MEMS device and forming method thereof

A device, the opposite direction technology, applied in piezoelectric devices/electrostrictive devices, semiconductor/solid-state device components, piezoelectric/electrostrictive/magnetostrictive devices and other directions, can solve the problem of large internal stress of the vibrating membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In a MEMS device with a vibrating membrane, how to reduce the internal stress of the vibrating membrane and improve the mechanical strength of the vibrating membrane has become one of the most important issues. Corrugations are often formed in the diaphragm to relieve internal stress in the diaphragm.

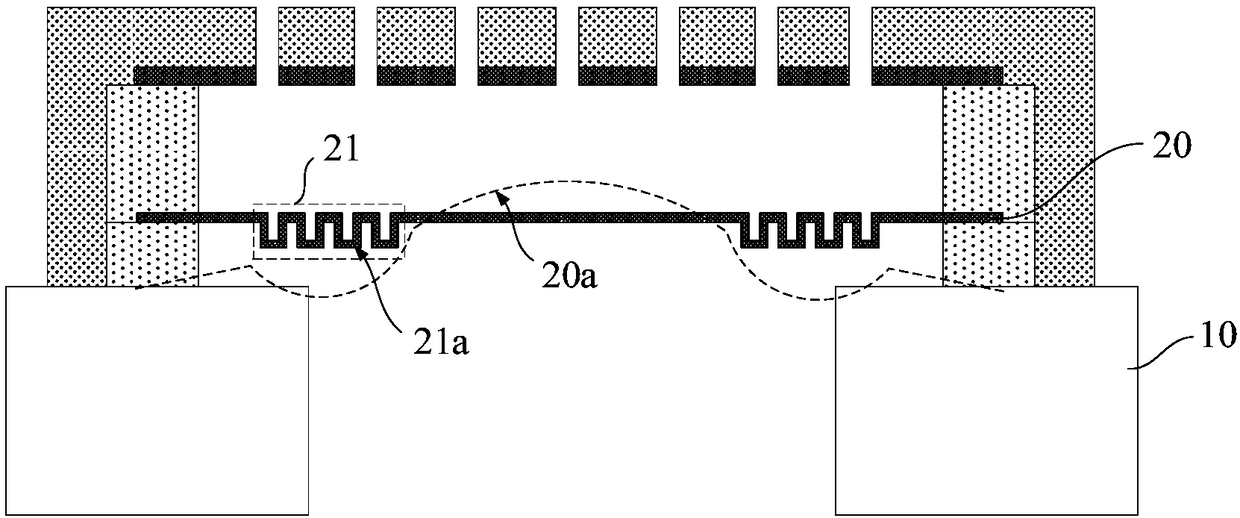

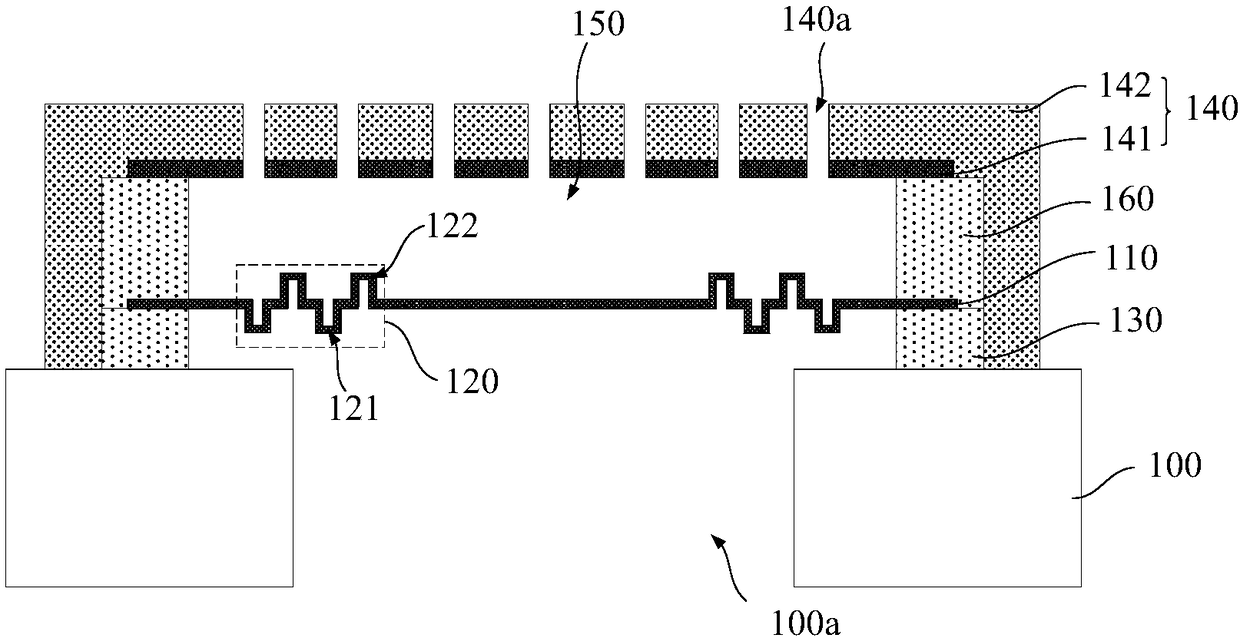

