Single-component room temperature vulcanized silicon rubber for sticking insulator

A room temperature vulcanization, one-component technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve problems such as poor leveling, slow curing speed, and low bonding strength , achieve the same moisture content inside and outside, improve the bonding strength, and improve the leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

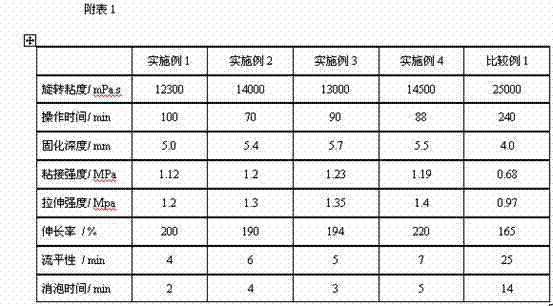

Examples

Embodiment 1

[0035] Example 1 Select a hydroxyl-terminated polydimethylsiloxane with a viscosity of 2000mPa·s and a dimethicone oil with a viscosity of 100mPa·s, and its components are as follows:

[0036] 100 parts of hydroxyl-terminated polydimethylsiloxane polymer;

[0037] 13 parts of fumed white carbon black;

[0038] 18 parts of silicone oil plasticizer;

[0039] Vinyl tributylketoxime silane 6 parts;

[0040] 1.7 parts of aminopropyltrimethoxysilane;

[0041] 10 parts of mineral oil;

[0042] Catalyst 0.5 parts.

Embodiment 2

[0043] Example 2 Select a hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000mPa·s and a dimethicone oil with a viscosity of 100mPa·s, and its components are as follows:

[0044]100 parts of hydroxyl-terminated polydimethylsiloxane polymer;

[0045] 10 parts of fumed white carbon black;

[0046] 18 parts of silicone oil plasticizer;

[0047] 5 parts of vinyl tributylketoxime silane;

[0048] 1 part of methyl tributylketoxime silane;

[0049] 1.7 parts of aminopropyltrimethoxysilane;

[0050] 1 part of glycidyl etheroxytrimethoxysilane;

[0051] 12 parts of mineral oil;

[0052] Catalyst 1 part.

Embodiment 3

[0053] Example 3 Use a hydroxyl-terminated polydimethylsiloxane with a viscosity of 20,000 mPa·s and a dimethicone oil with a viscosity of 100 mPa·s, and its components are as follows:

[0054] 100 parts of hydroxyl-terminated polydimethylsiloxane polymer;

[0055] 11 parts of fumed white carbon black;

[0056] 25 parts of silicone oil plasticizer;

[0057] Vinyl tributylketoxime silane 6 parts;

[0058] 1.7 parts of aminopropyltrimethoxysilane;

[0059] 1 part of glycidyl etheroxytrimethoxysilane;

[0060] 15 parts of mineral oil;

[0061] Catalyst 1 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com