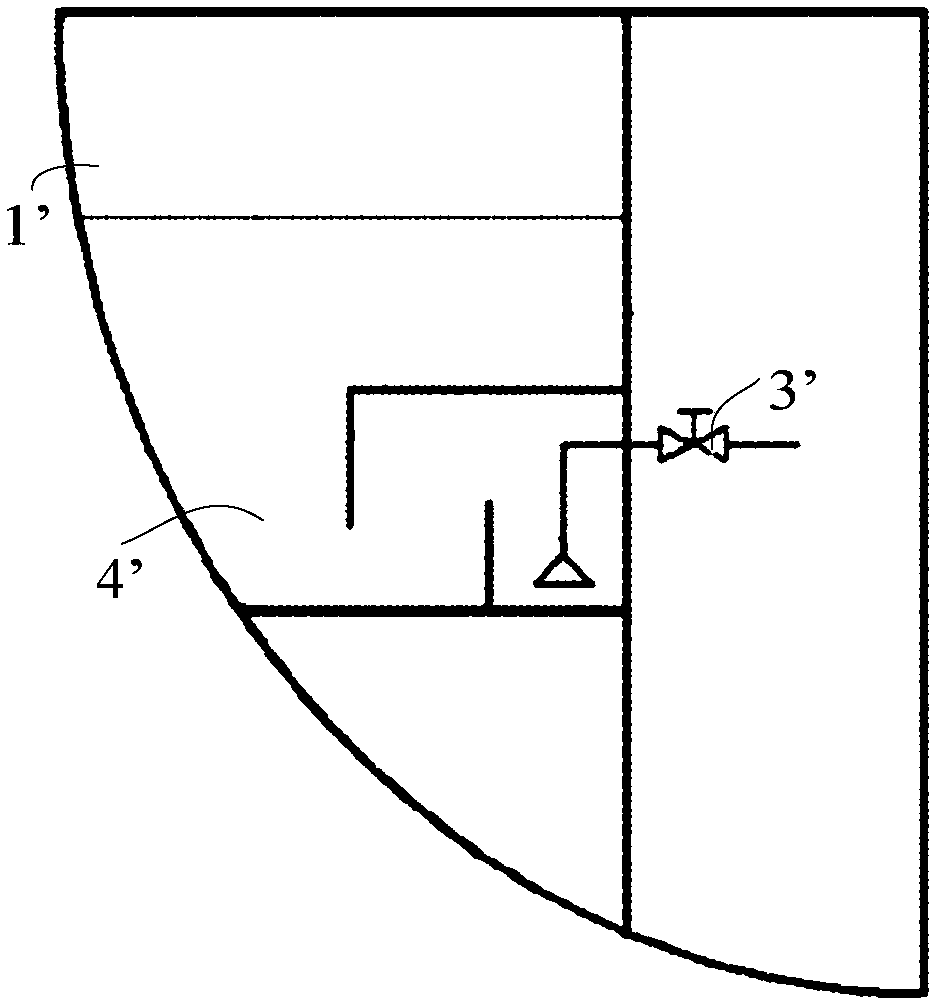

[0049] This embodiment provides a heat exchange box of a tank energy-saving system, which is located in the storage tank 500 where fuel oil is stored. Please refer to it together Figure 5 to Figure 9 . Figure 5 Is a front view of a heat exchange box of a tank energy-saving system provided by an embodiment of the present invention; Image 6 It is an AA view of the heat exchange box of the tank energy-saving system provided by the embodiment of the present invention; Figure 7 It is a BB view of the heat exchange box of the tank energy-saving system provided by the embodiment of the present invention; Figure 8 It is a CC view of the heat exchange box of the tank energy-saving system provided by the embodiment of the present invention; Picture 9 It is a flowchart of a ship fuel preheating system provided by an embodiment of the present invention.

[0050] It includes an oil injection pipe 100 and an oil suction pipe 200; at least part of the input end of the oil injection pipe 100...

Embodiment 2

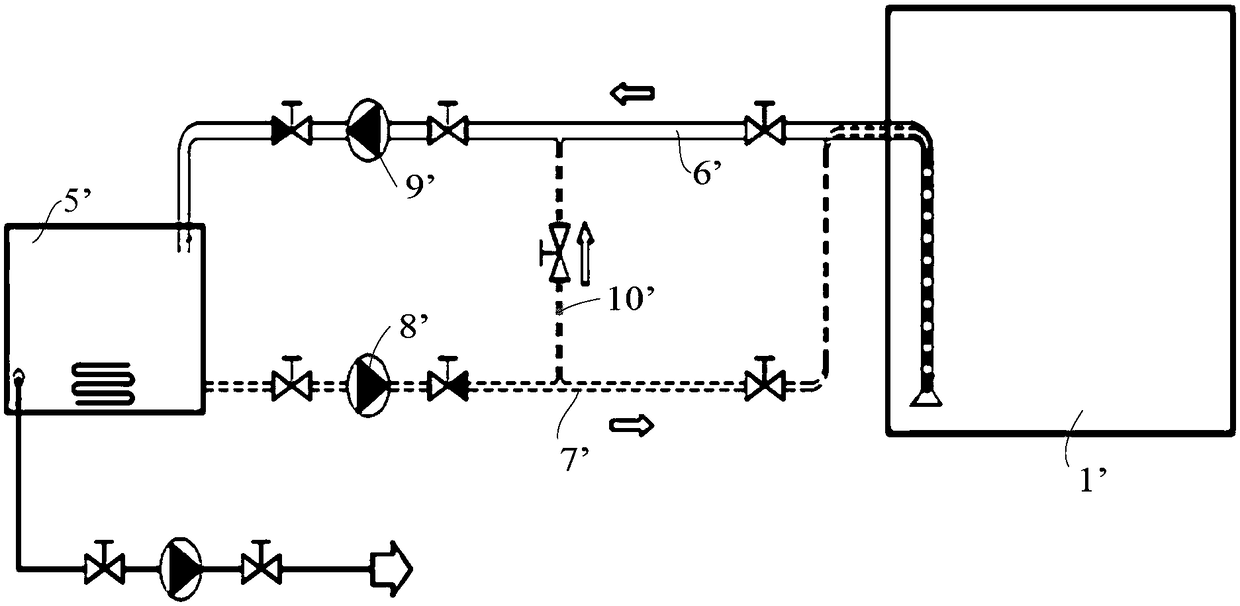

[0079] This embodiment provides a marine fuel preheating system, please refer to it together Figure 5 to Figure 9 . Figure 5 Is a front view of a heat exchange box of a tank energy-saving system provided by an embodiment of the present invention; Image 6 It is an AA view of the heat exchange box of the tank energy-saving system provided by the embodiment of the present invention; Figure 7 It is a BB view of the heat exchange box of the tank energy-saving system provided by the embodiment of the present invention; Figure 8 It is a CC view of the heat exchange box of the tank energy-saving system provided by the embodiment of the present invention; Picture 9 It is a flowchart of a ship fuel preheating system provided by an embodiment of the present invention.

[0080] The ship fuel preheating system includes the heat exchange box of the tank energy-saving system mentioned in Example 1 (for details, please refer to Figure 8 ), it also includes a settling tank 600, an oil fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com