Protective coating and its preparing method

A protective coating and coating technology, applied in the field of material science, can solve problems such as affecting the service life of the coating, and achieve the effect of eliminating voids, improving compactness and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

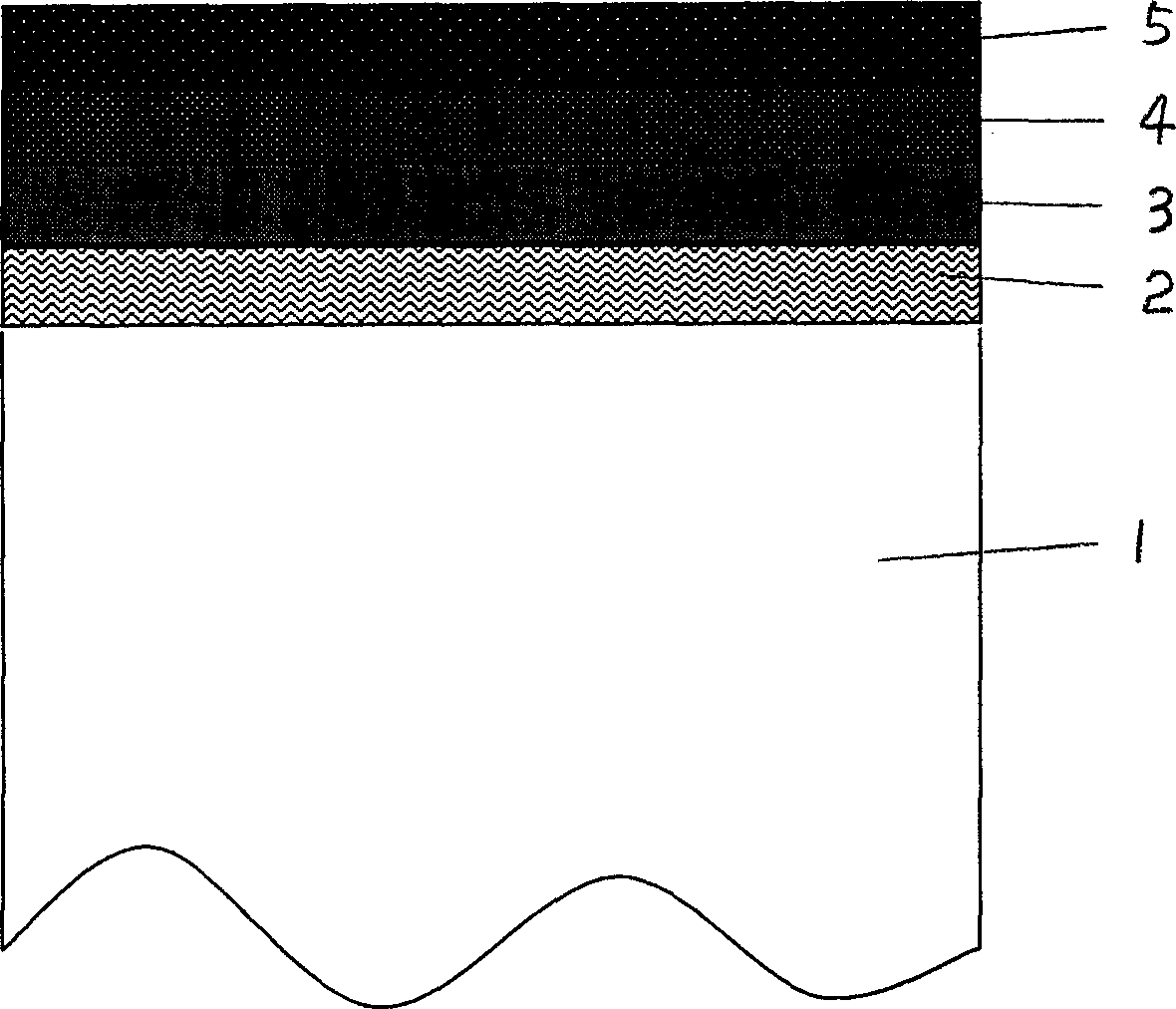

Embodiment 1

[0022] Aeroengine compressor blades, after surface grinding, decontamination, acetone ultrasonic cleaning and sprinkling rinse, are placed in a vacuum chamber. During the coating process, the plated parts revolve and rotate in the vacuum chamber. The targets are Al 10%, 20%, Al 30% (atomic percentage) of TiAl alloy and pure Ti. The total thickness of the coating is about 6 μm: first deposit a TiN alloy coating (2) with a thickness of about 1 μm on the surface of the substrate (1), the coating time is 20 minutes, the vacuum degree is 10 N layer (3), TiAl 20 N layer (4) and TiAl 30 N layer (5), the thickness of each layer is between 1-2μm, the deposition time is 10-20min, the vacuum degree is 0.3Pa, the electron gun beam current is 100A, the bias voltage is -900V, and the duty cycle is 20%, the substrate temperature is 400-480°C.

Embodiment 2

[0024] Aeroengine compressor blades, after surface grinding, decontamination, acetone ultrasonic cleaning and sprinkler rinse, are placed in a vacuum chamber. During the coating process, the plated parts revolve and rotate in the vacuum chamber. The target materials contain 10% and 20% Al respectively. , 30% (atomic percentage) TiAl alloy and pure Ti. The total thickness of the coating is 8 μm: first, a TiN alloy coating (2) with a thickness of about 2 μm is deposited on the surface of the substrate (1), the coating time is 20 minutes, the vacuum degree is 10 N layer (3), TiAl 20 N layer (4) and TiAl 30 N layer (5), the thickness of each layer is 1-2μm, the deposition time is 10-20min, the vacuum degree is 0.3Pa, the electron gun beam current is 900A, the bias voltage is -800V, and the duty cycle is 20%. The substrate temperature is 400-480°C.

Embodiment 3

[0026] Aeroengine compressor blades, after surface grinding, decontamination, acetone ultrasonic cleaning and sprinkler rinse, are placed in a vacuum chamber. During the coating process, the plated parts revolve and rotate in the vacuum chamber. The target materials contain 10% and 20% Al respectively. , 30% (atomic percentage) TiAl alloy and pure Ti. The total thickness of the coating is about 7 μm: first deposit a TiN alloy coating (2) with a thickness of about 1 μm on the surface of the substrate (1), the coating time is 20 minutes, the vacuum degree is 10 N layer (3), TiAl 20 N layer (4) and TiAl 30 N layer (5), the thickness of each layer is about 1-2 μm, the deposition time is 10-20 min, the vacuum degree is 0.3 Pa, the electron gun beam current is 80A during coating, the bias voltage is -900V, and the duty cycle is 20%. , The substrate temperature is 400-480°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com