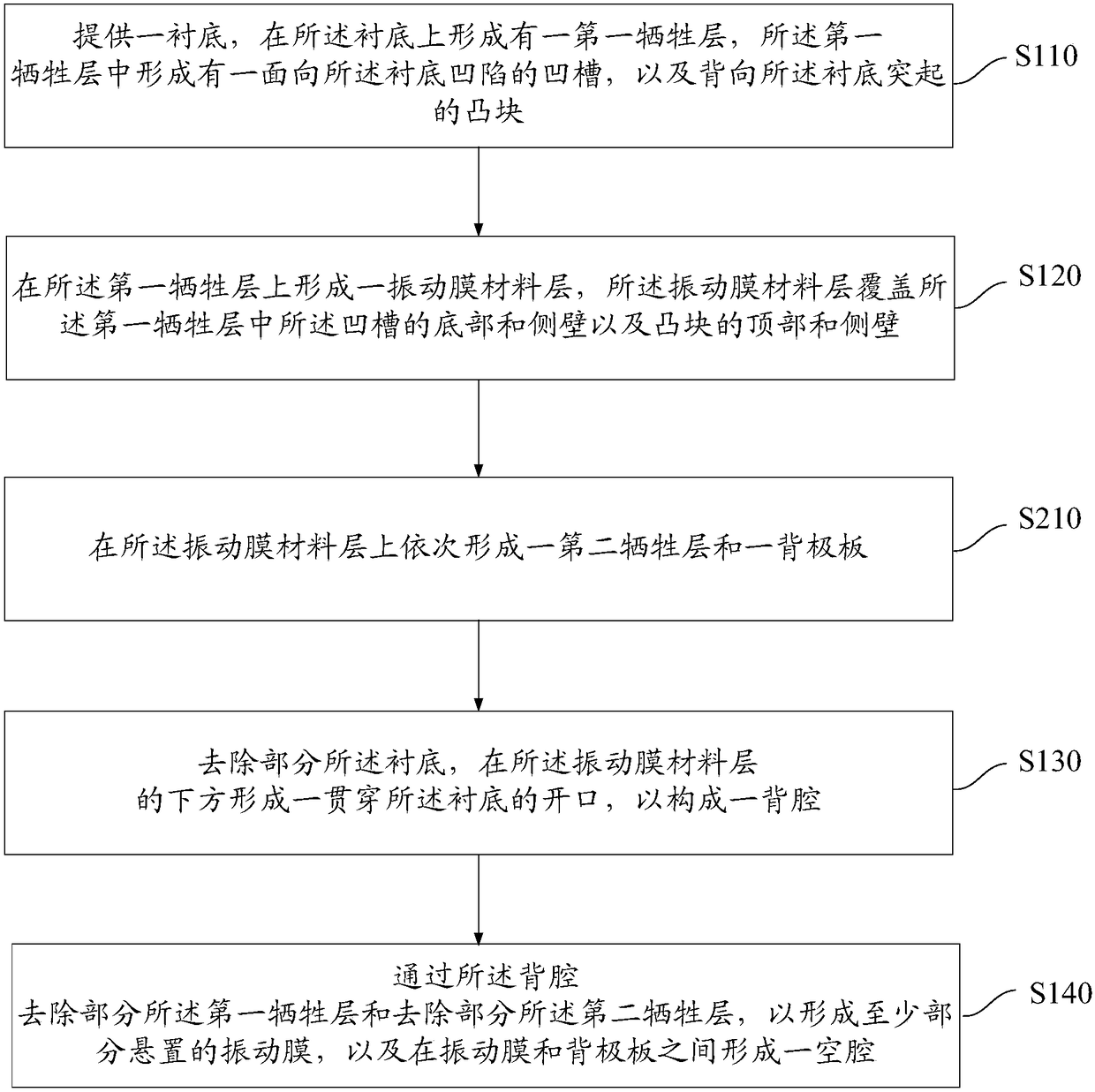

[0053] figure 1 is a structural schematic diagram of a MEMS device, such as figure 1 As shown, the MEMS device includes a substrate 10 and a vibrating membrane 20 formed on the substrate 10 . The vibrating membrane 20 has a bent part, and the bent part forms a corrugation 21, and the corrugation 21 includes a plurality of protrusions 21a. Since the corrugations 21 are provided in the vibrating membrane 20 , the internal stress of the vibrating membrane 20 can be released when the vibrating membrane 20 is formed.

[0054] continue to refer figure 1 As shown, generally, the protrusions 21 a protrude toward the substrate 10 relative to the non-bending part of the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com