Method for preparing cellulose fibers by dry-wet spinning

A cellulose fiber, dry-wet spinning technology, applied in the field of textiles, can solve the problems of large environmental pollution, and achieve the effects of less environmental pollution, fast spinning speed, and shortened process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Dissolve cellulose with a water content of 1% and a degree of polymerization of 500 in P 2 o 5 In the phosphoric acid / polyphosphoric acid composite solution whose mass percentage content is 72%, the mass fraction of cellulose is 10%, and the stock solution glue of liquid crystal state is prepared by a twin-screw extruder;

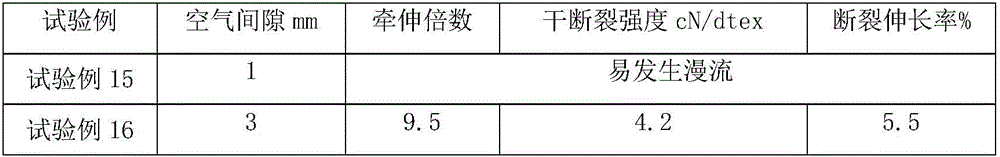

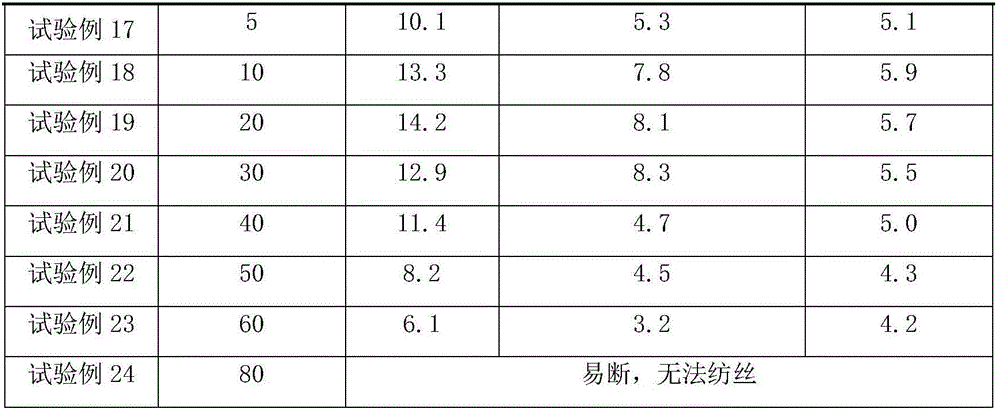

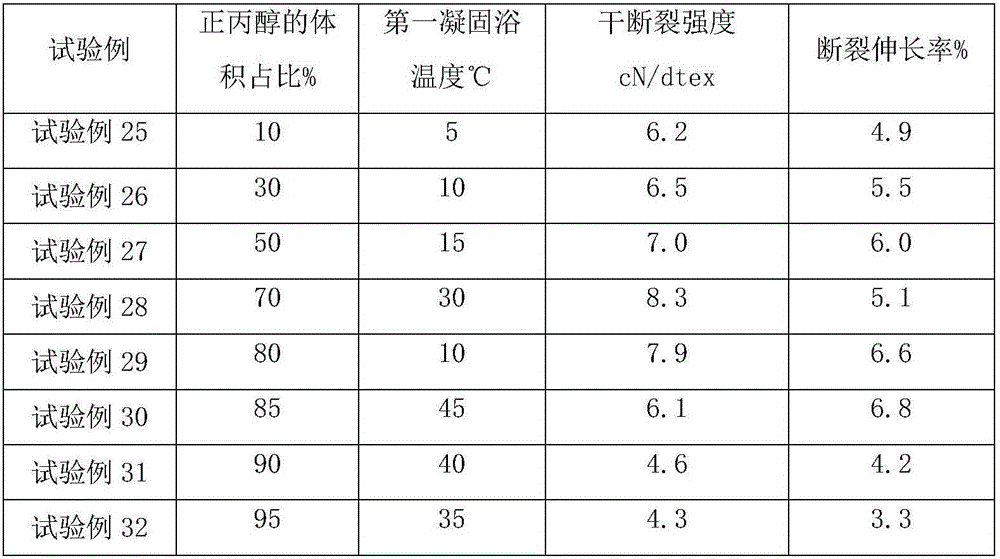

[0060] (2) Feed the glue with cellulose stock solution preheated to 50°C into the metering pump, set the spinning speed at 20m / min, set a certain amount of glue through adjustment, spray it out through the spinneret, and pass through the air bath, Wherein the air gap is 5 mm, and then pass through the first coagulation bath and the second coagulation bath to form primary filaments. Wherein, the volume of ethanol in the first coagulation bath is 85% of the volume of the three-component solution, and the temperature is 20°C, and the volume of ethanol in the second coagulation bath is 50% of the volume of the three-component solution, and the tempe...

Embodiment 2

[0064] (1) Dissolve cellulose with a water content of 10% and a degree of polymerization of 800 in P 2 o 5 In the phosphoric acid / polyphosphoric acid composite solution with a mass percentage content of 80%, the mass fraction of cellulose is 20%, and the stock solution glue in liquid crystal state is prepared by a twin-screw extruder;

[0065] (2) Feed the glue with cellulose stock solution preheated to 45°C into the metering pump, set the spinning speed at 150m / min, set a certain amount of glue by adjusting, spray out through the spinneret, and pass through the air bath, Wherein the air gap is 50 mm, and then pass through the first coagulation bath and the second coagulation bath to form primary filaments. Wherein, the volume of ethylene glycol in the first coagulation bath is 30% of the volume of the three-component solution, and the temperature is 45°C; the volume of ethylene glycol in the second coagulation bath is 30% of the volume of the three-component solution, and th...

Embodiment 3

[0069] (1) Dissolve cellulose with a water content of 5% and a degree of polymerization of 1000 in P 2 o 5 In the phosphoric acid / polyphosphoric acid composite solution with a mass percentage content of 78%, the mass fraction of cellulose is 30%, and the stock solution glue of liquid crystal state is prepared by a twin-screw extruder;

[0070] (2) Feed the glue with cellulose stock solution preheated to 70°C into the metering pump, set the spinning speed to 250m / min, set a certain amount of glue by adjusting, spray out through the spinneret, and pass through the air bath, Wherein the air gap is 30 mm, and then go through the first coagulation bath and the second coagulation bath to form primary filaments. Wherein, the volume of acetone in the first coagulation bath is 10% of the volume of the three-component solution, and the temperature is 5°C, and the volume of acetone in the second coagulation bath is 5% of the volume of the three-component solution, and the temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com